Skyware Global 180 User manual

Assembly Instructions

Type 180 Antenna System

1.8 Meter Reflector with Az/El Cap Mount

8000352-03

Skyware Global

1315 Industrial Park Drive

Smithfield, NC 27577

Telephone: +1-919-934-9711

Internet: www.skywareglobal.com

Printed in U.S.A.

05/13 8000352-03 Rev D EC-01728

1

Skyware Global CORPORATION

VERY SMALL APERTURE TERMINAL (VSAT) PRODUCTS

TWELVE (12) MONTH LIMITED WARRANTY

Seller warrants that all Skyware Global manufactured VSAT products are transferred rightfully and with good title; that they are free from

any lawful security interest or other lien or encumbrance unknown to Buyer. Seller also warrants that for a period of twelve (12) months

from the date of shipment from Seller’s factory, all its VSAT products shall be free from defects in material and workmanship which arise

under proper and normal use and service. Buyer’s exclusive remedy hereunder is limited to Seller’s correction (either at its plant or at

such other place as may be agreed upon between Seller and Buyer) of any such defects by repair or replacement at no cost to Buyer,

except for the costs of any transportation in connection with the return of the defective VSAT products to be replaced or repaired, and

the costs to remove and/or reinstall the products, which shall be borne by Buyer. The limited warranty period shall not be extended

beyond its original term with respect to any part or parts repaired or replaced by seller hereunder.

This warranty shall not apply to VSAT products which (i) have been repaired or altered in any way so as to affect stability or

durability, (ii) have been subject to misuse, negligence or accident, (iii) have been damaged by severe weather conditions such as

excessive wind, ice, storms, lightning, or other natural occurrences beyond Seller’s control; (iv) have presented damages, defects or

nonconformances caused by improper shipping, handling or storage, and (v) have not been installed, operated or maintained in

accordance with Seller’s instructions.

Buyer shall present any claims along with the defective VSAT product(s) to Seller immediately upon failure Non-compliance with any

part of this warranty procedure may invalidate this warranty in whole or in part.

SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, OTHER THAN AS SPECIFICALLY STATED ABOVE. EXPRESSLY EXCLUDED

ARE ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING SHALL

CONSTITUTE ALL OF SELLER’S LIABILITY (EXCEPT AS TO PATENT INFRINGEMENT) WITH RESPECT TO THE VSAT PRODUCTS. IN

NO EVENT SHALL SELLER BE LIABLE FOR ANY LOSS OF PROFITS OR REVENUE, LOSS OF USE, INTERRUPTION OF BUSINESS, OR

INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND AS A RESULT OF THE USE OF THE

PRODUCTS MANUFACTURED BY SELLER, WHETHER USED IN ACCORDANCE WITH THE INSTRUCTIONS OR NOT. UNDER

NO CIRCUMSTANCES SHALL SELLER’S LIABILITY TO BUYER EXCEED THE ACTUAL SALES PRICE OF THE VSAT PRODUCTS

HEREUNDER.

In some jurisdictions, Buyer may have other rights under certain statutes that may imply non-excludable warranties. No representative is

authorized to assume for Seller any other liability in connection with the VSAT products.

DATE DESCRIPTION REVISION

11/08 5079577 Rev A

03/10 725 Rev B

04/10 753 Rev C

05/13 EC-01728 Rev D

MANUAL REVISION HISTORY

WARRANTY

DO NOT DISCARD CONTENTS

The product in this packaging was placed in the market after August 13, 2005. Its components must not be discarded with

normal municipal or household waste.

Contact your local waste disposal agency for recovery, recycling, or disposal instructions.

INTRODUCTIONINTRODUCTION

INTRODUCTION

BOLT TORQUE

Exceptions To The Chart Above:

M12 x 100 Round Head Square Neck Bolt (20 ft-lb) (Securing Antenna to AZ/EL Cap)

M6 x 20 Hex Head Bolt (4 ft-lb) (Securing Clamp to Junction Block)

M6 x 30 Hex Head Bolt (4 ft-lb) (Securing Side Feed Legs to Junction Block and Antenna)

DIN Class 5.6

M6 M8 M12 M16 M20 M22

5 N-m 15 N-m 51 N-m 125 N-m 168 N-m 230 N-m

4 ft-lb 11 ft-lb 32 ft-lb 38 ft-lb 92 ft-lb 124 ft-lb

DIN Class 8.8

M8 M12 M16

24 N-m 90 N-m 203 N-m

18 ft-lb 66 ft-lb 150 ft-lb

HARDWARE SORTER

ITEM 2

M12 x 100 mm

Round Head

Square Neck Bolt

ITEM 17

M12 x 25 mm

Round Head

Square Neck Bolt

ITEM 38

M6 x 20 mm

Round Head

Square Neck Screw

ITEM 26

M6 x 20 mm

Hex Head

Cap Screw

ITEM 31

M6 x 30 mm

Hex Head

Cap Screw

Note: Hardware illustrations are actual size.

Place hardware on top of illustration to identify.

Shipping cartons should be unpacked and contents checked for damaged or missing parts. Should there be any parts

that are damaged or missing, contact Skyware Global at the location on the front of this manual.

UNPACKING AND INSPECTION

This manual covers the assembly and installation of the Skyware Global 1.8 m SMC offset antenna system. Read this

manual thoroughly before beginning assembly. For best results in the assembly process, perform each step in the same

sequence as listed in this manual.

2

3

SITE SELECTION

The main objective of conducting a site survey, utilizing a compass and clinometer, is to choose a mounting location on the

roof or ground that will give you the greatest amount of swing for azimuth and elevation for present as well as future use.

A pre-installation site survey is strongly recommended because it can alert you to any “look angle”, soil, or other problems.

The first and most important consideration when choosing a prospective antenna site is whether or not the area can provide

an acceptable “look angle” at the satellite. A site with a clear, unobstructed view facing south, southeast or southwest is

required. Your antenna site must be selected in advance so that you will be able to receive the strongest signal available.

Also consider obstructions that may occur in the future such as the growth of trees. It is important to conduct an on-site sur-

vey with a portable antenna or with a compass and clinometer to avoid interference, obstructions, etc.

When selecting “look angle”, be sure to observe and take readings approximately 10° to the left and right, above and

below your selected “look angle”. Before digging is done, information regarding the possibility of underground telephone

lines, power lines, storm drains, etc., in the excavation area should be obtained from the appropriate agency.

Because soils vary widely in composition and load capacity, consult a local professional engineer to determine the appro-

priate foundation design and installation procedure. A suggested foundation design with conditions noted is included in this

manual for reference purposes only (see page 4). To assist in the foundation design, refer to Antenna Wind loads in Appen-

dix A on page 14.

Before Roof Mount installation, it must be determined that the roof used for mounting the antenna is structurally sound. If

in doubt, have it checked by an architect or structural engineer. It is the customer’s responsibility that proper construction

techniques and applicable codes are adhered to. As with any other type of construction, a local building permit may be

required before installing an antenna. It is the property owner’s responsibility to obtain any and all permits.

INTRODUCTION

Recommendations for Site Selection, Assembly Tools Required for assembly, a Pre-installation Checklist and a hardware

sorter have been included in this section to help you prepare for installing the 1.8m Offset Antenna System.

Read this section to insure optimum antenna performance and to make the assembly and installation process as efficient as

possible by having the tools and materials at hand.

ASSEMBLY TOOLS AND PRE-INSTALLATION CHECKLIST

PRE-INSTALLATION CHECKLIST

All Installations:

o Grounding Rod Clamp and Grounding Block: As required by the National Electric Code or local electric code.

o Ground Wire: #10 solid copper or as required by the National Electric Code or local electric code. (Length

required)

o Coaxial Cable: (Size and length required)

Ground Pole Installations:

o Concrete: (See Ground Pole Section for quantity.)

o #3 Rebar: (See Ground Pole Section for quantity.) Deformed steel per ASTM A615, Grade 40 or 60.

REQUIRED ASSEMBLY TOOLS

1 - Compass 1 - Torque Wrench 1- 0 mm Nut Driver

1 - Precision Clinometer 1 - Ratchet Wrench (13 mm or 1/2” Drive) 1- 0 mm Box/Open End Wrench

1 - 228 mm or 9” Magnetic Level 1 - 19 mm or 3/4” Socket (1/2” Drive)

1 - Phillips Screwdriver 1 - 19 mm or 3/4” Deep Socket (1/2” Drive)

(For bottom two Round Head Square Neck

Bolts securing Antenna to AZ/EL Cap)

4

POLE SPECIFICATIONS

Ground Pole - 4.50 O.D. SCH 40 (4.026 I.D.) Steel - (Metric = 114.3 O.D. x 102.3 I.D. mm)

NOTE:

1. Poles are not supplied (purchased locally to ASTM A501) and must be field drilled 5/8” Dia (15.9mm) for M10 #3 rebar, drilled

.218 (5.55mm) for 1/4 - 20 self tapping grounding screw and galvanized or painted for protection.

2. Pole and foundation design based on the following criteria:

a. Uniform building code Exposure C and 1.5 stability factory.

b. Vertical soil pressure of 2000 pounds per square foot. (9765 Kilograms/meter square).

c. Lateral soil pressure of 300 pounds per square foot. (145 Kilograms/meter square).

d. Concrete compressive strength of 2500 pounds per square inch (176 Kg/Cm2) in 28 days.

CAUTION: The foundation design shown does not represent an appropriate design for any specific locality, since soil conditions vary and

may not meet design criteria given in Note 2. You should consult a local professional engineer to determine you soil conditions and

Appropriate foundation.

GROUND POLE INSTALLATION

114 mm

(4.5 in O.D.)

L

#3 rebar x 10 in

(9.5 rebar x 254 mm)

Insert through hole in

tube and center.

#3 Rebar

C

Minimum

Diameter

25 mm

to 51 mm

(1” to 2”) slope

for water run-off

Grade

Below

Frost Line

25 mm to 51 mm (1” to 2”)

slope for water run-off

Grade

114 mm

(4.5 in O.D.)

C

Minimum

Diameter Below

Frost Line

Approx.

51 mm

(2 in)

1676 mm

(66 in) (See Note)

#3 rebar x .46 m (18”)

(9.5 rebar x 457 mm)

Insert through

hole in tube and center.

#3 Rebar

(6)#3 rebar x .6 m (24 in)

(9.5 x 610 mm)

at 60˚ apart (See note)

51 mm

(2 in)

Bubble

Level

Ground Pole Must Be

Vertical in All Directions

at Top

NOTE:

127 cm (50”) may

be increased to frost

line. Concrete and

length of rebar will

increase

accordingly.

Bottom View

Pier Foundations Deep Frost Line Foundations

Reflector Size: 1.8 m

Concrete Dimension

L A B C E

2438 mm 1270 mm 1359 mm 914 mm 424 mm

(96 in) (50 in) (53 in) (36 in) 16.7 in

Concrete Volume: .84 m3 (1.1 yd3)

*NOTE: Clearance increases at elevations greater than 23˚

A

B

*E (See Note)

Fill Completely

with Concrete

Reflector Size: 1.8 m

Concrete Dimension

L A D C

2438 mm 1359 mm 1092 mm 737 mm

(96 in) (53 in) (43 in) (29 in)

Concrete Volume: .72 m3 (.94 yd3)

*NOTE: 1676 mm (66 in) may be increased, concrete

and length of rebar will increase accordingly.

L

A

D

Fill Completely

with Concrete

Soil conditions vary and you should consult with a local professional engineer for modifications, if any, to suit local soil

conditions and code requirements.

Designs based on allowable vertical soil bearing pressure of 2000 psf and 125 mph wind velocity. Minimum compressive

Strength of concrete shall be 2500 psi at 28 days.

DESIGNS SHOWN BELOW DO NOT REPRESENT AN APPROPRIATE FOUNDATION FOR ANY

SPECIFIC LOCALITY OR ANTENNA INSTALLATION. THEY ARE PROVIDED FOR

REFERENCE PURPOSES ONLY.

5

ASSEMBLY AND INSTALLATION

NOTE: 10mm tools fit M6 hardware. Recommendations for Site Selection, Assembly Tools Required for Assembly,

a Pre-Installation Checklist and a Hardware Sorter are provided in this manual for your convenience.

The AZ/EL cap can be installed on a ground pole or roof mount support. Mount should be assembled and in place, or

ground pole set, before installing the AZ/EL cap.

NOTE: For ground pole installations, allow concrete to cure before proceeding with installation.

FIGURE 1.0 FIGURE 1.1

M12 LOCK WASHER

4 PLACES M12

HEX NUT

4 PLACES

TOP/BOTTOM

ANGLE

2 PLACES

RD HD

SQ NK

BOLT

M12 x 25mm

4 PLACES

AZ/EL

Cap

ELEVATION

ADJUSTMENT

BOLT

AZIMUTH

LOCKING

BOLTS

AZIMUTH

FINE TUNING

ADJUSTMENT

BOLT

6

3

2

17

7A

6

2

3

1

2

3

ASSEMBLY AND INSTALLATION

AZ/EL FRAME ASSEMBLY (FIGURE 1.0)

Assemble top/bottom angles (6), to housing frame (7A)

with M12 x 25mm round head square neck bolts (17),

lock washers (2), and hex nut (3), as shown in Figure 1.0.

M12 hex nuts (3), must be finger tight.

INSTALLING AZ/EL CAP ON GROUND POLE

Back out (do not remove) the four azimuth locking bolts

from AZ/EL cap. Install cap onto top of ground pole or

base tube. To hold the AZ/EL cap in place while installing

antenna, temporarily tighten one of the azimuth locking

bolts.

INSTALLING ANTENNA TO AZ/EL CAP

Insert M12 x 100mm round head bolts (1) into antenna

mounting holes, as shown in Figure 1.1. Lift antenna and

align mounting bolts with holes in AZ/EL cap. Secure with

M12 lock washers (2) and hex nuts (3). Torque to 20 ft-lbs

(27 N-m).

IMPORTANT: For correct orientation of antenna, the

“UP” arrow must be as shown in Figure 1.1 and

Figure 1.2.

After M12 x 100mm antenna bolts are torqued, then

torque top/bottom angle bolts (17) and hex nuts (3) to 38

ft-lbs (51 N-m).

5

NOTE: 10mm tools fit M6 hardware. Recommendations for Site Selection, Assembly Tools Required for Assembly, a

Pre-Installation Checklist and a Hardware Sorter are provided in this manual for your convenience.

The AZ/EL cap can be installed on a ground pole or roof mount support. Mount should be assembled and in place, or

ground pole set, before installing the AZ/EL cap.

NOTE: For ground pole installations, allow concrete to cure before proceeding with installation.

AZ/EL FRAME ASSEMBLY (FIGURE 1.0)

Assemble top/bottom angles (6), to housing frame (7A)

with M12 x 25mm round head square neck bolts (17),

lock washers (2), and hex nut (3), as shown in Figure

1.0. M12 hex nuts (3), must be finger tight.

INSTALLING AZ/EL CAP ON GROUND POLE

Back out (do not remove) the four azimuth locking bolts

from AZ/EL cap. Install cap onto top of ground pole or

base tube. To hold the AZ/EL cap in place while install-

ing antenna, temporarily tighten one of the azimuth

locking bolts.

INSTALLING REFLECTOR TO AZ/EL CAP

Insert M12 x 100mm round head bolts (1) into Reflector

mounting holes, as shown in Figure 1.1. Lift Reflector and

align mounting bolts with holes in AZ/EL cap. Secure

with M12 lock washers (2) and hex nuts (3).Torque to 20

ft-lbs(27 N-m).

IMPORTANT: For correct orientation of

Reflector, the“UP”arrow must be as shown in

Figure 1.1 and Figure 1.2.

After M12 x 100mm Reflector bolts are torqued, then

torque top/bottom angle bolts (17) and hex nuts (3) to

38ft-lbs (51 N-m).

6

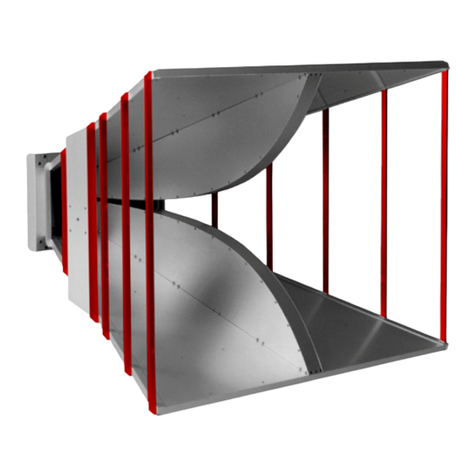

FEED & FEED LEGS INSTALLATION

Refer to Manufacturer’s Instructions packed with feed to as-

semble and install feed assembly.

Insert bottom feed leg (33) into clamp (39) and align hole in

feed leg with alignment pin inside clamp. Install bottom feed

leg (33) with clamp (39) onto bottom edge of antenna, se-

curing with two M6 x 20mm round head square neck bolts,

lock washers and hex nuts (35, 36 and 38). Do not tighten.

NOTE: Bottom feed leg is the one with open

round ends on both ends and a lance on one

end and alignment hole in opposite end. Insert

end with hole into bottom feed leg clamp (39).

Install side feed legs (30) to sides of antenna (37) as shown

in Figure 1.2. Secure with M6 x 20mm hex bolt, lock

washer and hex nut (34, 35 and 36). Do not tighten.

Insert one side feed leg (30) into junction block (29) and

secure with M6 x 30mm hex bolt and flat washer (31 and

32). Do not tighten.

Insert bottom feed leg (33) into junction block (29) until

lance on leg is engaged.

Insert opposite side feed leg (30) into junction block (29)

and secure with M6 x 30mm hex bolt and flat washer (31

and 32).

IMPORTANT: Tighten and torque hardware

securing side feed legs and bottom feed leg

to junction block and antenna to 4 ft-lbs (5.4

N-m).

Refer to Manufacturer’s Instructions to assemble and install

feed assembly.

Use bottom feed leg as conduit and route coaxial cable up

thru leg. Leave approximately 12” of length beyond junction

block. Install “F” connector onto cable for assembly to LNB.

NOTE: OTHER FEED ASSEMBLIES MAY USE DIF-

FERENT FEED LEGS. REFER TO SUPPLEMENTAL

INSTRUCTIONS PACKED WITH THE FEED LEGS.

PARTS AND HARDWARE

FIG. 3.2 - KU FEED SUPPORT LEGS

NO. DESCRIPTION QTY.

28 CLAMP 1

29 JUNCTION BLOCK 1

30 SIDE FEED LEG 2

31 HEX HD BOLT M6 X 30mm 2

32 FLAT WASHER,1/4” x 3/4” O.D., S.S. 2

33 BOTTOM FEED LEG 1

34 HEX BOLT M6 x 20mm 2

35 LOCK WASHER, M6, S.S. 4

36 HEX NUT, M6, S.S. 4

NO. DESCRIPTION QTY.

38 RD HD-SQ NK BOLT, M6 x 20mm, S.S. 2

39 CLAMP, BOTTOM FEED LEG 1

*

*

*Supplied with Feed Assembly

FIG. 1.2 - INSTALLING FEED AND FEED SUPPORT LEGS TO ANTENNA

ASSEMBLY ALIGNMENT PROCEDURE

7

Alignment with the satellite is obtained by setting polarization,

elevation, and azimuth. Charts 1, 2 and 3 are to determine the

values for your earth station antenna site. “∆L” is the difference

between the earth station antenna site longitude and the satellite

longitude. Use “∆L” and your earth station latitude to obtain

polarization, elevation or azimuth setting.

Elevation Alignment

Refer to Chart 1 to determine your elevation setting.

IMPORTANT: Before adjustment, loosen the two

bolts (13) (18) on each side of this housing (1/2

turn). Re-tighten all four bolts after adjustment is

completed.

Turn elevation adjustment bolt, Item 9, clock-wise, to decrease

elevation, and counterclockwise to increase elevation. Align the

edge of bracket with the appropriate mark at the desired eleva-

tion reading (See Figure 2.0).This will be an approximate setting.

Optimum setting will be achieved when Fine Tuning. Refer to

Figure 2.3.

NOTE: When the reflector face is vertical,while

the beam elevation (beam) axis is 22.62°,the

offset angleof the antenna.(See Appendix,Outline

Drawing,Page 14).

Azimuth Alignment

Use Chart 3 and determine your azimuth setting. Values in

chart must be adjusted for magnetic deviation for

your location for correct compass reading. Equally

tighten the four azimuth locking bolts (15) until snug, and back off

1/8 turn. This will allow azimuth rotation with slight resistance,

without AZ/EL cap tilting on pole. Rotate the reflector and AZ/EL

cap, pointing it to the correct compass reading for your location

and satellite. Refer to Figure 2.1. If desired signal is not found,

increase or decrease elevation setting and repeat the azimuth

sweep until desired signal is found. Tighten progressively (1/8

turn each) all four azimuth bolts (15).Repeat until 70-80 ft-lbs (95-

108 N-m) torque is reached.

Fine Tuning

Snug tighten hex bolt/nut in curved slots (13) and pivot bolts (18)

(refer to Figure 2.0). Use a signal strength measuring device for

final adjustments to obtain maximum antenna performance. Alter-

nate between elevation and azimuth fine tuning to reach maxi-

mum signal strength, until no improvement can be detected. Top

plate locking bolts (18), 4 places, should be torqued to 6-8 ft-lbs

(8-11 N-m). See Figure 2.3. Turn the azimuth adjusting nuts (3)

clockwise or counter clockwise for azimuth fine tuning. Tighten

and torque all hardware(refer to Torque Chart on Page 2).

Polarization of Feed

Loosen two feed horn clamp bolts (26) and turn feed clockwise

or counterclockwise, depending on being east or west of the sat-

ellite as shown on Chart 3. Align marks on the horn clamp and

appropriate mark on the horn scale. Polarization chart assumes

antenna system polarization is Tx vertical and satellite vertical Pol

is perpendicular to plane of geostationary arc. For horizontal Tx

of antenna, feed must be rotated 90° from values shown. Start-

ing point for polarization adjustment is 0°, as shown in figure

2.0. Tighten and torque clamp bolts to 4 ft-lbs (5.4 N-m), after

setting.

ANTENNA ALIGNMENT PROCEDURE

Alignment with the satellite is obtained by setting polarization, ele-

vation and azimuth. Charts 1, 2 and 3 are to determine the values

for your earth station antenna site. “∆L” is the difference between the

earth station antenna site longitude and the satellite longitude. Use

“∆L” and your earth station latitude to obtain polarization, elevation

or azimuth setting.

Elevation Alignment

Refer to Chart 1 to determine your elevation setting. IMPORTANT:

Before adjustment, loosen the two bolts (13) (18) on each side

of this housing (1/2 turn). Re-tighten all four bolts after adjust-

ment is completed. Turn elevation adjustment bolt, Item 9, clock-

wise, to decrease elevation, and counterclockwise to increase ele-

vation. Align the edge of bracket with the appropriate mark at the

desired elevation reading (See FIgure 2.0). This will be an approxi-

mate setting. Optimum setting will be achieved when Fine Tuning.

Refer to Figure 2.3. NOTE: When the reflector face is vertical,

while the beam elevation (beam) axis is 22.62˚, the offset angle

of the antenna. (See Appendix, Outline Drawing, Page 14).

Azimuth Alignment

Use Chart 3 and determine your azimuth setting. Values in chart

must be adjusted for magnetic deviation for your location for

correct compass reading. Equally tighten the four azimuth locking

bolts (15) until snug, and back off 1/8 turn. This will allow azimuth

rotation with slight resistance, without AZ/EL cap tilting on pole.

Rotate the reflector and AZ/EL cap, pointing it to the correct com-

pass reading for your location and satellite. Refer to Figure 2.1. If

desired signal is not found, increase or decrease elevation setting

and repeat the azimuth sweep until desired signal is found. Tighten

progressively (1/8 turn each) all four azimuth bolts (15). Repeat until

70-80 ft-lbs (95-108 N-m) torque is reached.

Fine Tuning

Snug tighten hex bolt/nut in curved slots (13) and pivot bolts (18)

(refer to Figure 2.0). Use a signal strength measuring device for final

adjustments to obtain maximum antenna performance. Alternate

between elevation and azimuth fine tuning to reach maximum signal

strength, until no improvement can be detected. Top plate locking

bolts (18), 4 places, should be torqued to 6-8 ft-lbs (8-11 N-m). See

Figure 2.3. Turn the azimuth adjusting nuts (3) clockwise or coun-

terclockwise for azimuth fine tuning.Tighten and torque all hardware

(refer to Torque Chart on Page 2).

Polarization of Feed

Loosen two feed horn clamp bolts (26) and turn feed clockwise or

counterclockwise, depending on being east or west of the satellite

as shown on Chart 3. Align marks on the horn clamp and appropri-

ate mark on the horn scale. Polarization chart assumes antenna

system polarization is Tx vertical and satellite vertical Pol is per-

pendicular to plane of geostationary arc. For horizontal Tx of anten-

na, feed must be rotated 90˚ from values shown. Starting point for

polarization adjustment is 0˚, as shown in figure 2.0. Tighten and

torque clamp bolts to 4 ft-lbs (5.4 N-m), after setting.

ALIGN THIS EDGE

WITH SCALE FOR

ELEVATION

READING

ELEVATION ADJUSTING

BOLT (9) ELEVATION

LOCKING

BOLT (13)

ELEVATION

PIVOT

BOLT (18)

AZIMUTH LOCKING

BOLTS (15)

EXAMPLE SHOWN

AT 22.6 DEGREES

AZIMUTH

-40 +40

0

26

ALIGNMENT

MARK

ARROW

FIG. 2.0 - SETTING ANTENNA ELEVATION

FIG. 2.1 - ROTATING ANTENNA FOR AZIMUTH

FIG. 2.2 - POLARIZATION OF FEED

AZIMUTH

ADJUSTING

NUTS (3)

AZIMUTH

ADJUSTING

SCREW (24)

ADJUSTING

SCREW (21)

PIVOT BOLT

AZIMUTH

LOCKING

BOLTS (15)

TOP PLATE

LOCKING

BOLTS (18)

FIG. 2.3 - AZ/EL CAP MOUNT w/AZ

FINE TUNE

GROUNDING

ALL INSTALLATIONS TO CONFORM TO

THE LATEST ISSUE OF THE

NATIONAL ELECTRIC CODE.

8

Ground pole, antenna mount assembly and feed cables must be grounded in accordance with current National Electric Code

and local electric codes to protect from surges due to nearby lightning strikes.

Clamps that provide a solid connection between ground wire and ground source should be used.

GROUNDING

ALL INSTALLATIONS TO CONFORM TO

THE LATEST ISSUE OF THE

NATIONAL ELECTRIC CODE.

Ground pole, antenna mount assembly and feed cables must be grounded in accordance with current National Electric

Code and local electric codes to protect from surges due to nearby lightning strikes.

Clamps that provide a solid connection between ground wire and ground source should be used.

GROUND WIRE

(Typical #10 AWG Copper, #8 Aluminum)

Refer to NEC Section 810 and local electric

codes for the specific area requirements.

¹⁄₄" - 20 UNC x ⁵⁄₈"

HEX HEAD, TYPE "D" POINT,

SELF TAPPING SCREW

GROUND LUG

¹⁄₄" EXTERNAL TOOTH

LOCK WASHER

Drill hole through one wall with

⁷⁄₃₂" (5.5mm) Dia. twist drill.

Apply sealant here, after

assembly, to improve

corrosion resistance.

GROUND POLE

REF

10"-12"

38"

APPROX.

TYPICAL ELECTRICAL GROUNDING

FOR ANTENNA GROUND POLE

50

125

120

115

110

105

100

95

90

85

80

75

70

65

50

47.5

45

42.5

40

37.5

35

32.5

30

27.5

25

47.5

45

42.5

40

37.5

35

32.5

30

27.5

25

LATITUDE/LONGITUDE CHART

GROUNDING FEED CABLES

Ground Wire

(NEC Section

810-20)

Ground Block

(NEC Section

810-20)

Coaxial Cables (To Receiver)

Coaxial

Cables

(From LNB)

GROUNDING FEED CABLES

GROUNDING

8

ALL INSTALLATIONS TO CONFORM TO

THE LATEST ISSUE OF THE

NATIONAL ELECTRIC CODE.

Ground pole, antenna mount assembly and feed cables must be grounded in accordance with current National Electric

Code and local electric codes to protect from surges due to nearby lightning strikes.

Clamps that provide a solid connection between ground wire and ground source should be used.

GROUND WIRE

(Typical #10 AWG Copper, #8 Aluminum)

Refer to NEC Section 810 and local electric

codes for the specific area requirements.

¹⁄₄" - 20 UNC x ⁵⁄₈"

HEX HEAD, TYPE "D" POINT,

SELF TAPPING SCREW

GROUND LUG

¹⁄₄" EXTERNAL TOOTH

LOCK WASHER

Drill hole through one wall with

⁷⁄₃₂" (5.5mm) Dia. twist drill.

Apply sealant here, after

assembly, to improve

corrosion resistance.

GROUND POLE

REF

10"-12"

38"

APPROX.

TYPICAL ELECTRICAL GROUNDING

FOR ANTENNA GROUND POLE

50

125

120

115

110

105

100

95

90

85

80

75

70

65

50

47.5

45

42.5

40

37.5

35

32.5

30

27.5

25

47.5

45

42.5

40

37.5

35

32.5

30

27.5

25

LATITUDE/LONGITUDE CHART

GROUNDING FEED CABLES

9

POLARIZATION CHART

EARTH STATION LATITUDE IN DEGREES NORTH OR SOUTH OF EQUATOR

FEED ROTATION

(Facing Antenna)

For + Polarization Rotate Counter Clockwise

For - Polarization Rotate Clockwise

Antenna

Polarization Chart Sign Values (+ or -) Northern Hemisphere Southern Hemisphere

Antenna Site West of Satellite Longitude - +

Antenna Site East of Satellite Longitude + -

Feed

10

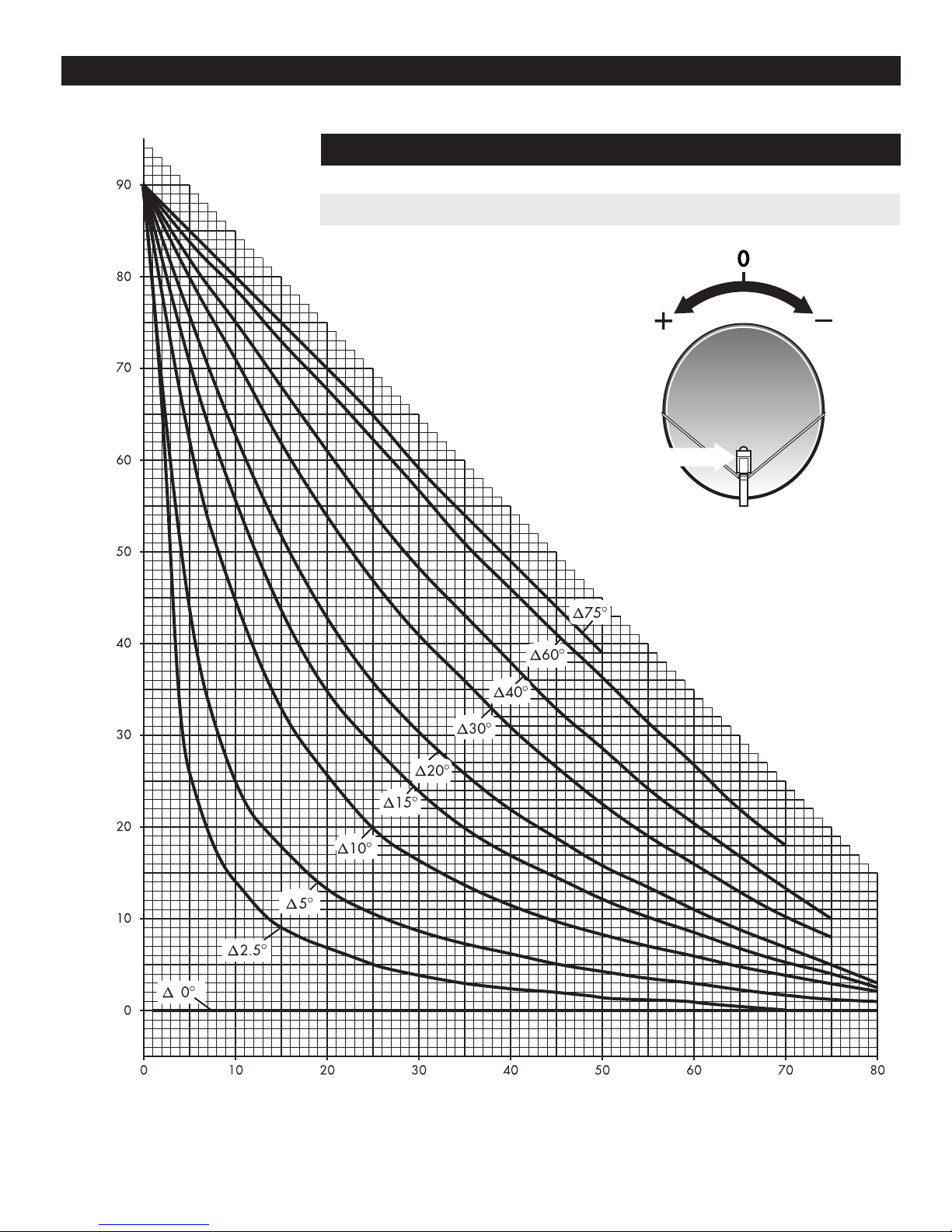

ELEVATION CHART

Use of Elevation Chart

n Determine = the difference between your site longitude and the satellite

longitude.

n Find you latitude on horizontal axis.

n Follow your latitude up until you intersect the curve for your .

n Read Elevation value on vertical axis.

ELEVATION IN DEGREES

11

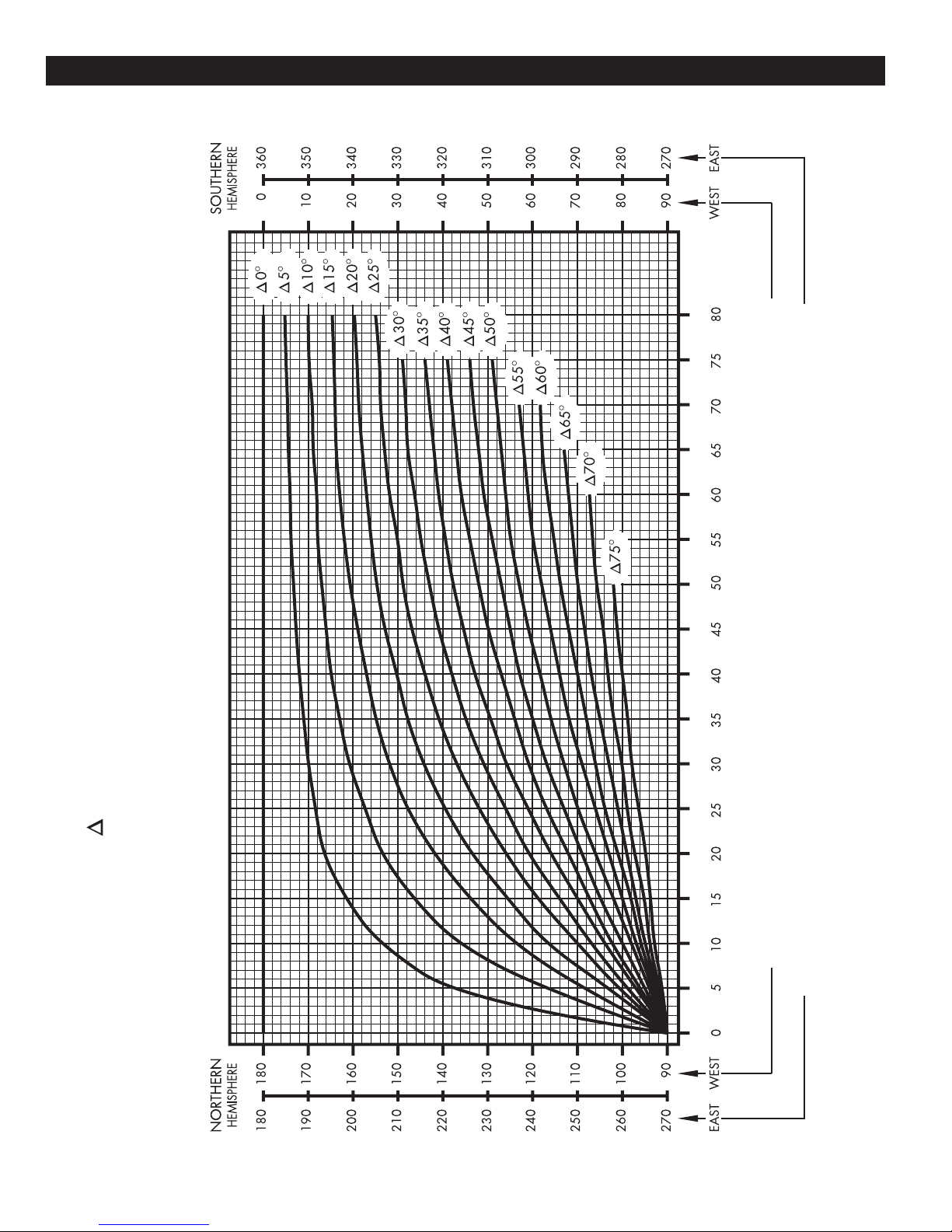

ANTENNA ALIGNMENT PROCEDURE

“ “ IS THE DIFFERENCE BETWEEN THE EARTH STATION

ANTENNA SITE LONGITUDE AND THE SATELLITE LONGITUDE

EARTH STATION ANTENNA AZIMUTH IN DEGREES

EARTH STATION ANTENNA AZIMUTH IN DEGREES

EARTH STATION ANTENNA LATITUDE IN DEGREES NORTH OR SOUTH OF EQUATOR

AZIMUTH COLUMN READING WHEN EARTH STATION IS WEST OF SATELLITE

AZIMUTH COLUMN READING WHEN EARTH STATION IS EAST OF SATELLITE

AZIMUTH CHART

12

PARTS & HARDWARE

NO. DESCRIPTION QTY.

1 RD HD SQ NK BOLT, M12 x 100mm, GALV. 4

2 LOCK WASHER, M12 16

3 HEX NUT, 1/2” , GALV., M12 17

4 SPLIT PIN, M3.2 x 25mm 1

6 TOP/BOTTOM ANGLE 2

7 BACKFRAME HOUSING ASSEMBLY 1

8 FLAT WASHER - M12 7

9 HEX HD SCREW, SPCL, M12 x 210mm 1

10 SPHERICAL WASHER 1

11 CASTLE NUT, M12 1

12 SWIVEL NUT, M12 1

1

PARTS AND HARDWARE

1

23

14

13

18

28

17

6

7

2

3

20

8

2

3

2

36

9

810

11

4

12 3

2

8

18

3

3

19

24

16

23

22

15

2

18

21

FIG. 3.0 - AZ/EL CAP

NO. DESCRIPTION QTY.

13 HEX HD BOLT, M12 x 25mm 1

14 LABEL, ELEVATION 1

15 HEX HD BOLT, M12 x 30mm 4

16 CANISTER WELDMENT 1

17 RD HD SQ NK BOLT, M12 x 25mm 4

18 RD HD SQ NK BOLT, M12 x 35mm 7

19 FLAT WASHER - LARGE 2

20 SPRING PIN, M8 X 20mm 1

21 HEX HD BOLT, M8 X 25mm 1

22 LOCK WASHER M8 1

23 HEX NUT M8 1

24 BOLT, SPADE M12 x 135mm 1

13

PARTS & HARDWARE

14

APPENDIX A

Outline Drawing

Type 180 1.8m Offset SMC Reflector with Rx Mount

(197.2cm)

77.6in

(182.2cm)

71.7in

(141.0cm)

55.5in

(239.5cm)

94.3in

(39.6cm)

15.6in

(171.5cm)

67.5in

22.6

O

(38.1cm)

15in

ANTENNA

L

C

MECH. AXIS

BEAM AXIS

(151.1cm)

59.5in

(183.8cm)

72.4in

22.6

O

12.6

O

L

C

MECH. AXIS

BEAM AXIS

L

C

POLE

HORIZONTAL ANTENNA

(8.9cm)

3.5in

(31.0cm)

12.2in

10.0

O

L

C

POLE

(64.0cm)

25.2in

(114.3mm)

4.5in O.D.

Type 180 1.8m Antenna System with AZ/EL Cap Mount

NOTES: Dimensions shown are for ground pole (4.50” D.D. Schedule 40, Fy = 50KSI) or 4”, Pipe SCH 80,

Fy = 36KSI (4.5” O.D. x 3.83 I. D.) Purchased locally

METRIC GROUND POLE DIMENSIONS

114.3mm O.D. x 97.3mm I.D. Fy = 248 Mpa

15

L

APPENDIX B

1.8m ANTENNA SURVIVAL WINDLOADS AT 125 MPH VELOCITY

ELEVATION FORCE MOMENTS

DEGREES (POUNDS)* (FOOT-POUNDS)**

MECH. BEAM FHFVMTMO

0 23 1824 -47 1073 8,436

10 33 1726 -365 1035 7,983

20 43 1677 -710 984 7,756

30 53 1519 -1008 892 7,025

40 63 1337 -1215 756 6,184

50 73 1166 -1337 635 5,393

60 83 972 -1398 491 4,496

70 93 729 -1082 378 3,372

MoBASED ON 55.5” FROM MOUNTING SURFACE TO C OF ANTENNA.

*kg = Pounds x .45359

** N.m = Foot-Lbs. x 1.35582

Values shown above represent maximum forces for any wind direction.

Height and exposure factors from the uniform building code are NOT included.

FIG. 4.0

To ensure peak performance of the antenna system and to maintain validity of the warranty, the user should perform a

periodic inspection every 6 months or following any severe weather event, As a minimum the following items should be

inspected.

1. Installation Mount

Check for loose hardware - tighten if necessary.

Check integrity of anchor bolts or hardware securing mount to the building or foundations

Check ballast of Non-Penetrating Roof Mounts - cracked or broken blocks must be replaced.

Check hardware and structural members for signs of corrosion - repair or replace as needed

2. Antenna Back Structure or Az/El Mount

Check for loose hardware - tighten if necessary.

Check for signs of structural damage such as bending or cracking

Check hardware and stuctural members for signs of corrosion - repair or replace as needed

3. Reector

Check intergrity of bolts securing reector to back structure or az/el mount. Tighten any loose hardware.

Check for signs of damage such as cracking. Inspect reector face for impact damage.

Check hardware for signs of corrosion - repair or replace as needed.

4. Feed Support Structure

Check for loose hardware - tighten if necessary.

Check for signs of structural damage such as bending.Check hardware and stuctural members for signs of corrosion -

repair or replace as needed

5. Feed & RF Components

Check for loose hardware - tighten if necessary.

Check hardware for signs of corrosion - repair or replace as needed.

Check feed lens or window for damage or signs of leaking.Check waveguide connections between feed and RF electronics

6. Electrical

Check for loose cables and connectors - tighten if necessary

Check for tight grounding connections

Check cables for weathering or cracks

PERIODIC INSPECTION & MAINTENANCE

INSTALLATION MOUNT

ANTENNA BACK STRUCTURE OR AZ/EL MOUNT

REFLECTOR

FEED SUPPORT STRUCTURE

FEED & RF COMPONENTS

ELECTRICAL

16

Table of contents

Other Skyware Global Antenna manuals

Popular Antenna manuals by other brands

Betso

Betso Sharkie user manual

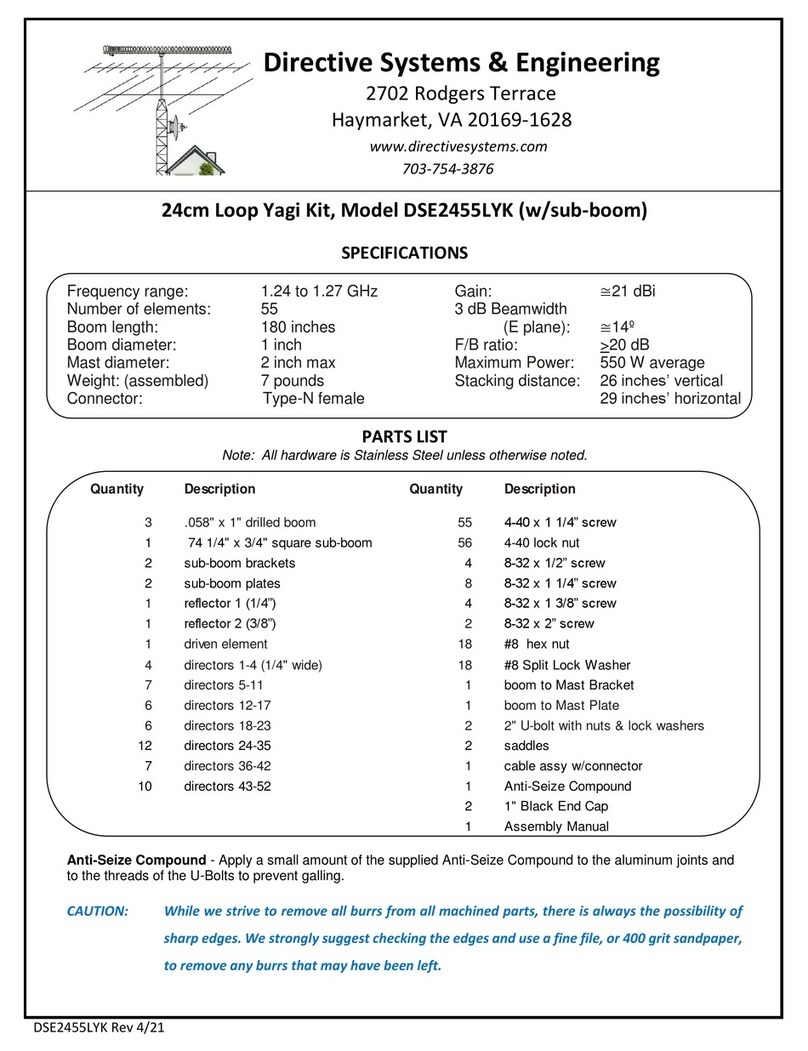

Directive Systems & Engineering

Directive Systems & Engineering DSE2455LYK Assembly

KVH Industries

KVH Industries TracVision TV3 installation guide

CommScope

CommScope F-042-GL-E instruction sheet

COBHAM

COBHAM Sea Tel 4010W-33 installation manual

Lorex

Lorex ACCANT08 quick start guide