Slee MCS II User manual

2 Manual_MCS_II_2021-10-003.00_EN.docx

Content

1. Safety Instructions.............................................................................................. 4

1.1. About this Manual.................................................................................................... 4

1.2. Used Symbols and their meanings ............................................................................. 4

1.3. Emission................................................................................................................... 5

1.4. Hazard Sources......................................................................................................... 5

1.5. Personal protective equipment .................................................................................. 5

1.6. Transport and stocking ............................................................................................. 6

1.7. Environmental conditions.......................................................................................... 6

1.8. Safety measures on installation location .................................................................... 6

1.9. Intended Use............................................................................................................ 7

1.10. Approved Operators.............................................................................................. 7

2. Information about MCS II .................................................................................. 8

2.1. Technical Data.......................................................................................................... 8

2.2. Shipment ................................................................................................................. 8

3. Overview components of the MCS II ................................................................ 9

3.1. Operating Panel Buttons ..........................................................................................11

3.2. Type plate ...............................................................................................................11

4. Operation.......................................................................................................... 12

4.1. Power-on the MCS II................................................................................................12

4.2. Main Screen (Setting 1)............................................................................................12

4.3. Setting 2 .................................................................................................................13

4.4. Conveyor operation .................................................................................................13

4.5. Operation menu ......................................................................................................13

4.5.1. Program setting................................................................................................14

4.5.2. Installation .......................................................................................................15

4.5.3. Individual operations.........................................................................................15

4.6. Installation of external exhaust system......................................................................18

4.7. Loading Xylol...........................................................................................................19

4.8. Loading mounting media.........................................................................................20

4.9. Adjusting the CG head ............................................................................................21

4.10. Start the process ..................................................................................................22

4.11. Power-off the device ............................................................................................23

4.11.1. Replace the xylol in the dispenser reservoir.....................................................23

4.11.2. Seaking the dispenser needle overnight .........................................................24

Manual_MCS_II_2021-10-003.00_EN.docx 3

5. Troubleshooting ............................................................................................... 25

5.1. The message window ..............................................................................................25

5.2. The alarm codes ......................................................................................................27

5.2.1. Definitions of alarm codes ................................................................................27

5.3. List of error codes....................................................................................................27

5.3.1. Motion errors ...................................................................................................27

5.3.2. Details of driver errors.......................................................................................28

Task errors......................................................................................................................29

5.3.3. System errors....................................................................................................29

5.3.4. Network errors .................................................................................................29

6. Cleaning, Maintenance and Recycling ............................................................ 30

6.1. Cleaning Instructions ...............................................................................................30

6.2. Cleaning and maintenance plan...............................................................................31

6.3. Abandonment / Recycling ........................................................................................31

4 Manual_MCS_II_2021-10-003.00_EN.docx

1. Safety Instructions

1.1. About this Manual

This manual will help you to handling the device. Please read the manual completely and follow

the advice. Acquaint yourself to the control elements and their functionality by studying the

figures. This way, an adequate use of the device, is ensured. If you have problems, feel free to

contact the competent SLEE medical GmbH contact person.

The device present is offered with two different power supply variations. Please check the tool

identification plate to make sure that the device’s power supply matches your local power supply.

Different power supply variations mean no difference in handling and functionality of the device.

1.2. Used Symbols and their meanings

Danger!:

This symbol warns you of risks for the life or health of persons. Danger warnings

are marked by a red framed triangle.

Warning!:

This symbol warns you of risks for machine, material or environment. Warnings are

marked with a yellow warning triangle.

Crushing hazard!:

Working with this machine contain crushing hazard from the movable parts.

Flammable hazard!:

Working with this machine contain flammable hazard from used reagents .

Notice:

Notices, meaning important information for the user, that are not classified as

danger or warning, are marked with an information symbol.

Manual_MCS_II_2021-10-003.00_EN.docx 5

1.3. Emission

The emission caused by the use of reagents in the unit is absorbed by the powerful fans and the

activated carbon filter, which need to be routine maintenance and output by targeted central

exhaust system. The connection for your exhaust system is already installed.

1.4. Hazard Sources

1.5. Personal protective equipment

When working with the MCS II, it is necessary, according to your security policies applicable in

any case, to wear protective clothings to avoid direct contact with the biologic samples. The same

applies, for example, when cleaning the unit.

Check your exhaust system for correct functionality before you start working with

the MCS II and reagents.

Many reagents and reagent vapors are flammable! Inform yourself before working

with the reagents.

Eat, drink and otherwise consume of reagents or reagent vapors are forbidden. Do

not eat, drink or smoke in the environment of the device. In case of absorb or

inhalations a reagent immediate seek medical advice!

The use of solvents always represents a danger for health! Observe the safety

regulations applicable!

Always wear protective clothing (e.g. lab coat, gloves,) to prevent accidental

contact with biological samples.

6 Manual_MCS_II_2021-10-003.00_EN.docx

1.6. Transport and stocking

Observe the following notes for transport and stocking the MCS II.

1.7. Environmental conditions

The permissible ambient conditions for operation of the device are listed below. Operation at

other ambient conditions is not permitted.

•Operation is only allowed in enclosed rooms,

•Ambient temperature from +15°C to +40°C (without strong fluctuations),

•Only set it on a vibration-free, the weight of the device corresponding

laboratory bench,

•Relative air humidity max 80% non-condensing,

•The unit must not be expos ed to direct sunlight,

•Maximum height of 2000 m (according to EN 61010-1:2001),

•Mains voltage fluctuation is within + / - 10 % of rated voltage.

1.8. Safety measures on installation location

The MCS II must be installed on a stable, level and horizontally oriented base to ensure the safe

and reliable operation.

"

Protect from wetness

": The packaged unit must be protected from excessive

humidity and must be stored and transported in covered.

„Top“: The packaged unit must always be transported and stored so that the

arrows point upwards at any time.

The MCS II is supplied in a safety transport box. Transporting them always upright

and avoid shocks and extreme temperature fluctuations! For the storage of the

device an ambient temperature of +5 ° C to +50 ° C is permissible.

Don’t use the device in an explosive area.

Manual_MCS_II_2021-10-003.00_EN.docx 7

1.9. Intended Use

The exclusive application of the Slee MCS II is the cover slipping of pathological, histological or

cytological slides with biologics on it. The device may only be used for this purpose, so as not to

endanger the safety of people and the preservation of property values of replacement issues.

1.10. Approved Operators

Only persons who have been thoroughly trained by the operator and commissioned can handle

the MCS II. The operator is responsible for other people in the work area. The operating company

make the instruction manual accessible to the operator and make sure, that the operator have

read and understand the instruction manual.

Unauthorized modifications to the device are forbidden due to safety reasons.

When replacement damaged parts of the device only original spare parts must be

used.

8 Manual_MCS_II_2021-10-003.00_EN.docx

2. Information about MCS II

2.1. Technical Data

Model

MCS II

Coverslipping speed:

10 to 20 sec per slide, changeable 7-shift speed

Dispensing volume:

0.04 to 0.2 cm³, adjustable

Mountant container

Commercially avaible container or our standard

container

Coverglass:

Size – Standard:

24 x 40, 50, 55, 60 mm

Size – Option:

24 x 32, 36 mm

25 x 40, 50, 55, 60 mm

Dimensions (L/W/H)

500 x 540 x 640 mm

Weight:

59 kg

Power supply:

230 V / 50 -60 Hz / 460 VA

2.2. Shipment

The shipment includes:

•1x MCS II

•1x Mains supply 230V

•1x Xylol container

•1x 3 magazine

•1x coverglass container 50mm and 60mm

•1x nozzle for dispenser 1,5mm

•2x reservoir xylol

•1x fill bottle

•1x duck bill

•4x Fuses, fine

•1x Instruction manual MCS II

Manual_MCS_II_2021-10-003.00_EN.docx 9

3. Overview components of the MCS II

Protection hood

Operating

panel

Pull-out magazine

for basket loading

Power switch

Mains socket

Type plate

10 Manual_MCS_II_2021-10-003.00_EN.docx

Connection for

external exhaust-

system

Unloading station for

basket

Coverglass container

Holder for

covermedium and

xylol container

Dispenser for

dispense the

mounting media on

the coverglass

Loading station for

basket

Holder for

covermedium

Xylol container to

prevent the

dispenser-nozzle for

drying-out

Motion-head to put

the coverglass on

the slides

Manual_MCS_II_2021-10-003.00_EN.docx 11

3.1. Operating Panel Buttons

3.2. Type plate

Power: Switch on the MCS II

Start /Restart: Starting the program

Light: Covermedium remaining quantity

Stop: Stop the running program

Finger: Opening and closing the OT holders

Emergency: Immediately stop the running programn

Serial number of the

device

Rated voltage of the

device in V

Type of device

Device ouput in VA

Fuse type

Rated frequency of

the device in Hz

12 Manual_MCS_II_2021-10-003.00_EN.docx

4. Operation

4.1. Power-on the MCS II

Plug in the power cable into the power-socket (backside of the device). Switch the power-switch

in the “I”-position. Press the Power button to turn on the MCS II. When the system starts, the

standby screen appears.

After the device is started, the main screen is displayed on the screen

4.2. Main Screen (Setting 1)

Operation mode

with counter for

covered baskets

Program number

Actual used size of

cover glass

Cycle time for the

dispense process

Change the amount

of the mountting

medium

Buttons for entering

the different menus

Dispense method

Manual_MCS_II_2021-10-003.00_EN.docx 13

4.3. Setting 2

4.4. Conveyor operation

This button is used to switch to the screen for the individual operations of the conveyor belt

control. You can carry out the withdrawal or removal of the cage container. This button is

disabled while the unit is running (it can not be operated).

4.5. Operation menu

Use to change the values of the different parameter.

The menus

Maintentance

,

Test run

,

Maintenance menu

and

Language

change are only for service technican.

Change the length

of the conintuous

discharge between

10-40 mm

Change the position

of the intermittent

discharge between

0-30 mm

Change the

mounting speed of

the covering

between 60-120 rpm

Change the

discharge amount

between 1 - 10

14 Manual_MCS_II_2021-10-003.00_EN.docx

4.5.1.Program setting

4.5.1.1. Program setting 1

4.5.1.2. Program setting 2

Program 0

can not be edit. You can only edit program 1-4.

Change the number

of the program

between 1-4 which

you want to edit.

Change the cycle

time for the

complete covering-

process between 12-

20 sec

Change the amount

of discharge

between 0-250

Press this button to

save the changed

parameters

Change the number

of the program

between 1-4 which

you want to edit.

Change the length

oft he used cover

glass

Change the width of

the used cover glass

Press this button to

save the changed

parameters

Manual_MCS_II_2021-10-003.00_EN.docx 15

4.5.1.3. Program setting 3

4.5.2.Installation

This button is used to switch to the screen where the liquid is filled for the axis of the pump, as

well as the attachment and detachment of the xylene bottle.

4.5.3.Individual operations

This button is used to switch to the screen on which the individual operations are performed for

each individual axis.

Only use this menu when instructed by telephone by a service technician to rectify

faults.

Change the number

of the program

between 1-4 which

you want to edit.

Change the length

of the conintuous

discharge between

10-40 mm

Change the position

of the intermittent

discharge between

0-30 mm

Change the

mounting speed of

the covering

between 60-120 rpm

Change the

discharge amount

between 1 - 10

Press this button to

save the changed

parameters

16 Manual_MCS_II_2021-10-003.00_EN.docx

4.5.3.1. CG Head

You can use the CG head menu to control a single deck process by pressing and holding the

keys. The suction of the coverslips is activated with the [Suction ON] button. Press the [Suction

ON] button again to turn off the suction of the covers.

The [Positiv rotation] key forwards the DG head forward. The [Reverse rotation] key allows the

CG head to be reversed.

4.5.3.2. Pump operation

Press the [Pump] key to enter the Dispenser control menu.

You can use the pump menu to control the dispenser by pressing and holding the Suction /

Discharge buttons. Press and hold the [Suction] button to turn on the pump for the cover glass

suction, press the [Single discharge] key to start the application of the cover media.

The valve of the dispensing opening of the pump can be opened and closed with the [Valve

open] key. If the pump valve is left in the open state for more than 20 seconds, the pump valve

closes automatically. The current status of the pump valve can be determined using the [valve

open] key:

•[Valve open] is lit: Pump valve is open.

•[Valve open] does not light: Pump valve is closed.

If the pump valve remains open for a long time, there is a risk that the pump

(dispenser) will heat up strongly.

Individual operation

button

Solenoid valve

on/off button

Reset button

Individual operation

button

Single discharge

button

Limit lamps

Reset button

Valve open / close

Manual_MCS_II_2021-10-003.00_EN.docx 17

4.5.3.3. Elevator operation

Press “Elevator” to enter the elevator control menu. You can use the elevator menu to control

the lift by pressing and holding the “Up” / “Down” button. The elevator is controlled until you

release the buttons. Press “Single layer move” to raise / lower the elevator by one step.

4.5.3.4. Conveyor operation

Press “Conveyor” to enter the conveyor control menu.

Use “Container in” / “Container out” to control the conveyor belt axis. The conveyor belt is only

controlled until you release the buttons. Press “Positioning” for at least 2 seconds to move the

conveyor to the position where the slides are detected. If you press Positioning” for less than 2

seconds, positioning is not performed.

If no basket container with object carriers is used on the conveyor belt axis, the

positioning can not be performed correctly.

Individual operation

button

Limit lamp

Single move button

Reset button

Individual operation

button

Conveyor position

button

18 Manual_MCS_II_2021-10-003.00_EN.docx

4.5.3.5. Finger operation

Press “Finger” to enter the finger control (gripper) menu.

Use the Finger menu to control the finger by pressing and holding “Up” / “Down”. The finger is

controlled until you release the buttons.

4.5.3.6. Fan setting

This button is used to switch to the screen for the use and adjustment of the exhaust fan and

the drying fan.

4.6. Installation of external exhaust system

You can choose on which side the external exhaust

system can be installed. Remove the connection for

the external exhaust system on the left or right side.

Before you connect the adapter for the external

exhaust system connect the cable from the device

(P504-L) with the cable from your external exhaust

system (J504). For the installation on the right side

connect the cable (P504-R) with the cable from your

external exhaust system (J504).

Now connect the Adapter for the external exhaust

system (the picture shows the installation on the left

side). After this install the removed cover on the

other side of the device.

Individual operation

button

Limit lamp

Finger open / close

button

Reset button

On / off buttons for

the exhaust fan

On / off buttons for

the drying fan

Manual_MCS_II_2021-10-003.00_EN.docx 19

4.7. Loading Xylol

Fill the xylol in the xylol container between the min and max marks.

Take the fill bottle from the accessorie kit and fill the bottle with xylol. Now put the nozzle in the

small hole of the second xylol container and fill the second container with xylol to the marked

line in the picture.

Please refill the xylol bottle frequently to prevent the covering prcoess against

bubbles in the mounting media.

Check daily whether the cotton is soaked with xylene. If not, top up the xylene

until the cotton is completely saturated.

The level of the

container should

always be between

the two markings

Use the fill bottle

from accessorie kit

Put the nozzle in the

small hole and fill the

container to the red

line with xylol

20 Manual_MCS_II_2021-10-003.00_EN.docx

4.8. Loading mounting media

To fill the system with mounting media proceed as follow:

1. Purge the system with xylol if you fill the system for the first time.

2. Remove the cover from the mounting media bottle and connect the cover with the tube

from the MCS II. After this connect the bottle with the MCS II.

3. Close the bottom drawer and the hood.

4. Start the MCS II by pressing the ON switch.

5. Press “Operation menu” at the main display to go into the operation menu.

6. Press “Installation”.

7. Press “Start” for about 2-5 seconds to start the system. Whenever the button “Start” is

lighting blue, the system is operating.

8. Press “Finish” to stop the system.

9. If the button “Start” do not light up blue anymore, the system has finished the process.

10. Press “Return” to go to the operation menu.

If you loading the mounting media at the first time make sure that you purge the

system with xylol before you fill the system with mounting media.

To abort the process, press the button “finish” for about 2-5 seconds.

Should you put the MCS II back into operation after a longer service life, then rinse

the roofing system with xylene before filling in the roofing material.

If the pump valve remains open for a long time, there is a risk of overheating the

pump dispenser.

Table of contents

Other Slee Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Leupold

Leupold RX-1000i Operation manual

Essilor Instruments

Essilor Instruments TEN 070 user manual

FMC

FMC INVALCO WCM 7300 Installation & operation manual

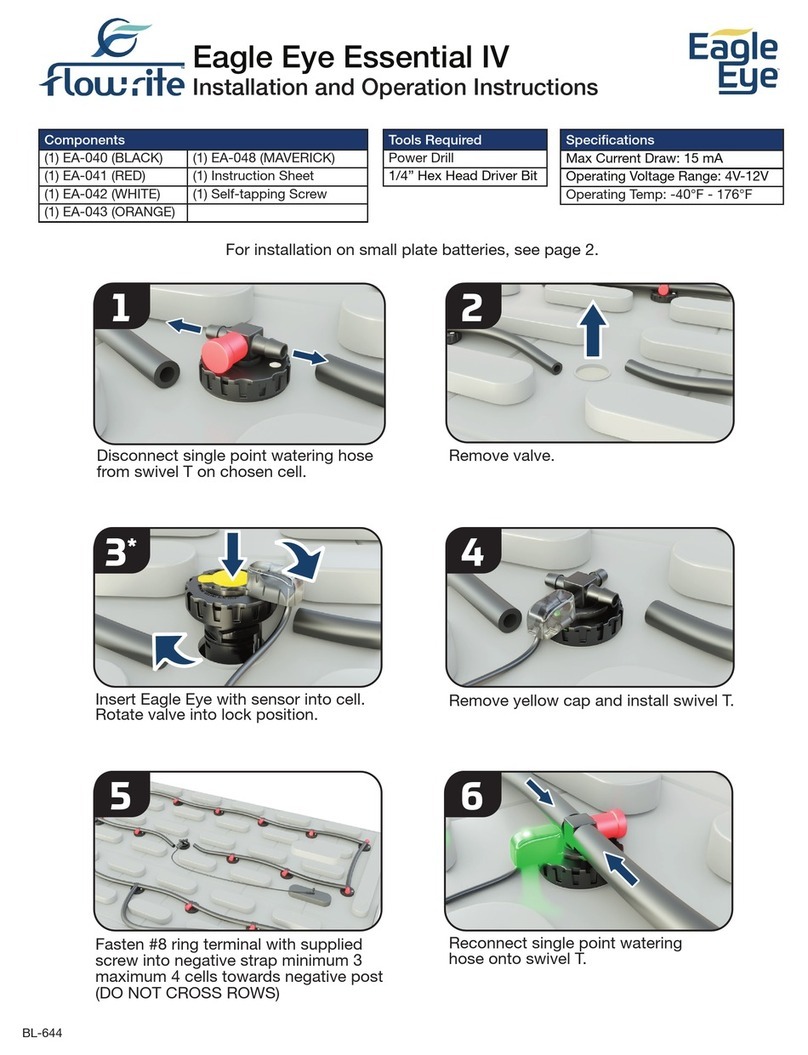

Flow-Rite

Flow-Rite Eagle Eye Essential IV Installation & operation instructions

RS PRO

RS PRO RS-3809 instruction manual

TOTALINE

TOTALINE MultiRef User and service manual