CONTENTS

1. SAFETY ………………………………………………..............................................………….… 1

2. COMPONENT IDENTIFICATION …………………………………………………….…………… 3

3. CONTROL SYSTEM …………………………………………………………………...…………… 4

4. PRE-OPERATION INSPECTION ……………………………………………….………………… 5

5. OPERATION ………………………………………………………………………………………… 7

6. STARTING THE ENGINE ………………………………………………………………………..… 9

7. STOPPING THE ENGINE ………………………………………………………………………… 11

8. MAINTENANCE …………………………………………………………………………………… 11

9. STORAGE ………………………………………………………………...……………………… 14

10. TROUBLESHOOTING ……………………………………………………………...…………… 15

11. ELECTRIC DIAGRAM ……………………………………......…………………………….…… 18

12. SPECIFICATION ……………………………………………………………………….…………19

SAFETY

Our company's water pump is designed to give safe and reliable service if operated according

to instructions. Read and understand the Owner’s Manual before operating the water pump.

Failure to do so could result in personal injury or equipment damage.

Safety Messages

Your safety and the safety of others are very important. We have provided important safety

messages in this manual and on water pump and engine.

Please read these messages carefully.

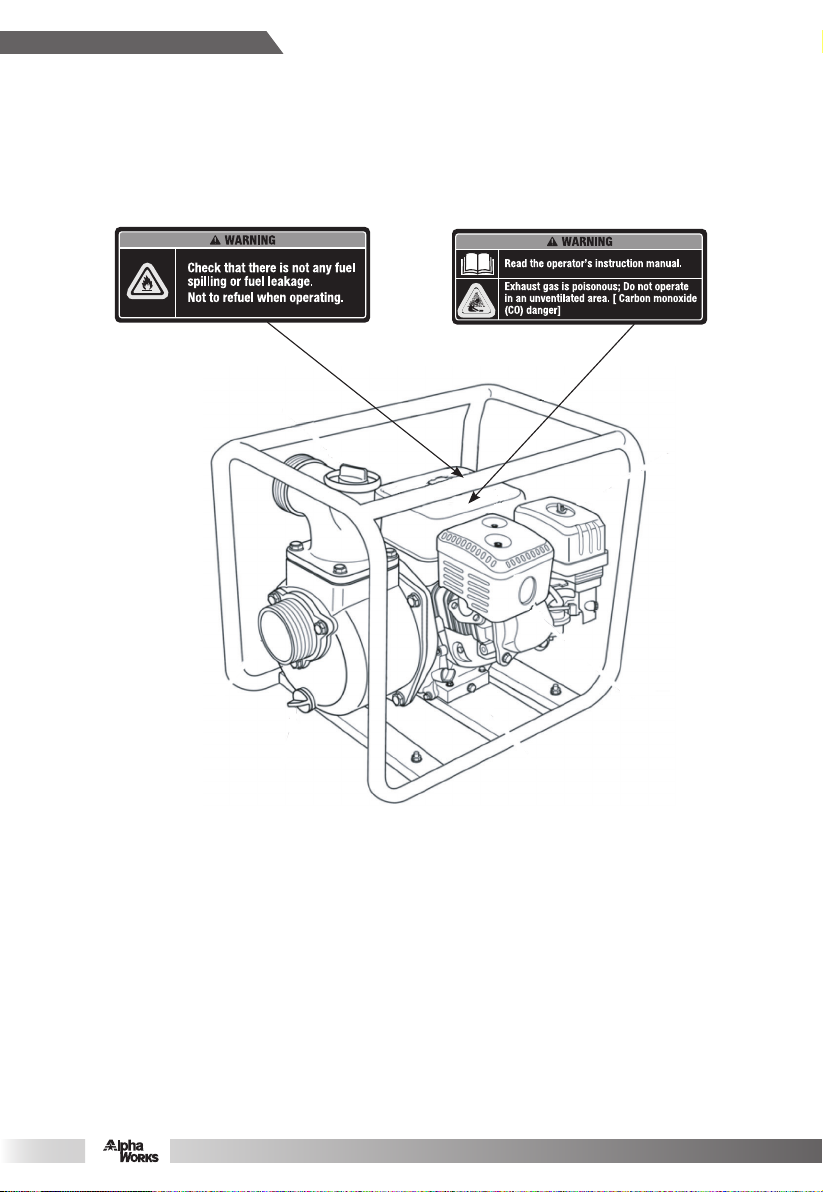

Safety label - on the water pump and engine.

A safety message - alerts you to potential hazards that could hurt you or others. Each safety

message is preceded by a safety alert symbol and one of three words: WARNING, CAUTION,

or NOTICE. These mean:

You CAN be KILLED or SERIOUSLY HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow instructions.

NOTICE: Your water pump or other property could be damaged if you don’t follow instructions.

Safety Instruction

1. Clean water pump and high pressure pump are only designed for pumping clean water.

2. To prevent fire hazards and to provide adequate ventilation, keep the pump at least 1 meter

away from each of the building walls and other equipment during operation. Do not place

flammable objects close to the pump and do not fill the fuel tank with gasoline before long

distance transportation.

3. The muffler becomes very hot during operation and remains hot for a while after stopping the

engine. Be careful not to touch the muffler while it is hot. Let the engine cool before storing

the water pump indoors.

4. Gasoline is highly flammable and explosive. Don’t smoke in the refueling and fuel storage

area.

5. Place the pump on a firm, level surface. If the pump is tilted or overturned, fuel spillage may

result.

6. Refuel in a well-ventilated area with the engine stopped, and in places for refueling or storing

gasoline. If spilling occurs, immediately clean it.

7. After refueling, cover the fuel tank well and screw it down.

8. Exhaust contains poisonous carbon monoxide gas that can build up to dangerous levels in

closed areas. Breathing carbon monoxide can cause unconsciousness or death.

1