SJE Rhombus Installer Friendly Series User manual

Installer Friendly Series®

Technical Support: +1 800-746-6287

www.sjerhombus.com

Technical Support Hours: Monday-Friday, 7 A.M. to 6 P.M. Central Time

Installer Friendly Series®

Installation and Operation Manual

This control panel must be installed and serviced by a licensed electrician in

accordance with the National Electric Code NFPA-70, state and local electrical codes.

UL Type 4X enclosures are for indoor or outdoor use.

Warranty void if panel is modifi ed.

E1

For information regarding operation,

available options, or servicing

questions, please call SJE Rhombus

Technical Support.

SJE Rhombus oers a ve-year limited warranty on the control panel

and the C-Level™ sensor.

For complete terms and conditions, please visit www.sjerhombus.com.

Products returned must be cleaned, sanitized, or decontaminated as necessary

prior to shipment to ensure that employees will not be exposed to health

hazards in handling said material. All applicable laws and regulations shall apply.

?

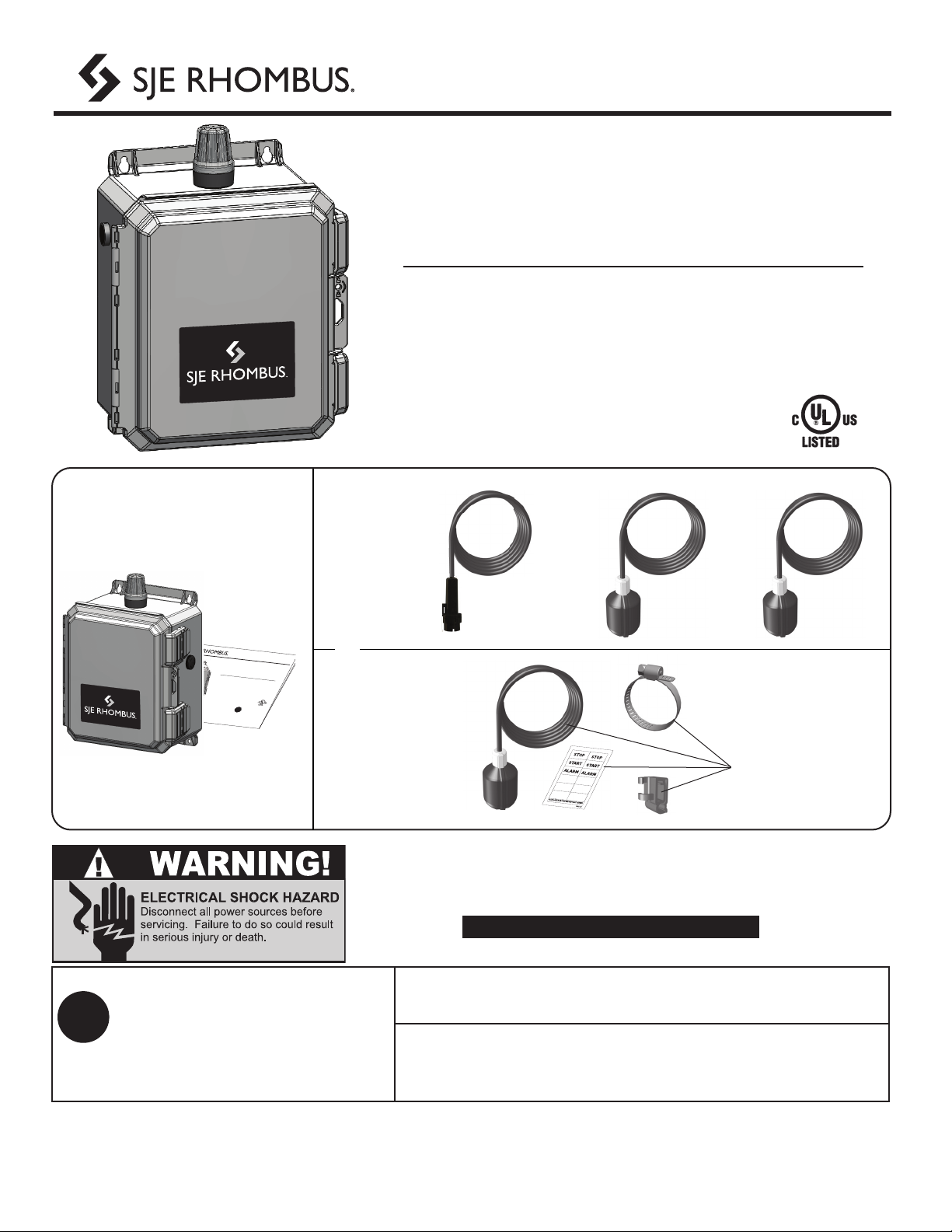

High Water FloatRedundant O FloatC-Level™Sensor

Parts included

Manufactured by:

SJE Rhombus

Detroit Lakes, MN, USA

*Control panel may be

ordered with or without

C-Level™ Sensor/Floats. C-Level™

Sensor

Models

Float

Switch

Models 3x

or

4x

Installer Friendly Series®

Installation and Operation Manual

This control panel must be installed

and serviced by a licensed electrician

in accordance with the National Electric

Code NFPA-70, state and local electrical

codes.

UL Type 4X enclosures are for indoor or

outdoor use.

Technical support,

service questions:

1-800-Rhombus

(1-800-746-6287)

Monday - Friday

7:00 AM to 6:00 PM CST

?

Installer Friendly Series

®

OROR

Installing the C-Level™Sensor & Float Switches

The IFS control panel operates with a C-Level™ sensor and 1 or 2

recommended oat switches or with 3 to 4 oat switches. For C-Level™

sensor operation, C-Level™ sensor operates the Pump Start, Stop and

Alarm functions and the back-up oat switches are for redundant o and

high level alarm. For oat switch operation, the oat switches operate the

Pump Start, Stop and Alarm functions.

Mounting the Control Panel

NOTE

Do not splice the C-Level™ sensor

cable.

Do not run C-Level™ sensor cable

or oat switch cables in the same

conduit as the pump cables.

E2

Ensure all supply power to the control panel

is turned OFF before installing or servicing

the C-Level™ sensor, oat switches or pumps

in the tank. Failure to do so could result in

serious or fatal shock.

Power from Breaker

O

Floats require free range of motion.

They must not touch each other or

any equipment in the pump chamber.

Timed Dose

Float Switch Installation

Make sure hose clamp

band does not interfere

with oat operation.

Tighten

the

clamp.

Hose clamp is 18-8

stainless steel.

3.5”

(9cm)

Do not install cord under

hose clamp.

Demand Dose

Duplex 3-Float

Simplex Duplex 4-Float

Simplex/Duplex

Timer Override

(optional)

Alarm

Timer Enable

Redundant O

(optional)

Alarm

Start

Stop

Lag/Alarm

Start

Stop

Lag

Alarm

Start

Stop

E3

Demand Dose Application

high water

alarm oat

(recommended)

redundant

o oat

(recommended)

lag (duplex

only)

high water

alarm

start

stop

0

Timed Dose Application

high water

alarm oat

(recommended)

redundant o

oat

(recommended)

high water

alarm

timer

enable

timer

override

redundant

o

0

Float Switch Positioning

CAUTION!

If the C-Level™sensor or oat

switches are not mounted and

connected correctly, the pumps

and alarm will not operate

properly.

3.5”

(9 cm)

C-Level™ Sensor Positioning

Keep vent above water level. hose

clamp

4 inch (10.2 cm)

minimum set level

0 inch (0 cm) liquid

level measured from

approximately this point

1 inch (2.5 cm)

minimum from bottom

of tank or from sludge

hose

clamp

Stow excess tube using a

cable tie.

Caution: Do not overtighten

and pinch vent tube.

Do not use the hose clamp

to attach the vent tube.

Doing so will cause sensor

to fail.

cable

tie

C-Level™Sensor and Float Switch Installation

E4

PN 1067499A 11/21

© 2021 SJE, Inc. All Rights Reserved.

SJE Rhombus is a trademark of SJE, Inc.

Wiring the Control Panel

1Locate conduit entrance at the bottom of the enclosure as

shown. Check local codes for the number of power circuits

required. The schematic is located on the inside cover of the

control panel.

Be sure the incoming voltage is the same as the pump motor

nameplate.

Providing separate pump and control/alarm power sources is

recommended.

Type 4X conduit must be used to maintain a Type 4X rating

of the control panel.

CAUTION!

CAUTION!

Seal the electrical conduit with an approved

sealing compound to prevent moisture or

gases from entering into the control panel.

Connect the following wires to the proper terminals:

• incoming power for each pump circuit breaker

• incoming power for control/alarm

• pump 1

• pump 2 (duplex only)

• C-Level™ sensor

• oat switches (recommended)

See schematic label on inside cover of the control panel for

details.

2

Duplex Model Shown

Setup and Operation

Rotate dial and press to select the corresponding pump’s mode indicator or panel settings icon.

3Verify correct operation of control panel after installation is

complete.

If redundant o oat is not used, a jumper must be

installed in its place.

2

Alarm System (Indicator Light and Horn)

When an alarm condition occurs, the red light and

horn will be activated.

If the TEST/SILENCE button is pressed and released,

the horn will be silenced. When the alarm condition

is cleared, the alarm system is reset.

Circuit Breakers

Each pump circuit has a thermal-magnetic circuit

breaker that provides branch circuit protection and a

means to disconnect the pump.

Float Test Switches

Push to simulate a oat closure condition for each

input.

Dry Auxiliary Contacts

Normally Open - Contacts are OPEN under normal

conditions and CLOSED when alarm condition is

present. CLOSED during power loss.

Automatically resets once alarm condition is cleared.

Aux contact rating: 120V, 5A

1

2

4

3

NOTE

1

3

4

HAND

OFF

AUTO

1

HAND

OFF

AUTO

2

PUMP 2

(duplex only)

SETTINGS

Counts and ETMs - Displays pump run time and counts of pump run and alarms

Timer Settings - Congures timers (Timed Dose mode only)

Level Settings - Congures level setpoints

Alternation (duplex only) - Congures alternation mode for duplex panels

Advanced - Congure advanced functions and view troubleshooting tools

PUMP 1

HOA

Installer Friendly Series®

Soporte técnico: +1 800-746-6287

www.sjerhombus.com

Soporte técnico, Horario: Lunes a viernes 7 A.M. a 6 P.M., hora del Centro

Installer Friendly Series®

Manual de instalación y operación

ADVERTENCIA

RIESGO DE CHOQUE ELÉCTRICO

Desconectar todas las fuentes de poder

antes de efectuar mantenimiento o reparaciones.

No obedecer estas indicaciones podría resultar

en serias lesiones o mortales.

La instalación, el mantenimiento y la reparación de este panel de control deben ser

efectuados por un electricista certicado conforme al Código Eléctrico Nacional de

EE.UU. NFPA-70 y los códigos estatales y locales. Las cajas/gabinetes clasicación

UL tipo 4X son para uso interior o exterior.

La garantía queda anulada si se modifi ca el panel.

S1

SJE Rhombus ofrece una garantía limitada de cinco años para el panel de

control y el sensor C-Level™. Para consultar los términos y condiciones, visite el

portal www.sjerhombus.com.

?

Flotador de

nivel alto

Flotador de

apagado redundante

Sensor C-Level™

Piezas incluidas

Fabricado por:

SJE Rhombus

Detroit Lakes, MN, USA

*Es posible solicitar el panel

de control con o sin sensor

C-Level™/otadores.

Sensor

C-Level™

Modelos

Interruptor

de otador

Modelos 3x o 4x

Installer Friendly Series®

Installation and Operation Manual

This control panel must be installed

and serviced by a licensed electrician

in accordance with the National Electric

Code NFPA-70, state and local electrical

codes.

UL Type 4X enclosures are for indoor or

outdoor use.

Technical support,

service questions:

1-800-Rhombus

(1-800-746-6287)

Monday - Friday

7:00 AM to 6:00 PM CST

?

Installer Friendly Series

®

O BIENO BIEN

Para información acerca del

funcionamiento, las opciones

disponibles o para preguntas

acerca del mantenimiento, por

favor comunicarse con Soporte

técnico de SJERhombus.

Los productos devueltos deben estar limpios, desinfectados y

descontaminados según sea necesario antes de enviarlos de modo que se

garantice que los empleados no van a estar expuestos a riesgos de salud

durante la manipulación de dicho material. Se aplicarán todas las leyes y

normas vigentes.

Other manuals for Installer Friendly Series

2

This manual suits for next models

1

Table of contents

Languages: