Skipper DL2 User manual

DL2

Dual Axis Doppler Speed Log System (SOG+STW)

Installation Manual

SKIPPER Electronics AS Telephone: +47 23 30 22 70

Enebakkveien 150 Telefax: +47 23 30 22 71

P. O. Box 151, Manglerud E-mail: support@skipper.no

0612 Oslo, Norway Co. reg. no: NO-965378847-MVA

www.skipper.no

Document no: DM-M002-SA

Rev: 1723A

Date: 2018-05-28

(for softwares up to 1.0.14 &1.1.0)

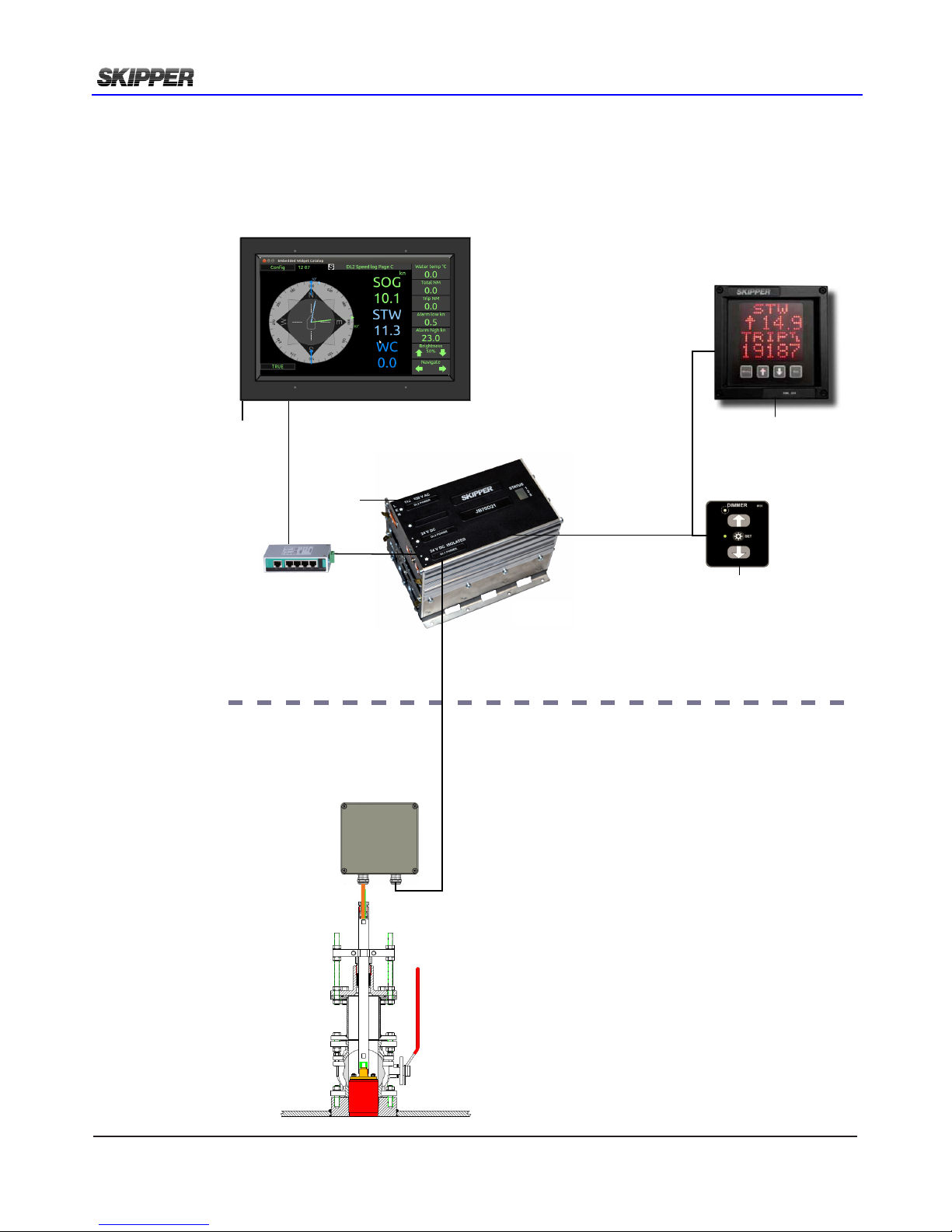

BRIDGE

FORE PEAK

115-230VAC

/ 24VDC

DL21SG-SA

DL21 sensor

w/40m cable

in Sea valve

SB-100-SB

JB21-SA

Junction box

JB70D21-SA

Electronic Unit

Sensor extension cable.

Yard supply.

6 x twisted shielded pairs

Dimension: see DL2 manual Chapter 3.

JB12-SA

Junction box

DL2SG-SA

DL2 sensor

w/40m cable

in Sea valve

SB-100-SB

JB70D2-SA

Electronic Unit

Sensor extension cable.

Yard supply.

3 x twisted shielded pairs

Dimension: see DL2 manual Chapter 3.

CU-M001-SA Operator Unit for DL2

LAN cable. CAT6. Max. 100m

24VDC

Page 2 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

INSTALLATION MANUAL

DL2 DUAL AXIS DOPPLER SPEED LOG SYSTEM

Copying of this document, and giving it to others and the use

or communication of contents thereof, are forbidden without

express authority. Offenders are liable to the payment of dam-

ages.

Sin nuestra expresa autorización, queda terminantemente

prohibida la reproducción total o parcial de este documento,

asì como su uso indebido y/o su exhibición o comunicación

a terceros. De los infractores se exigirá el correspondiente

resarcimiento de daños y perjuicios.

Weitergabe sowie vervielfältigung dieser unterlage, verwertung und mitteilung ihres

Inhaltes nicht gestattet, soweit nicht ausdrücklich zugestanden. Zuwiderhandlungen

verpichten zu schadenersatz.

Toute communication ou reproduction de ce document, toute Exploitation ou

communication de ou son contenu sont interdites, sauf autorisation expresse.

Tout manquement à cette règle est illicite et expose son auteur au versement de

dommeges et intèrèts.

2018-05-28 Page 3 of 60

Installation DL2 Doppler Speed Log System

COMMUNICATING WITH US

If you need more information, support or other assistance from us, do not hesitate to contact us:

SKIPPER Electronics AS

P. O. Box 151, Manglerud

NO-0612 Oslo

Norway

Phone: (+47) 23 30 22 70, Fax: (+47) 23 30 22 71

E-mail: support@skipper.no

SOFTWARE UPDATES AND TECHNICAL SUPPORT

Find us on the internet: www.skipper.no

YOUR FEEDBACK IS APPRECIATED

If you nd errors, misspellings or poorly explained sections in this document, please do not hesitate

to contact us at:

support@skipper.no

Page 4 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

CONTENTS

TERMINOLOGY......................................................................................................................... 5

Terms used in this manual................................................................................................................................... 5

CHAPTER 1: GETTING STARTED ........................................................................................... 7

Overview DL2...................................................................................................................................................... 7

Optional items DL2.............................................................................................................................................. 8

Items Not supplied by SKIPPER ......................................................................................................................... 9

Power supply requirements................................................................................................................................. 9

CHAPTER 2: HARDWARE MOUNTING ................................................................................... 10

Placement of the Operator unit ........................................................................................................................... 10

Placement of the electronic unit .......................................................................................................................... 11

Placement of the electronic unit IP22 approved.................................................................................................. 11

Placement of JB12 Junction box ......................................................................................................................... 11

Placement of repeaters ....................................................................................................................................... 11

Placement of the sea valve ................................................................................................................................. 12

Placement of the Sensor in sea valve ................................................................................................................. 13

CHAPTER 3: WIRING................................................................................................................ 16

Clamping the cables............................................................................................................................................ 16

CU-M001-SA Operator unit wiring....................................................................................................................... 17

JB70D2-SA Electronic Unit Wiring ...................................................................................................................... 18

Connectors supplied with JB70D2 ...................................................................................................................... 19

SENSOR CONNECTION J3 ............................................................................................................................... 20

NMEA CONNECTION J1 .................................................................................................................................... 21

AUX/Alarm CONNECTION J2............................................................................................................................. 22

Additional NMEA, Aux and analog Out................................................................................................................ 22

Yard supplied extension cable from sensor to JB70 Electronic unit.................................................................... 23

The junction box (JB12)/splice ............................................................................................................................ 23

CHAPTER 4: SETUP PROCEDURE......................................................................................... 26

CONFIG .............................................................................................................................................................. 27

CU-M001 setup ................................................................................................................................................... 28

JB70D2 setup...................................................................................................................................................... 29

DL2 setup ............................................................................................................................................................ 30

Reset.............................................................................................................................................................. 33

Software options............................................................................................................................................. 34

Communications setup (NMEA/UDP) ................................................................................................................. 36

NMEA............................................................................................................................................................. 36

LAN UDP........................................................................................................................................................ 36

NMEA sentences received ............................................................................................................................. 38

NMEA sentences transmitted ........................................................................................................................ 39

Alarm/Alert setup................................................................................................................................................. 40

Setup AUX........................................................................................................................................................... 44

System Diagnostics ............................................................................................................................................ 45

Available options in the diagnostic page ............................................................................................................. 45

Error messages ................................................................................................................................................... 45

Saving and locking ............................................................................................................................................. 46

Status LEDs ....................................................................................................................................................... 46

Hardware options ................................................................................................................................................ 47

CHAPTER 6: SOLVING PROBLEMS........................................................................................ 48

Software upgrade ................................................................................................................................................ 48

APPENDIX 1: INSTALLATION DRAWINGS ............................................................................. 49

APPENDIX 2: DATA SHEETS ................................................................................................... 55

APPENDIX 3: MULTI EXTENSION PCB................................................................................... 58

APPENDIX 4: CONNECTING 2 SYSTEMS .............................................................................. 59

APPENDIX 4: COMMISIONING CHECKLIST........................................................................... 60

2018-05-28 Page 5 of 60

Installation DL2 Doppler Speed Log System

TERMINOLOGY

Terms used in This manual

_________________________________________________________

Units

Unless otherwise stated, all values shown on the display are as follows:

Speed Knots

Distance (Vessel) Nautical miles

Depth Meters

Tilt ° Degrees

Temperature ° Centigrade

Rotation Degrees per minute

Heading Degrees

Abbreviations

In addition, the following symbols are used

WT Water track

BT Bottom track

STW Speed through water

SOG Speed over ground

Trip Text for trip/total

ECDIS Electronic Chart Display and Information System

INS Inertial Navigation System

VDR Voyage Data Recorder

ROT Rotation from Gyro

GYRO Gyroscopic heading / rotation sensor

HDG Heading

DL2 2 Axis Doppler Log (with speed over bottom and Speed through water)

DL1 1 Axis speed through water sensor (part of DL21 system)

DL21 A system with combined DL1 and DL2 in the same housings

UDP User Datagram Protocol.

SFI System function Id

LAN Local Area Network

Symbols

In addition, the following symbols are used

Indicating that the information presented is partly from the GPS input, and therefore not

from this sensor. (Outputs may show invalid data in this mode)

Symbolising that the data presented is longitudinal (forward or backwards)

Symbolising the data is transversal (port or starboard)

Page 6 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

Alarm active. Unacknowledged (ashing)

Alarm active. Silenced (ashing)

Alarm active. Acknowledged

Alarm active - Responsibility transferred alarm

Alarm rectied - Unacknowledged

Simulator mode - The system is using a simulator to generate the speed and depth

Option - Mute mode. The system has a sync option activated and is currently being

muted (No acoustics)

Symbolising the resultant speed direction

2018-05-28 Page 7 of 60

Installation DL2 Doppler Speed Log System

CHAPTER 1: GETTING STARTED

Overview dl2

The DL2 dual axis Doppler speed log is a Navigational Doppler Speed log system that measures

speed in two axis (longitudinal and transversal) through the water and over the sea bed. The system

requires no external inputs, however adding inputs from other navigational systems enhances the

functionality and allows comprehensive quality control of the data.

The system fullls all class and type regulations based on MED B (wheelmark) and is manufactured

in Norway under stringent production controls.

The system comprises of 5 units;

1. The Operator unit – CU-M001-SA

The system is to be tted with a touch

display panel where full setup and

operation can be performed.

2. The electronic unit – JB70D2-SA

This unit comprises of a processor

and a power supply. It is a compact

single euro cabinet. It enables the

user to interface to both modern and

older navigation systems with all the

expected connectivity. The unit has a

built-in web server, allowing the system

to be fully integrated into existing

navigation systems (extra approvals

may apply).

3. Junction box JB12-SA. To connect

sensor cable to yard supplied extension

cable.

4. The sensor – The sensor (DL2SG-

SA) contains acoustic elements and

a fully programmable transceiver unit,

allowing the system to adapt itself

to the conditions and requirements.

In addition the sensor contains a

temperature sensor and tilt sensors.

5. Sea valve. The sensor may be installed

into a sea valve for single bottom hull

(SB-100-XX) or sea valve for double

bottom hull (DB-100-XX).

BRIDGE

FORE PEAK

115-230VAC

/ 24VDC

DL21SG-SA

DL21 sensor

w/40m cable

in Sea valve

SB-100-SB

JB21-SA

Junction box

JB70D21-SA

Electronic Unit

Sensor extension cable.

Yard supply.

6 x twisted shielded pairs

Dimension: see DL2 manual Chapter 3.

JB12-SA

Junction box

DL2SG-SA

DL2 sensor

w/40m cable

in Sea valve

SB-100-SB

JB70D2-SA

Electronic Unit

Sensor extension cable.

Yard supply.

3 x twisted shielded pairs

Dimension: see DL2 manual Chapter 3.

CU-M001-SA Operator Unit for DL2

LAN cable. CAT6. Max. 100m

24VDC

Page 8 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

OpTiOnal iTems dl2

The following optional items are SKIPPER supplied:

- Speed Repeater CD401MR-SB

- External NMEA dimmer IR31DIM-SA

- LAN switch

BRIDGE

FORE PEAK

115-230VAC

/ 24VDC

CD401MR-SB

Repeater NMEA

IR31DIM-SA

External

dimmer

NMEA

24VDC

24VDC

I/O DL2

DL21SG-SA

DL21 sensor

w/40m cable

in Sea valve

SB-100-SB

JB21-SA

Junction box

JB70D21-SA

Electronic Unit

Sensor extension cable.

Yard supply.

6 x twisted shielded pairs

Dimension: see DL2 manual Chapter 3.

JB12-SA

Junction box

DL2SG-SA

DL2 sensor

w/40m cable

in Sea valve

SB-100-SB

JB70D2-SA

Electronic Unit

Sensor extension cable.

Yard supply.

3 x twisted shielded pairs

Dimension: see DL2 manual Chapter 3.

CU-M001-SA Operator Unit for DL2

LAN cable. CAT6. Max. 100m

24VDC

LAN switch

(option)

2018-05-28 Page 9 of 60

Installation DL2 Doppler Speed Log System

iTems nOT supplied by sKipper

The following items are not SKIPPER supplied:

- LAN cable (minimum CAT6) from Operator unit to Electronic unit.

- The sensor is manufactured with a 40m cable. The cable may be cut or extended. Extension cable

is minimum CAT7 type. See chapter 3 for lengths and dimensions.

pOwer supply requiremenTs

The following power supplies are required

- CU-M001-SA. Operator Unit. 24VDC. Max 10W, Typical 6W.

- JB70D2-SA. Electronic unit: 24VDC and/or 115/230VAC. Max 60W typical 15W.

There are no power switch on the CU-M001-SA or JB70D2-SA.

The power input should be including a manual circuit breaker.

There are no input fuse on the CU-M001-SA or JB70D2-SA.

The power input should be including a fuse rated for 100% - 200% of max power installed components.

Example: 24V DC to power CU-M001-SA and JB70D2-SA should have a 3A slow blow fuse.

Optional items power supply requirement:

- CD401MR repeater. 24VDC. Max 10W, Typical 6W.

- IR31DIM-SA. External dimmer: 24VDC

- LAN switch: 24VDC

Page 10 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

CHAPTER 2: HARDWARE MOUNTING

placemenT Of The OperaTOr uniT

The operator unit is placed on the bridge.

Some standards require some operations of

the unit to be available from ‘standing position’.

These operations are available from the operator

unit and multi-repeaters if both input and output

are connected.

Dimensional drawings are found in Appendix 1.

Flush mount installation

Wall mount installation

2018-05-28 Page 11 of 60

Installation DL2 Doppler Speed Log System

placemenT Of The elecTrOnic uniT

The electronic unit can be installed on a DIN rail or directly

screwed onto the wall.

All parts of the system are connected to the electronic unit.

There are no buttons (like ON/OFF) in the electronic unit.

Access is only required for service purpose.

Placement is typically in or near the bridge where the

interfaced systems are available, but no nearer than 0.5 m

to the GYRO heading sensor.

placemenT Of The elecTrOnic uniT ip22 apprOved

If IP22 is required for electronic unit then:

- Alternative 1

Horisontal installation. PCB’s vertical. IP22 Drip plate installed.

-Alternative 2

Vertical installation

Alternative 1 Alternative 2

Drip plate

placemenT Of repeaTers

Repeaters are typically installed on the overhead console and/or the bridge wings. These can be

routed using NMEA signals. These require a local +24 V DC supply.

66

31,5

165,5

141

161

70

125

144

6,1 (4x)

Approved by - date

HK 2012.02.09

Designed by - date

1 of 1

JB12 Outline Drawing

Scale

OD-JB12

Revision

X0

Sheet

Edition date

Name

Drwg. no.

CN

Checked by

Material

Eur. projection

Gen. tolerance

1:2

ISO2768m

E

D

Electronics AS

B

A

8

7

6

4

D

C

5

1

2

3

A

B

4

3

2

1

C

F

E

placemenT Of Jb12 JuncTiOn bOx

The junction box JB12 is an option for connecting sensor cable to a yard

supplied extension cable (See chapter 3).

It is placed in a dry place within reach of the 40m sensor cable.

Page 12 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

placemenT Of The sea valve

Mounting instructions for the sea valve is available from the SKIPPER web site in separate manual

depending on the chosen type. When placing the speed log sensor, consider the following moments:

• Free sight to the bottom (it should be possible to draw a cone of +-45 degrees from the

sensor to the bottom).

• The active face of speed sensor must be in parallel to the horizontal line, max offset +-1°.

• Do not mount transducers aft of bow thruster, propeller outlets or aft of other hull

installations (such as outlets, vents or other protruding details) that may create aeration or

turbulence.

• It is necessary to select a part of the hull that is submerged and free from turbulence and

aeration under all load and speed conditions, and to avoid positions where air is trapped in

heavy weather.

• If a at, horizontal section is not available for transducer tting, the shipyard must construct

a suitable bed. Welding seams in this area and forward should be smoothed and rounded

off in order not to create turbulence or aeration and maintain a laminar waterow at all

speed ranges of the vessel.

• Select an area that is acoustically quiet. The system operates at frequencies between 270

kHz and 284 kHz.

There are 2 channels in DL2.

The acoustic signal is sent in

a 30deg angle in forward and starboard

directions.

In addition a tilt sensor is used to

compensate for vessel movement.

FWD

PORT STRB

AFT

DL2

Longitudal speed

channel

DL2

Transversal speed

Channel

A

Bubbles

Sensor installation

A

Bubbles

Side view

Bottom view

Sensor placed

fore

Water relative speed is measured at a depth

between 0.3 and 3 m below transducer.

(DL1)

2 axis Water relative speed is measured at a

depth between 0.3 and 3 m below

transducer. (DL2)

Bottom track is measured down to 150m

depth

2018-05-28 Page 13 of 60

Installation DL2 Doppler Speed Log System

The generally best placement on larger vessels is in the front region of the vessel just behind the

bulbous bow (see g above). This area is generally designed such that the bubbles are pushed to

either side of the bulb, leaving a clear area under the bulb and just behind. The sensor is installed in

a sea valve in order to service the sensor (clean or replace) without docking the vessel.

It is recommended (but not required) to install the sea valve in a dry area, like a bow thruster room.

This will enable easy cable access to junction box and additionally increase the lifetime of the sea

valve.

The sensor DL2 is installed into sea valve

100mm for single bottom SB-100-SB or

double bottom DB-100-SB.

Please see sea valve manual for installation

procedure.

Manuals available as downloads from

www.skipper.no

The sensor includes 40m moulded in cable.

The cable is 11 mm in outer diameter with a

bending radius of 56 mm. The cable can be

cut or extended if required

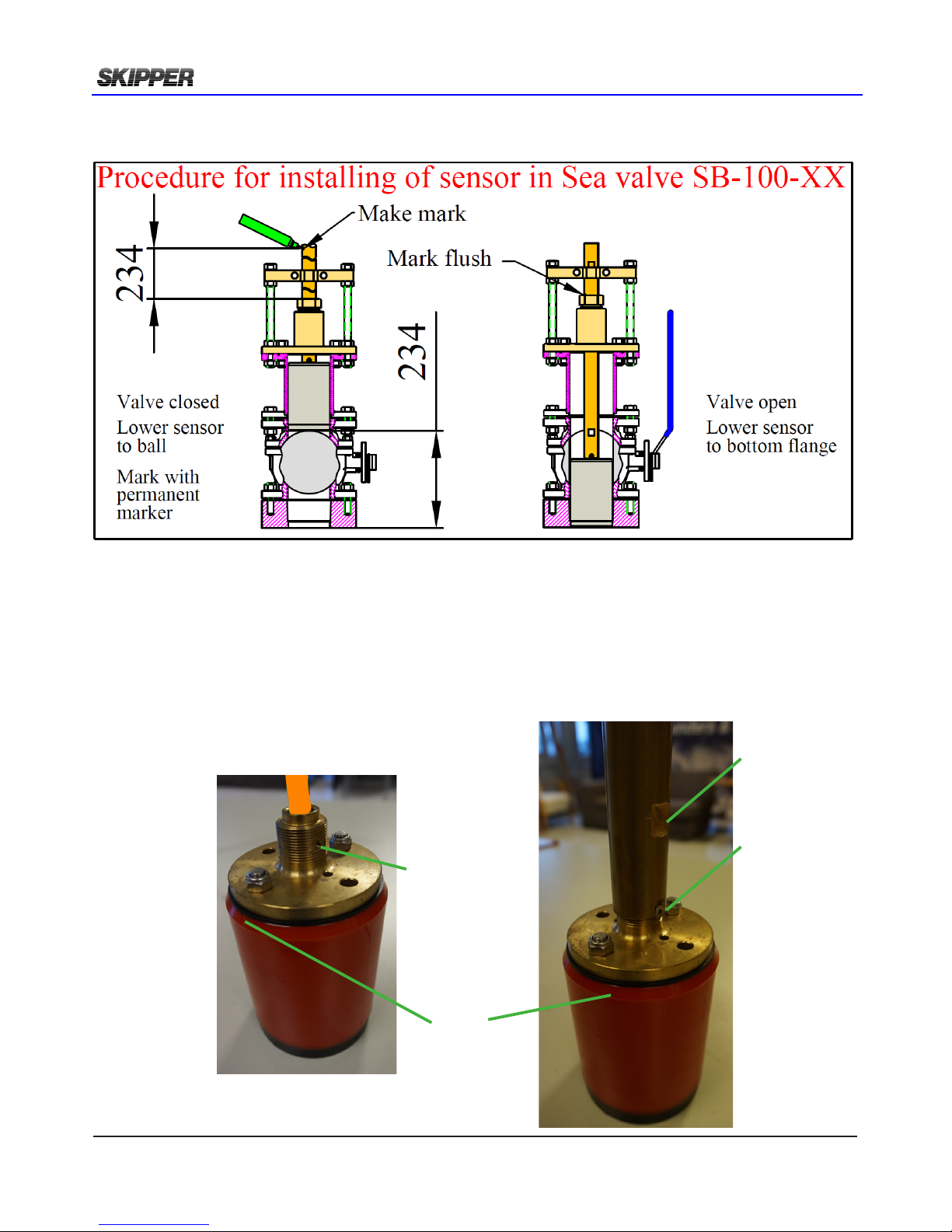

placemenT Of The sensOr in sea valve

NOTE

During physical installation of sensor into sea valve please make special care of the following points:

• Sensor to be lowered completly into bottom ange making sensor head ush with outer hull.

• Sensor forward direction to be aligned +/-10deg. (Fine adjust by software in calibration page)

• Clamping unit nuts and nut M50 to be tighten to secure sensor position.

Page 14 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

Sensor forward direction.

It is important to align sensor forward direction.

Pictures showing forward direction alignment in sea valve SB-100-SB.

Sensor lowered ush with outer hull.

Pictures showing lowering procedure in sea valve SB-100-SB.

Threaded hole

Port side

Forward

position mark

in moulding

Screw M4

In threaded

hole

Port side

Flat area

Port side

2018-05-28 Page 15 of 60

Installation DL2 Doppler Speed Log System

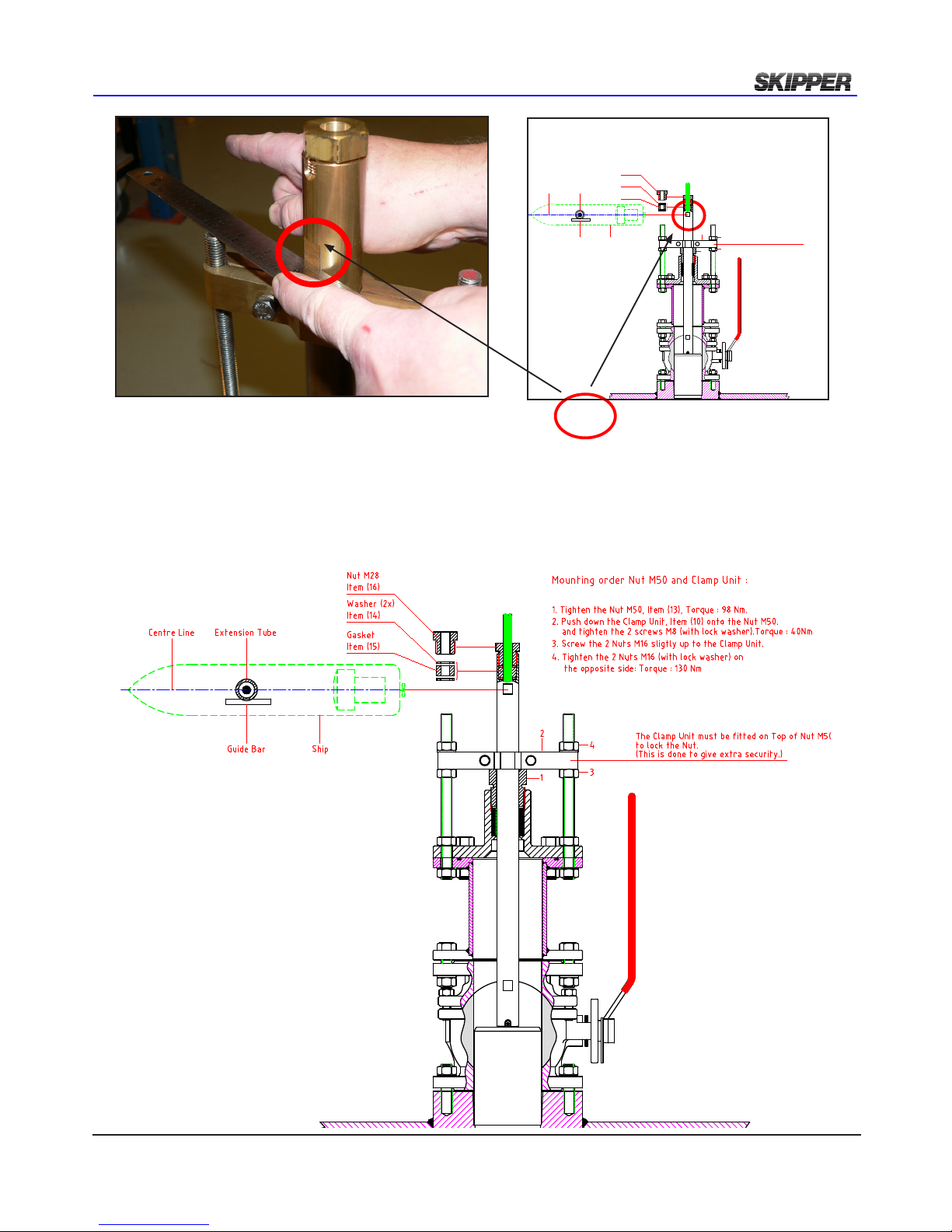

A at object points fore/aft. The at side should be on the port side.

DB-2039

Nut M28

DB-2037

Washer (2x)

Gasket

DB-2038

Final Assembly

1. Tighten the Nut M50 (DB-2036). Torque : 98 Nm

2. Push down the Clamp Unit (DB-2033) onto the Nut M50.

and tighten the 2 screws M8 (with lock washer).Torque : 40Nm

3. Screw the 2 Nuts M16 sligtly up to the Clamp Unit.

4. Tighten the 2 Nuts M16 (with lock washer) on

1

2

3

4

Mounting order Nut M50 and Clamp Unit :

the opposite side: Torque : 98 Nm

The Clamp Unit must be fitted on Top of Nut M50

to lock the Nut.

(This is done to give extra security.)

Extention TubeCente Line

Guide Bar Ship

Secure sensor by tightening clamping unit and nut M50

Page 16 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

CHAPTER 3: WIRING

The JB70D2-SA does not contain a physical switch (only software) and should be connected to a

circuit breaker for removal of power.

Power may be nominal 24V DC (No more than 32V DC) and/or 115-220V AC. Max 60W typical 15W.

The AC input is an optional back up for JB70D2-SA only. The operator unit CU-M001-SA requires a

24V DC power supply.

There are no input fuse on the CU-M001-SA or JB70D2-SA.

The power input should be including a fuse rated for 100% - 200% of max power installed components.

Example: A 24V DC to power both CU-M001-SA and JB70D2-SA should have a 3A slow blow fuse.

clamping The cables

Cables should be connected to WAGO connector, leaving

approximately 3 cm of tail. They should be stripped with 6-7 mm of

metal showing and these should be connected as in the diagram

above. A small screwdriver with blade size approx 3.5 mm can be

used. WAGO part no 210-719 is ideal for this use.

Outer shields should be collected and grounded in a ground stud on

the edge of the cabinet. The outer insulation should be cable tied to

the plastic handle of the connector, and securely anchored nearby.

The plugs when retted, must be installed such that their clips are

fully in the up position.

220V AC. 0,5A

115V AC. 1A

24V DC. 3A

2018-05-28 Page 17 of 60

Installation DL2 Doppler Speed Log System

cu-m001-sa OperaTOr uniT wiring

The operator unit has 2 connectors.

1 LAN connector for communication with Electronic unit.

2: WAGO connector CN1 for 24V power. Max 10W, Typical 6W.

Items supplied with CU-M001

1 x ZZN-01120.

Connector Female w/ejectors 6x2 pole, black. (CN 1)

1 x ZZN-01123. Strain relief plate, 6x2 pole, width 11 mm. (CN 1)

Note:

NMEA and

CANBUS are

options not yet

implemented

Page 18 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

Jb70d2-sa elecTrOnic uniT wiring

The JB70D2-SA is connected with Operator unit CU-M001 with the LAN connectors. The second

LAN connector may be used for set up/ service purpose.

PWR 3

Not in use on DL2

Power in PWR 2

24V DC

Power in PWR1

115-220V AC

Sensor J3

NMEA J1

2 x NMEA In

4 x NMEA Out

AUX/Alarm J2

Alarm relay

1 x AUX In

2 x AUX Out

2 x LAN

2018-05-28 Page 19 of 60

Installation DL2 Doppler Speed Log System

ZZN-01126 Relief Housing,

3 pole snap-on.

WAGO: 232-633

ZZN-01125 Plug, Female 3

pole,231-303 026

ZZN-01124 Plug, Female 2

pole, 231-302_032-000

ZZN-01123 Strain relief

plate, 6x2 pole, width 11 mm

WAGO 713-126

ZZN-01120 Connector Fe-

male w ejectors 6x2 pole, black

WAGO 713-1106/037-000

ZZN-01123 Strain relief

plate, 6x2 pole, width 11 mm

WAGO 713-126

ZZN-01130 Connector, Fe-

male w/ejectors 3x2 pole, black

WAGO 713-1103/037-000

cOnnecTOrs supplied wiTh Jb70d2

Page 20 of 60 2018-05-28

Installation DL2 Doppler Speed Log System

sensOr cOnnecTiOn J3

The sensor is connected to JB70D2-SA Connector J3. 6 pin WAGO connector.

The cable screen is connected to screen on sensor side and does not need to be grounded at

JB70D2-SA side, if the system has instability problems grounding at the JB70 unit may help. .

J3 Pin1

1

6

5

4

3

2

Other manuals for DL2

2

Table of contents