Skid Pro QA62 User manual

1

www.skidpro.com

QA62 And QA82 Mulcher

Operators Manual

Skid Pro Attachments

PO Box 982

Alexandria, MN 56308

www.skidpro.com

May 2023

2 www.skidpro.com

Following is a list of videos and documents available to help and enhance maintaining the brush mulcher.

Contact Product Guru to access correct link.

The list below was current at the time this manual was issued. Additional content may be available.

Activity Name Description

Hose Support Adjusting Hose Support And Length

Rotor Bearing Replacing Rotor Bearing.

Chain Couplers Replacing Chain On Chain Couplers.

Adding Zero Leak Relief Valve Zero Leak Valve Upgrade.

Zero-Leak Relief Valve Demonstrating And Troubleshooting Zero-Leak.

Hose Support Hose Support And Coupler Clearance Demo.

Motor Seal Motor Seal Replacement.

Belt Maintenance Installing Belt Assembly.

Belt Maintenance Testing And Adjusting Belt Tensioner.

3

www.skidpro.com

........................................................................................4

1.1 Introduction................................................................................................................4

.....................................................................................................................4

.............................................................................................5

...............................................................................................................................6

...................................................................6

3.2 Operational Hazards..................................................................................................6

..............................................................................7

.....................................................................................7

......................................................................................7

..................................................................................7

................................................................................................7

..............................................7

..................................................................................8

............................................................................................8

..........................................................................................8

.........................................................................8

................................................................................................8

.......................................................................9

............................................................................................10

....................................................................................................................12

4.1 Hydraulics .................................................................................................................12

.......................................................................................................................13

5.1 Pre-Operation Check List .......................................................................................13

5.2 Attaching And Detaching........................................................................................13

5.3 Operation..................................................................................................................13

..................................................................................................15

6.1 Inspections................................................................................................................15

6.2 Check Belt Tension ...............................................................................................15

6.3 Replace Cutting Teeth.............................................................................................16

6.4 Replace Coupler Chain ............................................................................................16

6.5 Lubricate Rotor Bearings ........................................................................................17

..........................................................................................................18

4 www.skidpro.com

Congratulations on your purchase of a Skid Pro Skid

Steer Mulcher. This equipment has been designed and

manufactured to meet the needs of a discriminating

buyer for ecient mulching of brush in land clearing

applications.

Safe, ecient and trouble free operation of your

mulcher requires that you and anyone else who will

be operating or maintaining the mulcher, read and

understand this Operator’s Manual.

This manual covers the Skid Pro Skid Steer Mulcher.

Keep this manual with the equipment for frequent

reference and to pass on to new operators or owners.

Call your Skid Pro dealer, distributor or the factory if

you need assistance, information or additional copies

of the manuals.

OPERATOR ORIENTATION - The directions left, right,

front and rear, as mentioned throughout this manual,

are as seen from the skid steer driver’s seat and facing

in the direction of travel.

Skid Pro warrants products purchased from Skid Pro

to the Original Purchaser to be free from defects in

material and workmanship for a period of twelve (12)

months from the warranty start date.

Skid Pro’s requirement for any issue with respect to

attachments shall be limited to repairing or replacing

the defective part, as this is a parts-only warranty and

does not include any labor to replace or install the

part or downtime from resulting issue. Skid Pro has

full technical support & assistance to assure customer

replaces the part properly for optimal performance

on attachment. Skid Pro warranty service does not

include:

1. Transportation to selling dealer’s business location

or, at the option of the original retail purchaser, the

cost of a service call.

2. Used equipment.

3. Components covered by their own non-Skid Pro

warranties

4. Normal maintenance service and expendable wear

out items.

5. Repairs or adjustments caused by improper use;

failure to follow recommended maintenance

procedures; accidents or other casualty.

6. Liability for incidental or consequential damages of

any type, including but not limited to lost prots of

expenses of acquiring replacement equipment.

No agent, employee or representative of Skid Pro has

authority to bind Skid Pro to any warranty except as

specically set fourth herein. Any of these limitations

excluded by local law shall be deemed deleted from

this warranty; all other terms will continue to apply.

Skid Pro, Inc.

Toll Free: 877.378.4642

E-mail: [email protected]

5

www.skidpro.com

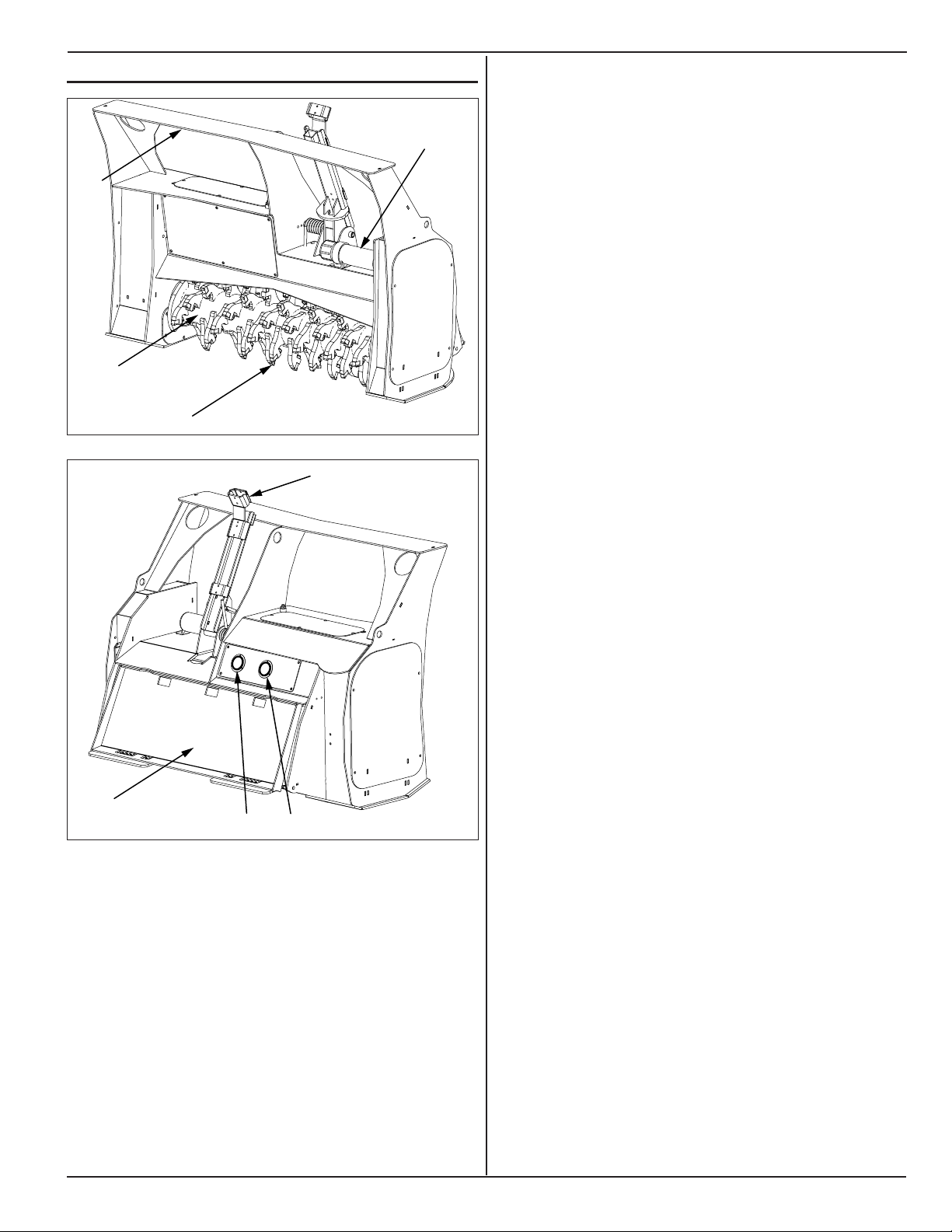

1

2

3

4

5

6

7

8

1. Operators Manual Holding Tube

2. Cutting Teeth

3. Rotor

4. Safety Push Bar

5. Case Pressure Gauge

6. Hydraulic Pressure Gauge

7. Quick Attach

8. Hydraulic Hose Holder

6 www.skidpro.com

You must read, understand and follow the instructions

given by the operating unit manufacturers, as well as

the instructions in this manual.

The safety information in this manual is denoted by the

safety alert symbol:

^

This symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The level of risk is indicated by the following signal

words:

^^

or serious injury.

^

result in death or serious injury.

^

or moderate injury.

NOTICE - Indicates a situation that could

result in damage to the equipment or other

property.

^

Prevent serious injury or death.

Read and understand this manual before

operating mulcher.

leaving operators seat.

operation.

Travel at a safe speed.

^

Prevent serious injury or death from

moving parts.

in place.

before adjusting or performing

maintenance.

^

applications.

Any other use may result in personal

^

Prevent serious injury or death.

hitch before operation or transport.

7

www.skidpro.com

^

^

Carefully read all safety messages in this manual and

on equipment safety signs. Keep safety signs in good

condition and replace missing or damaged safety

signs.

New equipment components and repair parts must

include the current safety decal.

Learn how to properly operate equipment. NEVER

operate or work around this equipment without proper

instruction, while fatigued or under the inuence of

alcohol, prescription or non-prescription medication or

if feeling ill.

Keep your equipment in proper working condition.

Know the regulations and laws that apply to you and your

industry. This manual is not to replace any regulations

or laws. Additional information may be found at:

www.asae.org or www.osha.gov.

If you do not understand any part of this manual,

contact Skid Pro at 866-232-8224.

Be prepared in case of emergencies. Keep a re

extinguisher and rst aid kit close to the machine.

Keep emergency phone numbers close to your phone.

Know your address so emergency services can locate

you if an emergency arises.

Replace missing or damaged safety signs.

Safety sign location are identied in Section 4.5 of this

manual.

Replacement safety signs are available from your

dealer.

NEVER lift or carry anyone on mulcher.

NEVER use mulcher as a work platform.

NEVER allow passengers on mulcher.

Keep mulcher low and move at slow speeds on rough

or uneven terrain.

The equipment may rollover, resulting in death or

serious injury. To help prevent rollover:

• Travel at a slow speed.

• Avoid sharp turns & sudden movement on slopes.

• Carry mulcher close to the ground.

• Avoid holes, ditches and other obstructions which

may cause equipment to rollover.

• Use caution when operating on slopes and do not

operate on excessively steep slopes.

• Do not exceed load capacity of equipment.

^^

Prevent electrocution.

Death or serious injury can result if

lines.

contact.

Check clearance before raising equipment.

Have local utilities locate and mark under ground wires,

cables, pipelines and other hazards before digging.

8 www.skidpro.com

DO NOT leave the operator’s seat if any part of the

equipment contacts electric lines or cables.

Detach mulcher on a rm and level surface. Mulcher

may fall over if detached on unlevel or soft surface.

Carry mulcher low.

Travel slow and avoid slopes.

^

Crushing hazard.

Raised, unsupported mulcher can fall,

resulting in death or serious injury.

Never enter the area under a raised

mulcher.

A raised mulcher can lower unexpectedly, resulting in

death or serious injury.

NEVER enter area under a raised mulcher.

Lower mulcher to ground, engage parking brake, shut

o engine and remove key before servicing.

^

Hydraulic hoses can fail from age, damage

and exposure.

searching for leaks. A tiny, almost invisible

leak can penetrate the skin, thereby

leaks, never use your hands.

Escaping uid under pressure can penetrate the skin

causing serious injury.

Prevent the hazard by relieving pressure before

connecting or disconnecting hydraulic lines. Verify all

connections are tight before applying pressure. Search

for leaks with a piece of cardboard or wood.

Protect hands and body from high pressure uids. If

an accident occurs, see a doctor immediately. Any uid

injected into the skin must be surgically removed within

a few hours or serious infection may result.

Doctors unfamiliar with this type of injury should

reference a knowledgeable medical source.

Before servicing, park machine on a rm and level

surface, set parking brake, chock wheels, and place

a “Do Not Operate” tag on control panel. Read and

understand this manual. If you do not understand any

part of the manual, contact Skid Pro at 866-232-8224.

Always wear face and/or eye protection, safety shoes,

and other protective equipment appropriate for the job.

Always use Skid Pro replacement parts.

^

Crushing hazard.

Before performing inspections, service or

•

•

•

• Place “Do Not Operate” tag on control

panel.

^

Keep clear of moving components.

performing maintenance.

9

www.skidpro.com

^

Keep clear of moving components.

appropriate for the job.

^

Burn hazard.

Hot and high pressure hydraulic oil.

Do not make any alterations to your mulcher. Altering

may cause your equipment to be unsafe and may void

the manufacturers’ warranty.

10 www.skidpro.com

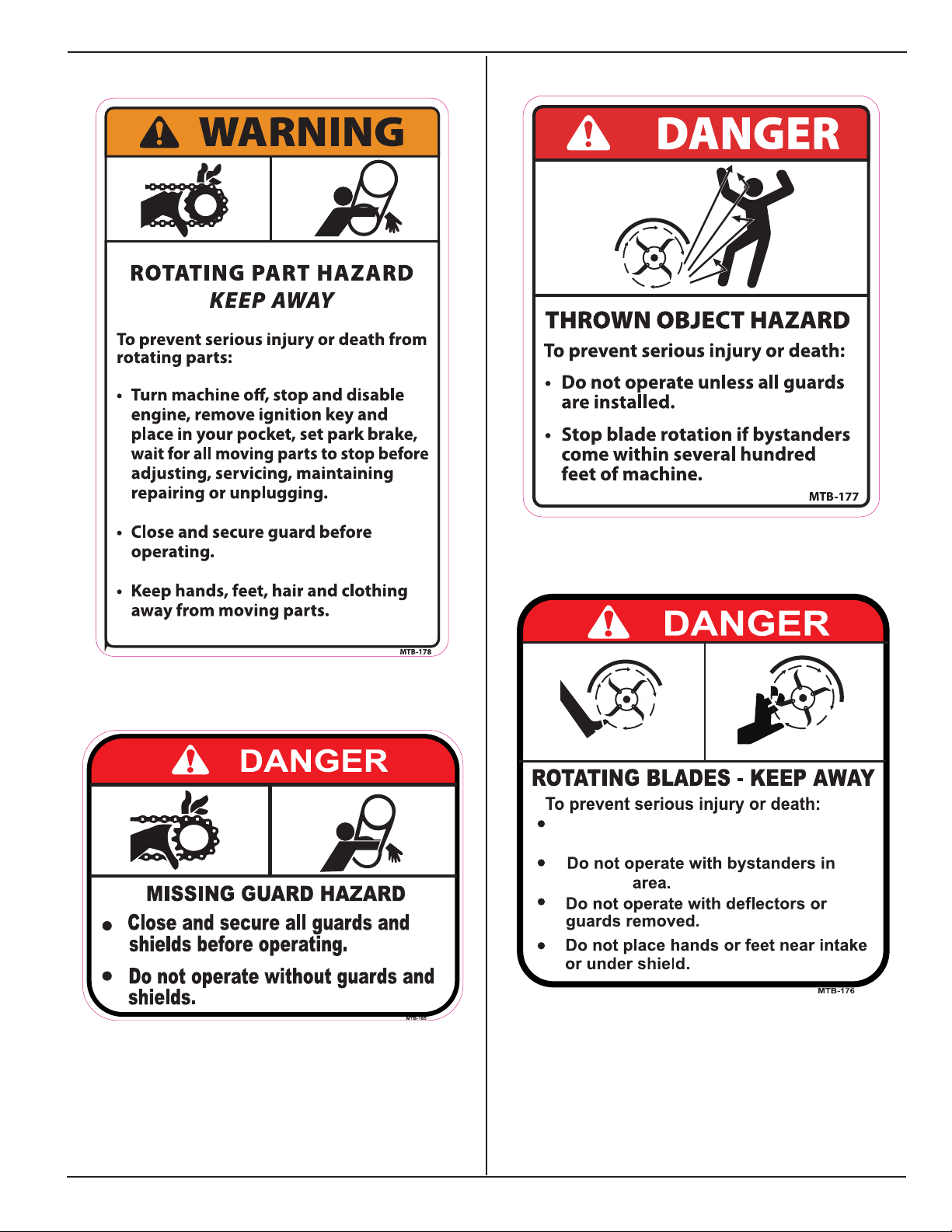

^

To protect you and others against death or

mulcher and must be legible.

If any of these labels are missing or

cannot be read, contact your dealer for

replacement labels.

4

3

2

1

5

7

6

7

6

Decal 1 - D005262

WARNING: This product can expose you to chemicals

including 1,3-Butadiene and lead, which are known to the state of

California to cause cancer and birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov.

D005262

Decal 2 - MTB-182

Decal 3 - MTB-175

11

www.skidpro.com

Decal 4 - MTB-178

Decal 5 - MTB-185

Decal 6 - MTB-177

Decal 7 - MTB-176

Never allow riders; especially children

on carrier or cutter.

cutting

12 www.skidpro.com

^^

before disconnecting and/or connecting

hydraulic hoses.

The mulcher is equipped with short hoses that are

connected to the hydraulic motor. You must connect

your skid steer hoses to these hoses.

Skid steer hoses must be the same size as the mulcher

hoses. Using smaller diameter hoses will decrease

hydraulic ow.

The mulcher will have a pressure, return and case

drain connections. Pressure hose on mulcher will have

a red tie band (1) on it.

The hose end size is 3/4 in. female JIC for the pressure

and return hoses, and 1/2 in. female JIC for the case

drain hose.

Connect skid steer hoses to the mulcher hoses. Be

sure mulcher pressure hose with red tie band (A) is

connect to skid steer pressure hose.

The mulcher is equipped with a bearing support housing

vent (2). If oil emerges from vent, safety seal in motor

has been activated. This is caused by an undersized,

disconnected or blocked case drain hose.

2

13

www.skidpro.com

^ Quick-Attach must always be fully engaged and

in the locked position.

^ Keep bystanders away from equipment while in

use.

^ Always wear face or eye protection, safety shoes,

and other protective equipment appropriate for

the job.

^ Do not operate, work on or around this machine

while under the inuence of alcohol, drugs or if

feeling ill.

^ Keep clear of moving machinery at all times.

^ Turn o machine before exiting operator station.

^ It is your responsibility to operate this equipment

safely. You must be familiar with the equipment

and all safety practices before use.

^ Do not allow untrained or unqualied people to

operate this equipment.

It is operators responsibility to perform the following

checks prior to operation of equipment.

Review and understand this manual and operating unit

manual.

Verify safety decals are installed and legible. Replace

if damaged or missing.

Verify that all hardware is tight.

Inspect hoses and ttings for wear, damage and leaks.

Replace damaged or leaking hoses before use.

Verify that local utilities have marked all underground

wires, cables and pipelines.

Refer to operating unit operator’s manual for prestarting

instructions.

1. Read and follow all safety instructions.

2. Attach skid steer to mulcher. See skid steer

Operator’s Manual.

3. Verify pins are secure in the correct position.

4. Connect hydraulic hoses. Verify hydraulic hoses

are clear of pinch areas and moving parts.

5. Move to a clear open area to test functions.

Operate all functions in an open area with skid steer in

idle to get a good feel for the controls.

^

Prevent serious injury or death.

leaving operator’s seat.

A hydraulic pressure gauge on mulcher is visible

from operator’s seat and indicates hydraulic system

pressure.

If gauge approaches maximum pressure, slow

ground speed or raise mulcher slightly so mulcher is

not operating at maximum operating pressure for an

extended period of time.

Operating at maximum pressure can shorten the life

of hydraulic components. Operating at slightly below

maximum pressure will allow for better productivity and

more ecient operation.

The push bar is used for pushing over brush and small

trees when mulching, not for pushing over standing

trees.

14 www.skidpro.com

1. Attach skid steer to mulcher. See Attaching And

Detaching in this section.

^

Prevent serious injury or death.

forestry guard to protect the operator.

2. Lower mulcher so skid plates are on ground.

3. Set engine speed to low idle and engage mulcher.

4. Slow increase engine speed to high idle. Verify

mulcher is operating smoothly and start forward

travel.

General Operation

Monitor hydraulic pressure gauge. Hydraulic pressure

will increase if ground speed is too fast.

If mulcher stalls, stop forward movement, slightly raise

mulcher and allow rotor to regain speed. Slow ground

speed to prevent further stalling.

^

Keep clear of moving components.

Lockout operating unit before performing

maintenance.

If mulcher jams, disengage hydraulics, lower mulcher

to ground and stop engine. Remove key and lockout

operaing unit to prevent accidental starting. Remove

debris from rotor.

The mulcher can mulch up to 1 in. (25 mm) below

ground level. Excessive ground contact will result in

rapid wear of the cutting teeth. Keep ground contact to

a minimum.

1. Set engine speed to low idle.

^

Prevent serious injury or death.

hydraulics are disengaged.

stopped and operating unit has been

locked out.

2. Lower mulcher so skid plates are on ground.

3. Disengage mulcher and allow rotor to stop.

4. Set parking brake, stop engine and remove key.

15

www.skidpro.com

Check hydraulic hoses and ttings daily for leaks.

Replace hose if worn or damaged.

Inspect the unit for any buildup of contamination (dirt,

stones, etc.).

Check cutting teeth every 2 hours of use. Keep cutting

teeth in good condition. Unit will cut faster and remaining

teeth will last longer if broken teeth are replaced.

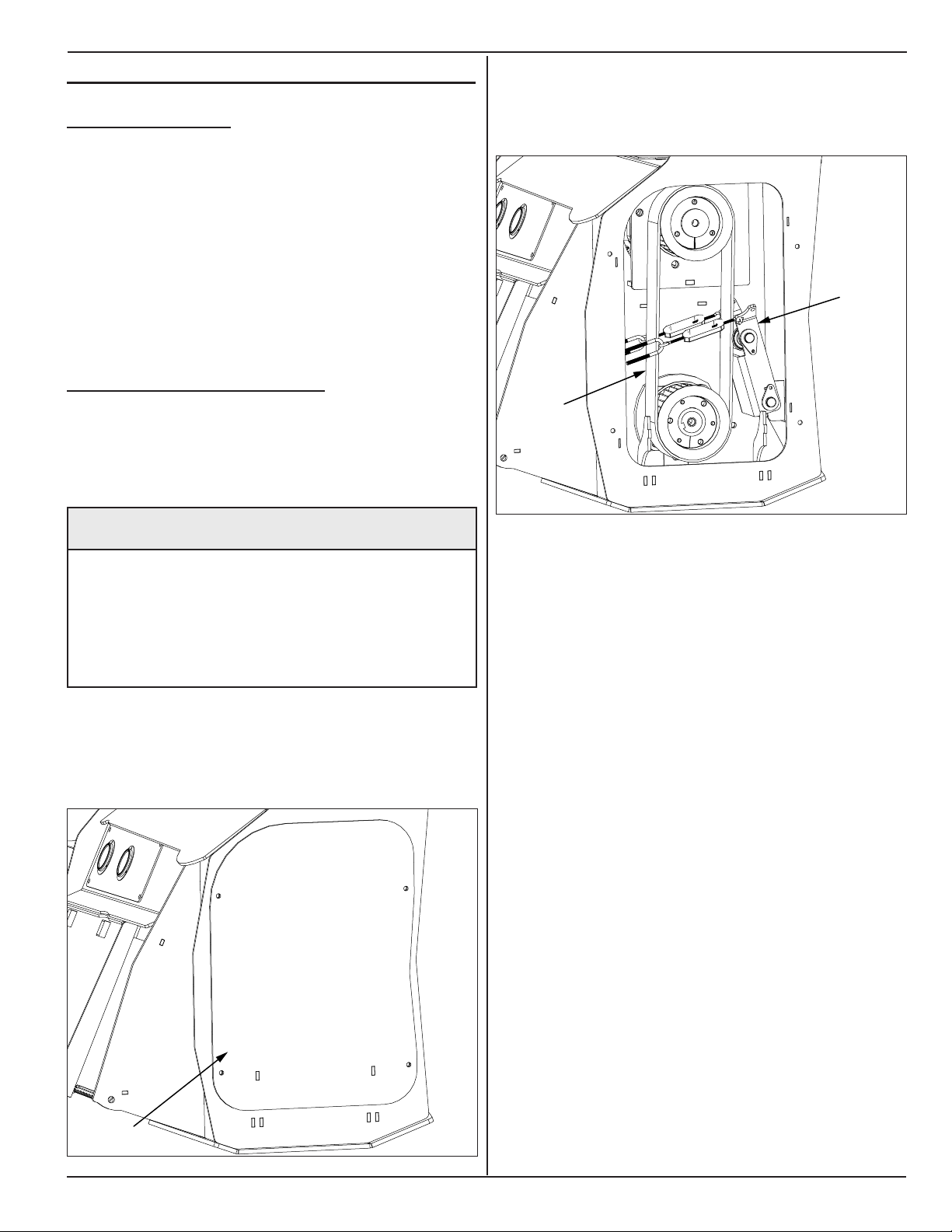

1. Lower mulcher to ground.

2. Set parking brake, stop engine and remove key.

^

Keep clear of moving components.

Lockout operating unit before performing

maintenance.

3. Inspect cutting teeth for damage. Replace individual

teeth as needed.

4. Remove inspection cover (1).

1

5. Inspect belt (2) for wear, damage and proper

tension.

6. Adjust idler (3) to set belt tension.

2

3

7. Install inspection cover (1). Do not operate mulcher

with inspection cover (1) removed.

16 www.skidpro.com

^

Crushing hazard.

Raised, unsupported mulcher can fall,

resulting in death or serious injury.

Never enter the area under a raised

mulcher.

NEVER enter area under a raised mulcher.

1. Lower mulcher to ground or properly support to

prevent falling.

2. Stop skid steer engine and remove key.

^

Keep clear of moving components.

Lockout operating unit before performing

maintenance.

3. Inspect cutting teeth for damage. Replace individual

teeth as needed.

4. Remove lock nut (1) and cutting tooth (2).

1

2

5. Install replacement tooth and lock nut. Tighten

locknut (1) to 95 lb/ft (129 Nm) of torque.

1. Lower mulcher to ground.

2. Stop skid steer engine and remove key.

^

Keep clear of moving components.

Lockout operating unit before performing

maintenance.

3. Remove cover (1).

1

4. Remove master link from coupler chain (2).

5. Remove coupler chain (2).

2

17

www.skidpro.com

Note: Coupler hub on rotor shaft and motor shaft do

not have setscrews. Setscrews are not needed in this

application.

6. Install coupler chain (2) and chain master link.

7. Install cover (1).

The bearings are factory lubricated with a general

purpose grease which is suitable for most applications.

The bearings should contain as much grease as

speed will permit. A full bearing with consequent slight

leakage through the seal is the best protection against

contaminant entry.

Extreme situations may require a change in lubricating

periods as dictated by experience.

Generally, a lower quantity of grease at frequent

intervals is more eective than a greater quantity at

extended lubrication intervals.

Typical lubrication quantity is 1 pump from a standard

grease gun every 250 hours.

In the higher speed ranges too much grease will cause

overheating. The amount of grease that the bearing

will take for a particular high speed application can be

determined only by experience. If excess grease in

the bearing caused overheating, it will be necessary

to remove grease tting to permit excess grease to

escape.

18 www.skidpro.com

Problem Probable Cause Solution

Rotor does not spin. Rotor jammed. Remove material from rotor.

Low oil. Check oil level in skid steer. Add if

necessary.

Not enough oil ow. Check ow control on skid steer.

See your dealer.

Rotor rotates slow or sluggish. Low oil. Check oil level in skid steer. Add if

necessary.

Oil lter plugged. Replace skid steer oil lter.

Relief valve not set properly. Set relief valve. Pressure should be

between 2,500 and 3,500 psi.

Not enough oil ow. Check ow control on skid steer.

See your dealer.

Drive belt loose. Tighten drive belt.

Excessive vibration. Cutting teeth worn or missing. Replace worn, broken or missing

teeth.

Debris lodged in rotor. Remove debris.

19

www.skidpro.com

20 www.skidpro.com

Skid Pro Attachments

PO Box 982

Alexandria, MN 56308

www.skidpro.com

May 2023

This manual suits for next models

1

Table of contents

Other Skid Pro Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions