Skeleton Technologies SkelStart Assembly instructions

INSTALLATION GUIDE

AND USER MANUAL

www.skeletontech.com

02-SMC-210408-1B

Skeleton Technologies

SkelStartTM Engine Module

12V / CCA 2100

Keep this user manual in your vehicle.

32

About the SkelStartTM

Engine Module

The SkelStart enables drivers to start a vehicle

engine in situations where the engine cannot be

started by normal batteries owing to, for example,

extreme weather conditions or aged batteries, or

start the engine. The SkelStartTM is able to supply

What do you need

for installation?

The additional materials that may be needed for

installation are listed below. These items are not

included with the SkelStartTM, but may be

necessary for isolating other vehicle electronic

non-starting loads from the starter system.

+bolt, washer, nut (M8)

+electrical insulation material (heat shrink)

for proper insulation

+cable to connect other vehicle electronic

non-starting loads to the positive (+)

battery terminal

+standard shop tools

WARNING

SKELSTART IS NOT A BATTERY

HIGH CURRENT HAZARD

DO NOT CONNECT CABLES FROM

THE BATTERY TO THE STARTER (S+)

TERMINAL OF THE SKELSTART

DO NOT CONNECT IN REVERSE POLARITY

DO NOT JUMP-START

DO NOT DROP THE SKELSTART

DO NOT SHORT CIRCUIT

Installing the

SkelStartTM

Mounting location

SkelStartTM installation usually requires the

installation of a bracket or a shelf on which to place

the Module. The shelf must be in a safe location,

away from any direct heat sources.

The Starter

Positive (+) Terminal

Status Button

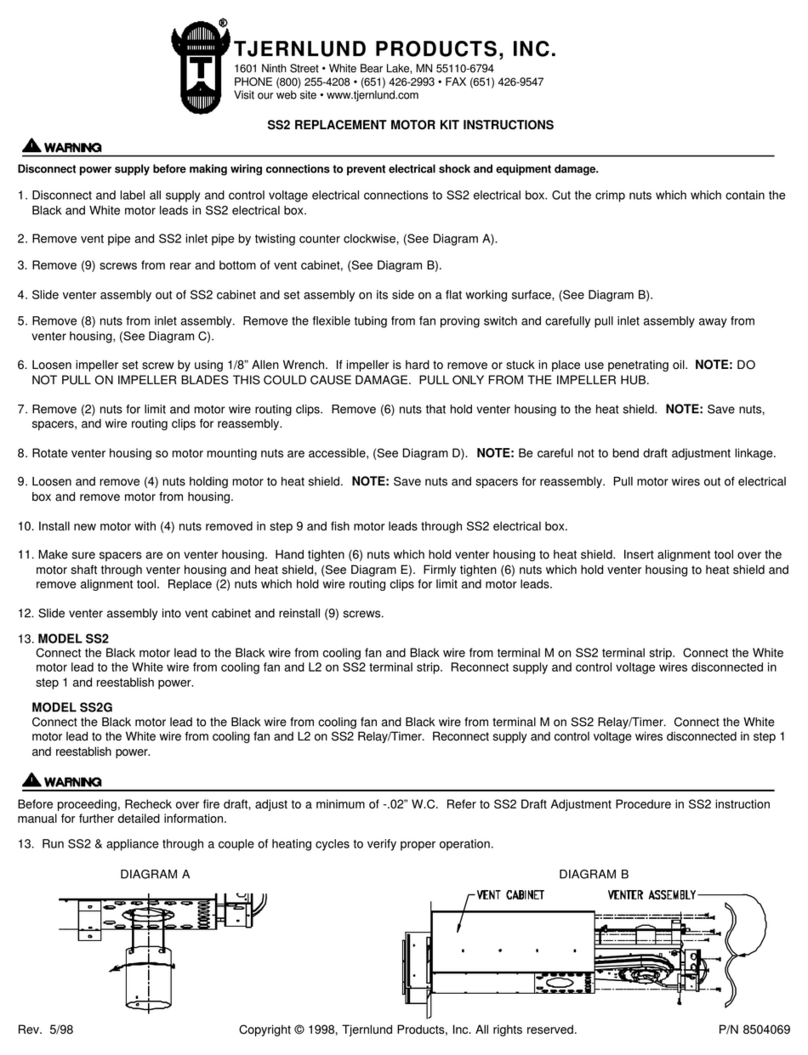

Status Indicator (LED) Fig 1. SkelStartTM 12V

Electrical installation

Do not connect cables from the battery

to the starter (S+) terminal of the SkelStart.

Cable selection

To install the SkelStartTM, you need new cables

from the “S+” terminal to the Starter Solenoid “+”

(positive) terminal and from the “B−” and “B+”

terminals to the vehicle mass, and 24V.

Pre-installation checks

Before installation of the SkelStartTM, you need to

remove all the cables from the vehicle batteries.

The vehicle batteries need to be charged. Clean the

battery terminals to remove any oxidation or grease.

Length of cable (m) 4.5–6 6.1–7.5 7.5–9 9.1–12

Cable size (mm2) 35 50 50 70

SkelStartTM

The battery

Positive (+) Terminal

yrettabehT

Negative (-) Terminal

(ground connection)

Unit SkelStartTM 12V

Weight kg 8.5

Dimensions mm 328(l) x 171(w) x 241(h)

Charging current A 16 (max)

Charging voltage range V 9–16

Operating temperature °C −40 to +65

Cold Cranking Amps (CCA)* A 2133

Maximum engine size L 16

Charge time (from 0 V) min 19

Standby current draw mA <10

Output voltage V 14.1 (max)

Peak power** kW 62.9

* Based on 1s ESR

** Based on 10ms ESR

12V SkelStartTM

12V

Starter

12V

Alternator

Wiring instructions

1. Before installation, remove all the cables from the

vehicle batteries.

NOTE: Do not connect the SkelStartTM

before instructed to do so!

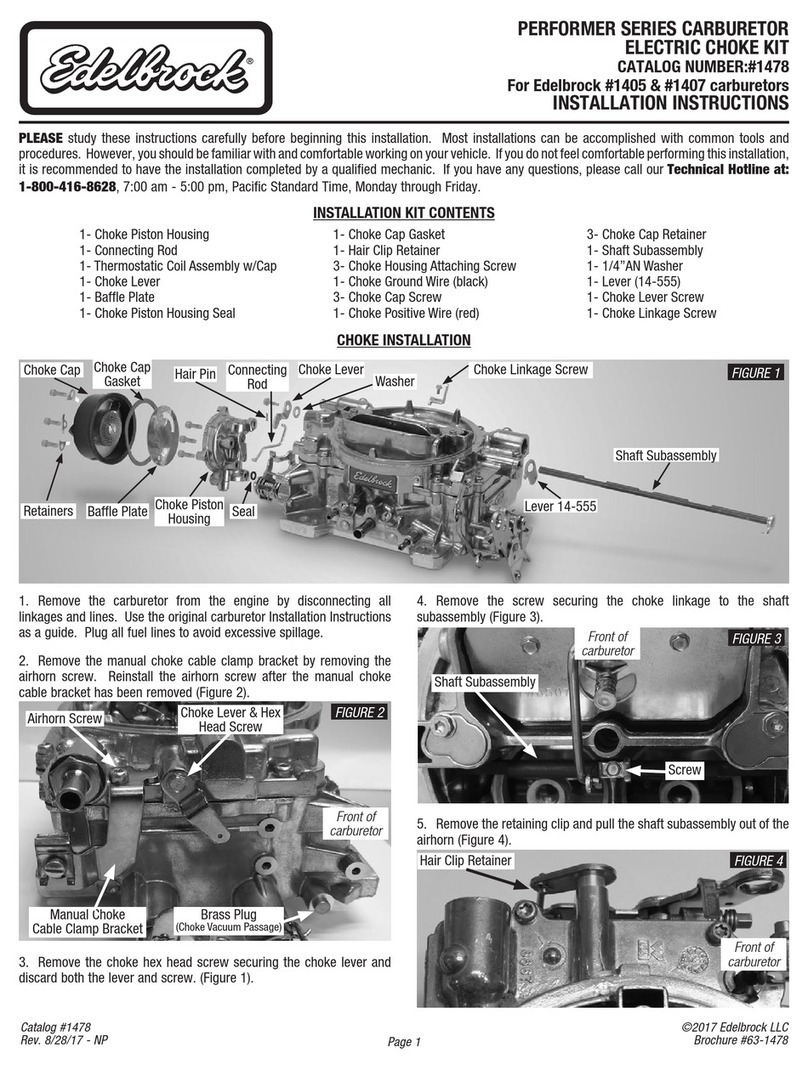

2. Most vehicle manufacturers connect the alternator

and other vehicle power cables to the starter

solenoid’s positive terminal. Therefore, all the cables

connected to the Starter Solenoid’s positive terminal

need to be removed (Fig. 2 cables 1, 2, 3 - cable 3 can

consist several cables). Note: the starter can include

an integrated magnetic switch, in which case the

short cable from the magnetic switch to the starter

can remain connected to the positive starter terminal.

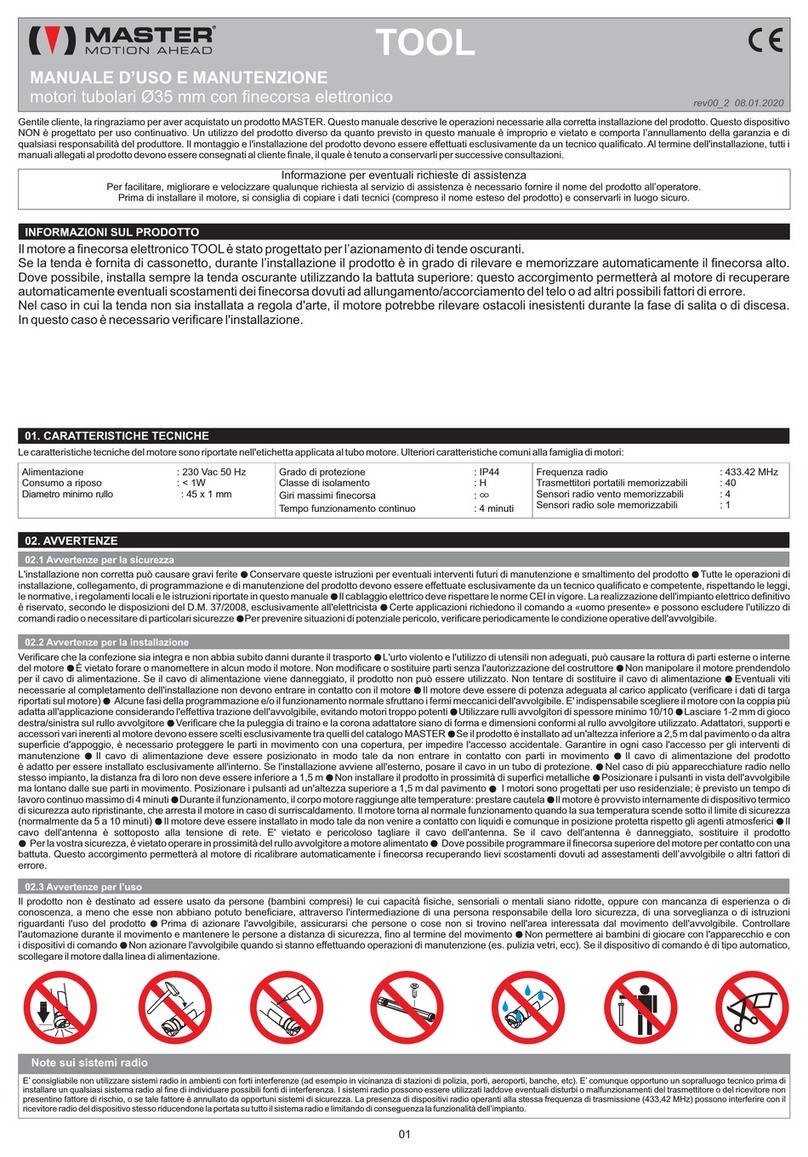

3. The cables removed from the positive starter

solenoid terminal should be connected using a

terminal block or a nut–bolt connection (use spring

washer or locknut). This connection will then have

to be isolated from the rest of the vehicle and

mounted securely. This can be achieved by bundling

the cables together using cable ties and covering the

connection with heat shrink (Fig 3. cables 1,2,3).

Note: the connection must be fully isolated from

the mass of the truck and should be secured in such

a way that vibration, abrasion or corrosion cannot

cause a short circuit.

4. Construct a new cable to connect the SkelStartTM

S+ to the positive terminal of the Starter Solenoid

(Fig. 3 cable 4). The recommended cable size - based

on the length of the total cable - can be found in the

above table.

5. Construct an additional new cable to connect the

SkelStartTM B+ to the 12 V line on the batteries

(Fig. 3 cable 6). The cable size should be at least

25 mm2 for lenghts of <5 m and 35 mm2when the

cable length exceeds 5 m.

6. Finally, a new cable is required for connecting the

SkelStartTM B- terminal with battery "-" terminal or to

the vehicle mass (Fig. 3 cable 5). This cable should be

sized according to the above table.

7. After assembling the cables, mount the SkelStartTM

securely and connect B+ terminal with the battery

"+" terminal. Then connect SkelStart B- terminal

with battery “-” terminal. In addition, reconnect the

vehicle batteries. Do not connect the starter cable yet.

8. Before making the nal connection, measure

the voltage between the starter cable and both the

positive and negative connections on the SkelStartTM.

In both cases, the multimeter should read 0 V.

A voltage reading other than zero between the starter

cable and either the positive or negative connections

on the SkelStartTM indicates that the starter solenoid

may be unreliable or that there is another path from

the solenoid to the batteries. Connecting the

SkelStartTM in this state can be dangerous and must

be corrected before continuing with the installation.

9. If the voltage reading between the starter cable

and both of the battery terminals reads 0V, then the

cable leading from the starter can be connected to the

SkelStartTM.

10. After ensuring that all the connections have been

fastened securely, the device is ready to be switched

ON. This is achieved by holding the power button for

5 seconds.

11. Charging has been successfully initiated when

the inbuilt green LED starts to ash slowly. This will

continue to ash until the SkelStartTM is fully charged.

12. When the charging stops, the SkelStartTM is ready

to be used to start your engine!

Fig 2. 12V system before SkelStartTM installation

Fig 3. 12V system after SkelStartTM installation

*12V SkelStartTM can be used to replace existing battery.

In 12V parallel connection minimum of one battery is required.

54

1

2

3

4

5

6

12V

Starter

12V

Alternator

1

2

3

SkelStart discharge

Prior to storing or packing the SkelStartTM, please

discharge as follows:

1. If the voltage between the SkelStartTM “S+”

terminal and the “−“ terminal of the batteries is

above 2V

a) Switch OFF the SkelStartTM by holding down the

button for 5 seconds.

b) Disconnect all the cables from the SkelStartTM.

c) Connect a 12V load, such as a headlight (or two

12V headlights connected in series) or a 12V blower

motor, across the “S+” and “B−” terminals. Leave

them connected until the light goes out or until the

blower motor stops running. This will discharge

the voltage stored in the SkelStartTM.

d) Verify that the voltage is 2V or less.

e) DO NOT use a cable, bare wire or low-/no-

resistance conductor to discharge the SkelStartTM!

2. Using a voltmeter, measure the voltage between

the “S+” and “B−” terminals. If the voltage is less

than 2V, the SkelStartTM is now considered safe for

handling and shipping.

Switching the SkelStart ON/OFF

The SkelStart includes a green light-emitting diode

that displays the status of the unit when the button

is pressed. Holding the button for 5 seconds will turn

the device ON or OFF.

NOTE: This will only affect the charging circuit;

it will not discharge the device or make it safe to

handle if fully charged.

A short press of the button will indicate the state

ofthe device; a single short ash will indicate that the

device is ON. In the OFF state, there is no response.

A blinking LED shows that the SkelStart is charging.

NOTE: if there is dust on the button, it should be

removed prior pressing the button.

Taking care of your SkelStartTM

The terminals should be periodically checked for

oxidation or for loose connections and should be

cleaned or tightened as necessary. Prior to removal or

system maintenance, ensure that the module has

been discharged. No other maintenance is necessary.

+incinerate +recycle with batteries

+crush +dispose of in trash

Dispose in accordance with the local regulations

for electronic waste.

Jump Starting

If a jump start is required, do not connect the jump

start cables directly to the SkelStart. Connect the

jump start cable to the batteries or to a junction box.

Guidelines for handling after

extended period of parking

If the vehicle does not crank the following procedure

should be followed:

+Make sure that the batteries are in charged to

specied limit

+Make sure that SkelStart is turned on and ready to

use. This can be done by pressing the button. After

which the LED will be lit for 5 sec.

+If led does not light up this means that the device is

not ON. To turn on the device press the button for 5

sec. If there is a need for the device to charge the led

will remain blinking.

+If the led stops blinking this means that the device

is ready to use. This can be validated by pressing the

button and led will be lit for 5 sec.

Removing the SkelStart from

the system temporarily

If there is a need to restore current ow directly from

the batteries to the starter, remove the cable from

SkelStart B+ terminal (battery + to SkelStart cable).

Then remove the cable from SkelStart S+ terminal

(starter to SkelStart cable). After removing cables

from terminals connect these two cables together

with a strong electrical connection. This restores

current ow from batteries to starter, leaving the

SkelStart out of the system.

NOTE: before this procedure disconnect cables

from batteries and make sure you don't touch

S+ terminal with a metal/conductive element

connected with ground.

6 7

WARNING

HIGH CURRENT HAZARD!

Power terminals pose an arcing hazard when the SkelStart is being charged.

Make sure to always discharge the SkelStart before removing

it from the system or handling it.

DO NOT CONNECT IN REVERSE POLARITY!

Do not connect the terminals in reverse (+ to - and/or - to +).Arcing will occur

if the SkelStart is charged, creating a electric shock and/or burn hazard.

The SkelStart will be permanently damaged.

WARNING

DO NOT CONNECT THE CABLES FROM THE BATTERY TO THE STARTER+

TERMINAL OF THE ESM. IT WILL CAUSE THE BATTERY

TO SHORT CIRCUITAND CAUSE ARCING.

WARNING

WARNING - THIS IS N

12V SkelStart recommended input voltage range 9-16V.

Do not operate/charge above 30V continuous/32V momentary

OT A BATTERY - DO NOT JUMP START ON THE ESM!

Do not connect battery or jump start cable across the STARTER + “S+” and

BATTERY - “B-” terminals. Chance of damage to the battery.

WARNING

Do not operate the SkelStart above the specified temperature range (+65°C / +149°F)

Make sure to protect the terminals from accidental shorting.

If a jump start is required, use an external jump post if possible, or jump across

any battery positive (+) and battery negative (-) terminal.

Avoid installing in locations with potentially high

temperatures. Higher temperatures have a negative

impact on lifetime.

Disposal

For your SkelStartTM, do not:

Headquarters

Skeleton Technologies GmbH

Schücostraße 8, Großröhrsdorf 01900, Germany

info@skeletontech.com

www.skeletontech.com

X-ON Electronics

Largest Supplier of Electrical and Electronic Components

Click to view similar products for Supercapacitors / Ultracapacitors category:

Click to view products by Skeleton Technologies manufacturer:

Other Similar products are found below :

C-TEC1225 P LX055105A SCCY73B407SLBLE FE0H473ZF MAL223551012E3 MAL223551014E3 MAL223551015E3

MAL223551016E3 MAL223551006E3 MAL223551007E3 MAL223551001E3 MAL223551008E3 MAL219612474E3 MAL219632473E3

DRE10/2.5 DRL106S0TI25RRDAP DRL226S0TK25RR 106DCN2R7M SCCT30B156SRB SCMR14C474MSBA0 SCMR22C155MSBA0

FT0H225ZF TV1020-3R0605-R SCCX50B207VSB PAS0815LS2R5105 HVZ0E475NF SCMR18F105PSBA0 FT0H565ZF FE0H224ZF

FCS0H473ZFTBR24 SCCT30E156SRB MAL222090006E3 SCCY68B407SSBLE CPH3225A-2K SCMT22C505PRBA0 207DCN2R7M

DB5U307W35050HA DB5U407W35060HA SCCX50B227SSBLE DGH505Q5R5 DGH505Q2R7 DGH705Q2R7 DGH506Q2R7

DGH357Q2R7 DGH335Q2R7 DGH256Q2R7 DGH255Q5R5 DGH207Q2R7 DGH155Q5R5 DGH107Q2R7

Table of contents