Skope CL Series User manual

CL & CC Series

SKOPE Counterline & Slimline Horizontal Chiller

Service Manual

MAN0682 Rev. 3.0 Feb. 2014

Model: CL400

Model: CL600

CC & CL Series

SKOPE Counterline & Slimline Horizontal Chiller

Service Manual

MAN0682

Rev. 3.0 Feb. 2014

© 2007 SKOPE Industries Limited. All rights reserved.

SKOPE Industries Limited reserve the right to alter specifications without notice.

is a registered trademark of SKOPE Industries Limited.

SKOPE INDUSTRIES LIMITED

Head Office

PO Box 1091, Christchurch

New Zealand

Freephone: 0800 947 5673

Fax: (03) 983 3896

E-mail: [email protected]

Website: www.skope.co.nz

Trademark Infringement

The SKOPE trademark on this product is infringed if the owner, for the time being, does

any of the following:

• Applies the trade mark to the product after their state, condition, get-up or packaging

has been altered in any manner

• Alters, removes (including part removal) or obliterates (including part obliteration) the

trade mark on the product

• Applies any other trade mark to the product

• Adds to the product any written material that is likely to damage the reputation of the

trade mark

Notice of the above contractual obligations passes to:

• Successors or assignees of the buyer

• Future owners of the product

SKOPE Counterline Series

Service Manual iii

CONTENTS

1 Specifications

Counterline Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Counterline Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Slimline Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Slimline Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Servicing Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Electronic Controller

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SKOPE Dixell XR30C Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Meaning of LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Programming the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parameters - Dixell XR30C . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Display Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

SKOPE CAREL ir33 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Defrost Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Continuous Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Temperature Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Set-Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Controller Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Default Program Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

BN Parameter Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Field Adjustable Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Display Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Wiring

CL400, CL600, CC300 & CC500 (CAREL controller,

fluorescent lights) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CL800 & CC700 (CAREL controller, fluorescent lights) . . . . . . . . 28

CL800r & CC700r (CAREL controller, fluorescent lights) . . . . . .29

CL & CC Integral (CAREL controller, LED lights) . . . . . . . . . . . .30

CL & CC Remote (CAREL controller, LED lights) . . . . . . . . . . . .31

4 Spare Parts

Cabinet Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Interior Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Integral Refrigeration Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Remote Refrigeration Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SKOPE Counterline Series

Service Manual

iv

5 Replacement Procedures

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Glass Swing Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Tension Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Torsion Bar Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Solid Swing Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Sliding Glass Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Door Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sliding Door Frame Cover Removal . . . . . . . . . . . . . . . . . . . . . . 46

Refrigeration Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Unit Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Unit Wiring Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Refrigeration Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Evaporator Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Recommended Service Procedures . . . . . . . . . . . . . . . . . . . . . . 49

Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CARELController Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Probe Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7 Troubleshooting

Diagnostic Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5

SKOPE Counterline Series

Specifications

Service Manual

1Specifications

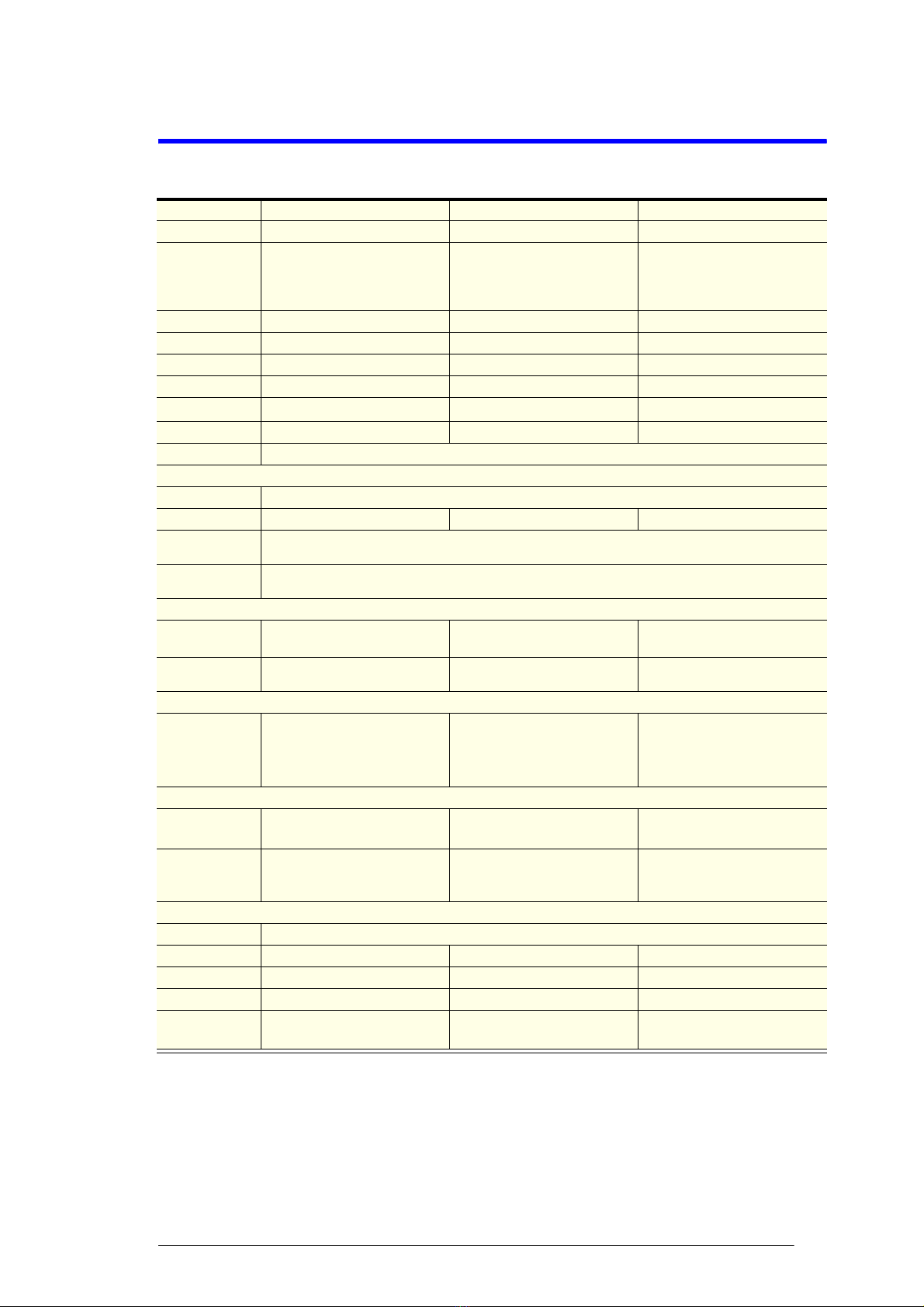

Counterline Integral

* Height excludes castors, legs or optional worktop

** Depth with optional worktop is 700mm

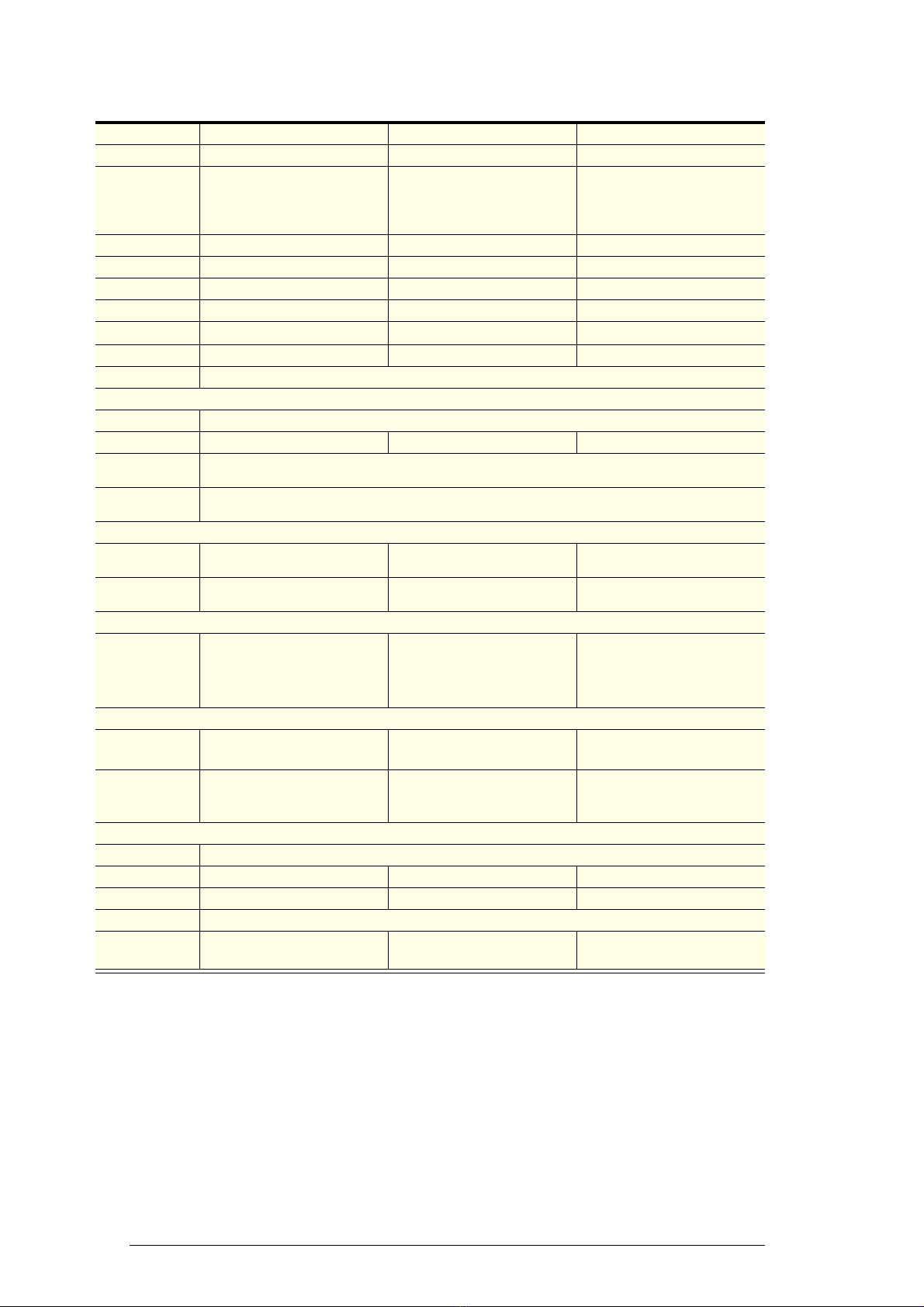

CL400 CL600 CL800

Description: 2 door integral counterline chiller 3 door integral counterline chiller 4 door integral counterline chiller

Type: JD2202 (swing door, fluoro light)

JD2102 (sliding door, fluoro light)

JD2202V (swing door, LED light)

JD2102V (sliding door, LED light)

JD2203 (swing door, fluoro light)

JD2103 (sliding door, fluoro light)

JD2203V (swing door, LED light)

JD2103V (sliding door, LED light)

JD2204 (swing door, fluoro light)

JD2104 (sliding door, fluoro light)

JD2204V (swing door, LED light)

JD2104V (sliding door, LED light)

Dimensions External Internal External Internal External Internal

Height: 725mm* 545mm 725mm* 545mm 725mm* 545mm

Width: 1600mm 1120mm 2210mm 1730mm 2820mm 2340mm

Depth:

680mm**

565mm

680mm**

565mm

680mm**

565mm

Floor area: 1.09m21.50m21.92m2

Internal volume: 390 litres 600 litres 810 litres

Shelves: 2 × adjustable height, white plastic coated wire shelves per door

Construction

Insulation: 42mm polyurethane foam

Doors: 2 3 4

Swing Self-closing, double glazed toughened single Low-E safety glass with aluminium extrusion or solid

swing doors - LH and RH hinged

Sliding Self-closing, double glazed toughened single Low-E safety glass sliding doors with black plastic door

extrusion and anodised aluminium outer frame

Operating conditions

Maximum

operating temp:

40°C (swing doors) or

32°C (sliding doors)

40°C (swing doors) or

32°C (sliding doors)

40°C (swing doors) or

32°C (sliding doors)

Cabinet temp

range:

+1°C to +4°C +1°C to +4°C +1°C to +4°C

Electrical

Current draw: 2.5A (swing door, fluo light)

2.3A (swing door, LED light)

2.5A (sliding door, fluo light)

2.5A (sliding door, LED light)

3.4A (swing door, fluo light)

3.2A (swing door, LED light)

3.4A (sliding door, fluo light)

3.4A (sliding door, LED light)

4.0A (swing door, fluo light)

3.8A (swing door, LED light)

4.0A (sliding door, fluo light)

4.0A (sliding door, LED light)

Internal lighting

Fluorescent: 1 x 21W T5 fluorescent Tube

(Ø16 x 850mm)

1 x 35 Watt T5 fluorescent tube,

(Ø16mm x 1450mm)

2 x 21 Watt T5 fluorescent tubes

(Ø16mm x 850mm)

LED: 1 x 20W T8 Frosted LED Tube

(Ø26 x 900mm, 5500K) -

Switched

1 x 24W T8 Frosted LED Tube

(Ø26 x 1500mm, 5500K) -

Switched

2 x 20W T8 Frosted LED Tubes

(Ø26 x 900mm, 5500K) -

Switched

Refrigeration unit

Description: Electronically controlled, side mounted, integral refrigeration unit

Unit model: UE11AAC-171 UE11AAC-171 UE21AAC-171

Nominal capacity: 581 Watts 581 Watts 737 Watts

Refrigerant: R134a / 425 g R134a / 425 g R134a / 425 g

Electronic

controller:

SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

6Specifications

Service Manual

SKOPE Counterline Series

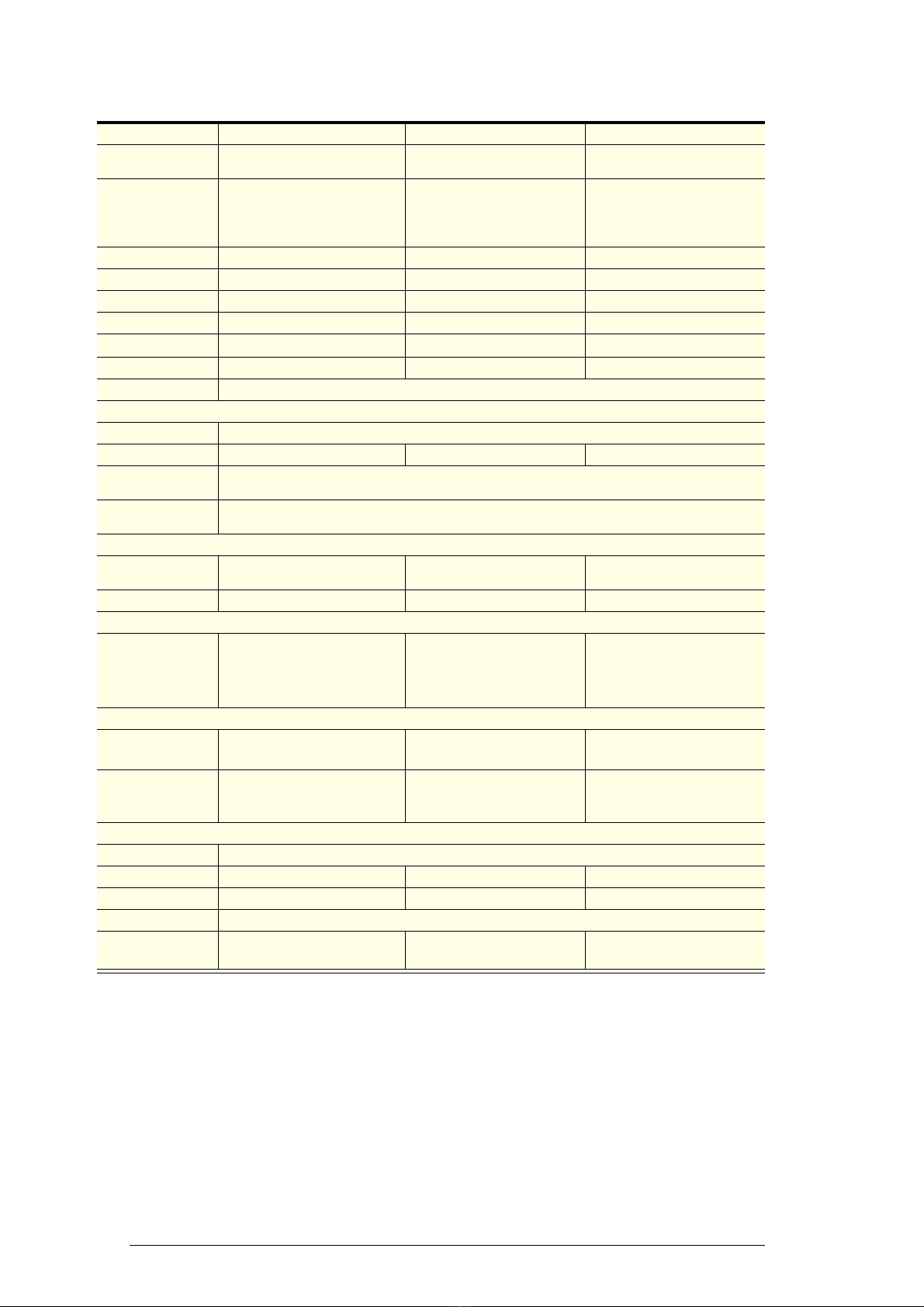

Counterline Remote

* Height excludes castors, legs or optional worktop

** Depth with optional worktop is 700mm

CL400r CL600r CL800r

Description: 2 door remote counterline chiller 3 door remote counterline

chiller

4 door remote counterline

chiller

Type: JD3202 (swing door, fluoro light)

JD3102 (sliding door, fluoro light)

JD3202V (swing door, LED light)

JD3102V (sliding door, LED light)

JD3203 (swing door, fluoro light)

JD3103 (sliding door, fluoro light)

JD3203V (swing door, LED light)

JD3103V (sliding door, LED light)

JD3204 (swing door, fluoro light)

JD3104 (sliding door, fluoro light)

JD3204V (swing door, LED light)

JD3104V (sliding door, LED light)

Dimensions External Internal External Internal External Internal

Height: 725mm* 545mm 725mm* 545mm 725mm* 545mm

Width: 1455mm 1120mm 2065mm 1730mm 2675mm 2340mm

Depth:

680mm**

565mm

680mm**

565mm

680mm**

565mm

Floor area: 0.99m21.40m21.82m2

Internal volume: 390 litres 600 litres 810 litres

Shelves: 2 × adjustable height, white plastic coated wire shelves per door

Construction

Insulation: 42mm polyurethane foam

Doors: 2 3 4

Swing Self-closing, double glazed toughened single Low-E safety glass with aluminium extrusion or solid

swing doors - LH and RH hinged

Sliding Self-closing, double glazed toughened single Low-E safety glass sliding doors with black plastic

door extrusion and anodised aluminium outer frame

Operating conditions

Maximum operating

temp:

32°C 32°C 32°C

Cabinet temp range: +1°C to +4°C +1°C to +4°C +1°C to +4°C

Electrical

Current draw: 0.4A (swing door, fluoro light)

0.3A (swing door, LED light)

0.5A (sliding door, fluoro light)

0.5A (sliding door, LED light)

0.8A (swing door, fluoro light)

0.7A (swing door, LED light)

0.9A (sliding door, fluoro light)

0.9A (sliding door, LED light)

1.1A (swing door, fluoro light)

1.0A (swing door, LED light)

1.3A (sliding door, fluoro light)

1.3A (sliding door, LED light)

Internal lighting

Fluorescent: 1 x 21W T5 Fluorescent Tube

(Ø16 x 850mm)

1 x 35 Watt T5 fluorescent

tube, (Ø16mm x 1450mm)

2 x 21 Watt T5 fluorescent

tubes (Ø16mm x 850mm)

LED: 1 x 20W T8 Frosted LED Tube

(Ø26 x 900mm, 5500K) -

Switched

1 x 24W T8 Frosted LED Tube

(Ø26 x 1500mm, 5500K) -

Switched

2 x 20W T8 Frosted LED Tubes

(Ø26 x 900mm, 5500K) -

Switched

Refrigeration unit

Description: Electronically controlled, side mounted, integral refrigeration unit

Unit model: UE11AAR-171 UE21AAR-171 UE21AAR-171

Nominal capacity: 480 Watts 480 Watts 750 Watts

Refrigerant: Selected at time of order: R134a, R404A, R507, R22

Electronic controller: SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

7

SKOPE Counterline Series

Specifications

Service Manual

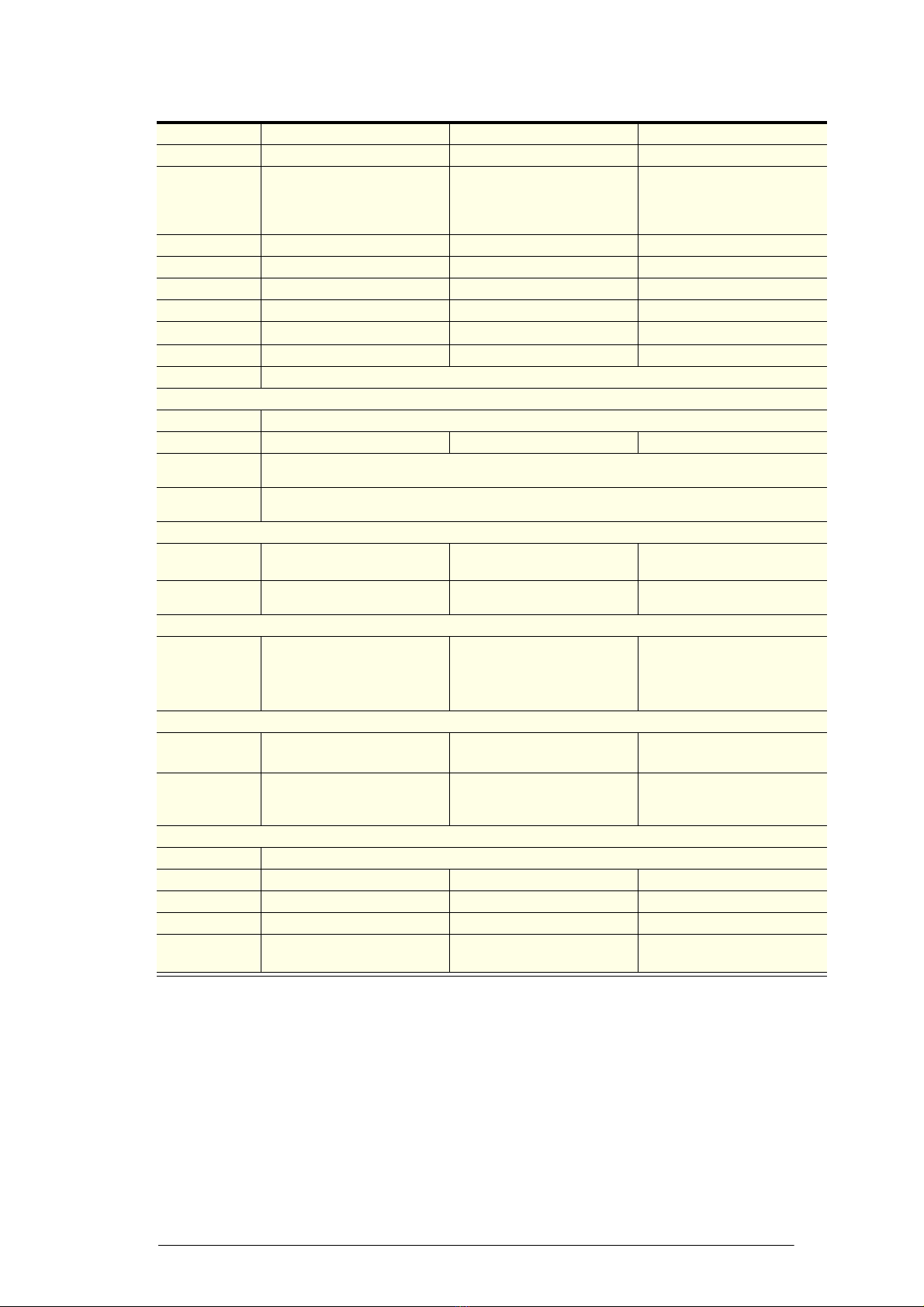

Slimline Integral

* Height excludes castors, legs or optional worktop

** Depth with optional worktop is 700mm

CC300 CC500 CC700

Description: 2 door integral slimline chiller 3 door integral slimline chiller 4 door integral slimline chiller

Type: JS2202 (swing door, fluoro light)

JS2102 (sliding door, fluoro light)

JS2202V (swing door, LED light)

JS2102V (sliding door, LED light)

JS2203 (swing door, fluoro light)

JS2103 (sliding door, fluoro light)

JS2203V (swing door, LED light)

JS2103V (sliding door, LED light)

JS2204 (swing door, fluoro light)

JS2104 (sliding door, fluoro light)

JS2204V (swing door, LED light)

JS2104V (sliding door, LED light)

Dimensions External Internal External Internal External Internal

Height: 725mm* 545mm 725mm* 545mm 725mm* 545mm

Width: 1600mm 1120mm 2210mm 1730mm 2820mm 2340mm

Depth:

600mm**

485mm

600mm**

485mm

600mm**

485mm

Floor area: 0.96m21.33m21.70m2

Internal volume: 335 litres 517 litres 700 litres

Shelves: 2 × adjustable height, white plastic coated wire shelves per door

Construction

Insulation: 50mm polyurethane foam

Doors: 2 3 4

Swing Self-closing, double glazed toughened single Low-E safety glass with aluminium extrusion or solid

swing doors - LH and RH hinged

Sliding Self-closing, double glazed toughened single Low-E safety glass sliding doors with black plastic door

extrusion and anodised aluminium outer frame

Operating conditions

Maximum

operating temp:

40°C (swing doors) or

32°C (sliding doors)

40°C (swing doors) or

32°C (sliding doors)

40°C (swing doors) or

32°C (sliding doors)

Cabinet temp

range:

+1°C to +4°C +1°C to +4°C +1°C to +4°C

Electrical

Current draw: 2.5A (swing door, fluoro light)

2.3A (swing door, LED light)

2.5A (sliding door, fluoro light)

2.5A (sliding door, LED light)

3.4A (swing door, fluoro light)

3.2A (swing door, LED light)

3.4A (sliding door, fluoro light)

3.4A (sliding door, LED light)

4.0A (swing door, fluoro light)

3.8A (swing door, LED light)

4.0A (sliding door, fluoro light)

4.0A (sliding door, LED light)

Internal lighting

Fluorescent: 1 x 21W T5 Fluorescent Tube

(Ø16 x 850mm)

1 x 35 Watt T5 fluorescent tube,

(Ø16mm x 1450mm)

2 x 21 Watt T5 fluorescent tubes

(Ø16mm x 850mm)

LED: 1 x 20W T8 Frosted LED Tube

(Ø26 x 900mm, 5500K) -

Switched

1 x 24W T8 Frosted LED Tube

(Ø26 x 1500mm, 5500K) -

Switched

2 x 20W T8 Frosted LED Tubes

(Ø26 x 900mm, 5500K) -

Switched

Refrigeration unit

Description: Electronically controlled, side mounted, integral refrigeration unit

Unit model: UE11AAC-171 UE11AAC-171 UE21AAC-171

Nominal capacity: 581 Watts 581 Watts 737 Watts

Refrigerant: R134a / 425 g R134a / 425 g R134a / 425 g

Electronic

controller:

SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

8Specifications

Service Manual

SKOPE Counterline Series

Slimline Remote

* Height excludes castors, legs or optional worktop

** Depth with optional worktop is 700mm

CC300r CC500r CC700r

Description: 2 door remote slimline chiller 3 door remote slimline chiller 4 door remote slimline chiller

Type: JS3202 (swing door, fluoro light)

JS3102 (sliding door, fluoro light)

JS3202V (swing door, LED light)

JS3102V (sliding door, LED light)

JS3203 (swing door, fluoro light)

JS3103 (sliding door, fluoro light)

JS3203V (swing door, LED light)

JS3103V (sliding door, LED light)

JS3204 (swing door, fluoro light)

JS3104 (sliding door, fluoro light)

JS3204V (swing door, LED light)

JS3104V (sliding door, LED light)

Dimensions External Internal External Internal External Internal

Height: 725mm* 545mm 725mm* 545mm 725mm* 545mm

Width: 1455mm 1120mm 2065mm 1730mm 2675mm 2340mm

Depth:

600mm**

485mm

600mm**

485mm

600mm**

485mm

Floor area: 0.87m21.23m21.60m2

Internal volume: 335 litres 517 litres 700 litres

Shelves: 2 × adjustable height, white plastic coated wire shelves per door

Construction

Insulation: 50mm polyurethane foam

Doors: 234

Swing Self-closing, double glazed toughened single Low-E safety glass with aluminium extrusion or solid

swing doors - LH and RH hinged

Sliding Self-closing, double glazed toughened single Low-E safety glass sliding doors with black plastic door

extrusion and anodised aluminium outer frame

Operating conditions

Maximum

operating temp:

32°C 32°C 32°C

Cabinet temp

range:

+1°C to +4°C +1°C to +4°C +1°C to +4°C

Electrical

Current draw: 0.4A (swing door, fluoro light)

0.3A (swing door, LED light)

0.5A (sliding door, fluoro light)

0.5A (sliding door, LED light)

0.8A (swing door, fluoro light)

0.7A (swing door, LED light)

0.9A (sliding door, fluoro light)

0.9A (sliding door, LED light)

1.1A (swing door, fluoro light)

1.0A (swing door, LED light)

1.3A (sliding door, fluoro light)

1.3A (sliding door, LED light)

Internal lighting

Fluorescent: 1 x 21W T5 Fluorescent Tube

(Ø16 x 850mm)

1 x 35 Watt T5 fluorescent tube,

(Ø16mm x 1450mm)

2 x 21 Watt T5 fluorescent tubes

(Ø16mm x 850mm)

LED: 1 x 20W T8 Frosted LED Tube

(Ø26 x 900mm, 5500K) -

Switched

1 x 24W T8 Frosted LED Tube

(Ø26 x 1500mm, 5500K) -

Switched

2 x 20W T8 Frosted LED Tubes

(Ø26 x 900mm, 5500K) -

Switched

Refrigeration unit

Description: Electronically controlled, side mounted, integral refrigeration unit

Unit model: UE11AAR-171 UE21AAR-171 UE21AAR-171

Nominal capacity: 400 Watts 540 Watts 660 Watts

Refrigerant: Selected at time of order: R134a, R404A, R507, R22

Electronic

controller:

SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

SKOPE Dixell XR30C or

SKOPE CAREL ir33

9

SKOPE Counterline Series

Specifications

Service Manual

Servicing Tools Tools required for servicing may consist of the following:

Screwdriver with Pozidriv PZ1 and PZ2 bit

Slotted screwdriver

Small slotted screwdriver (for electrical connectors)

10 Electronic Controller

Service Manual

SKOPE Counterline Series

2Electronic Controller

Overview

Introduction The electronic controller controls and displays the cabinet temperature and

signals temperature alarms, recording the minimum and maximum value

reached at the time of the alarm.

The electronic controller is located on the unit cover and is connected to the

refrigeration unit junction box.

Depending on the date of manufacture, the chiller will be fitted with either a

SKOPE customised CAREL ir33 controller or a SKOPE customised Dixell

XR30C controller (see Figures 1 & 2 below). Check the label on top of the

controller to verify the controller type.

Because the controllers are customised and unique to SKOPE, they cannot

be replaced with standard Dixell or CAREL controllers.

Variations Note: All SKOPE chillers previously manufactured with a SKOPE

customised Dixell XR30C controller will now use the SKOPE customised

CAREL ir33 controller. Failed SKOPE customised Dixell XR30C controllers

will be replaced with the SKOPE customised CAREL ir33. Dixell and CAREL

components are not interchangeable, all necessary replacement

components are supplied in a replacement kit when ordered as a spare part

(see page 39).

See “Electronic Controller” on page 51 for more information and

replacement procedures.

While both controllers are similar, there are some visual and functional

differences between the two. This manual covers both controller versions.

Figure 1: SKOPE Dixell

XR30C Customised

Controller

Figure 2: SKOPE CAREL

ir33 Customised

Controller

11

SKOPE Counterline Series

Electronic Controller

Service Manual

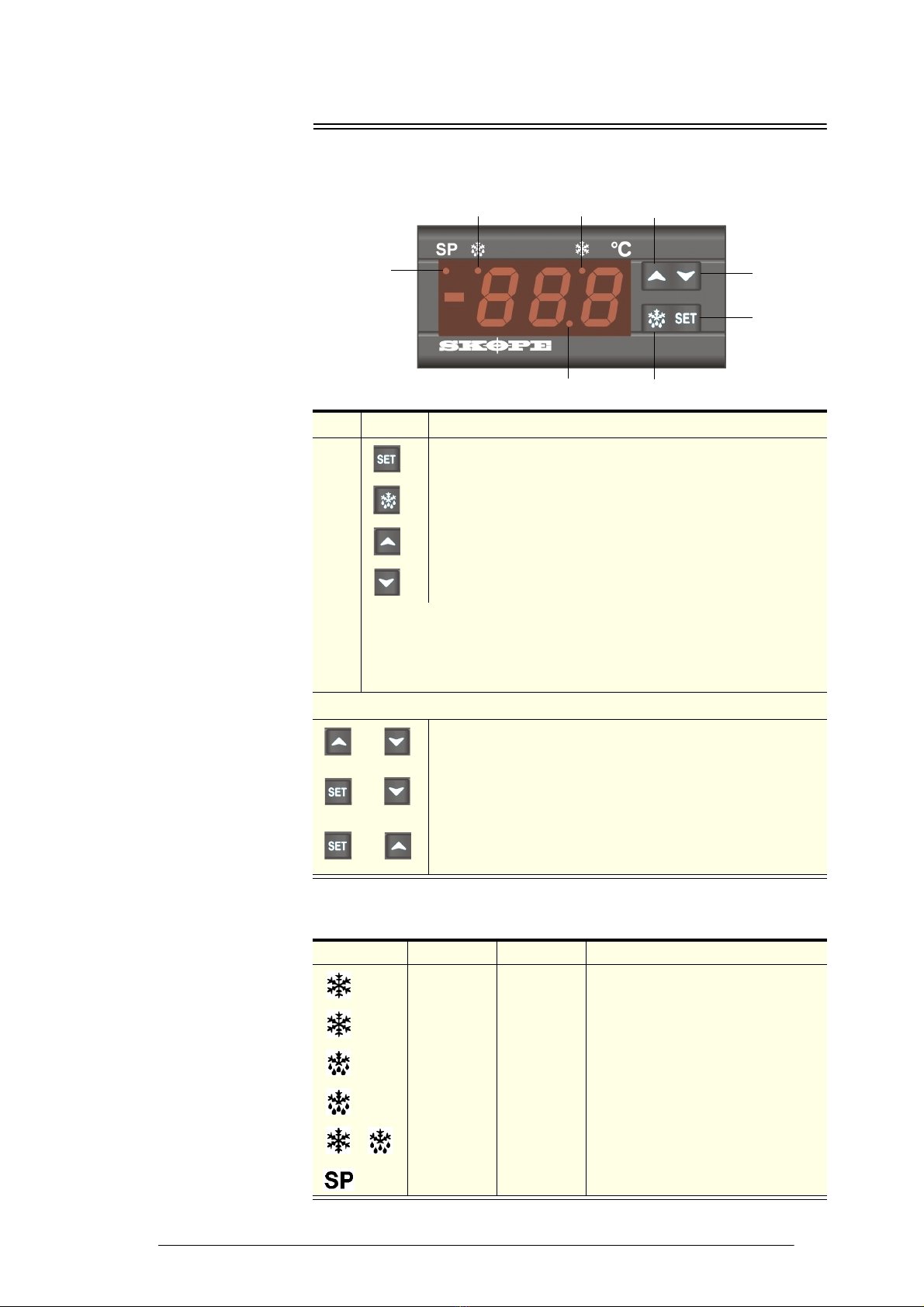

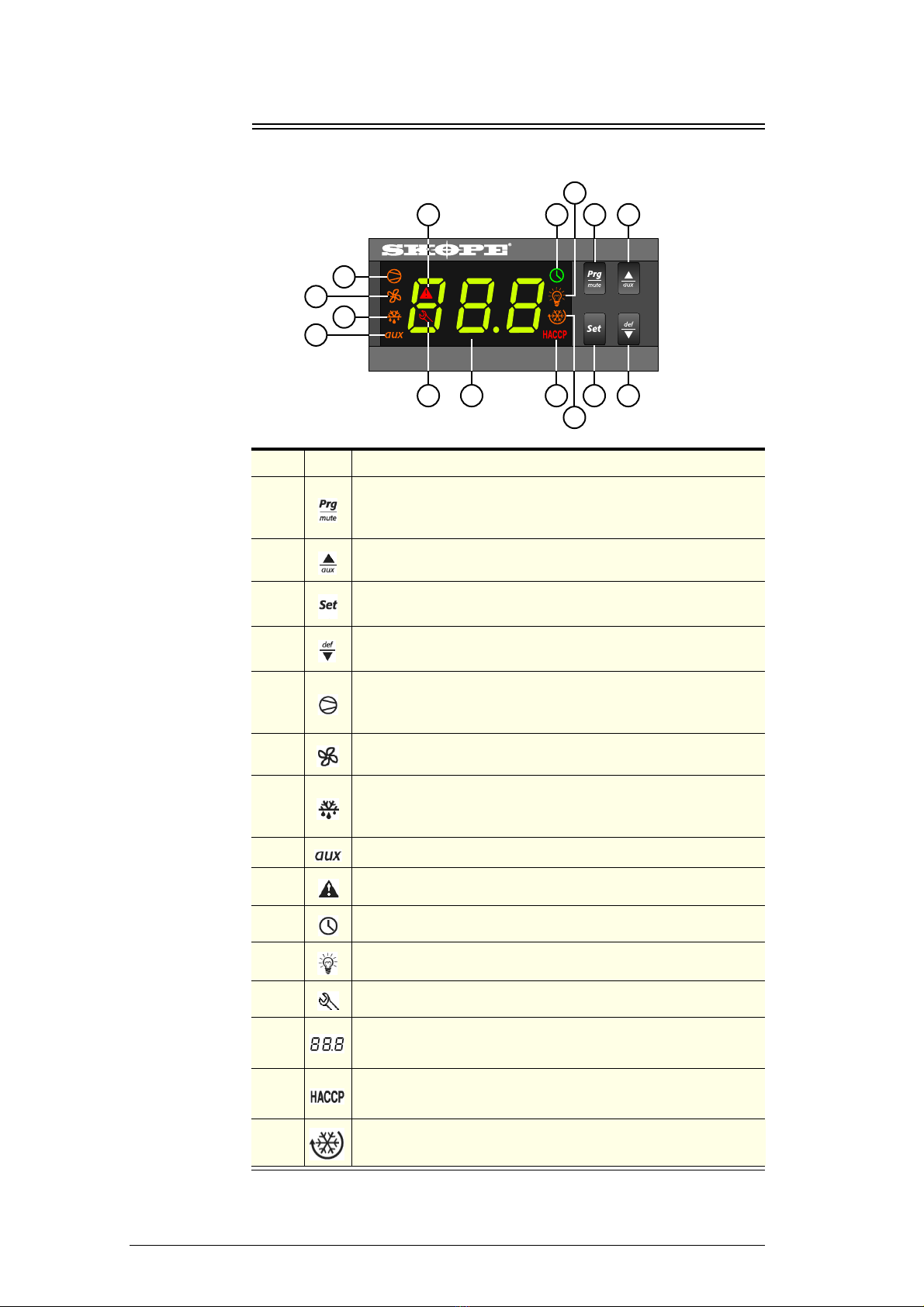

SKOPE Dixell XR30C Controller

Faceplate

Meaning of

LEDs

Each LED function is described in the following table:

Item Key Function

1SET: Press to display target set point. In programming mode it selects a

parameter or confirms an operation

2DEFROST: Press to start a manual defrost

3UP: Press to see the maximum stored temperature. In programming

mode it browses the parameter codes, or increases the displayed value

4DOWN: Press to see the minimum stored temp. In programming mode

it browses the parameter codes, or decreases displayed value

5Compressor ON indicator

6Defrost cycle ON indicator

7Set Point displayed indicator

8Decimal point indicator

Key Combinations

Press both keys simultaneously, to lock and unlock the keypad

Press both keys simultaneously, to enter the programming mode

Press both keys simultaneously, to return to room temperature display

Figure 3: Dixell

XR30C Faceplate

1

3

5

2

4

6

7

8

+

+

+

LED Item Mode Function

Item 5 ON Compressor enabled

Item 5 Flashing Anti-short cycle delay enabled

Item 6 ON Defrost enabled

Item 6 Flashing Drip time in progress

Item 5 & 6 Flashing Programming mode (see page 13)

Item 7 ON The Set Point is displayed

+

12 Electronic Controller

Service Manual

SKOPE Counterline Series

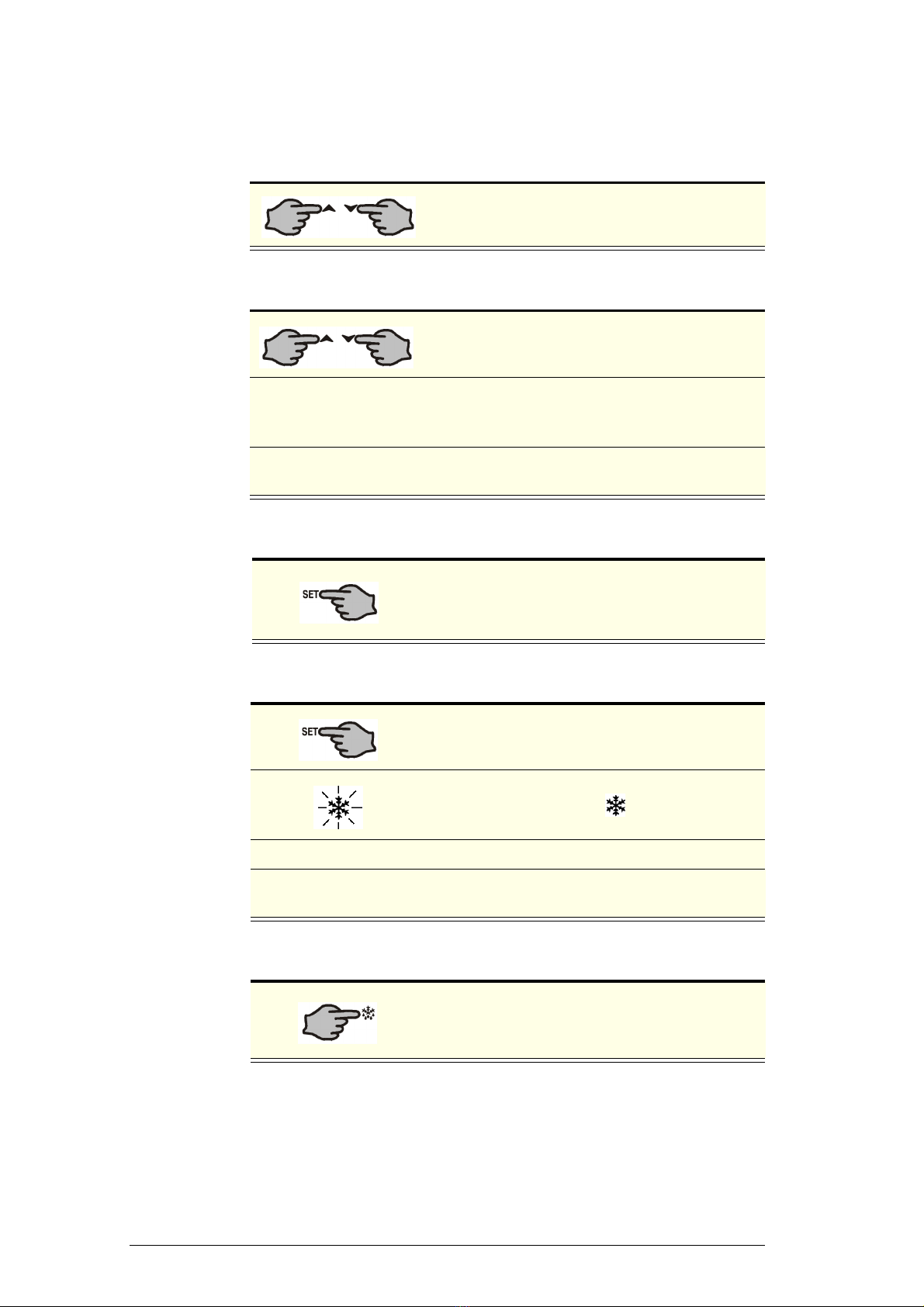

Programming

the Controller

The controller keypad must always be locked to prevent unauthorised

modification.

How to unlock the keypad (to modify parameters)

How to lock the keypad

How to display the Set Point

How to change the Set Point

How to start a manual defrost

1. Press both the UP and DOWN keys until

‘Pon’ is displayed.

1. Press and hold both the UP and DOWN

keys for more than 3 seconds.

2. The ‘PoF’ message will be displayed and the keypad will be locked. At

this point it will be possible only to see the Set Point or maximum or

minimum temperature stored.

3. If a key is pressed for more than 3 seconds, the ‘PoF’ message will be

displayed.

1. Press, and immediately release the SET

key. The display will show the Set Point

value, and the Set Point LED will be

highlighted.

1. Push and hold the SET key for more than

2 seconds.

2. The value of the Set Point will be

displayed, and the LED will start

blinking.

3. To change the Set value, push the UP or DOWN keys.

4. To memorise the new Set Point value, push the SET key again or wait

15 seconds.

1. Push and hold the DEFROST key for

more than 2 seconds.

13

SKOPE Counterline Series

Electronic Controller

Service Manual

How to change a parameter value

Notes:

1. The Set value is stored even when the procedure is exited by waiting for

the time-out to expire.

2. Dependent on customer requirements, the SKOPE electronic controller

has different parameter configurations.

Parameter configuration 160 = Beverage, and 170 = Food.

To establish correct controller parameter configuration, see label on

controller housing.

1. Enter the programming mode by pressing

and holding both the SET and DOWN

keys for 3 sec. ( and start

flashing).

2. Select the required parameter.

3. Press the SET key to display the Set value (now only the LED is

flashing).

4. Press the UP or DOWN keys to change the Set value.

5. Press the SET key to store the new value and move to the following

parameter.

6. To exit: Press both the SET and UP keys, or wait 15 seconds without

pressing any keys.

7. To lock in new parameter value: after one minute operation, disconnect

and reconnect cabinet into the mains power supply.

14 Electronic Controller

Service Manual

SKOPE Counterline Series

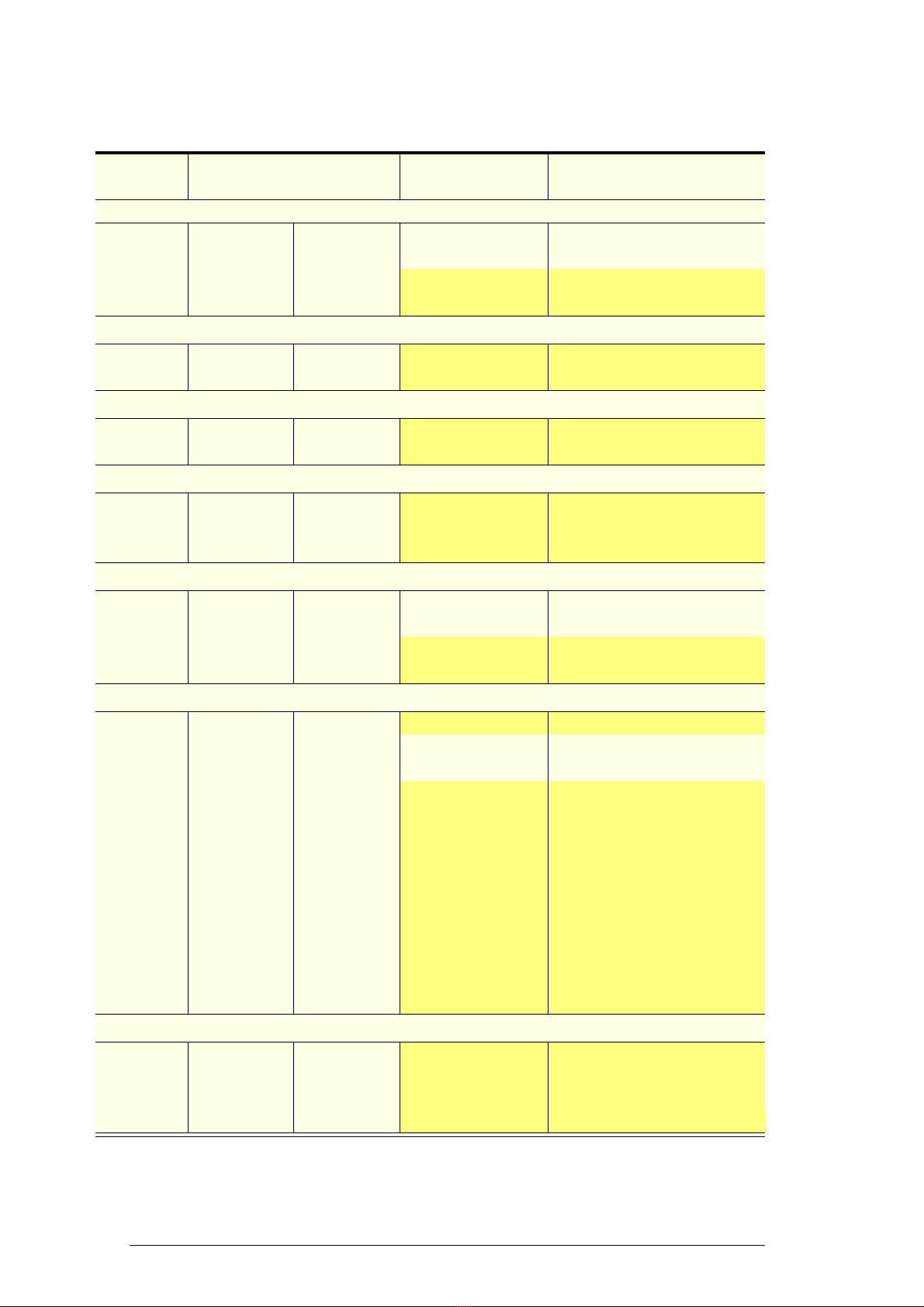

Parameters - Dixell XR30C

Parameters

Display Beverage 160 Food 170 Range Description of Parameter

Set Point Parameters

Set 2 1 LS to US Set Point

Hy 2 2 0.1°C to 25.5°C Differential

LS +1 -1 DO NOT ADJUST

US 15 5

Probe Parameters

Ot -0.7 0DO NOT ADJUST

OE 0 0

Control Parameters

OdS 0 0 DO NOT ADJUST

AC 3 3

Display Parameters

CF °C °C

DO NOT ADJUSTrES dE in

LoD P1 P1

Defrost Parameters

IdF 6 4 1 to 120 hours Interval between defrost cycles

MdF 20 20 0 to 255 minutes Maximum length for defrost

dFd dEF dEF DO NOT ADJUST

dAd 20 20

Alarm Parameters

ALc Ab Ab DO NOT ADJUST

ALU 12 7ALL to 150°C Maximum temperature alarm

ALL -2 -2 -50°C to ALU Minimum temperature alarm

AtH 1 1

DO NOT ADJUST

ALd 240 120

dAO 24 24

tbA n n

PA2 58 58

AU2 65 65

ACH 5 5

dL2 2 2

dA2 0 0

AOP CL CL

Other Parameters

dP1 - -

DO NOT ADJUST

dP2 - -

rEL - -

Ptb - -

15

SKOPE Counterline Series

Electronic Controller

Service Manual

Display Alarms A flashing LED indicates an alarm. The following is a list of the alarm

displays:

Note: Refrigeration system and cabinet lighting shut down with ‘P1’, ‘P2’

and ‘CSd’ alarms.

Alarm Recovery

• Condenser over temperature alarm ‘COH’ recovers when the

condenser is either cleaned or cools down.

• Condenser alarm ‘CSd’ temperature recovers by replugging the cabinet

power supply (or isolation switch). In this case, all the alarms are reset.

Alarm Description

Stage ONE - Maintenance required:

Immediately attend condenser (for auto alarm reset).

Stage TWO - Refrigeration Shut-Down:

Condenser over-temperature has shut-down system and cabinet

lighting. Attend condenser. To reset alarm, cabinet must be

replugged into power supply. For repeat alarms, contact an

authorised service agent.

Faulty Ambient probe (internal cabinet - return air)

Faulty High Temperature probe (condenser)

Internal cabinet - LOW temperature alarm

Internal cabinet - HIGH temperature alarm

16 Electronic Controller

Service Manual

SKOPE Counterline Series

SKOPE CAREL ir33 Controller

Faceplate

Item Icon Function

1

Mute / program: Mutes the audible alarm (buzzer) and

deactivates the alarm relay. To initiate program sets, press for 5

seconds.

2Up: To scroll settings up (in program mode).

3Set point: If pressed for more than 2 seconds displays and / or

enables changing the temperature setpoint.

4Manual defrost / down: Press for more than 5 seconds to initiate

manual defrost. To scroll settings down (in program mode).

5

Compressor: ON when the compressor and condenser fan

starts. Flashes when activation of the compressor is temporarily

delayed.

6Fan: Shows when the fan is operational.

7

Defrost: ON when the defrost is activated. Flashes when the

activation of the defrost is temporarily delayed due to procedures

in progress.

8Aux: n.a.

9Alarm: Flashes in the event of alarms.

10 Clock: n.a.

11 Light: n.a.

12 Service: Flashes in the event of malfunctions.

13 DISPLAY: Shows the cabinet temperature. Flashes when the

door is open.

14 HACCP: n.a.

15 CONTINUOUS CYCLE: On when chiller is running in continuous

run mode.

910

11

12

43

15

14

1312

8

7

6

5

Figure 4: Electronic

controller faceplate

17

SKOPE Counterline Series

Electronic Controller

Service Manual

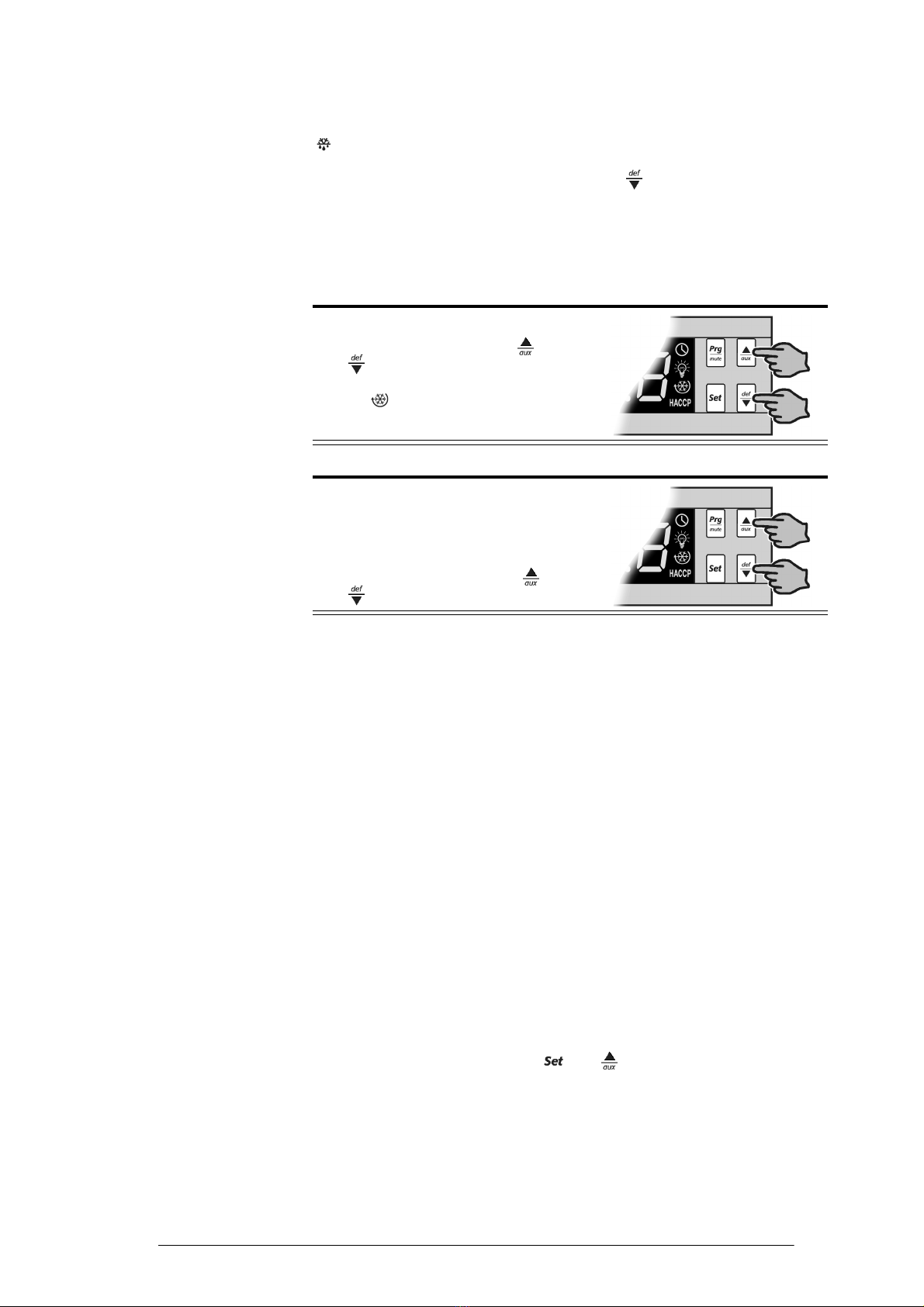

Defrost Cycle To ensure efficient operation, the electronic controller forces a defrost cycle

every six hours. During a defrost cycle, the compressor stops, DEF and the

will display on the electronic controller faceplate. The chiller will resume

normal operation once the defrost cycle has finished. A manual defrost can

also be initiated by pressing and holding the button.

Continuous

Cycle

The continuous cycle can be used to pull down the temperature of product

inside the chiller quickly. During a continuous cool down the compressor

runs continuously for a set time.

To start a continuous cycle

To stop a continuous cycle

Temperature

Probes Three temperature probes feed data to the electronic controller - the control,

condenser and evaporator probes. Refer to page 51 for information on

servicing the probes.

Control Probe

Used to determine cabinet temperature, temperature display and cabinet

temperature alarms. Located in return airflow on bracket in front of

evaporator face.

Condenser Probe

Used to determine refrigeration shutdown due to overheating of condensing

temperature. Located and insulated on outside middle tube of condenser.

Evaporator Probe

Used to determine defrost termination and evaporator fan activation.

Located inside evaporator coil between fins at bottom of coil.

Temperature Probe Reading

The temperature of each of the three temperature probes can be displayed

by pressing and holding both the and keys simultaneously for 5

seconds.

1. While the chiller is switched on and

running, press and hold the and

buttons for five seconds.

The symbol will display during a

continuous cycle.

1. The electronic controller will

automatically stop the continuous cycle

after a period of time.

The continuous cycle can be stopped

by pressing and holding the and

buttons for five seconds.

18 Electronic Controller

Service Manual

SKOPE Counterline Series

To display the temperature probe readings

Temperature probe readings

1. Press and hold both

the and keys simultaneously

for 5 seconds.

2. Press and hold the key to scroll the

probes (see table below). The key

is not active for this function. This

function will time out after 60 seconds

(cannot be turned off prior to 60

seconds elapsed time).

Display Description

P_1 Control probe temperature

P_2 Evaporator probe temperature

P_3 Condenser probe temperature

P_4 Unused

P_5 Unused

19

SKOPE Counterline Series

Electronic Controller

Service Manual

Alarms

The following table explains messages that the electronic controller displays and related alarms.

Alarms signal unexpected operational changes in the chiller and stop when action is taken to

resolve the problem.

Controller alarms

Code Display

Icon

Alarm

Description

Action

Flashing

Product HIGH

temperature alarm

1. Check the cabinet product loading to ensure ventilation slots are not

blocked and that product does not overhang the shelves.

2. Ensure the cabinet is installed with good refrigeration unit ventilation.

3. Check and clean the condenser coil.

4. Unplug cabinet from the power supply for 1 minute, then reconnect to

power supply.

The alarm will automatically reset once the product has returned to

temperature specification.

Flashing

Product LOW

temperature alarm

Refrigeration

system high

temperature

pre-warning (auto

reset)

1. Clean the condenser coil (see page 54).

2. Check refrigeration ventilation. Ensure clear airpath in front of the

cabinet.

3. Ensure the cabinet is installed in a suitable environment.

4. To reset the ‘CHt’ alarm - unplug the cabinet from the power supply for

1 minute, then reconnect to power supply.

If alarm persists:

5. Check that the doors are closing and sealing properly.

6. Check that parameters are set correctly.

7. Check that controller is reading correct condenser temperature.

8. Check that condenser fan and compressor are running correctly.

9. Investigate refrigeration system fault.

Refrigeration

system and cabinet

high temperature

shutdown (manual

reset)

Flashing

Control probe fault 1. Unplug cabinet from the power supply for 1 minute to reset alarm,

then reconnect to power supply.

If alarm persists, work through the following steps until the fault is

resolved:

2. Check probe connection and wiring. If necessary replace probe or

controller.

3. Check probe resistance. If necessary replace probe.

4. Replace controller.

Flashing

Evaporator probe

fault

Flashing

Condenser probe

fault

None Defrost over-time

limit

1. Unplug cabinet from the power supply for 1 minute to reset alarm,

then reconnect to power supply.

2. Check that controller is reading correct evaporator temperature.

3. Check that parameters are set correctly.

4. Check that evaporator fan is operating correctly.

5. If alarm persists, check the product temperature. If too cool, consider

raising setpoint and extending defrost time.

Flashing

Real-time clock

fault

1. Unplug cabinet from the power supply for 1 minute to reset alarm,

then reconnect to power supply.

2. If alarm persists, replace controller.

Flashing

Controller E prom

error

Flashing

Controller E prom

error

None Start defrost

request

None

None End defrost

request

20 Electronic Controller

Service Manual

SKOPE Counterline Series

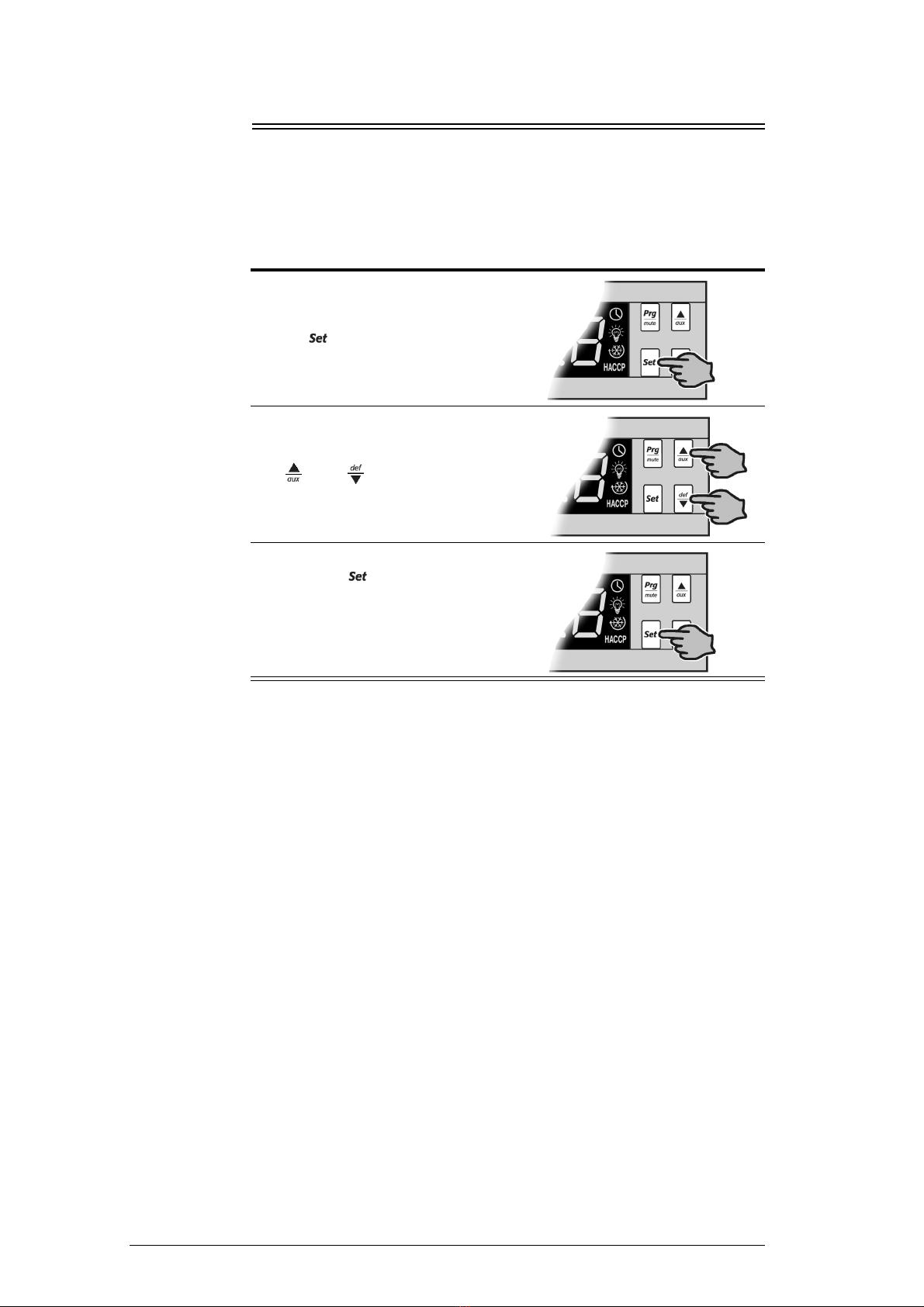

Programming

Set-Point The chiller is manufactured with a pre-set control temperature set-point of

+1.0°C. If this set-point does not match your required storage temperature

it is recommended that you change the set-point accordingly. The set-point

can be adjusted between a temperature range of 0°C and +3.5°C.

To view and adjust the temperature set-point

1. To view the set-point: press and hold

the key for 2 seconds, until the

set-point value flashes.

2. To adjust the set-point: press either the

and keys to display the

required set-point value.

3. Press the key again to memorise

the new set-point value. If this is not

done within 60 seconds, changes will

be lost and you will need to repeat the

above procedure.

This manual suits for next models

36

Table of contents