skals AMV1 User manual

1

Manual

Weighing Machine

AMV1

A/S SKALS MASKINFABRIK

HOVEDGADEN 56

DK-8832 SKALS, DENMARK

Tel.: +45 87 25 62 00

Fax: +45 86 69 49 99

Email: [email protected]

http://www.skals.dk/

2

1Contents

1Contents........................................................................................................................2

2Introduction ...................................................................................................................3

3Safety ............................................................................................................................4

3.1Pictograms.......................................................................................................................... 4

4In general ......................................................................................................................5

4.1Feed belt............................................................................................................................. 6

4.2Vibration chutes.................................................................................................................. 6

4.3Weighing tank..................................................................................................................... 7

4.4Cross conveyor................................................................................................................... 8

4.5Sack platform...................................................................................................................... 9

4.6Operating panel .................................................................................................................. 9

5Operation ......................................................................................................................9

5.1Set-up ................................................................................................................................. 9

5.2Electrical connection........................................................................................................... 9

5.3Start-up............................................................................................................................. 10

6Control.........................................................................................................................11

6.1Homescreen ..................................................................................................................... 11

6.2Settings............................................................................................................................. 11

6.3Skals................................................................................................................................. 12

6.4Automatic operation settings ............................................................................................ 13

6.5Manual operation settings ................................................................................................ 17

6.6Emptying the machine ...................................................................................................... 18

7Service and maintenance............................................................................................18

7.1Bearings ........................................................................................................................... 18

7.2Gear.................................................................................................................................. 18

7.3Belt ................................................................................................................................... 18

7.4Vibration chutes................................................................................................................ 20

7.5Cleaning ........................................................................................................................... 21

8Transport.....................................................................................................................22

9Troubleshooting ..........................................................................................................23

9.1Fault described in display. ................................................................................................ 23

3

9.2Other faults. ...................................................................................................................... 24

10Spare parts list .........................................................................................................25

10.1Weighing tank................................................................................................................... 26

10.2Vibrator chute ................................................................................................................... 27

10.3Feed belt........................................................................................................................... 28

10.4Cross conveyor................................................................................................................. 29

11Diagrams..................................................................................................................31

12EU Declaration of Conformity...................................................................................32

2Introduction

Read this user manual thoroughly before using the machine.

The machine is use for weighing potatoes, onions, carrots and other similar products.

The machine can weight portion sizes from 1–50 kg.

The machine can weigh large portions up to 1000 kg.

The machine may be operated in a temperature range of -10 to +40 C°.

The information plate and CE label are positioned on the side of the machine, close to the

control panel.

4

3Safety

Any persons working in the close vicinity of the machine must not wear loose-fitting

clothing as this will be hazardous.

3.1 Pictograms

Two types of pictograms are positioned on the machine. Warnings and instructions.

Warnings

HAZARD - ROTATING PARTS.

Avoid touching or coming into contact with the machine's

moving parts. This applies to fingers and clothing, since this

can lead to mutilation.

CRUSH HAZARD.

Avoid touching or coming into contact with the machine's

moving parts. This applies to fingers and clothing, since this

can lead to mutilation.

Instructions

HOOK

Describes where the hook must be positioned when the machine is to be

lifted by a crane.

STRAP HERE

Describes where the machine shall be secured during transport.

FORKLIFT TRUCK

Describes where the forks must be positioned when lifting with a forklift

truck.

5

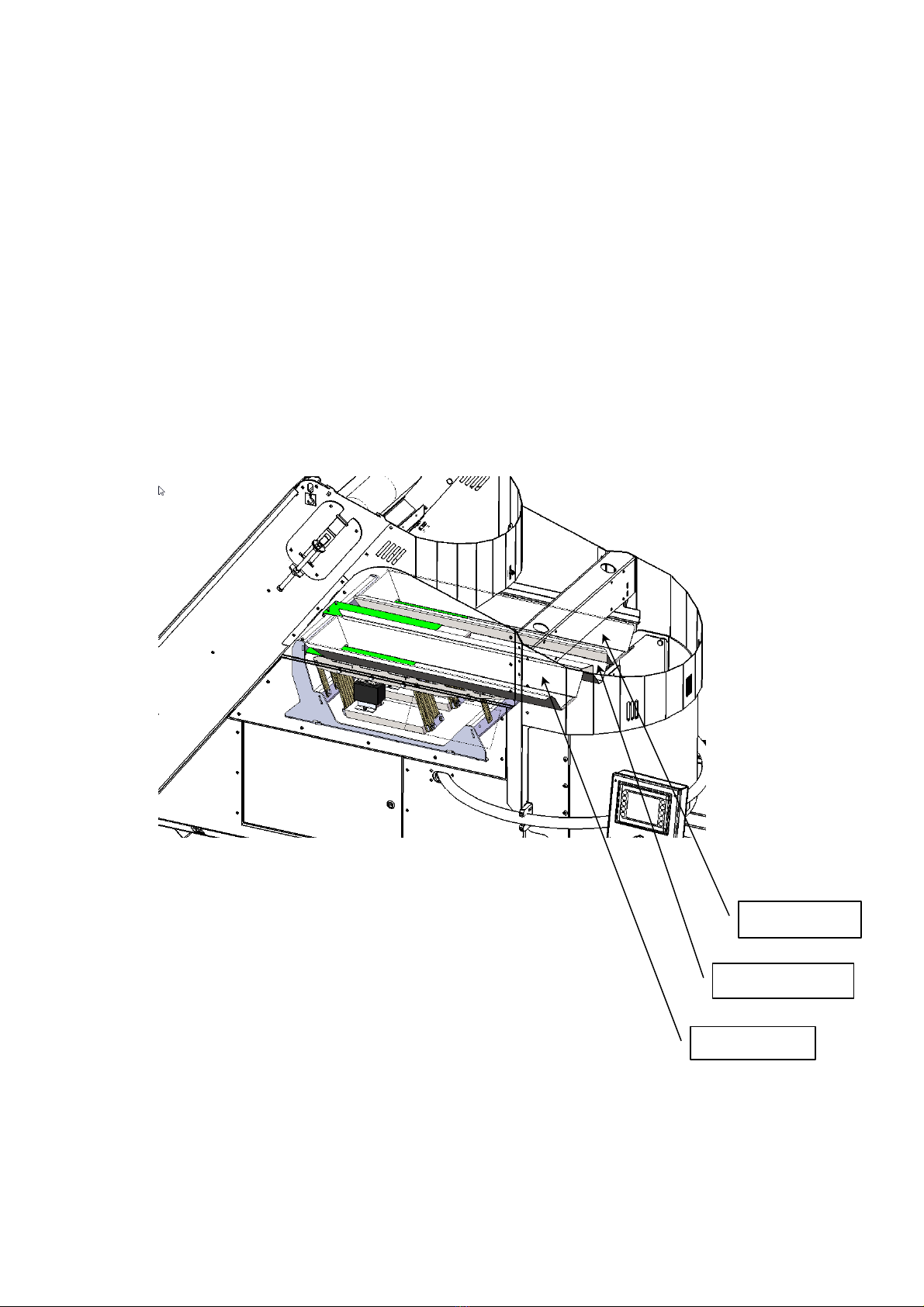

4In general

Description of machine

Buffer tank

Feed belt

Vibration chutes

Wei

g

hin

g

tank

Cross conveyor

Operating panel

Feed hopper

6

4.1 Feed belt

The feed belt transports the products from the feed hopper up to the buffer tank above the

vibration chutes. The buffer tank has two sensors that activate and deactivate the feed

belt.

To achieve optimal operation, it is important that the feed hopper is always filled

with products.

4.2 Vibration chutes

The machine is equipped with three vibration chutes, designed to fill and dose the

weighing tank.

All three of the vibration chutes switch on automatically when the weighing tank shall be

filled and only two of the chutes operate when dosing for the required weight.

Fill chute.

Dosing chute

Fill chute.

7

4.3 Weighing tank

The weighing tanks' volume capacity is 57 l.

The weighing tank must be checked regularly and if required, cleaned of any soil that has

accumulated.

During operation, the weighing tank must not be touched otherwise the weighing result will

not be correct.

8

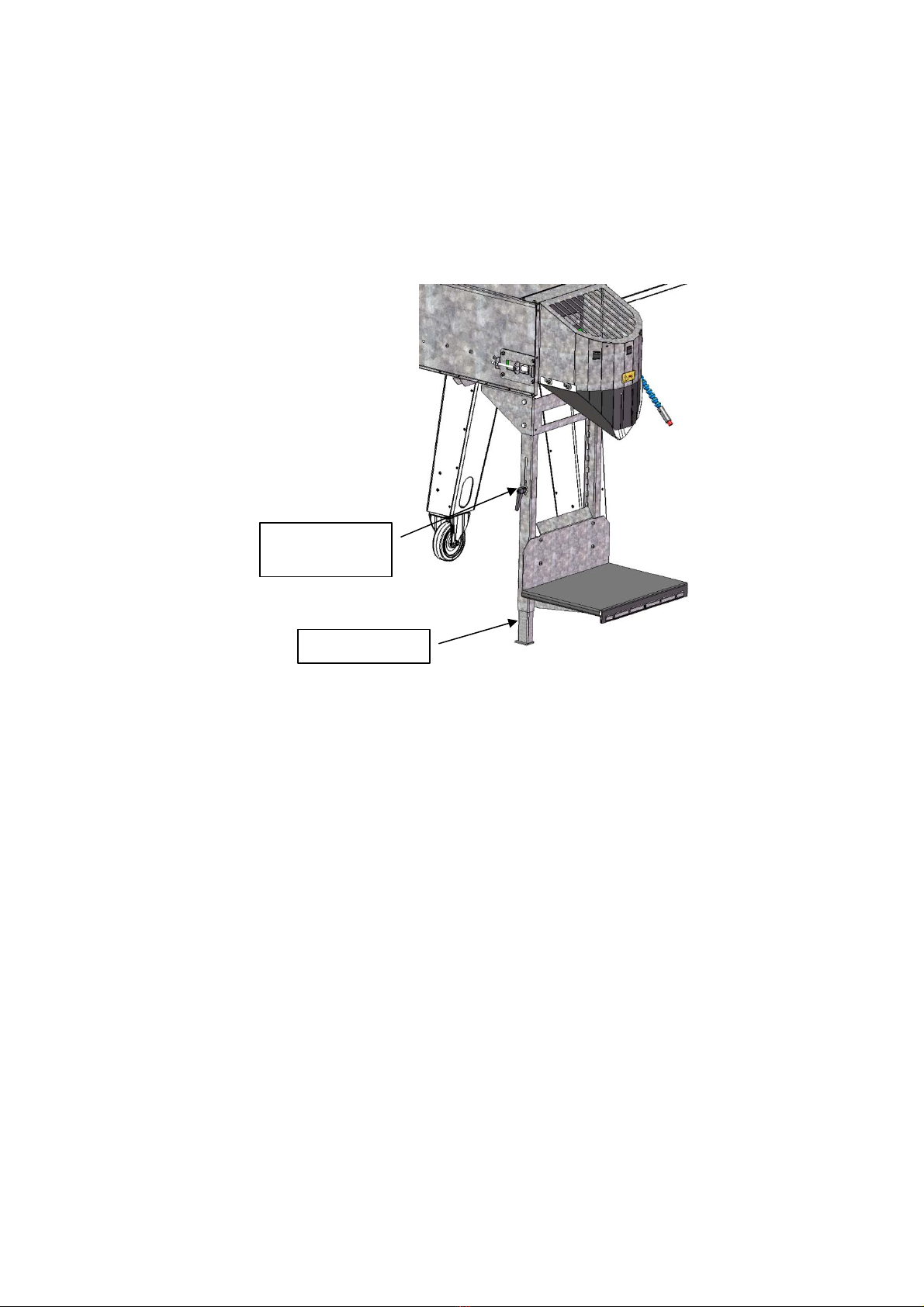

4.4 Cross conveyor

The cross conveyor allows the machine to be operated by two people at the same time.

When the operating sensor is activated on a specific side, the cross conveyor will transport

the next portion to that side.

NB: The machine 'remembers' an activation of the operating sensor, even though the

cross conveyor is not ready to deliver a portion!

The machine is supplied with four outlet hoppers as standard. Two hoppers for portion

sizes 1–9 kg and two hoppers for 10–50 kg.

Outlet hopper

Operation sensor

Sack platform

Handle for stabiliser leg

Outlet hopper 10–50 kg Outlet hopper 1–9 kg

9

4.5 Sack platform

When the height of the sack platform shall be changed, loosen the two finger screws on

the platform and raised/lower the platform and then re-tighten the finger screws.

When weighing portions that weigh more than 10 kg, lower the stabiliser leg at the sack

platform until it supports on the level surface.

4.6 Operating panel

The operating panel consists of a touch display and a stop.

All of the machine's electrical functions are operated via the touch display.

5Operation

Before commissioning the machine, check it to ensure it has not been damaged during

transport.

Any defects must be reported to the dealer immediately.

5.1 Set-up

To ensure correct weighing, the machine must be placed on a stable and level surface.

5.2 Electrical connection

The electrical connection must comply with national applicable regulations.

1 Phase 230 V - N + PE

Stabiliser leg

Handle for

stabiliser le

g

10

5.3 Start-up

1. Enter the desired portion size and total number of portions that are to be weighed

using the operating panel.

2. Next, select the programme that is to be used (potatoes, carrots, onions or

optional).

3. Press the "Start" button on the display.

4. The operating sensor is activated.

NB: In the case of start-up after the portion size has been changed the machine may

initially weigh inaccurately. The machine will regulate this automatically after a few

weighings.

11

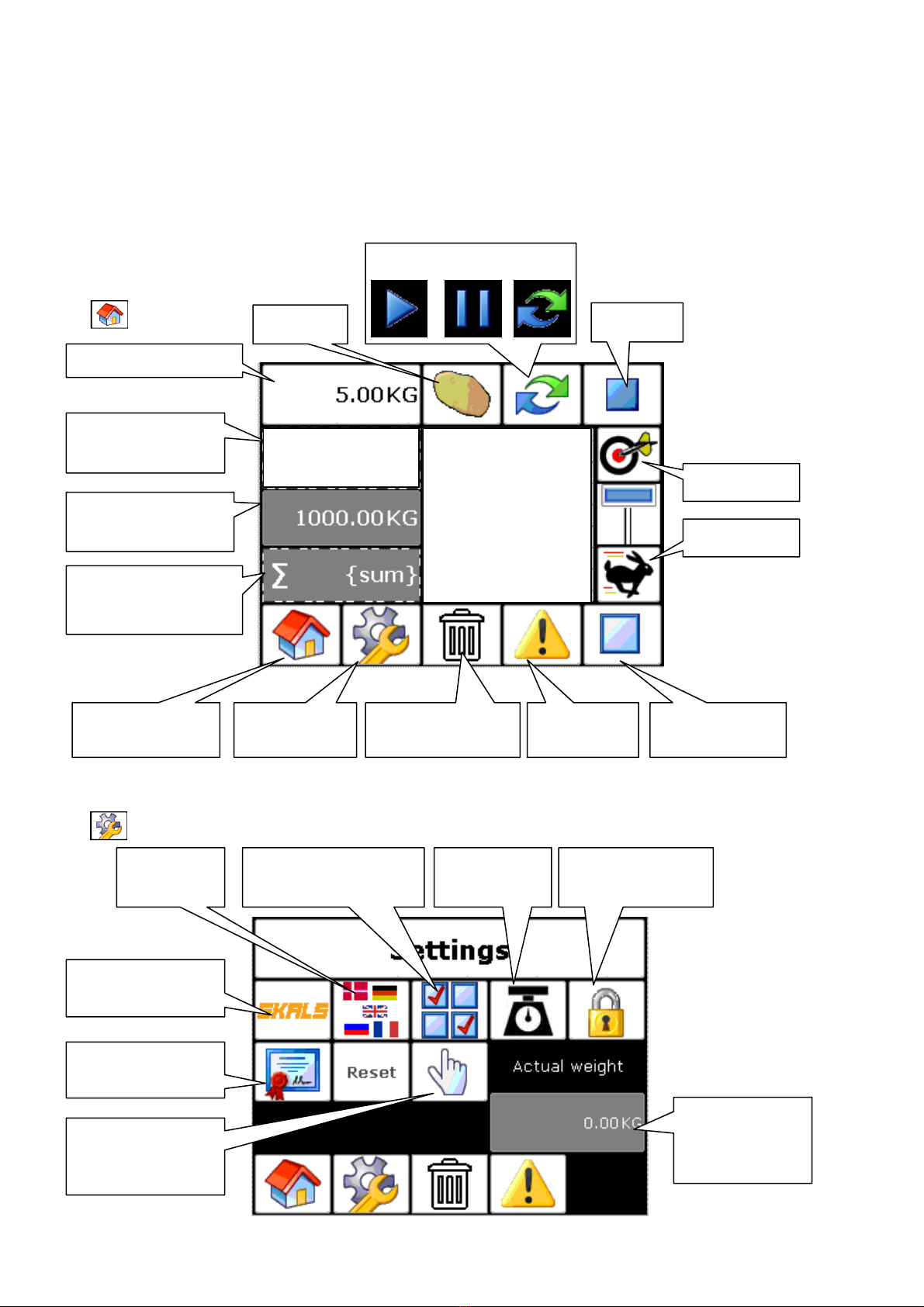

6Control

6.1 Homescreen

6.2 Settings

Portion sizes

Total number of

portions

Actual weight in

the weighing tank

∑Sum of weighings

X Average value

ϬStandard deviation

Return to

homescreen

Settings Empty function Alarms

Precision

Product

Start/Pause/Repeat

Stop

Reset alarms

Speed

6/10 6 5.01 kg

5 5.10 kg

4 5.04 kg

3 5.00 kg

2 5.03 kg

1 5.07 kg

Skals contact

information

Verification

Actual weight

in the

weighing tank

Language

setting

Automatic

operation settings

Scales settings

locked

Calibration

of scales

Manual

operation

settings

12

6.3 Skals

Skals contact information is shown here

Should you have any questions about the machine, contact your dealer in the first

instance.

Verification

The verification ID and date of last filling is show here.

13

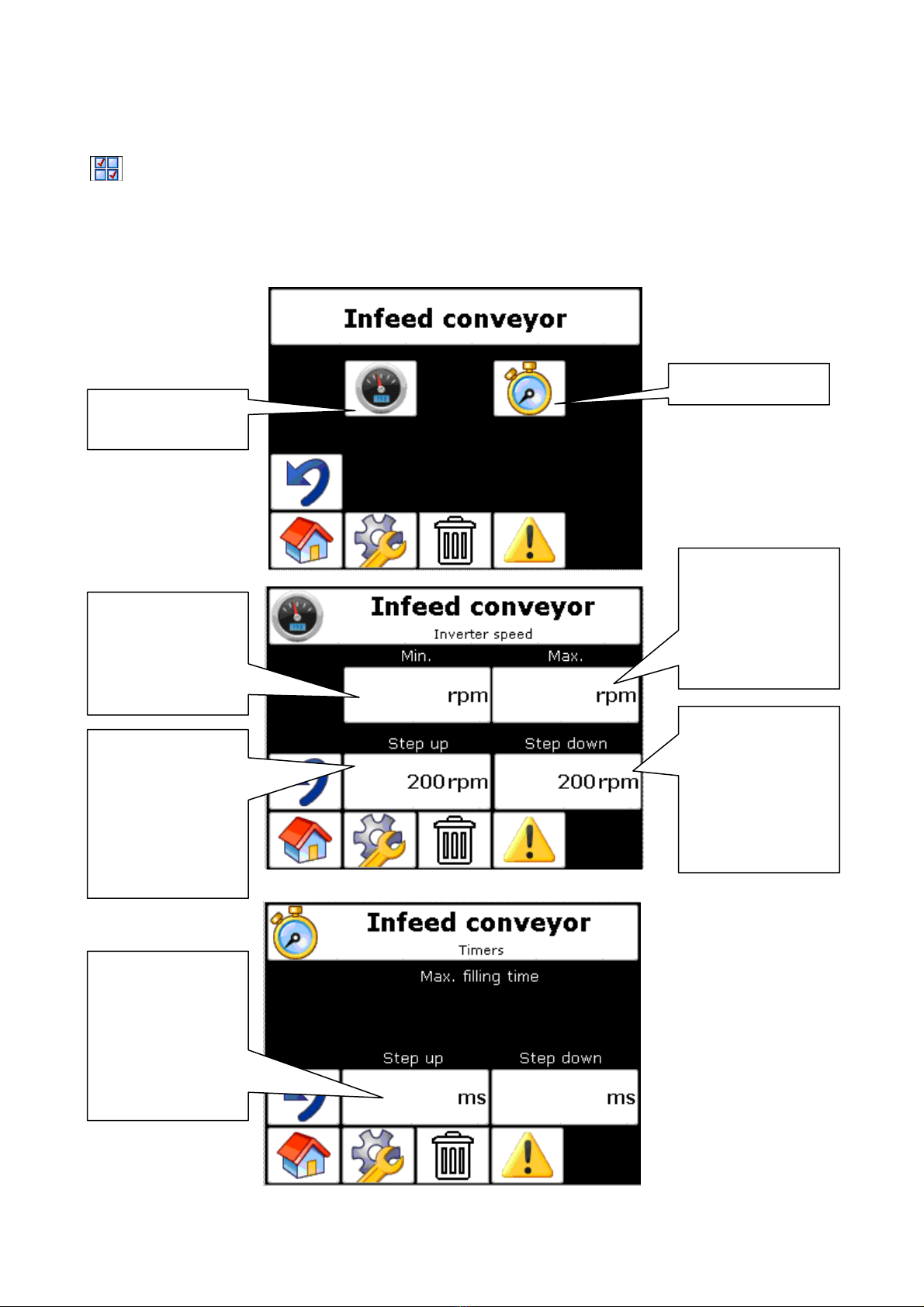

6.4 Automatic operation settings

There are four areas that can be set: Feed belt, vibration chutes, weight and cross

conveyor, of which the last three are relevant for normal operation.

Feed belt

Minimum rpm of

the drum motor

for the feed belt

should be set to

700 rpm.

Total rpm, the

drum motor

speed lowers

every time it de-

accelerates.

Should not be

changed.

Total rpm, the

drum motor

speed increases

every time it

accelerates.

Should not be

changed.

Maximum rpm

of the drum

motor for the

feed belt should

be set to

1500 rpm.

Time interval

between

automatic

change of

speed.

Speed, see next

image

Time setting

700 1500

1000 2000

14

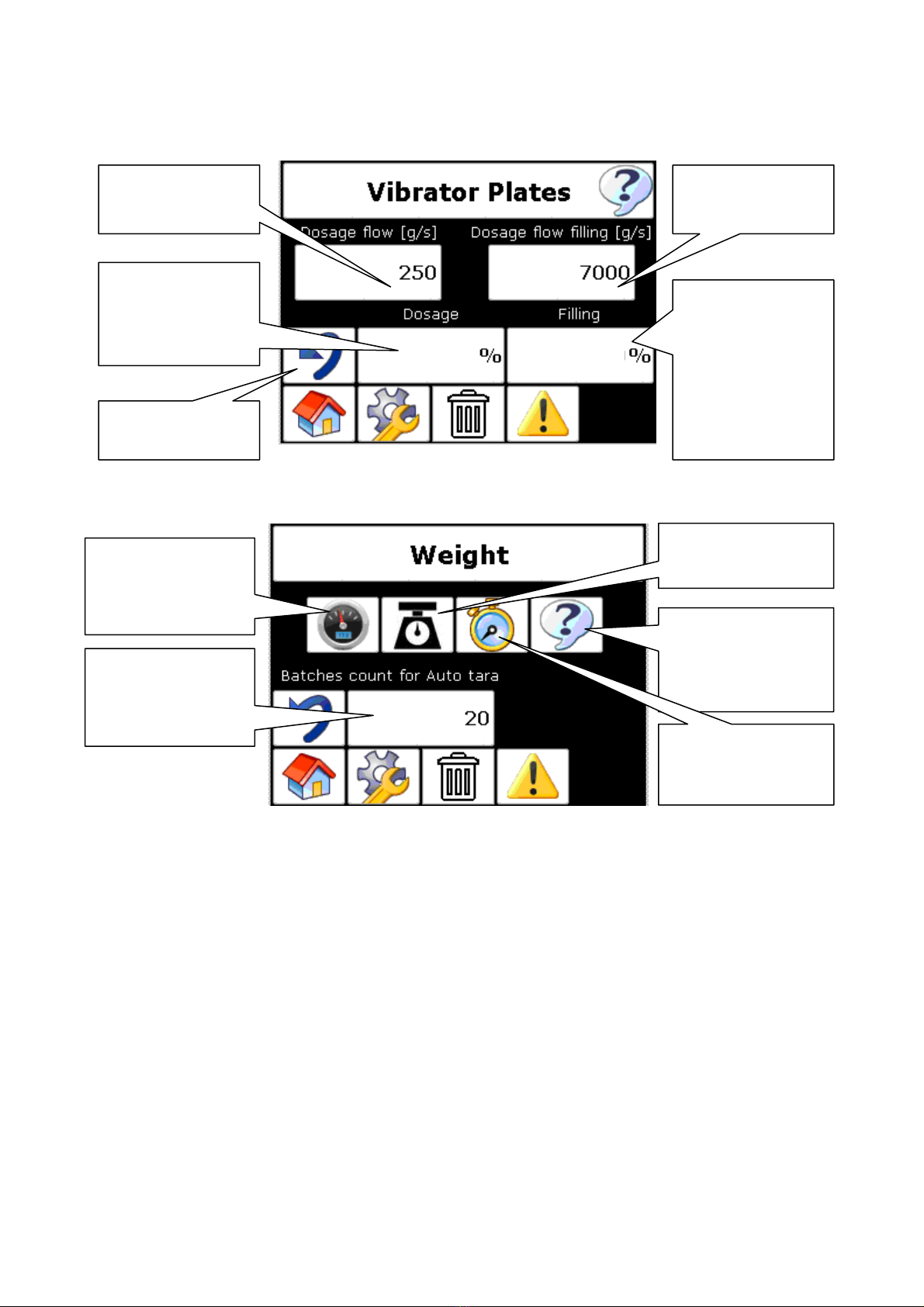

Vibration chutes

Scales

Auto taring

Automatically tares the scales zero point after a set number of portions (e.g. 20).

In the case of dirty products, it is relevant to have a low total number of weighings between

each auto taring. Build up of dirt in the weighing tank affects the weighing result.

Motor speed for

tank shutter

Should not be

chan

g

ed.

Total number of

portions between

each auto taring.

See explanation

Scales settings

See next image

Back to

previous menu

Estimated flow

when dosing

Vibration power

in percent.

Should not be

less than 55%

and should

always be

greater than

c

h

ute

2

Vibration power

in percent.

Should not be

less than 50% 75 85

Estimated flow

when filling

Product specific

settings.

(potatoes, carrots

etc.)

Alarm times

Should not be

changed.

15

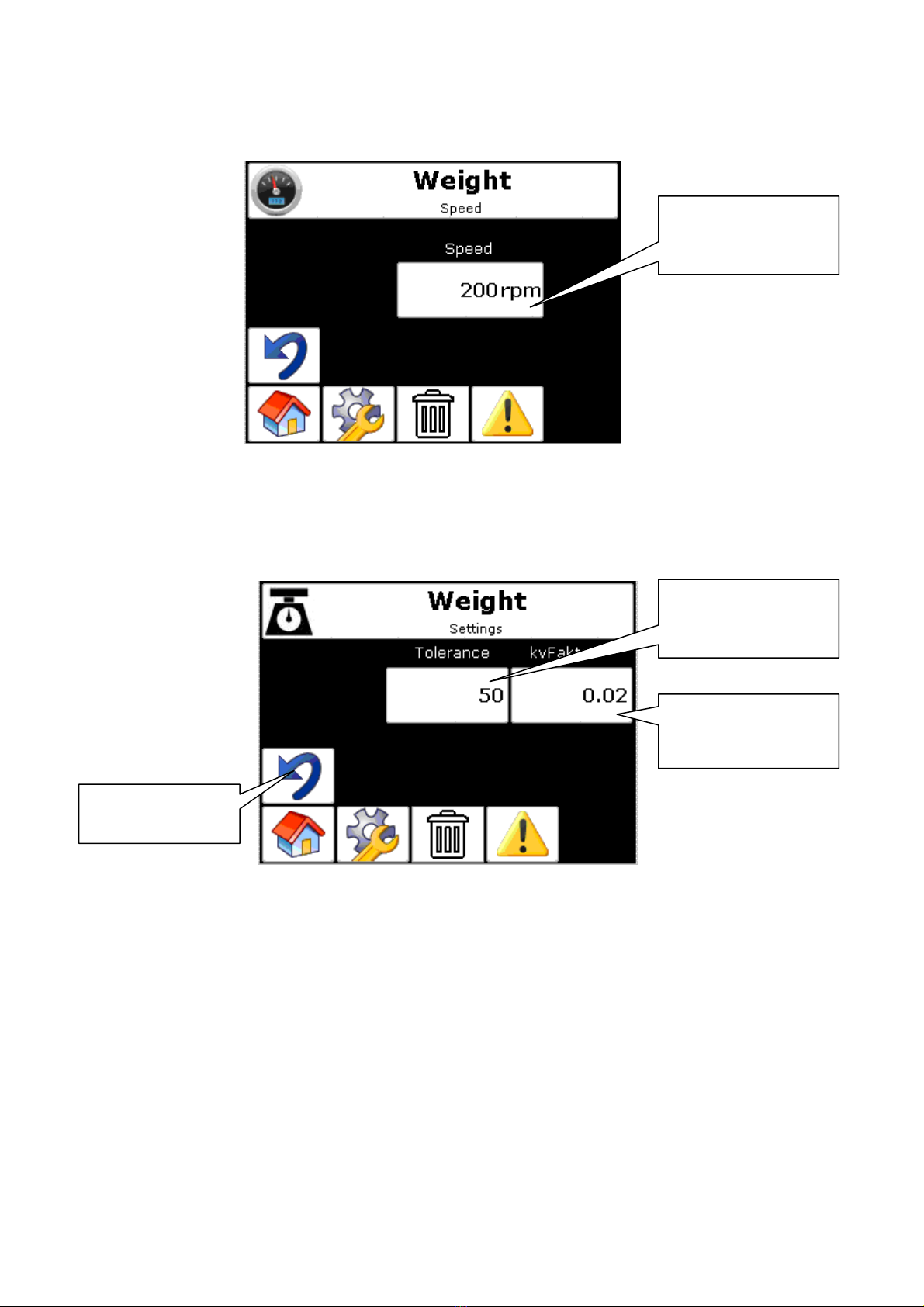

Weight Speed

Weight settings

Offset 25 kg:

When a double portion is made (over 25 kg), Offset 25 kg must be between 1500 and

3500 g to stop around the 25 kg. This is necessary to compensate for the run-on time and

prevent the weighing tank from becoming over filled with the first portion.

Tolerance

This is the limit for when the scales begins to be regulated.

If the products that are being weighed weigh up to 100 g, the tolerance must be the same

or 10 % greater.

Controller parameter

Parameter that determines how aggressive the controller reacts

Back to

previous menu

Controller

parameter

Tolerance interval

in grams, see

explanation

Weigher opening

speed

16

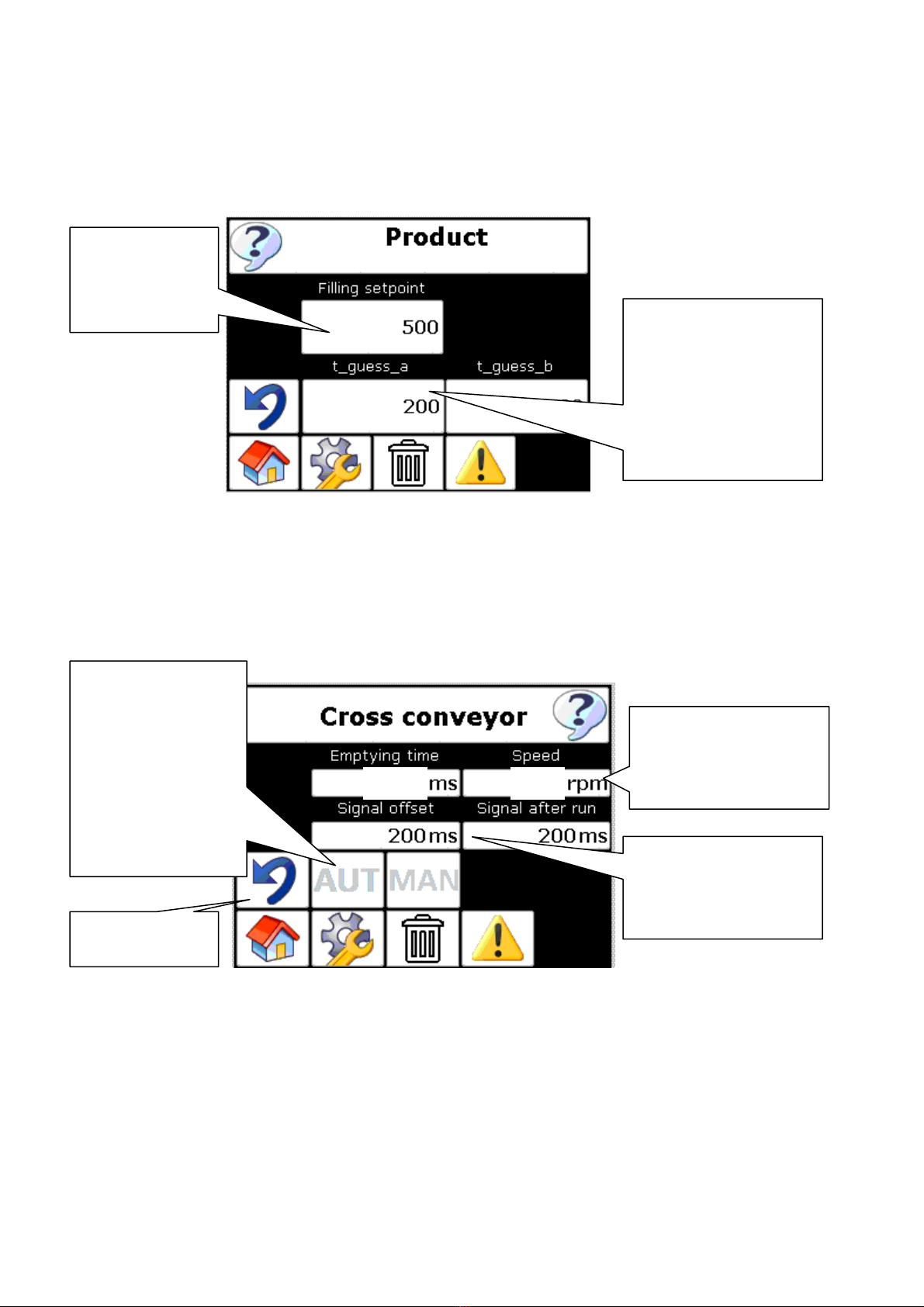

Product specific parameters

Cross conveyor

Empty time

The time that is set to ensure that the belt is completely empty.

Speed

If there are problems with the products coming out of the outlet hopper, reduce the speed.

Filling setpoint

is controlled by

the slider on

the main page

Delay and run-signal

to next machine

External signal

Back to

previous menu

2300 700

Time guess_a is a

value used for

portions up to 10kg.

Lighter products =

higher value.

The speed of the

cross conveyor

should be between

600 and 900 rpm

Aut. or manual

outfeed mode.

Manual = sensor

Aut. = after first

touch of the

sensor, next

portions are

feeded

automatically

17

6.5 Manual operation settings

During manual operation, all of the functions can be set and the machine operated.

NB: In manual operation mode, all of the alarms and sensors are de-activated.

Language

Five languages are available.

English

German

Danish

French

Russian

Lock

When the scales are locked, there is limited access to certain functions.

Scales guide

Programme 0-3

Scales guide (calibration)

To calibrate the scales, follow the instructions in the display.

Place a known weight in the weighing tank during calibration.

The weighing tank must be clean inside.

Every time the scales are calibrated a new ID number is generated, which can be seen

under the verification ID and a date for the last calibration.

Alarms

All of the alarms that can be triggered are shown in the troubleshooting section.

When an error is observed and corrected, the alarm is reset

18

6.6 Emptying the machine

If the machine is to be completely emptied, continue to weigh portions without filling the

intake hopper with any products. Once the vibration chutes have operated for a longer

period than normal, press Stop.

Next, empty the weighing tank and the cross conveyor by accessing the manual settings

and press to empty.

7Service and maintenance

During service and maintenance, ensure power has been disconnected at the main switch

and the main switch is locked.

7.1 Bearings

All of the bearings and motors and the loose drum have been lubricated at the factory and

require no maintenance.

7.2 Gear

The worm gear that drives the weighing tank's open/close function has been lifetime

lubricated with synthetic grease for operation in standard temperature range (-10 to +40

°C).

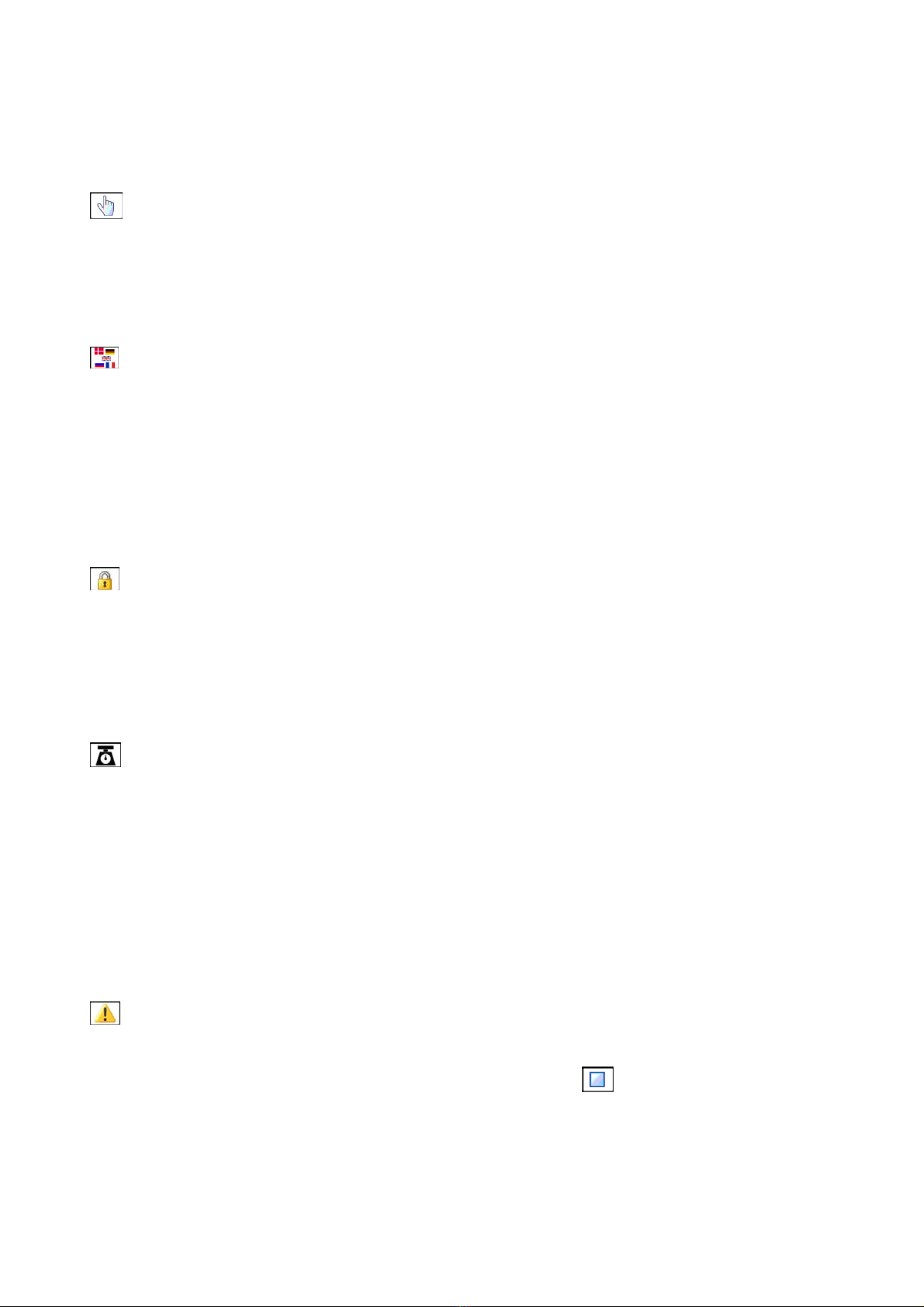

7.3 Belt

The machine has two PVC belts fitted. A feed belt and a cross conveyor.

Both belts must be checked regularly and adjusted if required to ensure a long lifetime.

Tighten the belts by loosening the two nuts marked with blue (on both sides) and then

tighten the belt by tightening the top nut. Once the belt has been adjusted, re-tighten the

19

bottom nut. The same procedure is used to adjust the belt to operate in the centre.

However, the tightening must only be done in the side the belt moves to.

At all times it is the responsibility of the owner to ensure the belts have been adjusted

correctly.

If the belts have not been adjusted correctly, the warranty for the belts is void.

20

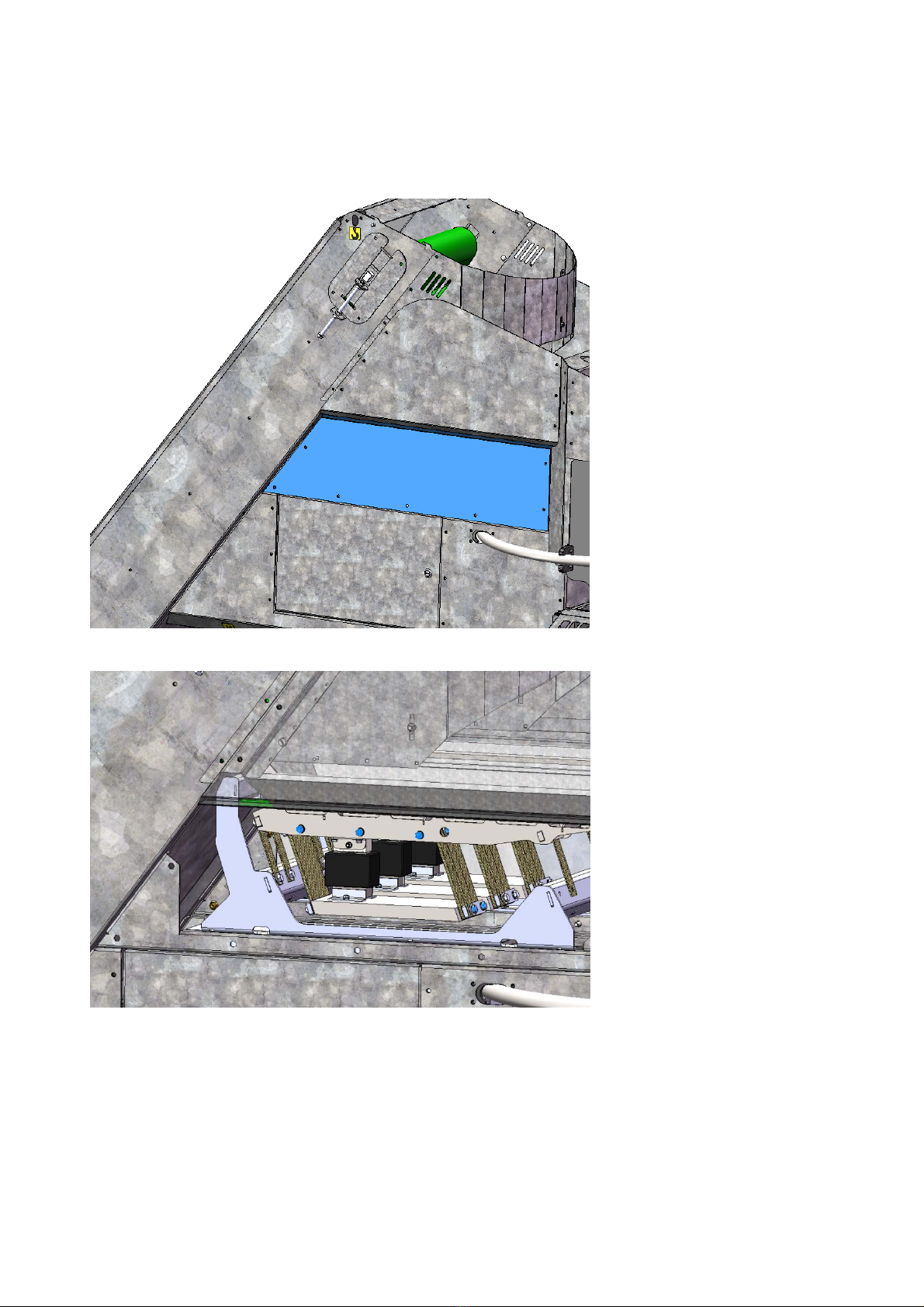

7.4 Vibration chutes

All bolts and vibration chutes should be re-tightened every 200 hours of operation.

To access the bolts, remove the screen marked in blue.

The bolts are marked in blue, and should be tighten to 18 Nm.

Table of contents