SKV-tec GmbH Operating Instructions

2.1 Intended use

•All provisions of this manual, including all safety

instructions have to be observed

•Inspection and maintenance intervals have to be

complied with

•he unit have to be operated exclusively for the

delivery of approved media. It is used for

compressing, conveying and suction of following

approved media:

◦dry air/gases, which are neither explosive,

inflammable, aggressive or toxic

◦Air or air-steam mixtures containing no solids. If

there are small amounts of fine dust a

corresponding filter has to be provided.

he rolling bearings used are sealed on both sides

only with shields. herefore they have to be changed

regularly as instructed in Chapter 7.3!

◦For media with a density greater than air (higher

thermal and mechanical loading on the machine)

the responsible representation of the SKV-

tec GmbH has to be contacted!

•he unit is for continuous operation. For this

purpose, it has to be ensured that waste heat can be

delivered freely to the environment and that a certain

minimum gas flow rate is guaranteed. Furthermore,

frequent switching operations cause an increase of

the temperature of the winding. In case of more

than 5 start-ups of the side channel blower in an

hour (when spread across the hour, even less

when the switching operations happen in a short

time), the responsible representation of the SKV-

tec GmbH has to be consulted!

•he following scenarios have to be avoided:

◦Overheating: he unit must not be operated

above the maximum permissible differential

pressure (see nameplate)! If this danger exists,

a vacuum or pressure relief valve has to be

provided.

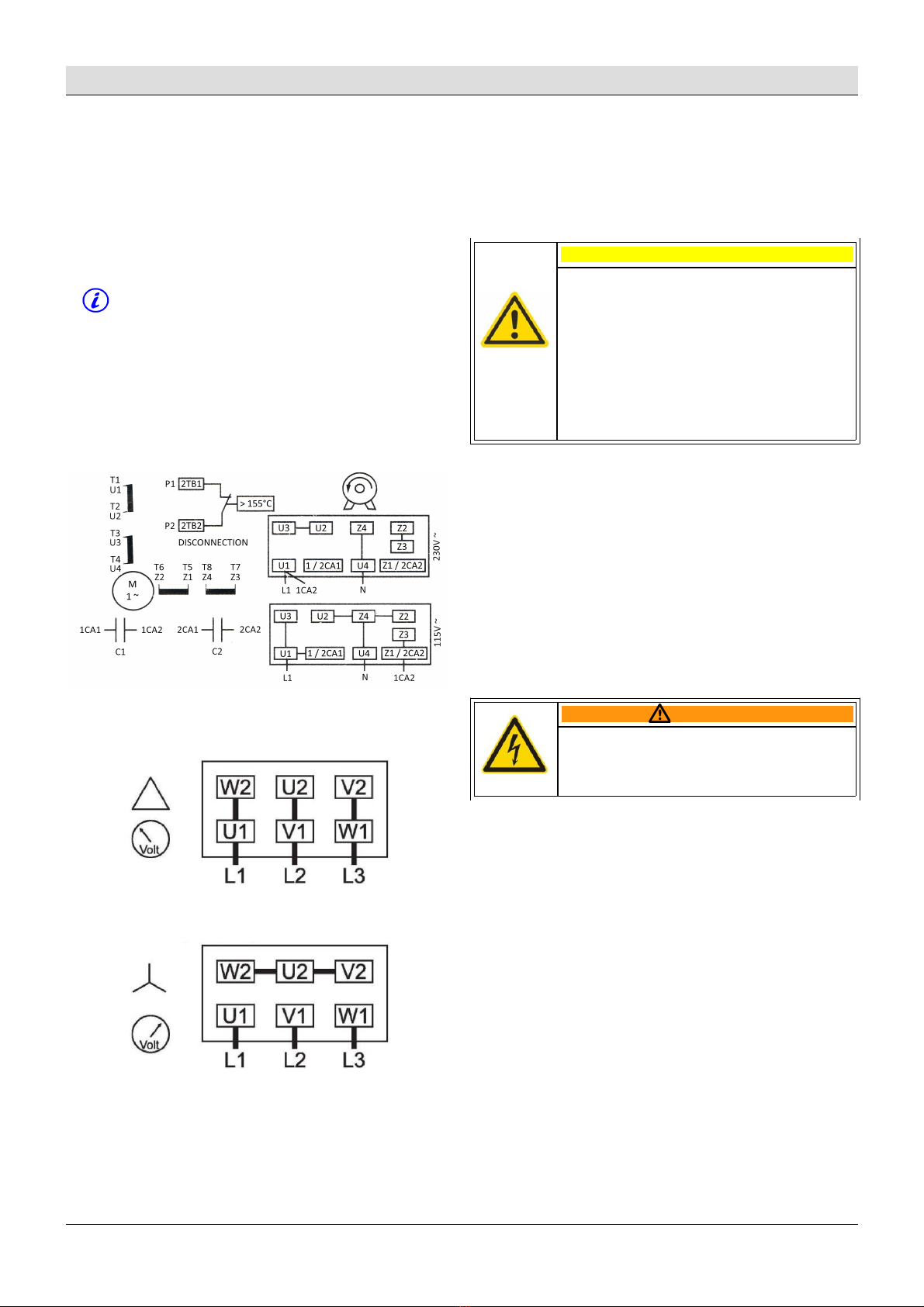

◦Motor damage:

he following parameters have to be observed:

the switching frequency of the unit, permissible

fluid and ambient temperatures

(nominal values: Fluid temperature = 15°C,

ambient temperature = 25°C)

he motor protection switch has to be set at the

nominal current as given on the nameplate.

By not respecting the permissible operating

temperatures, the temperature limit of the lubricating

grease of the rolling bearings may be exceeded.

•he unit is intended exclusively for professional use

•he handling of the unit is only permitted by qualified

personnel

Prior to handling of the side channel blower the

responsible staff for operation and servicing have to

completely read and understand the operating

instructions.

If in doubt, please contact the responsible representation

of the SKV-tec GmbH!

2.2 Potential misuse

•he operating limits of the unit concerning pressure,

temperature of the medium, density, viscosity and

velocity have to be observed and complied with

•he permissible density of the conveying medium

has to be respected, otherwise the unit will be

overloaded.

he power consumption of the motor increases with

the density of the conveying medium.

•Avoid sudden changes in the pressure of the

transported gas

•Sudden changes in the temperature of the

transported gas have also to be avoided

•Unauthorized opening of the unit will void any claims

for defects

•If the unit is not approved for the requested use,

operation is prohibited in the following scenarios

◦Operation in rooms where explosive gases may

be present

◦Extracting, delivering or compressing of

explosive, inflammable, aggressive or toxic

media

2.3 General safety instructions

he unit is designed and manufactured according to the state-

of-the-art of technology and the generally acknowledged rules

of safety. Nevertheless through exposure to the unit, danger to

the well-being or even the life of the user or third parties as

well as damage to the unit may occur.

herefore, the following guidelines have to be observed:

•he unit may only be operated in a technically

flawless condition and in compliance with the

regulations, safety precautions and warnings

included in this manual.

•Ensure that this manual and related documents are

complete and readable. In addition, make sure that

the staff has access to these documents at any time.

•Refrain from any operating mode which brings the

staff or third parties at risk

•In case of error which impacts on safety, immediately

shut down the unit and consult the person

responsible for fault diagnosis.

07/2018 SKV-Nx/-Hx-Series 5/30