FKM FKM3016C User manual

Model No. FKM3016C

Contents

Before Use

1. Preparations before Use

2. Safety Instructions

3. Icon Explanation

4. Maintenance

Product Description

1. Part Name

2. Switches and Keys Instructions

3. LCD Display

About the Instrument

1. Overview of the Instrument

2. Technical Indicators

Operation Guide

1. Data Holding

2. Frequency / Duty Cycle Switching

3. The Maximum and Minimum Value Measurement

4. RAN Measurement

5. Function Exchange

6. REL Measurement

7. Backlight and Clamp Head Lighting

8. Auto Shutdown

9. Buzzer

10. Measurement Preparation

11. Current Measurement

12. Voltage Measurement

13. Frequency / Duty Cycle Measurement

14. Resistance Measurement

15. Diode Test

16. Continuity Test

17. Capacitance Measurement

---------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------

------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

-------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------

--------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------

--------------------------------------------------------------------------------

---------------------------------------------------------------------------------

-------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------

--------------------------------------------------------------------------

----------------------------------------------------------------------

-------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------

-------------------------------------------------------------------

----------------------------------------------------

--------------------------------------------------------------------

--------------------------------------------------------

-----------------------------------------------------------

------------------------------------

-----------------------------------------------------------------------------

---------------------------------------------------------------------

---------------------------------------------------------------

------------------------------------------------------------------------

1

1

2

2

3

3

4

5

5

6

6

6

11

11

11

11

12

12

12

12

13

13

13

14

15

15

17

17

18

18

18. Temperature Measurement

Non-contact Voltage(NCV) Detection

Battery & Test Leads Replacement

1. Replace the Battery

2. Replace the Test Leads

Accessories

Disclaimer

Warranty

Contact Us

----------------------------------------------------------------

------------------------------------------------

-------------------------------------------------------

-------------------------------------------------------------------------------

-------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

19

20

20

20

21

21

21

22

23

Before Use

Warning

To avoid electric shock or injury, please read the "Safety Instructions"

and all relevant parts before using this product.

In order to give full play to the functions of the instrument and ensure

safety, please read and follow this manual carefully.

This instrument strictly follows GB/T 13978-92 generic specification for digital clamp

meter, in accordance with GB4793.1-1995(IEC-61010-1, IEC-61010-2-032)electronic

measuring instruments safety requirements, and belongs to the class-two of pollution.

The voltage standard is CAT IV 600V and CAT III 1000V.

Please follow the safety instructions, ensure the safety use of the instrument.

Use and protect the item in the right condition, the instrument will be in satisfactory

service.

The user must comply with the standards of safety rules when using this instrument:

After receiving the instrument, check whether it is damaged in transportation.

If the instrument is stored or shipped under poor conditions, check and confirm

whether the instrument is damaged.

Inspect the test leads before use. Do not use them if the insulation is damaged or

metal is exposed.

Use the test leads provided with the instrument to ensure safety. If you need to

replace the test leads, please replace them of the same or similar grade.

- To protect against electric shock

- To prevent the misuse of the instrument

1. Preparations before Use

Use the instrument as described in the manual and within the correct ranges.

During measurement, do not exceed the indicated value of the protection range of

each test.

When measuring circuit, do not touch the test leads tip (the metal part).

During the measurement, if the measured voltage is higher than 60V DC or 30V AC

(RMS), keep fingers behind the finger guards at all times.

Do not attempt to measure any voltage that might exceed AC 750V between the mea-

suring terminal and the ground.

Before turning the rotary switch to change the measurement function, the test leads

should be removed from the circuit under test.

Do not measure resistance, capacitance, diode and circuit continuity when the circuit

is connected.

Under the test of current, resistance, capacitance, diode and continuity, beware to

avoid connecting the meter to the power source.

Do not measure the capacitance before the capacitor is fully discharged.

Do not operate the instrument around explosive gas, vapor, or dust.

If there is any abnormality or malfunction of the instrument, stop using it immediately.

The instrument should not be used unless the bottom shell and the battery cover are

fully fastened in place.

Do not store or use the instrument in direct sunlight, high temperature or high humid-

ity conditions.

2. Safety Instructions

3. Icon Explanation

CAT III

Important information

Can be used for dangerous live conductor

Double insulated

In line with FCC certification

Ground

In accordance with the IEC-61010-1 over-voltage

standard (installation) level III. The pollution degree 2

refers to the pulse voltage protection levels.

Product Description

Please do not attempt to open the bottom shell to adjust or repair the instrument.

Such operations can only be performed by technicians who fully understand the

instrument and the danger of electric shock.

Remove the test leads from the circuit under test before opening the bottom shell of

the instrument or the battery cover.

To avoid false readings causing electric shock, replace the battery immediately when

the instrument displays “ ” symbol.

Use a damp cloth and mild detergent to clean the instrument; do not use abrasive

detergents or solvents.

When the instrument is not in use, turn off the power and turn the switch to the

“OFF” position.

If the instrument will not be used for a long time, the battery should be taken out to

prevent damage to the instrument.

4. Maintenance

This meter is a portable professional measuring instrument with an LCD digital display

and backlight, which is convenient for users to read. The switch can be operated with

one hand for easy measurement. Together with overload protection and a low battery

indicator, it is an ideal multi-functional instrument, whether used by professionals,

factories, schools, enthusiasts, or families.

Used for AC current, AC voltage sine wave true RMS value, DC voltage, frequency, duty

cycle, resistance, capacitance measurement and continuity, diode test, temperature

measurement and non-contact voltage detection.

Auto Ranging

Data Holding

Maximum Measurement Function

Minimum Measurement Function

Peak Measuring

Surge Measurement

Auto Shutdown

Relative Measurement

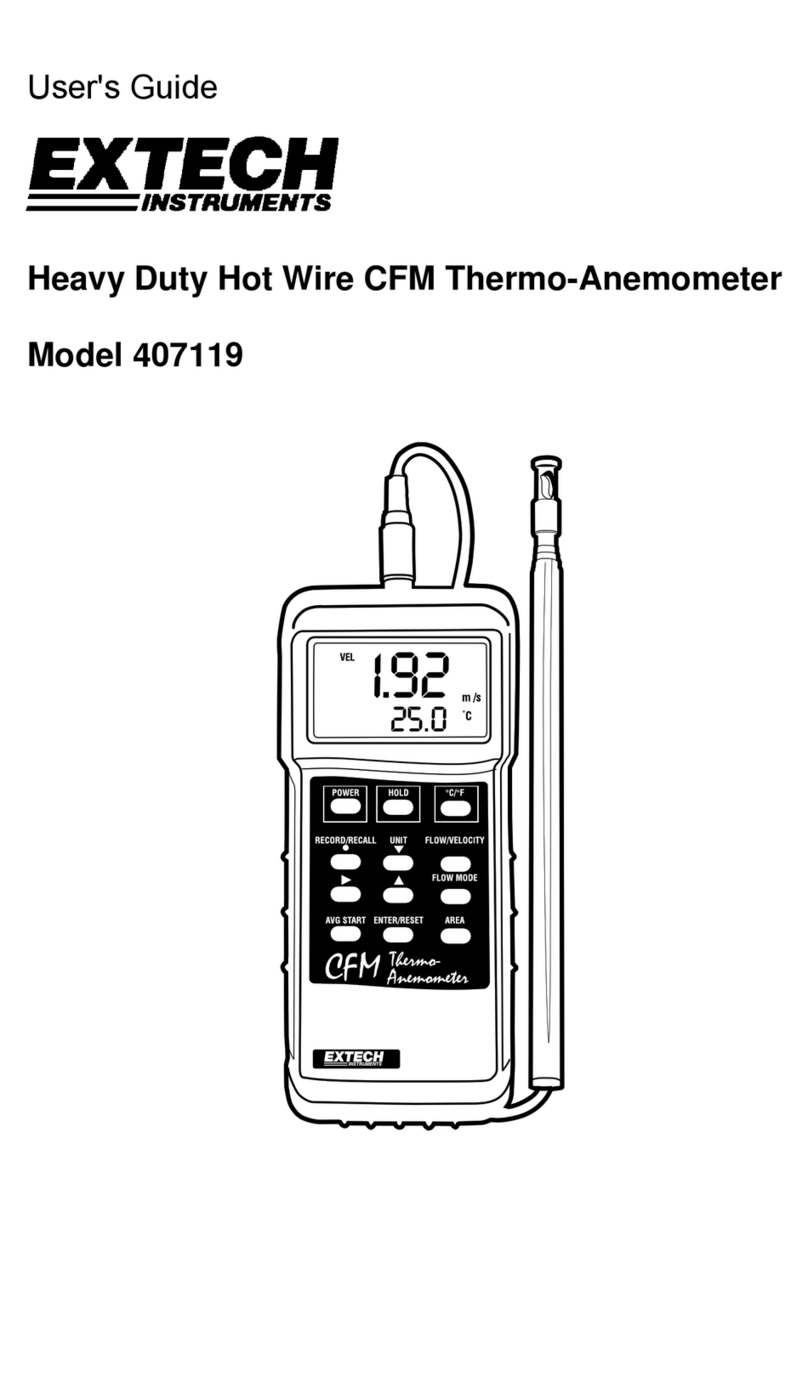

1. Part Name

Current Sensing Clamp: for current measurement

Flashlight

Panel

Trigger

Function Keys (SEL)

Relative Value / Frequency / Duty Cycle Switching Key (REL/Hz%)

Auto/ Manual Range Switching Key (RAN)

LCD Display Screen

COM Terminal

INPUT Terminal (for Resistance, Capacitance, Voltage, Frequency, Diode and Continuity)

Maximum / Minimum Button (MAX/MIN)

Data Hold Switch / Backlight Button ( )

Rotary Function Switch

HOLD

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

910

11

12

13

2. Switches and Keys Instructions

3. LCD Display

HOLD Key: For data holding or backlight control.

SEL Key: For function switching.

RAN Key:Switch between manual and automatic measurement functions.

REL/Hz% Key: For relative measurement / frequency measurement / duty cycle mea-

surement.

MAX/MIN Key:To switch the maximum and minimum measurement functions.

OFF:Used to turn off the meter.

INPUT Terminal: Voltage, resistance, capacitance, frequency, duty cycle, diode, conti-

nuity, temperature and other input terminals.

COM Terminal:Voltage, resistance, capacitance, frequency, duty cycle, diode, continui-

ty and temperature common terminal.

Rotary Function Switch: To select the function and range.

AC, DC

AUTO

P MAX-MIN

INRUSH

REL

H

%%

℃, ℉

AC / DC

Diode Test, Continuity Test

Automatic Range

Peak Hold

Inrush current measurement status

Relative Measurement Mode

Temperature Measuring Mode

Low Battery

Data Hold

mV, V

nF, μF, mF

A

Ω, kΩ, MΩ

Hz, kHz, MHZ

MV, V

AMPERE (CURRENT)

nF, μF, mF

Ω, KΩ, MΩ

HZ, KHZ,MHZ (FREQUENCY)

1. Overview of the Instrument

2. Technical Indicators

The instrument shall specify the period of one year, and needs to be recalibrated under

the conditions of 18 ℃ (64.4℉) ~ 28 ℃ (82.4℉) and relative humidity less than 75%.

Automatic Measurement and Manual Measurement

Overload Protection

The Maximum Voltage Allowed between the Measuring Terminal and Earth: 1000V DC or

750V AC

Working Height: Maximum 2000m

Environment Temperature: 23±5℃ (73.4±41℉)

Relative Humidity: <75%

Display: LCD

Maximum Display Value: 5999

Polar Indication: Automatic indicator, '-' indicates negative polarity

Over Range Display: ‘0L’ or ‘-0L’

Sampling Time: about 3 times / sec

Display Unit: function / power

Auto Shutdown: 15 Minutes

Power: DC current 4.5V

Battery: 1.5V AAA

Battery Under-voltage Indication:

Temperature Coefficient: lower than 0.1 × Accuracy / ℃

Operating Temperature: 18 ℃ (64.4℉)~ 28 ℃(82.4℉)

Storage Temperature: -10℃ (14℉)~ 50℃ (122℉)

The maximum size of jaw opening: about 36mm (1.4 inches)

The maximum wire diameter that can be measured by the jaw: about 26mm (1 inch)

Size: 208 × 78 × 35mm(8.2×3.1×1.2 inches)

Weight: about 240g (8.5 oz)(Including battery)

About the Instrument

2.1 True RMS

2.2 AC Current

2.3 DC Voltage

Range

6A

60A

600A

Resolution Accuracy

±(2.5% + 10)

0.001A

0.01A

0.1A

For the measurement of sine wave signal, the true RMS measurement method has less

error than the traditional average response method.

The RMS meter can accurately measure the sine wave signal, but if the measured

signal is not input in the AC function (in the AC voltage function, the input terminal is

short-circuited), the clamp meter may display a value between 1 and 50. These devia-

tions are normal. Within the specified measurement range, they will not affect the

accuracy of the meter in measuring AC.

True RMS requires the input signal to reach a certain level before measurement.

Therefore, the range of AC voltage and current is specified between 2% and 100% of

full scale.

In the small voltage range, if the test leads are not connected to the circuit under test, the

meter may have a pulsating reading. This is normal. This is caused by the high sensitivity

of the meter and does not affect the actual measurement result.

Range

600mV

6V

60V

600V

Resolution Accuracy

±(1.0% + 5)

0.1mV

0.001V

0.01V

0.1V

- Maximum Input Current: 1000A AC

- Frequency Range: 50Hz

- Input Impedance: 10MΩ

- Maximum Input Voltage: 600V AC(Effective value)or 600V DC

Notice:

2.4 AC Voltage

2.5 Frequency

2.5.1 Through the V file:

In the small voltage range, if the test leads are not connected to the circuit under test, the

meter may have a pulsating reading. This is normal. This is caused by the high sensitivity

of the meter and does not affect the actual measurement result.

- Range: 10 ~ 10kHz

- Input Voltage Range: ≥ 2V AC (Effective value) (With the increase of the measured

frequency, the input voltage should be increased accordingly.)

- Input Impedance: 10MΩ

- Maximum Input Voltage: 600V AC (Effective value)

- Frequency: 10 ~ 1kHz

- Input Current Range: ≥ 20A AC (Effective value)

- Input Max Current: AC 6000A

Range

6V

60V

600V

Resolution Accuracy

±(1.0% + 5)

±(1.2% + 5)

0.001V

0.01V

0.1V

Range

99.99Hz

999.9Hz

9.999kHz

Resolution Accuracy

±(0.5% + 5)

0.01Hz

0.1Hz

0.001kHz

- Input Impedance: 10MΩ

- Maximum Input Voltage: 600V AC(Effective value)or 600V DC

- Frequency Range: 40 ~ 1000Hz

2.5.2 Through A File (From Clamp):

Notice:

2. 6 Duty Cycle

2.7 Resistance

Range

0.1 ‒ 99.9%

Resolution Accuracy

±3.0%0.1%

Range

600Ω

6kΩ

60kΩ

0.1Ω

0.001kΩ

0.01kΩ

0.1kΩ

0.001MΩ

0.1MΩ

600kΩ

6MΩ

60MΩ

Resolution Accuracy

±(0.8% + 3)

±(1.2% + 3)

- Frequency Response: 10 ~ 1kHz

- Input Current Range: ≥ 20A AC (Effective value)

- Maximum input current: AC 1000A

- Test Leads Circuit Voltage: about 0.4V

- Overload Protection: 250V DC or AC (Effective value)

- Frequency Response: 10 ~ 10kHz

- Input Voltage Range: ≥ 2V AC

- Input Impedance: 10MΩ

2.6.1 Through A file(From the clamp head):

2.6.2 Through the V file:

2.8 Continuity Test

2.9 Capacitance

2.10 Diode Test

Range

9.999nF

99.99nF

999.9nF

9.999μF 0.001μF

99.99μF 0.01μF

999.9μF 0.1μF

9.999mF 0.001mF

0.01mF

99.99mF

Resolution Accuracy

±(3.0% + 5)

±(5.0% + 5)

Uncalibrated

0.001nF

0.01nF

0.1nF

Range Resolution Accuracy

0.1Ω

- Overload Protection: 250V DC or AC (Effective value)

- Overload Protection: 250V DC or AC (Effective value)

- Positive DC Current: 1mA

- Reverse DC Voltage: 3.0V

- Overload Protection: 250V DC or AC (Effective value)

If the resistance of the tested circuit

is less than 50, the buzzer in the

meter may sound. If it is less than 10,

the buzzer will definitely sound.

Range Resolution Function

0.001V Show the approximate diode

forward voltage value.

In the process of measurement, if you need to hold the data, press the “ ”key,

and the value on the display will be locked. Press this key again to release the data hold.

When the meter is in the AC voltage and AC current range, if you press and hold the “

REL/Hz/%”key for more than 2 seconds, the meter will change to “Hz” measure-

ment, which will measure the frequency of the measured AC voltage and AC current

signal. Press the “REL/Hz/%”key again, and the meter will change to “%” mea-

surement, which will measure the duty cycle of the measured voltage and current

signals.

Press the “MAX MIN” key to enter the manual range mode and display the maxi-

mum value; press this key again to display the minimum value; press this key for the

third time to display the difference between “Max-Peak Min"; Repeat this cycle. Press

the “MAX MIN” key for more than 2 seconds to exit this mode.

After entering the Max mode, the measured maximum value is automatically saved.

After entering the Min mode, the measured minimum value is automatically saved.

After entering the Max-Min mode, the measured difference is automatically saved.

Press the “MAX MIN”key for more than 2 seconds to exit this mode, and then the

instrument is restored to the normal measurement state.

The meter cannot switch to frequency and duty cycle measurement mode in the maxi-

mum/minimum measurement state.

Operation Guide

1. Data Holding

2. Frequency and Duty Cycle Switching

3. The Maximum Value and Minimum Value Measurement

HOLD

If you press the “REL/Hz/%”key again, the meter will return to the state of measur-

ing voltage and current.

Notice:

The “RAN” key is an automatic/manual range switch key, which acts in a trigger mode.

When the meter is turned on or the rotary switch is turned, the preset range is auto range.

Click the “RAN” key to switch to manual range. In the manual range mode, each time

you press this key, you will jump one level up, and when you reach the highest level, press

this key again to jump to the lowest level, cycling in turn. Manual range is not set for

frequency and capacitance measurement. If you press the “RAN” key for more than 2

seconds or the rotary switch is switched, the manual range state will be exited.

In the resistance mode, press the“SEL” key to cycle through the four levels of resis-

tance, diode, continuity detection, and capacitance.

In the voltage mode, press the“SEL” key to switch between DC and AC.

In the temperature mode, press the “SEL”key to switch between ℃ and ℉.

The “REL” key is a relative value measurement key, which acts in a trigger mode.

When this key is touched, it enters the relative value measurement mode. The current

displayed value is stored in the memory as a reference value. In future measurement,

the displayed value is the difference between the input value minus the reference

value.

That is, REL△ (current reading) = input value - reference value.

Relative value measurement can only be performed within a certain range, that is to

say, this function is only available in manual measurement mode.

In the process of measurement, if the ambient light is too dark, which makes reading

difficulties, you can press the “ ”key for more than 2 seconds to turn on the

backlight, and it will automatically shut down in about 30 seconds.

After the backlight is turned on, press and hold the “ ” key for more than 2

seconds to turn it off.

In the Current range, the instrument will turn on the clamp head lighting while turning

on the backlight. The luminous body of the backlight is LED, and its working current is

relatively large. Although the meter is set to turn off regularly (the timing time is about

30 seconds), frequent use of the backlight will shorten the battery life. Therefore, in

unnecessary cases, the use of backlight should be minimized.

4. RAN Measurement

5. Function Exchange

6. REL Measurement

7. Backlight and Clamp Head Lighting

HOLD

HOLD

When the battery voltage ≤ 3.9V, the display shows “ ” (under voltage) symbol. But

in the case of using the backlight, when the battery voltage ≥3.9V, the battery voltage will

drop due to the large working current, and the “ ”symbol may be displayed (when

the “ ”symbol is displayed, the accuracy of the measurement is not guaranteed). At

this time, the battery does not need to be replaced, and it can be used normally without

the backlight source until the“ ”symbol is displayed.

If there is no operation within 15 minutes after starting up, the meter will enter the

sleep state and automatically shut down to save power. 1 minute before shutting

down, the buzzer will give 5 prompts, and it will enter the sleep state after a long sound

before shutting down.

After the auto shutdown, press the “SEL” key, and the meter will resume working

status.

If you press and hold the “SEL” key while powering on, the auto shutdown function

will be cancelled.

When pressing any key or turning the function rotary switch, if the function key is valid,

the buzzer will issue a “Beep” sound (about 0.25 seconds). When the measured voltage

or current is greater than the set alarm value, for example, the AC voltage is greater than

600V, the DC voltage is greater than 600V, or the AC / DC current is greater than 600A, the

buzzer will continue to sound as an over-range warning. About 1 minute before auto shut-

down, the buzzer will emit 5 consecutive warnings, and before shutdown, the buzzer will

emit a long warning; when the automatic shutdown function is cancelled, 5 consecutive

warnings will be emitted every 15 minutes.

Turn the rotary switch to turn on the power. If the battery voltage is insufficient

(approximately ≤3.9V), the display shows the “ ”symbol, and the battery should

be replaced at this time.

The “ ” symbol means that the input voltage or current should not exceed the

indicated value. This is to protect the internal circuit from being damaged.

8. Auto Shutdown

9. Buzzer

10. Measurement Preparation

Notice:

Warning

The risk of electric shock.

Remove the test leads from the meter before measuring with the current clamp.

Set the rotary switch to the required measurement function and range.

When wiring, connect the common test line first, and then connect the live test line.

When removing the wiring, the live test wire should be removed first.

11. Current Measurement

Set the range switch to the A range position. At this time, it is the AC current measure-

ment state, and select the appropriate range.

Hold the trigger to open the clamp head, and clamp a wire of the tested circuit in the

clamp.

Read the current value on the LCD display.

During measurement, clamping two or more wires of the tested line at the same time

will lead to failure to obtain correct measurement results.

In order to obtain accurate readings, center the wire under test in the clamp as much

as possible.

“ ” means that the maximum input AC current is 600 A.

When measuring current, please press the trigger to open the clamp head, use the

clamp head to clamp the conductor to be measured, and then slowly release the

trigger until the clamp head is completely closed. Please check whether the conductor

is centered in the clamp. If it is not centered in the clamp, additional errors will occur.

The clamp meter can only measure one current conductor at a time. If two or more

current conductors are measured at the same time, the measurement reading would

be wrong.

Notice:

Warning

The risk of electric shock.

Take extra care to avoid electric shock when measuring high voltages.

Do not input a voltage higher than the effective value of AC 600V.

Warning

The risk of electric shock.

Take extra care to avoid electric shock when measuring high voltages.

Do not input a voltage higher than the effective value of AC 750.

12. Voltage Measurement

13. Frequency and Duty Cycle Measurement

13.1 Voltage

Insert the black test leads into the COM terminal and the red test leads into the INPUT

terminal, and select the appropriate range.

Turn the rotary switch to the position. At this time, the instrument is in the DC

voltage measurement state. To measure AC voltage, press the “SEL” key to enter

the AC voltage measurement state.

Connect the test leads to both ends of the voltage source or load for measurement.

Read the voltage value on the LCD display.

In the small voltage range, if the test leads are not connected to the circuit under test,

the LCD will have a beat reading, which is normal. This is due to the high sensitivity of

the instrument. When the instrument is connected to the circuit under test, the real

measured value will be obtained.

In the relative measurement mode, the auto range is invalid.

“ ” means that the maximum input voltage is 600V AC or 600V DC.

If the reading measured by the meter is greater than 600V RMS AC, a "Beep" alarm will

sound.

Notice:

Warning

The risk of electric shock.

Remove the test leads from the meter before measuring with the current clamp.

13.2 AC Current

Insert the black test leads into the COM terminal and the red test leads into the INPUT

terminal.

Set the rotary switch to the position, and press the SEL key to enter the AC voltage

measurement state.

Long press “REL/Hz/% ”key to switch to the state of frequency measurement.

Connect the test leads to both ends of the signal source or load for measurement.

Read the voltage value on the LCD display.

Press the “REL/Hz/% ” key again to enter the duty cycle measurement state.

Set the range switch to the A range position. At this time, it is the AC current measure-

ment state, and select the appropriate range.

Hold the trigger to open the clamp head, and clamp a wire of the tested circuit in the

clamp.

Long press the “REL/HZ/%” key to switch to frequency test position.

Read the measurement data on the LCD display.

Press the “REL /Hz/%”key again to enter the duty cycle measurement state.

The measuring range of frequency is 50Hz ~ 100Hz.

The minimum input current is 20A.

“ ”means that the maximum input current is 600A AC (effective value).

The frequency measurement range is 10Hz ~10kHz. If the measured frequency is lower

than 10Hz, the LCD will display “00.0”. The measurement of frequencies below

10kHz is possible, but the accuracy is not guaranteed.

The measuring range of duty cycle is 10 ~ 95%.

“ ” means that the maximum input voltage is 600V AC (RMS).

Notice:

Notice:

Table of contents

Popular Measuring Instrument manuals by other brands

National Instruments

National Instruments PXIe-5668R Getting started guide

dacell

dacell DN-330 user manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS ICP X603C01 Installation and operating manual

Spectral Evolution

Spectral Evolution PSR-1100f Operator's manual

UEi

UEi Auto 2-2 instruction manual

MKS

MKS Ophir NOVA II quick reference