Jefferson Professional Tools & Equipment JEFSUBPIDW210-12 User manual

User Manual

v.1.1

JEFSUBPIDW210-12

500W

WATER PUMP

SUBMERSIBLE

110V~50Hz For Dirty Water • With Float Switch

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com

2

ABOUT THIS DOCUMENT

This manual has been compiled by Jefferson Tools and is an integrated part of the product with which it's enclosed and should be kept with it for

future reference. Please read all of the information supplied in this User Manual before operating this product.

This manual describes the purpose for which the product has been designed and contains all the necessary information to ensure its correct and

safe use. We recommend that you read the information supplied before carrying out any maintenance or repair. By following all the general safety

instructions contained in this manual you will help to ensure operator safety and extend the potential life span of the equipment.

All photographs and drawings in this manual are supplied by Jefferson Tools to help illustrate the operation of the product. Whilst every effort

has been made to ensure accuracy of information contained in this manual our policy of continuous improvement determines the right to make

modifications without prior warning. Contact your nearest Jefferson Dealer if you are unsure about any information included in this manual or

require any additional information about the safe use, operation maintenance, or repair of this equipment.

INTRODUCTION

500W Industrial submersible water pump with 2" outlet suitable for a wide range of applications including construction sites, agricultural and

commercial environments.

• Manufactured from corrosion resistant materials with aluminium motor case

• 110V ~ 50Hz power supply with UK 16A plug and 10M cable

• Designed for pumping dirty water with a maximum ow rate of 210L/Min

• Fitted with a oat switch

• 2" discharge hose connector

• 12M maximum head

SPECIFICATIONS

Model Number: JEFSUBPIDW210-12

Rated Power / Motor: 500W

Power Supply: 110V ~ 50Hz

Plug / Current UK / 16A

Maximum Flow Rate: 12600L/Hr •210L/Min

Maximum Head: 12M

Maximum Depth: 5M

Maximum Grain Size: 7mm

Maximum Temp: 40°C

Cable Length: 10M

Insulation Class: B

Ingress Protection: IP68

Outlet Diameter: 2"

Dimensions: 239 x 194 x 356mm

NW / GW: 12.8kg / 14.2kg

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com 3

1. 2" Outlet / Discharge Hose Connection

2. Power Cable & Plug

3. Carry Handle

4. Motor Casing

5. Float Switch

6. Base

1

EQUIPMENT IDENTIFICATION

4

6

Read and ensure that you understand all of the operating instructions, safety precautions and warnings in this Instruction

Manual before operating or maintaining this equipment. Most accidents that result from operation and maintenance are

caused by the failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing a

potentially hazardous situation before it occurs, and by observing appropriate safety procedures. Never use this equipment

or modify it in any way that has not been specically recommended by the manufacturer. Contact a qualied electrician for

advice on any issues relating to electrical safety in your working environment.

SAFETY GUIDELINES

• We recommend that you t a Residual Current Circuit Breaker (RCCB) in the main distribution board and that a Residual Current Device

(RCD) is used when operating this equipment.

• The Electricity at Work Act 1989 includes legislation that places legal implications on employers to ensure the safety of electrical devices

in the workplace. The regulations dictate that all portable equipment must be inspected regularly and tested to ensure that it is safe for use.

'Portable equipment' means any electrical item that can be moved and this is often referred to as Portable Appliance Testing (PAT). PAT

testing should be carried out regularly on this equipment by trained, authorised personnel, as required by the legislation.

• The Health and Safety at Work Act 1974 states that it is the responsibility of the owner of electrical appliances to ensure that both the

equipment and working environments are maintained to ensure safe operation at all times.

2

3

5

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com

4

SAFETY GUIDELINES

• Check that all equipment cables are secure, correctly insulated, free from damage, and protected against short circuit and overload before

connecting to the power supply. Do not use worn or damaged cables, plugs, sockets or other ttings.

• Ensure that the power supply matches voltage requirements specied on the equipment and that the plug is wired correctly and tted with

the correct fuse.

• If the electrical fuse blows, ensure it is replaced by an identical type of fuse with the same rating.

• Never pull or manoeuvre this equipment into position using the power cable (move using the handle).

• Ensure the power cable is kept away from heat, oil and sharp edges.

• We recommend that the equipment is connected directly to the power supply without the use of extension leads as the resulting voltage drop

can reduce motor and pump performance.

• Always disconnect the from the power source and remove any water from the pump before servicing, inspecting, maintaining, cleaning,

replacing or checking any parts.

• Do not carry the pump while it is connected to its power source.

• Do not use this appliance in potentially explosive environments or in the vicinity of ammable liquids or gases.

• Do not try to connect or disconnect to the power supply or operate the equipment with wet hands.

• Ensure the connection is made to earthed sockets which have been properly installed and tested according to local standards and regula-

tions.

• Ensure mains voltage and fuse meet the ratings stated in the technical data. Do not use extension cables with this equipment.

• Do not use the equipment to pump water from bodies of water where people or animals are present (eg. swimming pools, sh ponds etc.)

• When not in use, the pump should be stored in dry place. Keep out of reach of children. Keep children and animals away from the work area.

• Watch what you are doing and remove any potential distractions before use. Use common sense at all times.

• Do not operate this equipment when you are tired or if you are under the inuence of alcohol, drugs or medication that makes you drowsy.

• Keep all screws, bolts, and plates tightly mounted. Check regularly.

• If the equipment appears to be operating unusually, making strange noises, or otherwise appears defective, stop using it immediately and

arrange for repairs by a authorized service centre.

• Only use Jefferson approved replacement parts. Non-approved parts will void your warranty and can lead to malfunction and resulting

injuries. Genuine parts are available from Jefferson your dealer.

• Do not modify the equipment for any use other than which it was designed for by the manufacturer. Do not tamper with or attempt to adjust

the tank, pressure switch or safety valve. Never strap anything to the tank. Do not subject the tank to impact, vibration, heat, abrasion or

corrosive materials.

• Always contact an authorized service centre for advice on any repairs. Unauthorized modication may not only impair the equipment

performance but may also result in accident or injury to repair personnel who do not have the required knowledge and technical expertise to

perform the repair operations correctly.

• When the pump is not in use ensure that it is switched off, disconnected from the power supply and the air and all residual moisture drained

before putting into storage.

• This pump must be used in accordance with Health & safety, government, local authority, and water authority rules and regulations.

• Disconnect the pump from the mains power before changing accessories, servicing or performing any maintenance.

• Ensure that the pump is kept in good condition

• Only use for pumping water not exceeding 35ºc. Do not use in freezing temperatures.

• If the pump is used to pump water from a well, drain or deep receptacle, take adequate precautions to stop persons and animals falling in.

• Use the built-in handle to lower or raise the pump. it may be necessary to attach a suitable rope or pulley to the handle to assist when

operating at maximum depths.

• If the bed of the water container contains sludge, sand, gravel or mud etc, suspend the pump or place it on a raised base to operate above

the solid matter. Abrasive substances will reduce the working life of the pump, and invalidate your warranty if equipment damage is caused.

• In ood situations the user is responsible for ensuring that the appropriate risk assessments, back-up procedures, alarms etc are correctly

installed in case of pump failure.

• This pump is not designed for continuous use in a sh pond or similar water feature or display.

• Do not operate the pump if any parts are damaged or missing as this may cause failure and/or possible personal injury.

• Do not operate the pump out of water. the pump pick up area must be completely submerged during operation.

• Do not exceed the maximum submersible depth or any other rated specications (see equipment specications).

• Do not allow uncontrolled discharge of contaminated water which would pollute the environment.

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com 5

OPERATION

1. Fit the appropriate discharge pipe to pump outlet and secure with a clip.

2. Ensure the diameter of the discharge pipe is the same as or greater than the outlet diameter, as a smaller pipe will adversely effect the pump

ow rate.

3. Position the pump in the water accordingly, and place the outlet pipe securely in the discharge receptacle or area. Submerge the pump at

an angle into the water to prevent air pockets from forming on the underside of the appliance. Once submerged it can be straightened up and

positioned for operation. It is recommended that the pump is sunk with its discharge outlet facing up, to release any trapped air.

4. Connect the pump to the electrical mains supply and turn it on to begin pumping.

5. As the water level lowers, the oat will automatically switch the pump off as it reaches the

minimum height.

6. The oat can be adjusted by shortening or lengthening the cable using the xing clip.

7. The pump will switch on if the water level is up to or above the maximum length of the oat

cable.

8. To function correctly the oat must be allowed to move freely without obstruction. The pump

requires an area of 50cm x 50cm to operate correctly. Refer to equipment specications to

determine the suitability of the pump to the task and working environment. Contact your Jefferson

Dealer for advice if required.

9. Ensure the oat can do so and that the cable is not restricted.

10. Check that the pump and discharge are working correctly.

11. The water into which the pump is placed will act as the motor’s cooling agent so it is important that the pump remains submerged at all times.

Operating the pump in shallow water for prolonged periods of time can result in the motor overheating and will invalidate the warranty.

MAINTENANCE

• Ensure all maintenance and repair operations are carried out by fully trained and competent persons.

• Ensure the pump is disconnected from the mains power supply before attempting any service or maintenance.

• Keep all parts of the pump clean. rinse, drain and allow to dry before storing the pump.

• Visually check the equipment for damage before use.

• Regularly check the water inlet on the base of the pump to ensure that there are no blockages. to access the impeller, carefully undo the

base screws and remove the base. Clean the impeller and replace the base ensuring that the o ring is correctly positioned

• Do not dismantle any other part of the unit for maintenance purposes.

TROUBLESHOOTING

FAULT CAUSE REMEDY

The motor is running as normal but there

is no suction.

1. The water level is below the minimum suction depth.

2. Air bubbles in pump accumulated during submersion, or

oat is incorrectly positioned so the pump does not stop at

minimum level and is sucking in air.

3. Clogged intake lter or discharge pipe.

1. Stop the pump.

2. Release air by inclining the pump and re-immersing it

in water.

3. Remove the blockage, and clean the unit.

Reduced water volume for level of water. 1. The discharge pipe is bent, or pinched.

2. The discharge pipe too narrow for the ow rate.

3. The pump is partially blocked.

1. Straighten pipe.

2. Use wider diameter discharge pipe.

3. Clean pump.

The pump will not start or suddenly stops

during operation.

1. No electrical power.

2. The oat is not working.

3. The impeller is jammed.

1. Check the cable, plug and fuse.

2. Contact your authorised service agent.

3. Clean the pump.

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com

6

PARTS DIAGRAM

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com 7

PARTS LIST

# Description # Description

1Bolt 28 Bearing

2Washer 29 Thermal Protector

3Protector 30 Stator

4Cable Presser 31 Mechanical Seal

5Washer 32 "O" Ring

6Screw 33 Nut

7Nut 34 Washer

8Handle 35 Connection Part

9Screw 36 Screw

10 Flange 37 "O" Ring

11 Cable Protector 38 Bolt

12 Float Switch 39 Oil Seal

13 Capacitor Cover 40 Washer

14 Bolt 41 Impeller

15 Washer 42 Washer

16 Cable 43 Spring Washer

17 Gasket 44 Nut

18 Capacitor 45 Gasket

19 "O" Ring 46 Outlet Connector

20 Upper Cover 47 "O" Ring

21 Screw 48 Bolt

22 Spring Washer 49 Washer

23 Washer 50 Flange

24 Line Protector 51 Gasket

25 Undulated Washer 52 Pump Casing

26 Bearing 53 Base Plate

27 Rotor 54 Bolt

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com

8

WEEE Waste Electrical and Electronic Equipment Statement

Information on Disposal for Users of Waste Electrical & Electronic Equipment

This symbol on the product(s) and / or accompanying documents means that used electrical and electronic products should

not be mixed with general household waste. For proper treatment, recovery and recycling, please take this product(s) to

designated collection points where it will be accepted free of charge.

For private households:

Dispose of this product at the end of its working life and in compliance with the EU Directive on Waste Electrical and Electronic

Equipment (WEEE). Contact your local solid waste authority for recycling information for this equipment.

Disposing of this product correctly will help save valuable resources and prevent any potential negative effects on human health and the

environment, which could otherwise arise from inappropriate waste handling.

Please contact your local authority for further details of your nearest designated collection point.

Penalties may be applicable for incorrect disposal of this waste, in accordance with you national legislation.

For business users in the European Union:

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for further information.

Information on Disposal in other Countries outside the European Union:

This symbol is only valid in the European Union. If you wish to discard this product please contact your local authorities or dealer and ask for the

correct method of disposal.

RoHS Directive 2011/65/EU

We hereby declare that this equipment has been tested and found to be compliant to RoHS Directive 2011/65/EU of the European Parliament and

the Council from 08/06/2011 on restriction of the use of certain hazardous substances in electrical and electronic appliances.

Determination of levels of regulated substances in electrotechnical products, elements of Cadmium (Cd), Lead (Pb), Mercury (Hg), Chromium (Cr)

and Bromine (Br) contents were measured by XRF Spectroscopy and chemical conrmation test for RoHS restricted substances.

ENVIRONMENTAL PROTECTION

Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools, accessories and packaging

should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable, reaches the end of its working life and requires disposal, drain off any

uids (if applicable) into approved containers and dispose of the product and the uids according to local regulations.

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com 9

EC DECLARATION OF CONFORMITY

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

Directive: Description:

2014/30/EU (as amended)

Electromagnetic Compatibility

2006/42/EC (as amended) Machinery Directive

2014/35/EU (as amended) Low Voltage Directive

2011/65/EU (as amended) RoHS Directive

Equipment Category: Water Pump

Product Name/Model: JEFSUBPIDW210-12 - 500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

Notified Body Ente Certicazione Macchine Srl

Via Ca’ Bella, 243 – Loc. Castello di Serravalle – 40053 Valsamoggia (BO) - ITALY

+39 051 6705141 +39 051 6705156

Notified Body Number: 1282

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 12th June 2020

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park, Chester, United Kingdom,

CH4 9QR

Telephone: +44 (0)1244 646 048 Fax: +44 (0)1244 241 191

Email: [email protected]

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com

10

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects in workmanship

or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or components of this product

that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal

operations, improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then

the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• JEFSUBPIDW210-12 - 500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days cover or the

remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is recommended as it eliminates the need to

provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or replacement at an

authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange collection and

transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability under this

warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.) caused by

the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by Jefferson with respect to its

products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for possible

wear and to correct any issues prior to cable failure.

LIMITED WARRANTY STATEMENT

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com 11

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where

final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form online and submit it

to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised Jefferson

repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together with a copy of

the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions of their road haulage association directives.

NOTE: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is defective and in need

of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all equipment presented must have been

used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer (normally within 7

working days).

NOTE: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per hour plus

return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause of the problem, a

minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working days upon receipt

of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not immediately available Jefferson will

contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to warranty@

jeffersontools.com

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for

illustration purposes only.

USER MANUAL

JEFSUBPIDW210-12

500W INDUSTRIAL SUBMERSIBLE WATER PUMP 110V

www.jeffersontools.com

12

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

www.jeffersontools.com

www.jeffersontools.com

Table of contents

Other Jefferson Professional Tools & Equipment Water Pump manuals

Popular Water Pump manuals by other brands

SFA-SANIFLO

SFA-SANIFLO SANICUBIC 1 instruction manual

Wilo

Wilo Wilo-FAG Installation and operating instructions

Debem

Debem EQUAFLUX Instructions for use and maintenance

Gardena

Gardena 6000 1777 Operation instructions

Franklin Electric

Franklin Electric INLINE 1100 SPECPAK owner's manual

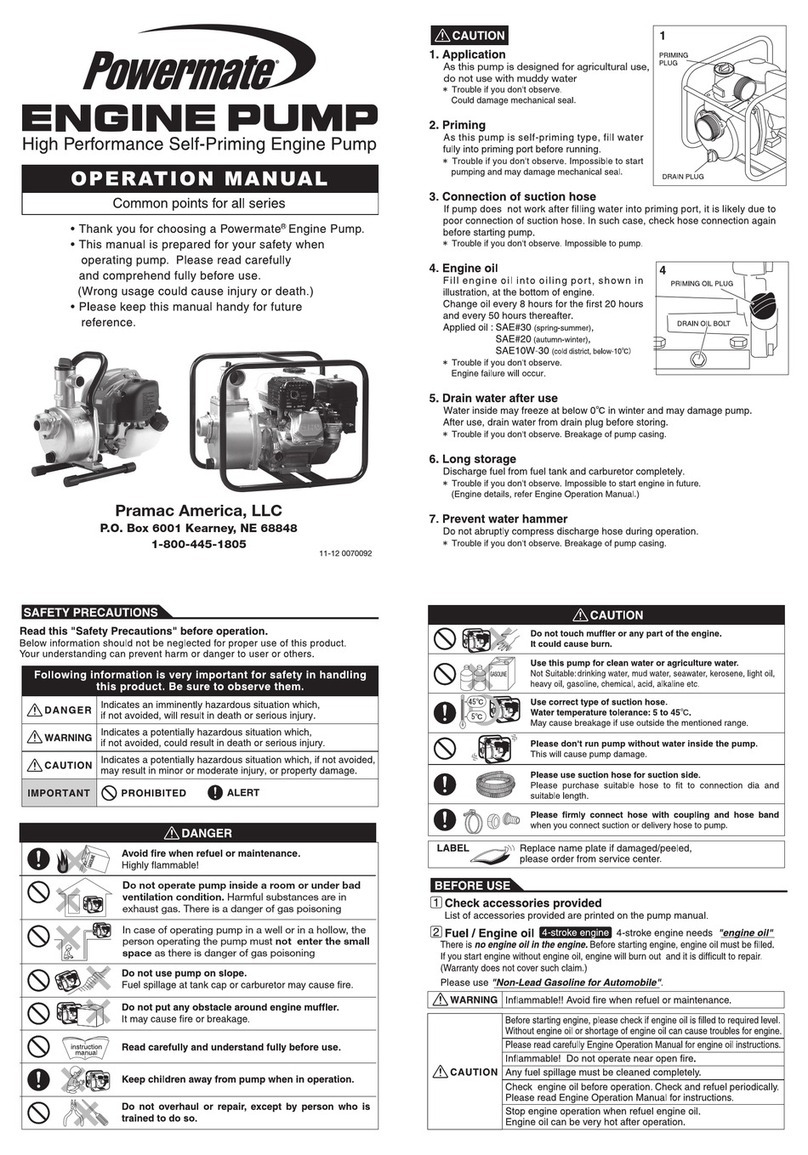

Powermate

Powermate PP0100381 Operation manual

Graco

Graco NXT Air Motor M02LN0 Instructions and parts

Trolla

Trolla 12823 quick start guide

Pentair

Pentair SRM4T2 owner's manual

Pacific hydrostar

Pacific hydrostar PACIFIC HYDROSTAR 1/3 HP Submersible Sump Pump with Vertical Float... manual

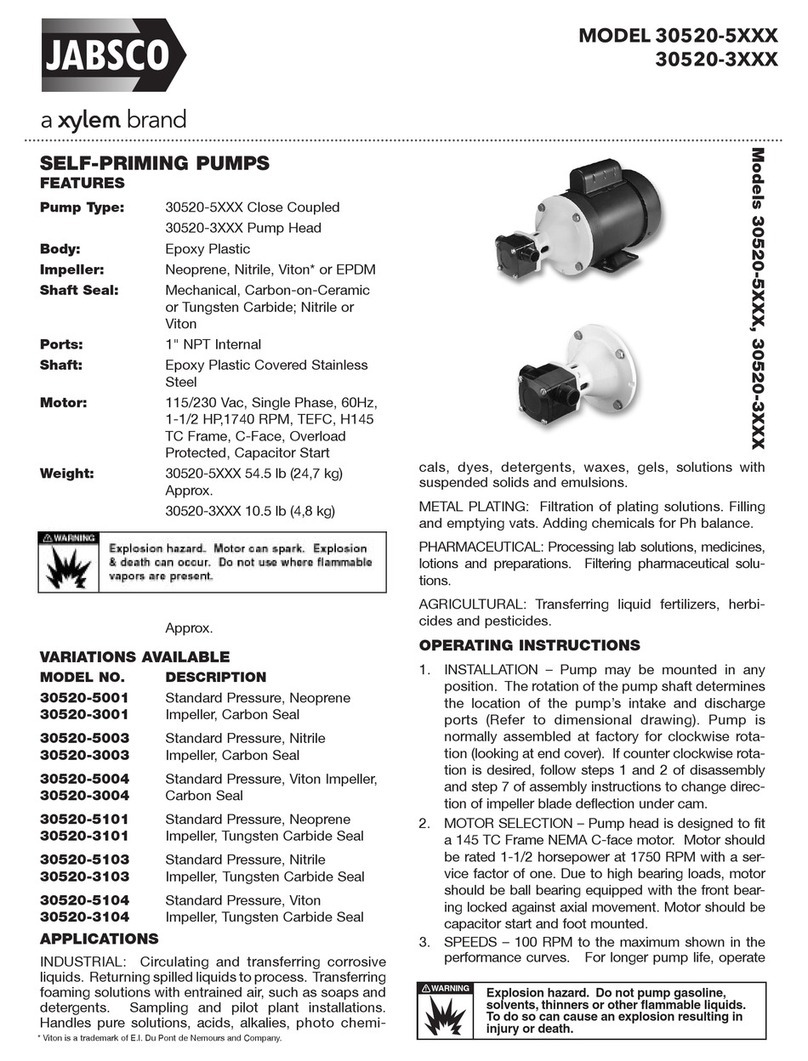

JABSCO

JABSCO 30520-5 Series manual

KNF

KNF N87.9 Operating and installation instructions