Slee MTM II User manual

DESIGN &

MANUFACTURING

MADE IN GERMANY

O P E R A T I N G

M A N U A L

TISSUE PROCESSOR

MTM II

COSTEFFECTIVE PREMIUM TISSUE PROCESSING

HIGHEST RELIABILITY

EASY CLEANING

2 Manual_MTM_II_2021-10-010.00_EN.docx

Manual_MTM_II_2021-10-010.00_EN.docx 3

CONTENTS

1. INTENDED USE

............................................................ 4

2. SYMBOLS

............................................................ 4

3. SAFETY NOTES

............................................................ 5

4. COMPONENTS

............................................................ 8

5. SPECIFICATIONS

............................................................ 9

6. UNPACKING AND INSTALLATION

............................................................

11

7. INITIAL OPERATION

............................................................ 14

8. REAGENT MANAGEMENT

SYSTEM

............................................................ 26

9. OPERATION

............................................................ 41

10. ALARMS

............................................................ 69

11. CLEANING AND MAINTENANCE

............................................................ 82

12. SERVICE

............................................................ 84

13. OPTIONAL ACCESSORIES

............................................................ 88

14. WARRANTY

............................................................

89

15. DISPOSAL

............................................................ 89

4 Manual_MTM_II_2021-10-010.00_EN.docx

1. INTENDED USE

The vacuum tissue processor MTM II is intended for automated fixation, dehydration

and paraffin infiltration of histological samples for professional use in routine and

research laboratories in the fields of biology, medicine and industry.

MTM II is equipped with an enhanced heat exchanger (EHE) that allows conventional

overnight tissue processing, semi-rapid processing of larger samples and fast processing

of biopsies.

The MTM II tissue processor recycles the air utilized to move the reagents to and from

the processing chamber. An effective charcoal filter on the external air-outlet reduces

the exhaust fumes to acceptable and safe levels. The wax and reagent bottles can be

rapidly removed and easily reinstalled in their housing slots. The control devices

(hardware and software) are based on the most up-to-date processing control

technologies. Up to 18 different programs can be permanently stored and be easily

modified. The 18th program is a special “REVERSED” program that is used to de-process

samples that have not had good infiltration.

During a run, every step and action is displayed on the screen, such as current step and

function (emptying, filling, etc.), processing chamber and wax heating chamber

temperatures, processing chamber pressure, completion time and date, and any other

parameter necessary to simplify the use of the instrument. In the event of power

failures, the computer saves all the data necessary to restart the process exactly where it

was interrupted. If the interruption happens during the wax stages, particular

precautions are taken to guarantee melting before any wax filling or emptying begins.

2. SYMBOLS

Dangers, warnings and cautions are marked by this symbol

Flammable solvents and reagents are marked with this

symbol.

Special instructions regarding the operation of the

instrument are marked by this symbol

Manual_MTM_II_2021-10-010.00_EN.docx 5

i

3. SAFETY NOTES

The institution which owns the unit and the persons working with the unit, servicing or

repairing it have the responsibility for a hazard-free use.

•

Severe damage can result if the instrument is connected to a

power supply different from the rating stated in the identification

tag placed on the rear of the instrument.

•The instrument must NEVER be used without being connected to

an appropriate and fully efficient ground connection.

•If damages due to transport occur, DO NOT use and DO NOT

connect the instrument to a power source. Contact our technical

service.

•This instrument has been designed to work 24/7; for this reason

and for operative precautions, the power switch is placed on the

rear of the instrument.

•Access to the instrument’s internal components is reserved only to

specialists trained in the service of the instrument.

•Always disconnect the processor from the electrical main source

before accessing the electronics and internal parts.

•BEFORE replacing fuses, disconnect the instrument from the power

source.

6 Manual_MTM_II_2021-10-010.00_EN.docx

•

Always make certain to correctly engage the reagent bottles.

•DO NOT open the processing chamber lid when the instrument is

working without following the instructions contained in this

manual.

•Use specific precautions in handling flammable reagents such as

ethanol (wear protective gloves and eyeglasses).

•Use specific precautions in handling liquid waxes as they can cause

burns.

•The emptying and filling of reagent bottles must only be done only

by qualified technicians.

•Due to the presence of flammable substances inside reagents

bottles, it is recommended to:

oAvoid smoking near the instrument

oAvoid using open flames near the instrument (e.g. Bunsen

burner)

oDO NOT wear clothes that can create electrostatic charges

while handling reagents (wool, synthetic fibers, etc.)

•Contaminated reagent waste must be disposed off in accordance

with all applicable local laws, ordinances and safety standards.

•Use only original spare parts supplied by the manufacturer or by

authorized dealers.

•DO NOT extract bottles, replace reagents or do other maintenance

operations when the instrument is operating.

•To complete the knowledge on the instrument safety please read

also the chapter SAFETY DEVICES near the end pages of this

manual.

Manual_MTM_II_2021-10-010.00_EN.docx 7

3.1ELECTRICAL POWER CONNECTION

Do not use any extension lead.

Make sure that electric power is constant:

•

This should be examined during installation of the unit by a

competent person.

•Use a dedicated fuse for the unit.

•Do not connect another unit to the same power circuit.

•Before turning on the instrument, check if the voltage of the mains

supply is identical with the name plate of the unit.

8 Manual_MTM_II_2021-10-010.00_EN.docx

4. COMPONENTS

The Slee vacuum tissue processor MTM II is provided with the following standard

components:

MTM I MTM II

Basic unit with rotary valve

•

•

Enhanced heating element (EHE)

•

15’’ Color-LCD-Touchscreen

•

•

Cassette basket

(2x 150 cassettes; stainless steel)

•

•

10x reagent container

•

•

4x+1 paraffin container

•

•

2x System cleaning solution container

•

•

1x charcoal container

•

•

1x condensate container

•

•

Sieve insert

•

•

Mains cable

•

•

Operation manual

•

•

Manual_MTM_II_2021-10-010.00_EN.docx 9

5. SPECIFICATIONS

Type

Vacuum tissue processor

Principle

pressure / vacuum

Reagent containers

10 reagent container

4+1 paraffin container

2 system cleaning fluid container

Volume

2.5 litres

Reagent agitation

air bubbling

Capacity

300 histology cassettes

2 baskets (150 cassettes each)

Temperature range

MTM I

55 – 65 °C (paraffin)

RT, 35 – 45 °C (reagents)

MTM II

55 - 65 °C (paraffin)

RT, 35 - 45 °C (reagents)

EHE-element for preheated reagents

Pressure range

Vacuum

400 hPa (0.4 bar)

Pressure 1200 hPa (1.2 bar)

Programmes

18

Safety aspects

closed system

1 charcoal filter

Sample safety

remote alarm system (optional)

UPS (optional)

10 Manual_MTM_II_2021-10-010.00_EN.docx

Vacuum function

Programmable, vacuum or pressure

Cleaning cycles

automatic system cleaning cycle

paraffin cleaning cycle

Delay timer

up to 14 days, 23 hours, 59 minutes

Display

15'' Color-TFT-Monitor, Touchscreen

Interfaces

USB

Fill and Drain

Manual or automatic remote filling

and draining

Reagent Management

fully automatic, programmable

automatic shifting of reagents

Power

100 - 240 V 50/60 Hz

1500 W

IEC1010 classification

Protective Class 1, Pollution deg. 2

Overvoltage category II

800 V impulse (115 V version

1500 V impulse (230 V version)

Dimensions and weight

[width x depth x height]

720 mm x 600 mm x 1.080 mm without monitor

720 mm x 600 mm x 1.430 mm with monitor

Weight

without accessories

MTM I

120 kg

MTM II

135 kg

Manual_MTM_II_2021-10-010.00_EN.docx 11

6. UNPACKING AND INSTALLATION

Before moving or transporting the instrument, it is essential to carefully read this

chapter, paying particular attention to the instrument setup instructions.

The warranty is invalid if the instrument is improperly operated. Be certain to follow the

instructions and recommendations provided by this manual. The manufacturer is not

responsible for damages resulting from improper operation or handling of the

instrument.

Pay particular attention to the outside of the shipping container. In the event of

concealed damage, save all shipping crates and packing material. DO NOT unpack the

instrument if damage is apparent. Immediately notify the carrier of any damage and

contact the shipper to initiate any claims.

6.1 UNPACKING THE INSTRUMENT

The proper steps to be taken are:

Open the top of the box

Lift the side walls out of the way

Raise the instrument to the vertical position

Remove the plastic layers that wrap the instrument

Carefully check the external condition of the instrument. In the event of evident

damage, DO NOT connect the instrument. Immediately notify the carrier and promptly

contact the seller

For the setup of the instrument, see the specific chapter (Installation and Start-up) in this

manual.

Save the box and all the internal packaging in the event that the unit requires future

shipment.

12 Manual_MTM_II_2021-10-010.00_EN.docx

6.2 INSTALLATION SITE REQUIREMENTS

The site for installation should meet the following requirements:

•

A maximum ambient temperature of +10 °C to +35 °C

•

Avoid vibrations, direct sunlight and strong temperature variations

•

The instrument must be set up in a well ventilated area free from any ignition

sources.

•

A free ventilation of fresh air from underneath the instrument should be

guaranteed

6.3INSTALLATION

After unpacking and the electrical connection to the main line the following steps have

to be performed to prepare the instrument for its use.

•

Installation of the charcoal filter on the slot C1. Remove the cap from the

charcoal filter bottle and make a hole with a screwdriver or a pencil in the

tape that seals the air intake on the top rear of the bottle.

•

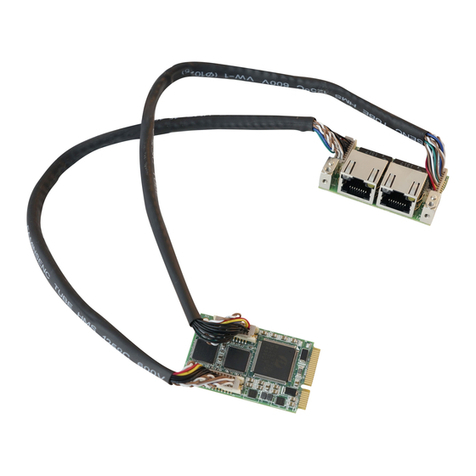

Connect the LCD screen. The LCD screen is transported unconnected in a

separate cardboard box. The screen must be placed on the top left of the

instrument housing. The electrical connection is made by connecting the three

connector on the instrument rear panel.

•

Connect the instrument to the main power. The main power supply

connection must provide:

230 Volt versions: 230 V AC +/- 10%, 50 Hz, 5A, grounded.

115 Volt versions: 115 V AC +/- 10%, 60 Hz, 10A, grounded.

It is recommended that the instrument is plugged into a wall socket equipped

with Ground Fault Circuit Interruption (GFCI) protection, as an additional

electrical safeguard.

In addition to the MTM II anti-blackout feature, an uninterruptible power

supply can be utilized to provide power in the event of power outages and

some protection against power fluctuations, line noise and power spikes.

It is highly recommended that the instrument be operated away from heat

(radiators, stoves, direct sunlight, etc.) and moisture (sinks, drains, etc.).

Manual_MTM_II_2021-10-010.00_EN.docx 13

6.4PACKAGING AND/OR PREPARATION FOR TRANSPORT

To transport the instrument, perform the following steps:

•Remove all reagents (waxes included) from their bottles.

•Remove and close, with the proper threaded cap, the charcoal filter bottle,

put also some adhesive tape on the air inlet to avoid charcoal pellets to get

out.

•Transport the charcoal filter bottle separately from the instrument, wrapped

and securely closed in a protective nylon bag.

•If the original box has been saved, follow the unpacking instructions in the

reverse order, using all the interior packaging to avoid serious damage to the

instrument during shipping.

6.5TRANSPORTATION

Before shipping, please keep in mind that:

•The instrument is fragile;

•The instrument is equipped with electronic parts;

•Contact with water and/or any other liquid is to be avoided; please ensure

that the internal plastic protection bag that wraps the instrument is utilized;

•Transporting and storing temperature(s) must be between -10 °C to +50 °C;

•Using the original box, the instrument is to be transported horizontally;

•Transporting the instrument vertically is highly discouraged as its centre of

gravity is quite high.

14 Manual_MTM_II_2021-10-010.00_EN.docx

7. INITIAL OPERATION

7.1 MAIN MENU

The user interface is based on “Touch Screen” technology. Therefore there isn’t any

traditional keyboard, all the instrument functions are activated by a finger touch.

7.2 EHE (ENHANCED HEAT EXCHANGER)

The EHE (Enhanced Heat Exchanger) is a device capable to warm up the reagents

(container 01 to 10) during their transfer to the SPC. The heating of the reagents up

to 55 °C to 60°C allows performance of faster processes especially for very small

samples (biopsies).

The EHE device is capable to increase the reagents temperature of 30-35°C without

relevant delays; the reagents filling lasts only a few seconds more (approx. 15’’) than

the filling made directly without using the EHE.

The reagent heating up to 50 °C to 60 °C allows the reduction of the processing time,

in the MTM II this reduction is increased due to the fact that the reagent heating is

made during the reagents filling (through the EHE) without any delay.

Manual_MTM_II_2021-10-010.00_EN.docx 15

The EHE is intended to perform fast BUT SAFE reagents heating; this is accomplished

thanks to safety devices but also thanks to its special conformation, the reagent

during its transfer into the EHE is never in contact with hot spots so its temperature is

increased in a homogeneous and gentle way. In the SETUP screen, the first row on the

top indicates the current software version.

7.3 EHE ACTIVATION

The EHE must be activated by this function in order to keep it at the default

temperature of 65°C when the MTM II is NOT processing to make sure that it will be

always ready to

perform a fast processing program.

During a process the EHE is set (independently from the setup activation) following

this

plan:

• Warm if in the running process one of the steps is scheduled to use the EHE.

• The EHE is switched OFF if no steps in the running process are scheduled for using

the EHE.

• Switched OFF after the last step/tank with EHE of the running process has been filled

into the SPC.

• At the end of a process the EHE is set ON to be ready to eventually perform a fast

process (but only if set active here).

By this function it is possible to set inactive the EHE in case it is known that the MTM II

will not (never or for a long time) be used for fast tissue processing. In this case it is

IMPORTANT to know that if a fast process is started there will be a delay up to 20

minutes for the EHE pre-heating!

By setting the EHE inactive it is possible to save electrical energy, please consider that

the EHE power is 700 Watts, when it is warm the power absorbtion goes down to

approximately 350 Watts, still this power has a significant impact on your laboratory

electricity bill, especially considering that a tissue processor is made to work 24/7 all

year

long.

7.4SOFTWARE VERSION

In the SETUP screen, under section PARAMS SETUP, the current software version is

displayed on the top right.

16 Manual_MTM_II_2021-10-010.00_EN.docx

7.5 LANGUAGES

Seven languages are currently available: English, French, German, Italian, Spanish, Czech

and Turkish.

7.6DATE FORMAT

In the USA the date format is: month/day/year. In Europe the format is: day/month/year.

Also the time is displayed in a different way. Here it is possible to choose the format.

7.7 ELEVATION

The ambient pressure is depending on the site elevation from the sea level (approx. 100

HPa less every 1.000 meter for the first 2000 meters). It is important to program the

instrument according to the level at which it is installed in order to avoid it to require the

air pump to reach differentials of pressure (levels of vacuum) impossible to make

especially when the elevation is higher than 800-1000 meters.

7.8 L/L ALARM

The displays of the ALERTs during the processing (low level not blocking alarms) can

here be enabled/disabled.

7.9 EOP SIGNAL

The End of Process acoustic signal can here be enabled/disabled.

7.10 PRINTER PORT

If the printer is not used/installed its port can/should be disabled. In this way the

program execution will be faster.

7.11 DATA BACKUP

From this function it is possible to enable/disable the instrument automatic data backup.

The instrument is equipped with a USB interface. Data backup can be performed

manually in the service menu, or it can be enabled automatic once a day. The backup

will save files with data regarding: process programs, settings, calibrations, progressive

data, etc. In case of memory failure, after its substitution, it will be possible to restore

the instrument data.

In case of instrument failure the USB memory must be

removed from the USB interface and stored in a safe place

available for service technicians. If the automatic data

backup is enabled a USB memory stick with sufficient free

memory must be inserted into the USB interface. Every 3 or

4 months it is advisable to substitute it with a new one.

Manual_MTM_II_2021-10-010.00_EN.docx 17

7.12 SPC LID OPENED/CLOSED SENSOR

The SPC lid status is controlled by a micro switch sensor. If the lid is closed but the

system displays that it is open, probably the micro switch is broken or out-of-position.

Waiting for service, from this function the sensor can be disabled, after that it is possible

to continue to operate the instrument.

If the micro switch is disabled the SPC lid indicator will show the label “DISAB.” Please

note that the sensor can reveal the lid complete opening but cannot sense its perfect

closing. Thus if the lid is simply turned down but the lock is not engaged, the sensor

may indicate lid closed, but the instrument will not be available for processing. The

instrument will allow the process or purge start but soon it will issue an alarm caused by

the impossibility to create vacuum or pressure in the SPC. Please always check the

correct lid closing and lock engagement before the start of any kind of operation.

7.13WWC SETPOINT

This function allows the setting of the WWC target temperature. The range is 55 °C to

65 °C. It is advisable to set its value to the highest point compatible with the laboratory

procedures. Particularly it is necessary to set the value at least 2°C over the declared

paraffin melting point. For example for paraffin with a melting point of 56 °C to 58 °C

the correct WWC target temperature would be 60°C.

7.14 REMOTE FILL/DRAIN CALIBRATION

This procedure allows the calibration of the volume of reagent filled from port 18 during

the RFD cycle (Remote Fill/Drain). To find the right value proceed as follow:

using the RFD execute a fill in one of the reagent bottles in a condition as close as

possible to the normal operation.

With a system sufficiently precise (+/- 10ml) take a measurement of the filled reagent

Set the calibration value considering that every increase/decrease of 1 corresponds to +/-

5-7 ml. Repeat the filling with the RFD to check if the correction has given the right

result. The standard precision of the RFD is +/- 1.5%, which corresponds, respect to the

standard value of 2.5 litres, to a maximum of 2.538 litres and a minimum of 2.463 litres.

Given that the MTM II can work properly with the bottles charged from a minimum of

2.4 to a maximum of 2.6 litres, the above cited values are compatible with the correct

functioning of the processor in normal conditions (from 1 to 300 standard cassettes).

It is important to consider that the reagent bottles, as well as any kind of plastic object,

are subject to ample dimensional variations due to: manufacturing tolerances, ambient

temperature, reagent temperature, aging and wearing.

The two level indicators placed in the bottle front correspond to the above cited values.

But due to what explained about plastic objects dimensional variance their level may not

correspond exactly to 2.4 – 2.6 litres.

18 Manual_MTM_II_2021-10-010.00_EN.docx

Furthermore, to guarantee the almost complete reagent filling, the bottles are placed in

the instrument slots in a way to be 3.5° inclined toward the front. In this position the

indicators are not true. The upper one will correspond to approximately 2.5 litres.

So the indicators are made for usage with the bottle on the horizontal position, outside

the instrument, during manual filling.

7.15UNINTERRUPTIBLE POWER SOURCE (UPS)

The MTM II can be equipped with an optional UPS. To be recognized by the MTM II

computer the UPS must be enabled by this function, as well as it can be disabled in case

of malfunctions. Please note that both enabling and disabling are related only to the

MTM II computer -> UPS unit communications. Even if disabled by this function, the UPS

will continue to supply power to the MTM II but its state will not anymore shown and

considered. In case of an attempt to enable the UPS when the UPS is not installed, the

command will be refused. In case of serious malfunctions of the UPS it may be not

sufficient the software disabling, in this case it is advisable or necessary to physically

disconnect it from the MTM II. Please call our technical service to perform the repair or

the disconnection.

7.16SCREEN SAVER TIME

After a period of not utilization of the touch screen, the LCD screen is completely

switched off to extend its life span and save energy.

This function allows the setting of the panel ON time:

- the minimum time is 10 minutes

- the maximum time is 90 minutes

The tissue processor will continue to work perfectly even when the screen is switched

off, by touching any point in the screen surface it will be switched on in not more than

2 seconds and the MTM II computer will emit a beep to confirm. It is advisable to not

press more than one time the screen surface and wait for the screen data and pictures

to be visible before to perform any command. The first touch will not be considered a

command but any subsequent touch may be recognized as a command.

Manual_MTM_II_2021-10-010.00_EN.docx 19

7.17PASSWORD SETUP

The MTM II software includes a password system that allows the access restriction to

separate functions of the instrument.

Password general rules:

•

every time the password is requested there are 15 seconds time to type it and

press ENTER to confirm, after that time, if ENTER is not pressed, the system

goes back to the originating screen

•

in case of wrong password the system shows a specific error message and after

3 seconds goes back to the originating screen

•

after three wrong password insertions, the system issues the ALERT 34 (see

Alarms chapter), but the system continues to work and it is possible to continue

to type passwords

•

the password length is from 1 to 6 characters or numbers (mix is allowed)

•

also empty spaces are omitted in the password composition

20 Manual_MTM_II_2021-10-010.00_EN.docx

Enable/Disable Password

This function allows the enabling and disabling of the Password. If the password is not

active the systems requires the definition of a new one.

If the password is active the system allows the disabling by typing the current password

correctly. We recommend to carefully keep note of the password before the activation

because once activated there is no way to deactivate it without knowing it. In case the

password is lost it is necessary the intervention of our technical service to deactivate or

retrieve it!

During the activation the password is clearly shown on the screen to avoid typing

mistakes, later on, to avoid others to see the typed password, in place of letters or

number it is shown an asterisk.

Password modification

The password can be modified any moment from this function, but of course, the

modification is allowed only after the correct typing of the current password. We

recommend to carefully keep note of the new password before the modification

because once modified there is no way to deactivate or modify it without knowing the

current one. In case the password is lost it is necessary the intervention of our technical

service to deactivate or retrieve it!

Table of contents