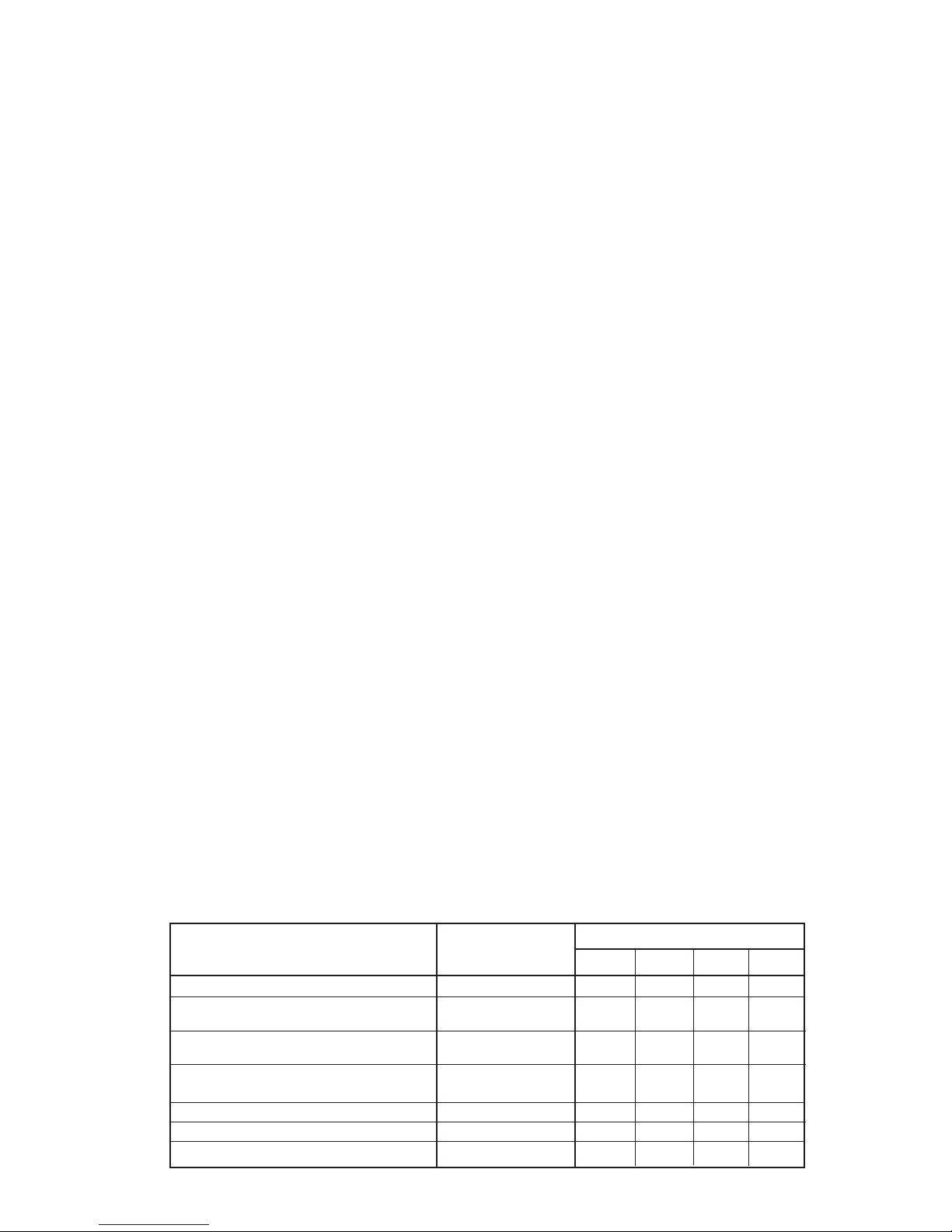

Used on heater model

Description Part Number WH-30 WH-40* WH-60* WH-80*

Temperature control -Honeywell 4080B-1295 664131000 X X X X

Temperature and pressure relief

valve - Watts 100 XL-8 664121000 X X X

Temperature and pressure relief

valve - Watts 40 XL-8 664122000 X

Trenton inverted nipple

3/4”MPT x 3/4”FPT x 21/2”long -brass 664129000 X

3/4” NPT brass tee 664126000 X X

1” NPT brass tee 664127000 X

3/4” NPT x 1” NPT reducer bushing - brass 664128000 X

REPLACEMENT PARTS LIST

OPERATING PROCEDURES

1. Filling the heater tank

a) Make sure all drain valves on the cold or hot water supply

piping are closed.

b) Open the nearest hot water faucet and any shutoff valves

on the domestic hot water supply piping from the tank out-

let.

c) Open the shutoff valve on the cold water supply piping to

the tank inlet.

d) Allow the cold water supply to fill the tank by leaving the hot

water faucet open until all air is purged from the tank and

piping, and a steady flow of water is observed from the

faucet.

e) Close the hot water faucet, but leave all piping shutoff

valves open.

f) Any other hot water faucets fed by this heater may be

opened to purge air from their supply piping, and then shut

off after a steady flow of water is observed from the faucet.

2. Filling the heater coil

a) Attach a hose to the drain valve on the coil outlet (return to

boiler). Place the end of the hose into a drain or bucket in a

manner that will prevent potentially hot water from spraying

on any persons in the area.

b) If a shutoff valve has been installed between the drain valve

and the boiler return, keep this valve shut at this time.

c) Open the shutoff valve (and on a zone valve system, man-

ually open zone valve) on the supply piping from the boiler.

d) Open the drain valve on the coil outlet to purge the air from

the coil. When a steady flow of water is observed from the

drain, then open the shutoff valve on the return piping to the

boiler. Additional air from the return piping should purge

itself at this time. Close the drain valve when the steady flow

of water is again observed.

e) Remove the hose from the drain valve. Leave the drain

valve closed. Leave all shutoff valves open. Return zone

valve to automatic operation.

f) Purge air from remaining zones, if necessary. Check boiler

gauge pressure reading afterward to be appropriate. 15 psi

is normal for most installations.

3. Operating the heater

a) After the system has been manually purged of its air, and

all components (valves, vents, controllers) have been set

properly, the boiler can be started. NEVER operate this

heater until this has been done.

b) The maximum setting for the boiler water supply to the

heater coil is 220° F.

c) The maximum setting for the heater tank temperature con-

trol is 160° F. Unless there is specific demand for very high

temperature domestic hot water, the control setting should

be set at the lower end of the temperature range of adjust-

ment to reduce the risk of scalding injury. Some areas

require that the tank control setting be below 130°.

d) When the temperature of the water in the heater tank is

below the setting on the tank control, the boiler and circu-

lator should start. If a zone valve is used for this zone, it

should open at this time. When the temperature of the

water in the heater tank reaches the temperature setting on

the tank control, the boiler and circulator should turn off

(and zone valve, if used, should close). If other zones for

heating are in demand, this would also run boiler and cir-

culator(s). Cycling of the boiler on high limit is not abnor-

mal, particularly if only one zone is in demand. On initial

startup with a cold tank, a considerable amount of time may

be required for the tank to reach desired temperature.

Maintenance recommendations:

1. Temperature and pressure relief valve operation check

a) Once a year, the T & P valve must be manually operated to

ensure safe and proper operation.

b) Make sure that the discharge line from the T & P valve is

directed towards a drain or some collection method, and

will not spray onto any person.

c) Use lever on T & P valve to open. A steady discharge of hot

water should be noticed. After releasing this lever, the

T & P valve should close and fully shut off this flow.

d) If the T & P valve does not function properly, it must be

replaced with the same model or its equivalent. DO NOT

plug the outlet of this valve if a dripping condition occurs.

2. Flushing the heater tank

a) Once a year, or if a persistent discolored water condition

exists, the heater tank should be manually flushed to

remove possible sediment accumulation.

b) Turn off the boiler before draining the heater tank.

c) Attach a hose to the drain valve on the cold water supply to

the tank. Place the end of the hose into a drain or bucket in

a manner that will prevent potentially hot water from spray-

ing on any persons in the area.

d) Close the shutoff valve on the cold water supply to the tank.

e) Open the drain valve on the cold water supply and drain

down tank completely. Open the T & P valve or a nearby

faucet to break vacuum on drain.

f) After the heater tank is drained, close the drain valve and

reopen the cold water supply valve to refill the tank. The

introduction of water into the tank should act to stir up sed-

iment accumulations which can then be drained through

the drain valve. Go back through the draining and filling

process until clean water is observed passing out the drain.

g) Once clear water conditions are accomplished, make sure

the heater tank and all domestic hot water supply piping is

purged of air and discolored water. Leave the drain closed,

check for the T & P valve to be properly seated, and make

sure all shutoff valves for the hot and cold water supply are

left open. The boiler can then be returned to operation.

7

*Also applies to double wall coil models WH-40 D, WH-60 D and WH-80 D.