Slee MPS P I User manual

DESIGN &

MANUFACTURING

MADE IN GERMANY

O P E R A T I N G

M A N U A L

EMBEDDING CENTERS

MPS P I / MPS P II

MPS P, W, C / CX

COMPACT AND MODULAR

PARAFFIN EMBEDDING CENTER,

DISPENSING MODULE,

PREWARMING MODULE,

COOLING MODULE

2/28 Manual_MPS_2021-10-022.00_EN.docx

Manual_MPS_2021-10-022.00_EN.docx 3/28

CONTENTS

1. INTENDED USE

................................................................ 4

2. SYMBOLS

................................................................ 4

3. SAFETY NOTES

................................................................ 5

4. COMPONENTS

................................................................ 6

5. SPECIFICATIONS

................................................................ 7

6. UNPACKING AND INSTALLATION

................................................................ 9

7. OPERATION

................................................................

10

8. MAINTENANCE

............................................................... 22

9. SERVICE

...............................................................

23

10. OPTIONAL ACCESSORIES

............................................................... 24

11. WARRANTY

............................................................... 26

12. DISPOSAL

............................................................... 26

4/28 Manual_MPS_2021-10-022.00_EN.docx

1. INTENDED USE

The paraffin wax embedding center type MPS P I and MPS P II are intended for embedding

histological tissue specimens in molten paraffin (wax) for use in pathology laboratories.

The modular system MPS P II consists of the paraffin dispensing element MPS P, the

preheating station MPS W and the cooling plate MPS C. All systems can easily be

upgraded with additional preheating stations or cooling plates.

MPS P consists of a heated paraffin container (capacity 5.5 liters; 30 – 80 °C), a heated

working area (450 x 240 mm; 30 – 80 °C) and a cooling spot (50 x 50 mm, down to

-5 °C). Optionally heated forceps for orientation of the specimen during embedding are

available.

MPS P I consists of a heated paraffin container (capacity 3.8 liters; 30 – 80 °C), a heated

working area (450 x 240 mm; 30 – 80 °C), two heated cassette and mould storage

containers (30 – 80 °C) for 120 cassettes and 250 embedding molds and a cooled working

area. Optionally heated forceps for orientation of the specimen during embedding are

available.

MPS W is a preheating station (30 – 80 °C) with heated areas and containers for storage

and preparation of approx. 500 moulds and embedding 320 cassettes.

MPS C is a cooling plate with a comfortable working area of 370 x 270 mm (capacity of

approx. 80 cassettes) made of anodized aluminum. The system easily cools down to

-15 °C*.

MPS CX is a cooling plate with a huge comfortable working area of 570 x 270 mm

(capacity of approx. 120 cassettes) made of anodized aluminum. The system easily cools

down to -15 °C*.

* All temperature specifications refer to an ambient temperature of + 20 °C and a relative humidity of 60 %.

2. SYMBOLS

Dangers, warnings and cautions are marked by this symbol.

i Special instructions regarding the operation of the device

are marked by this symbol.

Hot surfaces are marked by this symbol. Avoid direct

contact to prevent risk of burning.

Manual_MPS_2021-10-022.00_EN.docx 5/28

3. SAFETY NOTES

Slee paraffin wax embedding center are provided with the following safety features:

MPS P MPS P I

Hand heat protectors

•

•

In order to guarantee the performance of the device and ensure safe operation, the user

must observe the instructions, recommendations and warnings.

Magnifier:

Risk of glare and injury! Never look into the sun or any other

bright light source with optical devices! Do not look directly

into the light source. Fire hazard!

Lenses in optical devices can cause considerable damage due

to the "burning glass effect" if improperly handled or stored!

Make sure that optical lenses are never left in the sun without

a cover!

Use the supplied cover!

Certain surfaces of the device are hot during operation and

can cause burns if touched.

Do never fill xylene into one of the MPS devices.

Flammable substances should never be placed near to the

device.

The device may only be operated by trained specialists.

Paraffin is flammable and should be handled with care. Spillage should be avoided.

Paraffin on the surfaces must not be removed with sharp tools as it would ruin the coating.

It should be avoided to allow xylene to react on all surfaces.

Xylene is a flammable organic solvent. Its flash point is between 27

and 32 °C. Xylene vapors are heavier than air and can easily catch fire

on hot surfaces or sparks even over a greater distance.

To clean the condenser fins, switch the device off with the main switch and disconnect

it from mains. Prior to any maintenance and service action, the tissue embedding center

MPS must be disconnected from the power supply.

6/28 Manual_MPS_2021-10-022.00_EN.docx

4. COMPONENTS

Slee paraffin wax embedding centers are provided with the following standard

components:

MPS P I MPS P II

MPS P MPS W

MPS C or

MPS CX

Heated paraffin (wax) container

•

•

Heated dispenser element

•

•

Heated cassette / mould storage

containers

•

•

Cooled cassette / mould storage area

•

Heated working area

•

•

Cooled working area (cooling spot)

•

•

Magnifier

•

•

Paraffin collection tray

•

•

Working area illumination (light)

•

•

Foot switch for paraffin dispenser

•

•

Operation manual

•

•

•

•

Integrated electronic timer

•

•

•

•

Manual_MPS_2021-10-022.00_EN.docx 7/28

5. SPECIFICATIONS

MPS P MPS P I MPS W MPS C MPS CX

115 V 230 V 115 V 230 V 115 V 230 V 115 V 230 V 115 V 230 V

Nominal supply

voltage

115 V AC

+/-10 %

230 V AC

+/-10 %

115 V AC

+/-10 %

230 V AC

+/- 10 %

115 V AC

+/-10 %

230 V AC

+/-10 %

115 V AC

+/-10 %

230 V AC

+/-10 %

115 V AC

+/-10 %

230 V AC

+/-10 %

Nominal frequency 60 Hz 50 / 60 Hz 60 Hz 50 / 60 Hz 60 Hz 50 / 60 Hz 60 Hz 50 / 60 Hz 60 Hz 50 / 60 Hz

Power draw 400 VA 650 VA 320 VA 150 VA 250 VA

Protective Class (1) I

Power fuses 2xT4 A 2xT2,5 A 2xT10 A 2xT4 A 2xT4 A 2xT2,5 A 2xT10 A 2xT4 A 2xT10 A 2xT4 A

Pollution degree

(1)

2

Overvoltage

installation

category

II

Maximum heat

emission

400 J / s 650 J / s 320 J / s 150 J / s 450 J / s

Operating

temperature range

+10 to +35 °C

Temperature

range during

storage

+5 to +55 °C

Relative humidity max. rel. 80 % non-condensing

Humidity during

storage

max. rel. 80 % non-condensing

Dimensions

(L*W*H) [mm]

450 x 600 x 290 450 x 600 x 290 300 x 600 x 290 400 x 600 x 290 600 x 600 x 290

Weight [kg] 21 23 15 25 36

Paraffin tank 5.5 l 3.8 l

Cooling spot Peltier Peltier

Forceps holders 2 x 4 2 x 3

Light LED LED

Temperature

range cool plate

up to -15 °C

programmable

up to -15 °C

programmable*

MPS P MPS P I MPS W MPS C MPS CX

Cooling gas R 134 a R 134 a

8/28 Manual_MPS_2021-10-022.00_EN.docx

MPS P MPS P I MPS W MPS C MPS CX

Work area 270 x 370 mm

80 cassettes,

250 moulds

270 x 570 mm

120 cassettes,

375 moulds

Cassette bath,

storage for moulds

approx. 120

cassettes,

approx. 250 moulds

30 – 80 °C

approx. 320 cassettes,

approx. 500 moulds

30 – 80 °C

Installation

requirements

< 2.000 m NN, 15 cm distance to wall

(1) According to IEC 1010, EN 61010

*All temperature specifications refer to an ambient temperature of + 20 ° C and a relative humidity of 60%.

Manual_MPS_2021-10-022.00_EN.docx 9/28

6. UNPACKING AND INSTALLATION

6.1 UNPACKING THE DEVICE

Remove the upper cover and the upper supporting foams.

Lift the device out of the wooden transportation case. The devices may only be lifted

holding them at the sides of the base plate of the housing.

For repacking use the original cases. Keep the packing material.

Place the device onto the selected bench.

It must be avoided to tilt or turn the cool plate MPS C and MPS CX.

These positions will inevitably cause damage to the compressor.

6.2 INSTALLATION

The site for installation should meet the following requirements:

•

The unit should be positioned onto a plane, vibration-free surface. Please

ensure that there is no air condition vent nearby.

•

A free ventilation of fresh air from underneath the device should be

guaranteed. The back of the device must be at least 15 cm away from the

wall.

•

The vicinity of the work area must be free of oil and chemical vapors.

6.3 ELECTRICAL POWER CONNECTION

Make sure that electric power is constant +/-5 - 10 %:

•This should be examined during installation of the unit by a

competent person.

•Use a dedicated fuse for the unit.

•Before turning on the device, check if the voltage of the mains

supply is identical with the name plate of the unit.

Connect each unit to the mains supply and switch on with mains switch at the rear of

each unit.

10/28 Manual_MPS_2021-10-022.00_EN.docx

7. OPERATION

The MPS series provides a programmable interface, which helps the user to configure

this device for the appropriate usage within your preferred circumstances.

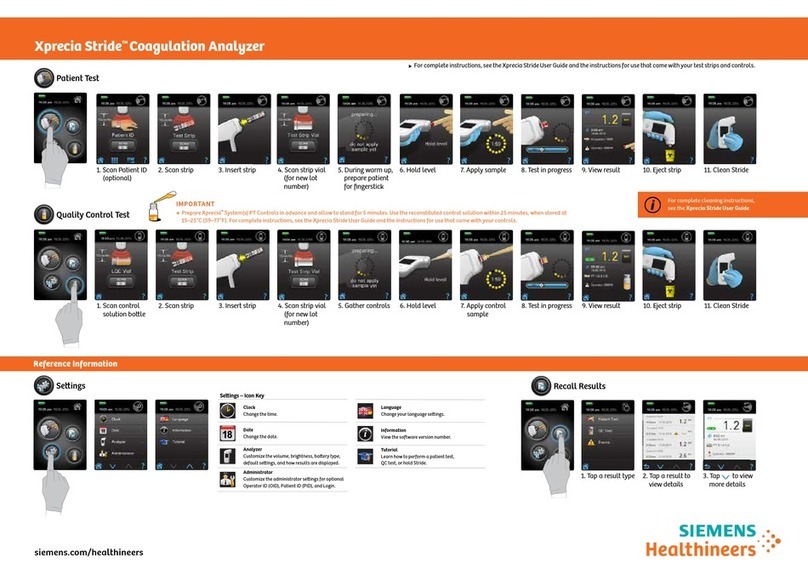

7.1 DISPLAY AND USER INTERFACE

The display (light green area) and the integrated buttons are the central interface (Human-

Machine Interface, abbr. HMI) for programming the device and setting the respective

values. There are two kinds of HMI’s, first one for MPS C and MPS W and the second one

for the MPS P version as shown below. The functions of the buttons are explained later

in the respective part of this chapter.

HMI MPS C, MPS CX & MPS W

HMI MPS P, MPS P I

Manual_MPS_2021-10-022.00_EN.docx 11

/28

7.2 INITIAL STATE OF THE DISPLAY

While the device is in standard working mode, the display shows the home screen

(actual date, time and the temperatures), including the target temperature in brackets.

Explanation Date/Function Time/Settings

Actual date / time 17.09.10 16:45:00

Paraffin tank temperature (actual vs. target) Paraffin 60 ºC (65 ºC)

Surface temperature (actual vs. target) Surface 38 ºC (40 ºC)

Cooling Spot status Cooling

Spot

Off

Home Screen of the Display: MPS P

Within this view there are no options for manual settings as it only provides an

indication of the actual status of the device.

The names and sequence of the temperature controllers depend on the device:

•MPS C, MPS CX Surface

•MPS W Upper / Lower

•MPS P Paraffin / Surface / Cooling Spot (only On / Off)

•MPS P I Paraffin / Surface / Bowl / Cooling Spot (only On / Off)

Devices which are not equipped with every single function have an empty line instead of

actual and target temperature for the built-in feature, e.g., MPS C only has a line for

surface temperature but shows no other information.

7.3 STANDBY MODE

If the Standby mode is activated, the display indicates date, time and the starting time for

the following operation cycle, if the timer is programmed. If no timer program is set, the

device shows that the heating / cooling functions are switched off. The standby mode

lasts until the next time the device is started by the timer or the user.

Standby display for MPS P:

Explanation Date/Function Settings

Actual date / time 17.09.10 20:45:00

Timer settings for paraffin tank Paraffin >> Fr07:00

Timer settings for surface Surface >> Fr09:00

Cooling Spot status Cooling Spot

Off

12/28 Manual_MPS_2021-10-022.00_EN.docx

Standby display for MPS P I:

Explanation Date/Function Settings

Actual date / time 17.09.10 20:45:00

Timer settings for paraffin tank Paraffin >> Fr07:00

Timer settings for surface Surface >> Fr09:00

Timer settings for cassette / mould storage Bowl >> Fr09:00

Standby display for MPS W:

Explanation

Date/Function

Settings

Actual Date / Time 17.09.10 20:45:00

Timer settings for upper heating Upper >> Fr07:00

Timer settings for lower heating Lower >> Fr09:00

Standby display for MPS C and MPS CX:

Explanation Date/Function Settings

Actual date / time 17.09.10 20:45:00

Timer settings for surface Surface >> Fr09:00

Within this view there are no options for manual settings as it only provides an indication

of the actual status of the device.

While the device is in standby mode, the display illumination is switched off and all

functions, even light and Peltier element are set inactive. To reactivate the apparatus the

second menu item in the Main Menu, named Operation must be selected. Alternatively,

the device will be switched on by the timer, if it is programmed.

7.4 MAIN MENU

The table Main Menu provides the possible settings of the MPS P and MPS P I software.

The columns Cursor, Function and Settings are a representation of the characters shown

on the display. As the display only shows 4 lines you can navigate to the other positions

listed in the following tables by pressing . The menu will roll down to all included items.

The item Configuration is only available for technicians authorized by SLEE medical GmbH.

Manual_MPS_2021-10-022.00_EN.docx 13

/28

Main Menu display for MPS P:

Explanation Cursor Function Settings

Manual activation of Standby mode > Standby

Manual activation of Operation mode

Operation

Timer MPS P Timer

Tank heating function On / Off

Paraffin On

Adjustment of tank heating temperature

Paraffin Temp. 40 ºC

Surface heating function On / Off

Surface On

Adjustment of surface temperature

Surface Temp. 40 ºC

Set actual date

Date 17.09.10

Set actual time

Time 16:45:00

Change language (English, German)

Language English

Setting of Contrast for the display

Contrast 14

Software Version and Date

Version

Switch to configuration menu

(Configuration per SLEE medical GmbH

authorized technician)

Configuration

14/28 Manual_MPS_2021-10-022.00_EN.docx

Main Menu display for MPS P I:

Explanation Cursor Function Settings

Manual activation of Standby mode > Standby

Manual activation of Operation mode

Operation

Timer MPS P I Timer

Tank heating function On / Off

Paraffin On

Adjustment of tank heating temperature

Paraffin Temp. 40 ºC

Surface heating function On / Off

Surface On

Adjustment of surface temperature

Surface Temp. 40 ºC

Settings for surface heating timer*

Surface Timer

Cassette / Mould storage heating function

On / Off

Bowl On

Adjustment of Cassette / Mould storage

temperature

Bowl Temp. 40 °C

Set actual date

Date 17.09.10

Set actual time

Time 16:45:00

Change language (English, German)

Language English

Setting of Contrast for the display

Contrast 14

Software Version and Date

Version

Switch to configuration menu

(Configuration per SLEE medical GmbH

authorized technician)

Configuration

Main Menu display for MPS W:

Explanation Cursor Function Settings

Manual activation of Standby mode > Standby

Manual activation of Operation mode

Operation

Timer MPS W Timer

Upper heating On / Off

Upper On

Adjustment of upper heating temperature

Upper Temp. 40 ºC

Lower heating On / Off

Lower On

Adjustment of lower heating temperature

Lower Temp. 40 ºC

Set actual date

Date 17.09.10

Set actual time

Time 16:45:00

Change language (English, German)

Language English

Setting of Contrast for the display

Contrast 14

Software Version and Date

Version

Switch to configuration menu

(Configuration per SLEE medical GmbH

authorized technician)

Configuration

Manual_MPS_2021-10-022.00_EN.docx 15

/28

Main Menu display for MPS C, MPS CX:

Explanation Cursor Function Settings

Manual activation of Standby mode > Standby

Manual activation of Operation mode

Operation

Timer MPS C, MPS CX Timer

Cooling function On / Off

Cooling On

Adjustment of cooling temperature

Cooling Temp. -15 ºC

Set actual date

Date 17.09.10

Set actual time

Time 16:45:00

Change language (English, German)

Language English

Setting of Contrast for the display

Contrast 14

Software Version and Date

Version

Switch to configuration menu

(Configuration per SLEE medical GmbH

authorized technician)

Configuration

With and (for MPS P and MPS P I and ) you can move the cursor (column

Cursor) to the appropriate menu item (column Function). By pressing (for MPS P II

) you can activate the setting and the value begins to flash. Now the value can be adjusted

by pressing or and must be confirmed with .

The items marked with an asterisk (*) guide the user to the submenu Timer, which is

explained in chapter 7.6 TIMER.

To leave the menu and get into the next higher level just push . This will not make any

changes to the device’s current settings.

i

With the timers, the start of work is determined; the respective start

time (already programmed) is included in the calcu

lation. Please

enter only the time for starting work!

16/28 Manual_MPS_2021-10-022.00_EN.docx

7.5 ACTUAL DATE AND TIME

Before you can use the timer function as explained in chapter 7.6 TIMER you need to

adjust the actual time and date to match your current location. Following explanation is

valid for all devices out of the MPS Series.

Go into the Main Menu and use or to go to the line showing Date. The format of

the date is DD/MM/YY.

Pressing will make the digits for the day blinking. Pressing or will raise or lower

the figure. Hitting will change from day to month and also to year which can be

adjusted in the same manner as the day.

Leaving the adjusting mode is always possible by pushing .

After leaving the date settings you are returning to the Main Menu. The next line below

the Date is the Time. The Time adjustment works even like the Date setting.

7.6TIMER

All devices of the MPS series and the cooling unit in the MPS C and MPS CX can be

switched on and off via an automatic time switch. A total of three switch-on and switch-

off phases can be defined. The respective time switch intervals can be set via the main

menu. The settings are activated when the respective time switch interval has been

switched on and the status "On" is displayed.

Explanation Cursor Turn-On Time Turn-Off Time

First of three On/Off Time settings > On 07:00

Off 12:00

Second of three On/Off Time settings On 13:00

Off 18:00

Third of three On/Off Time settings On 20:00

Off 22:00

Weekdays Mo

Tu

We

Th

Fr

Sa

S

Timer Settings

Setting the timer is made very easy and user friendly. Just go to the respective line which

you want to edit by pressing the or keys and confirm with .

The first two digits start to flash and signalize that they are ready to be adjusted. Now

you can edit the start time when the function should be switched on by pressing or

again. Using will make the next two digits flashing. Here you can adjust the

minutes for the start time.

After you set the start time settings you push to get to the stop time and adjust the

stop time equivalent.

The above-described procedure is even valid for assigning the weekdays for which you

want the timer settings to work. Pressing will switch through the days which can be

turned on and off by using the arrow keys and .

Hitting the arrow buttons once will apply a change of one unit, e.g., pressing will

change the start time (hours) from 05:00 to 06:00. Holding the arrow keys will raise or

lower the setting until you stop pressing the buttons.

Manual_MPS_2021-10-022.00_EN.docx 17

/28

7.7HEATED PARAFFIN (WAX) CONTAINER (MPS P and MPS P I module)

i

For a robust performance of the device the flow of molten paraffin

is exclusively driven by gravitation. To assure a rapid flow, please

refill the paraffin container before it empties completely.

The design of the MPS P and MPS P I allows two ways of working with your device.

The first common one is using the timer, which is explained in chapter 7.6 TIMER. This

allows you to have a ready to use unit in the morning with liquid paraffin in it. Therefore,

adjust the start time for tank heating with an appropriate lead time.

Another way is starting the heating manually by going to the Main Menu and activate the

paraffin heating by pressing after you went down the menu with (see cursor

position in table below). After pressing again the status (On or Off) starts blinking and

can be regulated by or .

One line below you can adjust the paraffin tank temperature and another line beneath

you will get to the timer menu. These steps are also valid for setting the Surface heating

to fulfil your specific requirements.

Explanation Cursor Function Settings

Manual activation of Standby mode

Standby

Manual activation of Operation mode

Operation

Timer MPS P, MPS P I Timer

Tank heating function On / Off > Paraffin On

Adjustment of tank heating temperature

Paraffin Temp. 40ºC

Surface heating function On / Off

Surface On

Adjustment of surface temperature

Surface Temp. 40ºC

Set actual date

Date 17.09.10

Set actual time

Time 16:45:00

Change language (English, German)

Language English

Setting of Contrast for the display

Contrast 14

Software Version and Date

Version

Switch to configuration menu

Configuration

The regular screen will show you the actual and the target temperature (in brackets). To

go back to the standard screen press .

Explanation Date/Function Time/Settings

Actual Date / Time 17.09.10 16:45:00

Paraffin tank temperature (actual vs. target) Paraffin 60 ºC (65 ºC)

Surface temperature (actual vs. target) Surface 38 ºC (40 ºC)

Cooling Spot Status Cooling

Spot

Off

18/28 Manual_MPS_2021-10-022.00_EN.docx

7.8 HEATED WORKING AREA (MPS P and MPS P I module)

As mentioned in chapter 7.7 HEATED PARAFFIN (WAX) CONTAINER you can heat the

working surface of your MPS P or MPS P I to allow you to place and align your tissue

sample while the paraffin keeps liquid. Even the temperature can be influenced in the

Main Menu.

You only have to go to the Main Menu by pressing and go down to the line Surface.

As you adjusted the tank settings you are able to set the working conditions to fit your

specific needs.

The function surface heating can be switched on and off manually and by the timer, the

temperature can be regulated in single degree steps.

7.9 COOLED WORKING AREA (MPS P and MPS P I module)

If the cooling element is switched on, the inbuilt cooling fan

is running. The lower and rear airing slots should never be

covered.

The actual temperature of the cooled working area may

vary dependent on the temperature set for the heated

working area and the ambient temperature.

Your new device has a cooling spot which provides a lowered temperature to harden the

liquid paraffin earlier than waiting for hardening with your local air temperature.

To switch the cooling spot on and off you only have to push . For the MPS P you will

see the status of the cooling spot on the standard screen in the last line.

7.10ILLUMINATED WORKING AREA (MPS P and MPS P I module)

For optimized visibility of your work there is a light included in the MPS P and MPS P I

device which you can switch on and off with . Additionally, you can adjust the light

module in the front by turning the black tube as shown in the picture below.

Manual_MPS_2021-10-022.00_EN.docx 19

/28

7.11 HEATED PARAFFIN DISPENSER (MPS P and MPS P I module)

The heated paraffin dispensing arm can be

operated manually or via a footswitch.

Manual operation

The heated paraffin dispensing arm is

equipped with a hanger directly behind the

dispense outlet.

To open the valve and start the paraffin flow,

press the bracket backwards or to the side.

The valve closes automatically when the

bracket is released.

Operation with Footswitch

The heated paraffin dispensing arm can be

operated with a footswitch.

To open the valve and start the paraffin flow,

press the foot switch.

The valve closes automatically when the foot

switch is released.

The paraffin flow can be regulated by the

adjusting screw on the dispense outlet.

open closed

7.12MAGNIFIER (MPS P and MPS P I module)

Each device is equipped with a magnifier

that can easily be turned to the right and left if

required.

The magnifier will keep its orientation even if

turned away temporarily.

20/28 Manual_MPS_2021-10-022.00_EN.docx

7.13 PARAFFIN TRIMMER (MPS P and MPS P I module)

The integrated paraffin trimmer makes efficient

removal of excess paraffin from each cassette.

As a result, the risk of a not adequately clamped

cassette in the cassette clamp is significantly

reduced.

Due to the generous design of the paraffin

trimmer in the heated work surface, the paraffin

melts and can thus immediately drain through

the drainage into the paraffin waste tray located

under the work surface.

7.14 PARAFFIN COLLECTION TRAY

(MPS P and

MPS P I module)

The paraffin from the paraffin waste tray should

not be reused.

To empty the tray, pull it out completely. The

paraffin waste tray should be cleaned daily.

7.15 HEATED FORCEPS (MPS P and MPS P I module) [if device is equipped with this accessory]

The device can also be equipped with electrically

heated forceps. The forceps will be activated by

plugging into the connection for heated forceps at

the front of the paraffin wax dispenser (MPS P and

MPS P I module).

The heated forceps tip allows a more precise

orientation of the dehydrated tissue. As soon as

the work is finished, insert the tips into the forceps

holder. This is drilled through so that the melting

paraffin drains through the drainage system, the

working surface into the paraffin waste tray. This

ensures a clean, tack-free and non-stick forceps

tip.

This manual suits for next models

5

Table of contents

Other Slee Measuring Instrument manuals