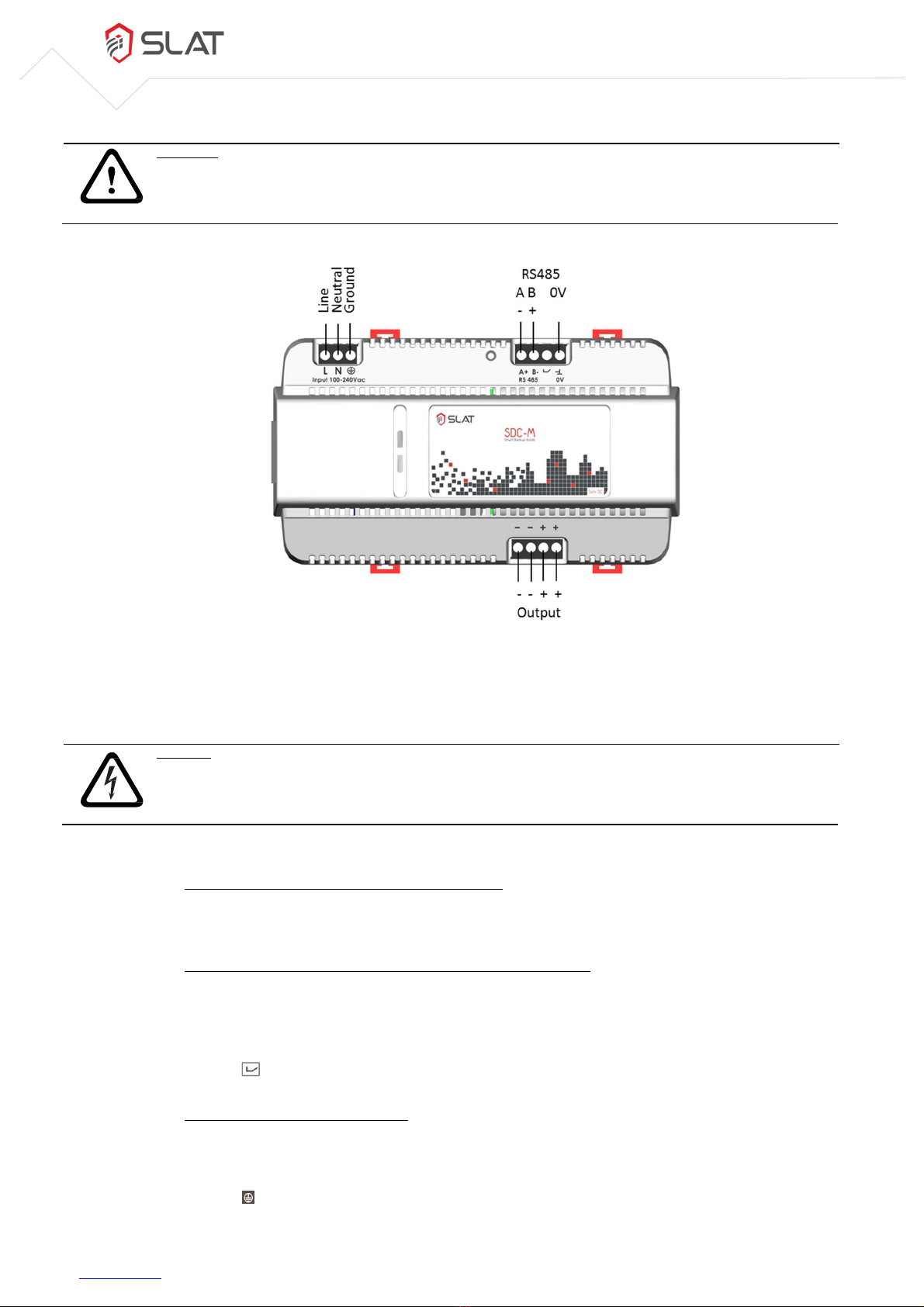

SLAT Safe DC SDC-M User manual

Table of contents

Other SLAT UPS manuals

Popular UPS manuals by other brands

Eaton

Eaton Ellipse ECO 500 Installation and user manual

Keatec Energy

Keatec Energy T SERIES user guide

Eaton

Eaton Ellipse ECO 500 Advanced user's guide

Viakom

Viakom OR1000ERM1U user manual

CyberPower

CyberPower 649532010004 Specification sheet

SurgeX

SurgeX SX-DS-154 DEFENDER SERIES MULTIPAK quick start guide

Bolid Security Systems

Bolid Security Systems RIP-12 02 instruction manual

Exide

Exide Inverterz GQP 12V 7009VA user manual

Eaton

Eaton 9395 UPS and Plus 1 UPS 650825 kVA Installation and operation manual

Centralion

Centralion ENDURE 750VA user manual

Minuteman

Minuteman PRO-E user manual

Huawei

Huawei SmartLi Series quick guide

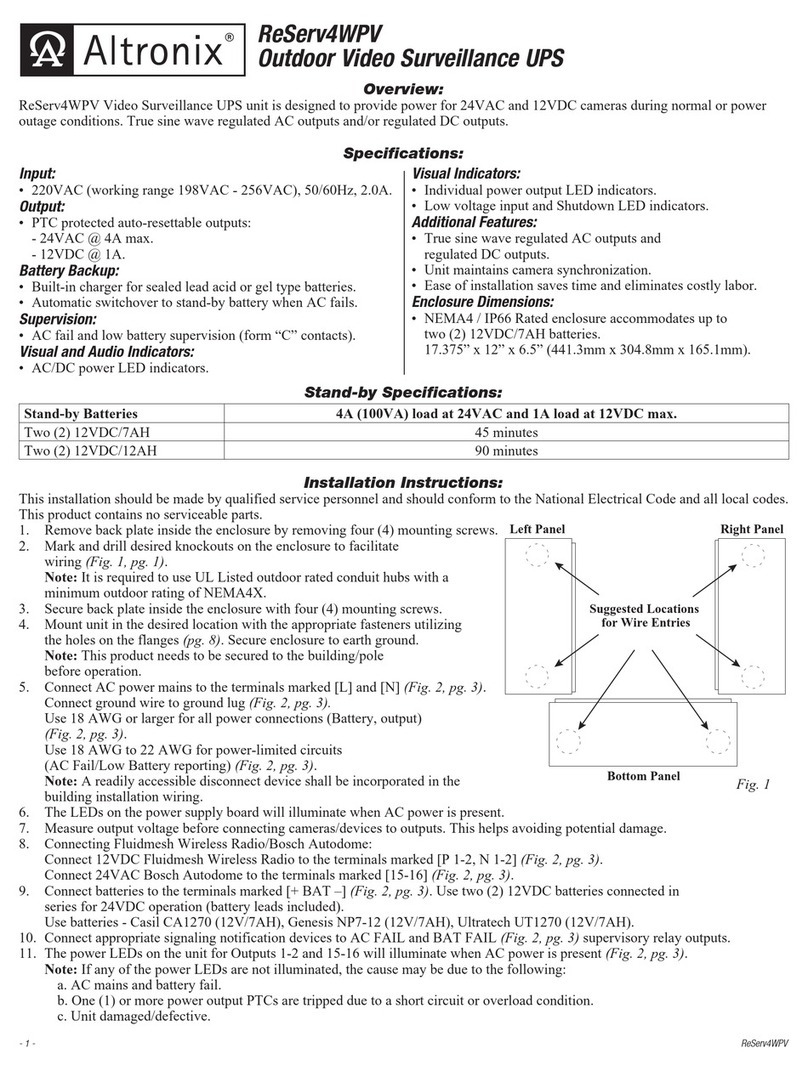

Altronix

Altronix ReServ4WPV quick guide

Liebert

Liebert Series 600 Operation & maintenance manual

CyberPower

CyberPower BU600E-FR Technical specification

WÄRTSILÄ

WÄRTSILÄ JOVYTEC L Series operating manual

Jovyatlas

Jovyatlas Wartsila JOVYTEC PNT 1000 VA operating manual

Chloride

Chloride ACTIVE A0K7XAU operating manual