SKLADOVA TEHNIKA Gloria User manual

INSTRUCTION

MANUAL FOR END-USERS

FOR SOLID FUEL COOKERS

SKLADOVA TEHNIKA

25 Sveti Knyaz Boris I St.

5100 Gorna Oryahovitsa

Republic of Bulgaria

phone: +359 618 60076

e-mail: info@st-bg.com

www.st-bg.com

2

CONTENTS

1. Introduction ....................................................................................................................................................................................... 3

2. Technical data .................................................................................................................................................................................. 3

3. Cooker assembling........................................................................................................................................................................... 3

4. Cooker operating.............................................................................................................................................................................. 4

5. Cleaning............................................................................................................................................................................................ 6

6. Important directions for fire-precaution and safety regulations ..................................................................................................... 7

7. Possible defects and their causes................................................................................................................................................... 7

8. Additional clause……………………………………………………………………………………………………….…...8

9. Significant information about disassemble, recycle after the service life expires………………………………..….8

3

Dear customers,

Your cooker is produced and tested in conformity with the requirements of standard EN 12815:2001 and responds to the approved technical

documentation.

Don’t leave the instruction manual unread. The assembly and the exploitation of a cooker are connected with different legal

obligations, which are explained in this instruction. According to the laws and regulations for safety, when using a cooker of such class,

the buyer and the user of the cookers are obligated, with the help of this instruction, to inform themselves for the assembling and the

right operation of the appliance.

1. Introduction.

Solid fuel cookers are designed for cooking and heating, and the used fuel can be wooden logs. The cooker can be used in kitchens and

houses, but it is not suitable for integrating into kitchen furniture.

2. Technical data.

The technical specifications of solid fuel cookers are mentioned in Table 1.

Table 1.

(*) PM = particulate matter, OGC = organic gaseous compounds, CO = carbon monoxide, NOx = nitrogen oxides

Overall dimensions of the oven

(mm)

width

410

depth

440

height

270 for Gloria, Gloria L 220, Plamak Eko

3. Cooker assembling.

For ensuring safe and correct operation of the cooker it is necessary to keep the following conditions:

The cooker has to be mounted in rooms which have enough fresh air supply, which is necessary for burning. After placing the cooker, it has to

be connected to the chimney with the proper fluepipes, but before connecting them, their functionality has to be checked and inspected.

Not every cooker can be mounted to every chimney. Before installation, the static pressure and the size of the chimney have to be checked if

they fit to the required parameters of the cooker. If the cooker is not compatible with the chimney, this will lead to weaker burning and contamination

of the glass with soot.

The chimney has to be high enough (not less than 5m.) It’s allowed only one more appliance to be connected to the same chimney. The flue

draught of the chimney has to be over 10Pa, and over 15 Pa for cookers with water boiler. If the chimney is very high (flue draught over 35Pa) it is

necessary to install additional valve for reducing the flue draught. The internal shape of the chimney has to be even and round to its full length, not

square or with changing shape.

To ensure safe operation, the cooker has to be connected to the chimney by means of a spigot on the wall, and the connection has to be

sealed very well. The connecting fluepipe between the cooker and the spigot has to be as short as possible, this means not to use horizontal and

angular connected fluepipes. It is recommended to use not more than two crooked fluepipes, in order to avoid tar accumulation on the horizontal

fluepipes and the chimney, which therefore leads to lower flue draught in the chimney.

The fluepipe does not have to enter in the chimney because this will reduce its draught.

The cooker should not be connected to a chimney, when there is already connected appliance with water boiler.

The chimney has to be designed in a way that it will allow easy mechanical cleaning.

cookers

Space heating output

(kW)

Efficiency (%)

Space heating emissions at

nominal heat output(*)

( mg/m

3

)

Overall dimensions

(mm)

Flue gas mass (g/s)

Flue gas temperature (°C)

Weight (kg)

Minimum flue draught at nominal

heat output (Pa)

Fuel quantity

(kg/h)

CO

РМ

NOx

OGC

width

depth

height

Gloria

9

79,30

1084

38,6

127,05

62,30

900

636

900

10,86

181

146

11

2,8

Gloria L

9

79,30

1084

38,6

127,05

62,30

900

636

900

10,86

181

135

11

2,8

Plamak Eko

8

80,67

837

39,2

127,62

105,85

840

613

890

10,20

156

136

12,5

2,3

4

The floor, where the cooker will be placed, should be smooth and leveled, made of non-combustible materials (such as mosaic, marble,

terracotta, etc.), and possessing the required load capacity.

If the floor in front of the cooker is not heat resistant (carpets, linoleums or others of the same kind) a stable, non-combustible platform should

be used, (made of steel, glass or ceramic, etc), which should come out: 50 cm in front and 30 cm from both sides, measured from the firedoor of the

cooker.

Distances at which the cooker should be installed for fire precaution:

Distance to near combustible materials:

Glolia, Glolia L

in front -80сm, side -30сm, back -30сm

Plamak Eko,

in front -60сm, side -30сm, back -30сm,

ceiling -85сm

If there are any easy inflammable materials and constructions, the cooker should be 80 cm away from them or it has to be supplied with non-

combustible shield.

The upper surface (frames and plates) should stay at least 1m away.

4. Cooker operating.

4.1. Fuel materials.

The most appropriate fuels are dry cleaved wood (wood logs). The wood logs, stored in the open under sheds, reach a humidity level of 10-

15% after 2 years, when they are most suitable for combustion. We recommend to burn wood dried as much as possible. The maximum heat output

of the cooker is reached after burning wood logs dried for at least 2 years period of time.

The fresh cut wood has little calorific effect, high humidity and burns poorly –they extract a lot of flue gases and additionally contaminate the

environment. This leads to minimizing the longevity of the cooker and chimney as well. When using them, the heat output of the cooker falls to 50%,

and the fuel consumption grows twice.

It is not recommended to use the following fuels in the cookers: wet or tarred wood, shavings, fine coal, paper and cardboard (except for the

ignition).

Do not use liquid fuels.

Do not use the cooker like a furnace for burning waste matters.

If the cooker is used for burning unalloyed fuels then the warranty is not valid

At each ignition of the cooker you should observe the following: Clean the bottom grate, and the ashtray if needed, but you should do this only

if the cooker is in cold condition.

4.2. Assembly parts.

Glass of the door of the combustion chamber (for Gloria, Gloria L)

It is a ceramic glass, resists up to 850ºC and cannot be damaged by the temperature, reached during the exploitation of the cooker. The glass

can be damaged by a mechanical act during the mounting, during the transportation of the cooker or by placing of huge chopped wood into the

combustion chamber.

The glass is a part of fast wear parts and is covered by the guarantee.

Soot of the glass

The design of the cooker prevents soot of the glass during the exploitation. Soot can be only in case of bad burning, caused because of the

following : static pressure and the size of the chimney do not conform to the required for the cooker parameters, the incoming air flow has been

stopped too early or the right burning material is not used.

We cannot act on these conditions and because of this we do not guarantee that the glass will be soot clean.

Glass on the oven door.

The mounted glass is tempered. During exploitation prevent cold water drops on the glass.

The glass is a part of fast wear parts and is covered by the guarantee.

Refractory bricks (shamote).

The combustion chamber of the cooker is sealed with refractory bricks. These bricks accumulate the heat and radiate it back into the

combustion chamber to increase the burning temperature. Higher burning temperature means more effective burning process. Because of too high

temperature or mechanic act the refractory bricks can be damaged. Too high temperatures can be reached when at higher chimney draught the

primary air adjuster is open –uncontrolled burning. Mechanical act is pushing the wood into the combustion chamber or using bigger size chopped

wood.

The refractory bricks can be easy replaced. If there is just a cleft on a brick it is not necessary to replace the brick. But if you can see the metal

parts between or under them it is necessary to replace the brick.

The refractory bricks are part of fast wear parts and are covered by the guarantee.

5

Seals

The seals of the cooker are made of a special glass fiber and of technical basalt cardboart. They do not contain asbest. The seals are wear

parts and must be changed with new ones after a period of exploitation. Your merchant can order the seals for you.

The seals are part of fast wear parts and are covered by the guarantee.

Fire-grates

The cooker is equipped with fire-grates. Cookers for Gloria, Gloria L have got just one fire-grate. The fire-grates can be clogged by nails, small

wooden pieces or by waste burning materials. Regularly clean the fire-grates to keep them in good operation condition. In case of too high

temperatures because of wrong operation or because of wrong burning material the fire-grates can be damaged.

The fire-grates are part of fast wear parts and are covered by the guarantee.

Coating of the cooker.

The coating can be : enamel, epoxy-polyester powder and high temperature resistant paint or just high temperature resistant paint.

The high temperature resistant paint resists at high temperatures, but not to corrosion. At wrong exploitation corrosion can be on the painted

cooker surfaces.

It is not covered by the guarantee.

During the initial putting of the cooker in operation it is necessary few hours to heat the paint to be calcined and to reach it final resistance.

The door of the combustion chamber must be slide open to prevent sticking of the seal of the door to the painted surface. During this period do not

put anything on the cooker and do not touch the surfaces to prevent damaging. The smell, caused because of the calcined paint will not be after few

hours. Fresh air must circulate in the premise.

If because of overheating or because of wrong servicing the color is changed to gray-white or a corrosion spot occurs –this is not a problem.

You may order a same color spray dose paint to your merchant.

Handles.

The handles of the cooker are plastic (phenoplastic), bronze or nicker coated. The advantage is that they are not wear parts. The handles are

heated as much as the front part of the cooker and because of this a thermo –resistant glove must be used to operate.

4.3. Ignition at operation.

Your cooker is designed for intermittent burning and operates only with doors closed. At each ignition you should observe the following:

4.3.1.

Ignition at lower combustion.

Lower combustion is obligatory used for cooking and baking in the oven, and when cooking the regulator for the flue gas, positioned to the flue

pipe outlet needs to be fully opened. With this regulator you can adjust the temperature for baking - up and down. The internal temperature of the

oven depends on the intensity of burning, the flue draught and the amount of fuel. The intensity of burning is regulated by the primary air. By

adjusting the primary air you can achieve proper regulation of the temperature inside the oven. If you want to reach high temperature in the oven

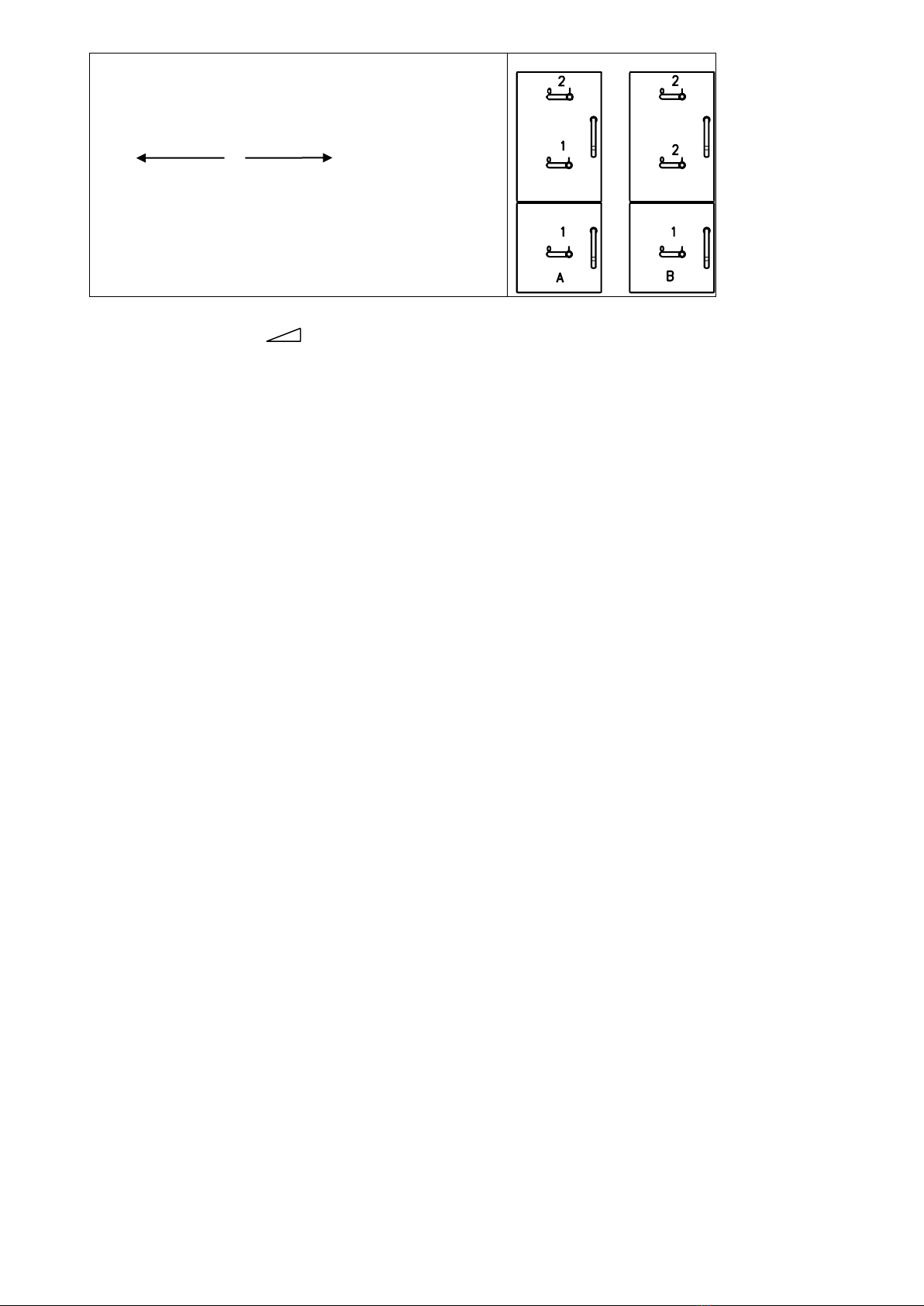

and the cooker is still cold it is recommended to ensure high heat and temperature in the cooker and to open the regulator for the oven (see fig.1)

and the regulator for the primary air. (see fig.2) by moving the adjuster in the given directions. When the required temperature is reached in the

oven the intensity of burning has to be decreased by closing the primary air regulator and the oven air inlet control. This will keep the temperature in

the oven constant.

When the air inlet control of the oven is positioned at:

rearmost position it is open;

foremost position it is close -the heat will go under the oven;

middle position -opened ½ the heat will go under and above the oven.

close open

Fig.1.

The air inlet control of the oven is positioned on the top plate of the cooker by the flue gas outlet.

Glolia, Glolia L

фиг.1.1

When the air inlet control of the oven is positioned at:

-rearmost position it is open “

←

I

”

- foremost position it is close “

0

→

”the heat will go under the oven

-по средата - отворен на ½- топлината минава под и над фурната

middle position -opened ½ the heat will go under and above the oven.

P

lamak

Eko

When the air inlet control for primary and secondary air supply are

positioned in:

End left position -close

End right position –open

0 –close I - open

They are located on the doors of the stove and are shown in Fig.2.

A-lower combustion B-upper combustion

1-regulator for primary air

2-regulator for secondary air

Фиг.2

On the Gloria stove the regulators are on the upper and lower facade.

When the primary and secondary air regulators are located

in:extreme left position ”closed” far right position "open".

The fuel is placed on the fire-grate, for cookers Plamak Eko on the top fire-grate, and and then it is fired. After that the intensity of the

burning is regulated by the regulators for primary and secondary air supply.

For constant burning you have to add wood or coals by spreading them on the whole grate.

Attention!

When the oven is used you need to add more fuel. The flue gas volume is bigger and the temperature heating will be even and constant.

4.3.2. Upper ignition.

The upper ignition is used when the cooker is used only for heating. Before ignition the top grate is removed and the firedoors are

closed.

The fuel is added from the top cover positioned on the top plate, and a vertical wood log is placed in the middle. After the fuel is well

ignited, ignition adjusting is enabled as when lower ignition process.

4.4. Recommendations for ventilation.

Very important factor for proper burning of the cooker is to ensure additional air supply in the room, which should be minimum 4m

3

/h for

kW of the total heating power. If there are additional heating appliances in the room it is necessary to provide additional 1.6m

3

/h for kW air supply

at every hour and at each kW form the total heating power.

A ventilator for suction of the air from the room (desiccators, tumble driers, etc.) working at the same time with the cooker leads to change

in the flue draught and consequently to bad burning conditions of the cooker. In this case for the proper burning to be achieved it is necessary to

let additional air into the room.

4.5. Heating during the transitional period

For the good functioning of the cooker, it is necessary to achieve enough draught of the chimney. This depends on both its height and the

ambient temperature. At temperature exceeding 14

C disturbances in the combustion caused by insufficient draught might occur. In this case it is

necessary to load the cooker with less fuel and the regulators to be left open so that the fuel to be burned faster (with flame) and thus reaching a

stable flue draught in the chimney. In this case it is necessary to clean the ashpan more often.

5. Cleaning.

The right exploitation of the cooker requires regular cleaning of the chimney, the fluepipes and the cooker itself, from the soot and tar.

You can clean the ashtray only when the stove is cold.

Cleaning can be done when the top plates are removed and the surrounding steel plates around the oven are cleaned. The soot is

collected under it. When the bottom plate is returned you have to ensure that the sealing is right.

Proper maintaining of the cooker can guarantee the good look of the product for a long time.

The surface of the cooker can be:

With enamel finish. They can be washed with standard commercial cleaning materials, which are acid free and you can polish them with

a soft towel.

Painted with epoxy-polyester powder. They have to be cleaned by the same way like the enameled parts. In order to preserve the

surface from damage this can be done only when the cooker is cold,

Painted with heat-resistant paint. This surface can be cleaned with dry and soft brush.

For Gloria, Gloria L under the bottom of the oven is situated a hole for cleaning. To clean the space under the oven it is necessary to

dismantle 6 pcs of wing nuts M6.

Attention!

When cleaning do not use sharp objects and abrasive materials!

After using the oven it has to be cleaned when it is still warm and then to be dried. When needed, the glass of the oven can be cleaned

only when it’s cold, by washing it with soap solution.

The manufacturer keeps the right to make changes in design and construction without violating the technical and operational

quality of the cookers.

7

6. Important directions for fire-precaution and safety regulations.

Please observe the following requirements for fire-precaution and safety regulations.

The door of the combustion chamber should always be firmly closed even when the cookers is not working. It should be serviced

only by some operating tools or heat-resistant glove, which is placed inside the cooker.

The cooker should be installed only on a non-combustible floor. Under the oven door there is a niche with door (for

Plamak Eko) and niche (for Gloriaq, Gloria L). They are decorative and storing easy inflammable materials in them is not

allowed.

The cooker and the flue draught pipes should be at least 80cm away from combustible objects or constructions.

Using easily inflammable liquids is not allowed at ignition.

Vertical connection of flue draught pipes with the chimney through floor structures is not allowed.

The presence of easily inflammable and explosive substances in the heated room is not allowed.

The ash disposal and cleaning of the cooker should be done only at safe places and when has cooled down.

The cooker is designed for local heating of rooms with normal fire danger.

It is prohibited to put combustible materials and objects on the cookers or in immediate proximity of it.

The cooker is not designed to be used by children and persons with limited physical, sensuous and mental

abilities, or by people with not enough experience and knowledge, except in cases when they are watched and

instructed how to work with this type of heater, by someone who is responsible for their own safety. Incineration

danger!

We recommend the following instructions when there is a fire in the chimney:

Close the combustion air regulator!

Call the fire brigade in your neighborhood!

Don’t try to extinguish the fire with water by yourself!

All easily inflammable materials to be away from the chimney!

When the appliance is set to work again it is necessary the chimney to be checked by a competent person for eventual

damages.

In cases when the cooker has been overworked above the permissible capacity and output, and/or fuels different from

the recommended ones had been used, the manufacturer cannot guarantee for the smooth and perfect operation of the

cooker.

Please complete regularly a full check of the functionality of the cooker with the help of a specialist. If there is need to replace

some parts, you have to change them with parts provided and produced only by the manufacturer.

7. Possible defects and their causes.

At ignition the cooker is smoking (not enough flue draught pressure):

The chimney and the flue pipes are not sealed;

The chimney is with wrong size;

If there is second appliance connected with the same chimney check the doors of the second product. They have to be

closed;

The room can’t be heated:

Bigger heat is needed;

Bad fuel;

There is a lot of ash on the grate;

The air supply is not enough;

The cooker releases too much heat.

The air supply is too much

The chimney pressure is really high.

The fuel is too much or the fuel is very calorific.

There are damages on the grate:

The cooker is overloaded many times;

The used fuel is not from the recommended types;

The primary air supply is too much;

The chimney flue draught pressure is really high;

When the product does not work well:

Open the regulator for the primary air. The regulator for the secondary air needs to be completely open;

Put less fuel;

Clean the ashtray regularly;

Check the chimney for blockage;

Check if the fluepipe has entered the chimney;

8

If the cooker is connected together with a second appliance in the chimney check the proper operation of the second

product;

Check if the needed pressure of the flue gas flow in your chimney requires the cooker characteristics;

Check if the passage to the chimney is not closed with top cover.

Overheating the cooker:

Close all air regulators. If it is necessary open the oven door.

The oven can’t reach high temperature:

Check if the oven door is firmly closed;

Open the air regulators.

Use good, well dried wood material.

8. Additional clause

Packaging protects the stove from damage during transportation. The included packaging materials are ecological and recyclable.

The Manufacturer recommends to throw away the different parts of the packaging as follows:

- take the plastic band and the cardboard into a disposal collection point or throw them away in the containers for waste separation;

- wooden parts can be burnt.

9. Significant information about disassemble, recycle after the service life expires.

After expiry of the stove`s service life, the manufacturer recommends:

- glass and metal parts to be disposed off at a disposal collection point;

- fireproof bricks and plates in a construction waste container or at a disposal collection point.

Pay attention to national regulations, please!

№ 28012022

This manual suits for next models

2

Table of contents

Other SKLADOVA TEHNIKA Cooker manuals