SlipStream 30 cc Super Chipmunk User manual

30 cc Super Chipmunk

Assembly Manual

Congratulations on your purchase of this excellent almost-ready-to-fly

RIC model! This ARF adopts the latest design features and emphasizes

high performance, light weight and fun. The plane is designed by

professional engineers and built by skilled craftsmen.

Specifications:

Wing Span: 80” (2030mm)

Length(Including Spinner): 69” (1750mm)

Wing Area: 935 in² (60.4 dm²)

Flying Weight: 11 to 13 lbs(5-5.5kg)

Engine: .91-1.20(2C) 1.10-1.40 (4C) 20 - 35cc Gas

Radio: 4+ Channels

Servos : 6 servos required 80 oz/in

FEATURES

1. Latest Structure

2. Light weight construction and high structural strength

3. Super Quality

4. Complete with accessories

5. Easy installation

6. Low wing loading

7. Anodized 6061 T-6 wheels

8. Advanced PU wheels

A QUICK WORD ABOUT SAFETY AND RADIO CONTROL FLYING MODELS

With radio control aircraft, like any hobby or sport, there are certain risks. The operator

of these models is responsible for these risks. If misused or abused, you may cause serious

bodily injury and/or damage to property. With this in mind, you will want to be certain that you

build your model carefully and correctly. If you are not an experienced flier, have your work

checked by an experienced pilot and ask for help in learning to fly the model safely. This

model aircraft is not a toy and must be operated and flown in a safe manner at all times.

Always perform a pre-flight check of the model which includes proper movements of all

control surfaces, proper function of the radio gear, structural integrity, and radio range.

Models are not insurable but operators are. You can obtain coverage through

membership in the Academy of Model Aeronautics (AMA). For an AMA information package

call 1-800-435-9262, ex t. 292 or visit theAMAwebsite at "www.modelaircraft .org".

By the act of using the final assembled model, the purchaser/operator accepts all

resulting liability.

Items Required to Complete This Model:

•20-35cc gas engine

•Appropriate propeller for your engine

•

Required engine and exhaust mounting

hardware

•Batteries for ignition and radio system

•Appropriate HD switches

•Receiver of your choice

•Appropriate HD extensions

•5-6 good quality servos (90oz/in)

•Covering iron and heat gun

•Assortments of hobby tools such as

screwdrivers, hobby knife, drill, pliers,

etc.

•Isopropyl alcohol

•Ruler or tape measure

•Blue thread-lock or equivalent

•Thin and thick CA

•30-minute epoxy

•Canopy Glue

Note:As with all kits, it's a good idea to read all the instructions and study the parts before you

begin construction. Handle the parts of this kit with care so you do not damage any of the

structure or covering. Inspect all the parts for any shipping damage and report any issues to

Slipstream dealers as soon as you can. Make sure you have a flat and sturdy workbench and

follow all safety advice for the tools and adhesives you plan to use.

AIRCRAFT COVERING:

1. With all ARFs, varying temperatures and storage delays can cause the covering

material to loosen over time during transportation. Slipstream recommends lightly going over

all the covering with a covering iron set at medium temperature. Be sure to use a soft

covering over your iron so that you do not scratch the covering surface. Be sure you go over

all seams and edges of the covering to assure it is secure to the airframe and other covering.

Be careful not to apply too much heat or you may cause bubbles or damage to the covering,A

heat gun may also be used along with a soft cotton cloth to shrink loose coverings. Be

extremely careful when using a heat gun.

2. Be sure to seal any exposed wood with a thin coating of epoxy to prevent engine oil

from soaking in. This is especially important around the engine compartment and servo

openings with exposed areas.

3. Some modelers prefer to seal the hinge gaps using strips of appropriate covering or

clear trim tape. We have found this to be helpful with models intended for higher speed flight

or models with unusually large hinge gaps. Slipstream aircraft utilize a very tight double

beveled hinge line and do not normally require this step. Sealing the hinge gaps is therefore

left as an option for the modeler.

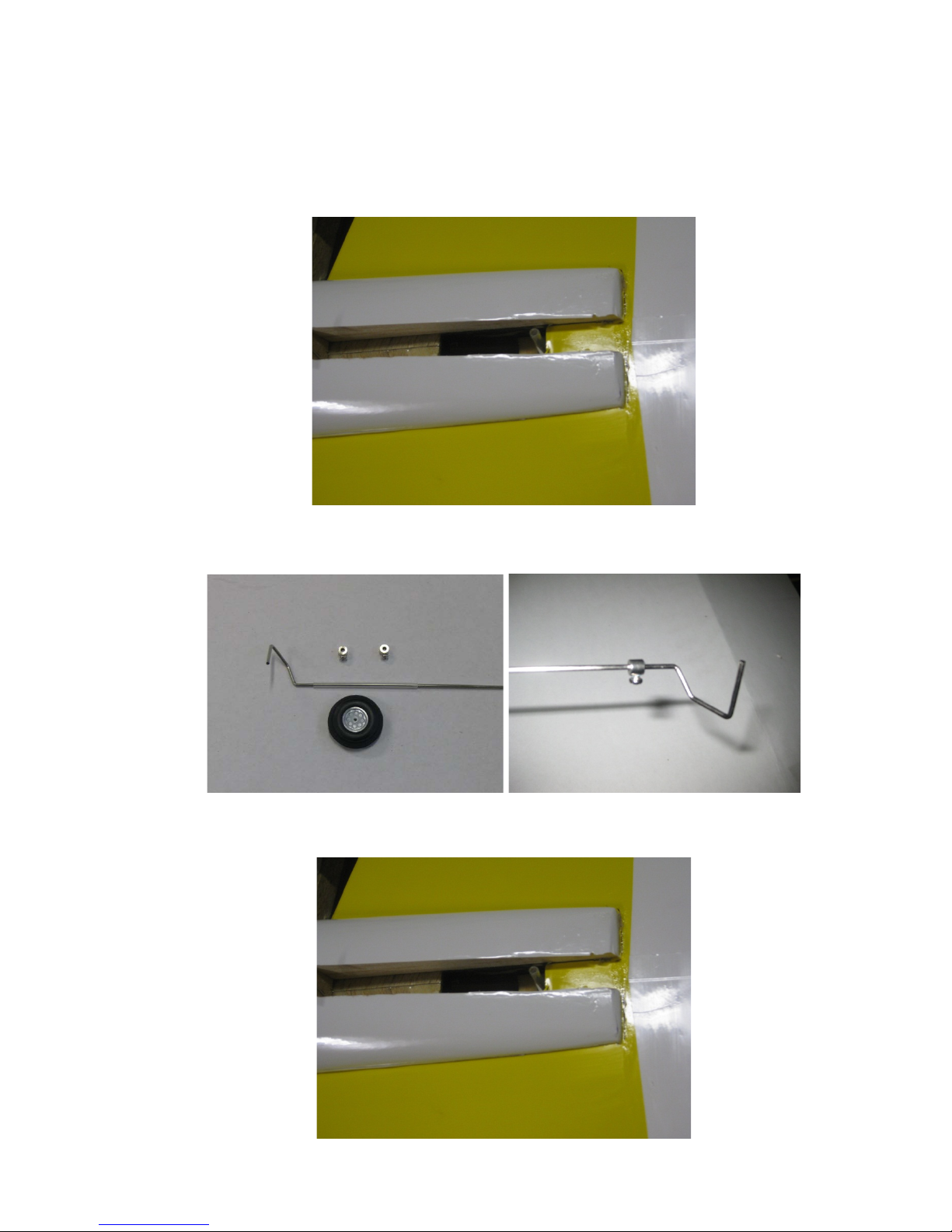

FUSELAGE, STABILIZERS AND TAIL WHEEL ASSEMBLY:

NOTE: Please review this section carefully as you are required to mount the tail wheel

at the same time.

1. Start by prepping the fuselage. Locate the hole for the tail gear at the bottom rear of

the fuselage and use the soldering iron carefully to make a nice clean opening if

necessary.

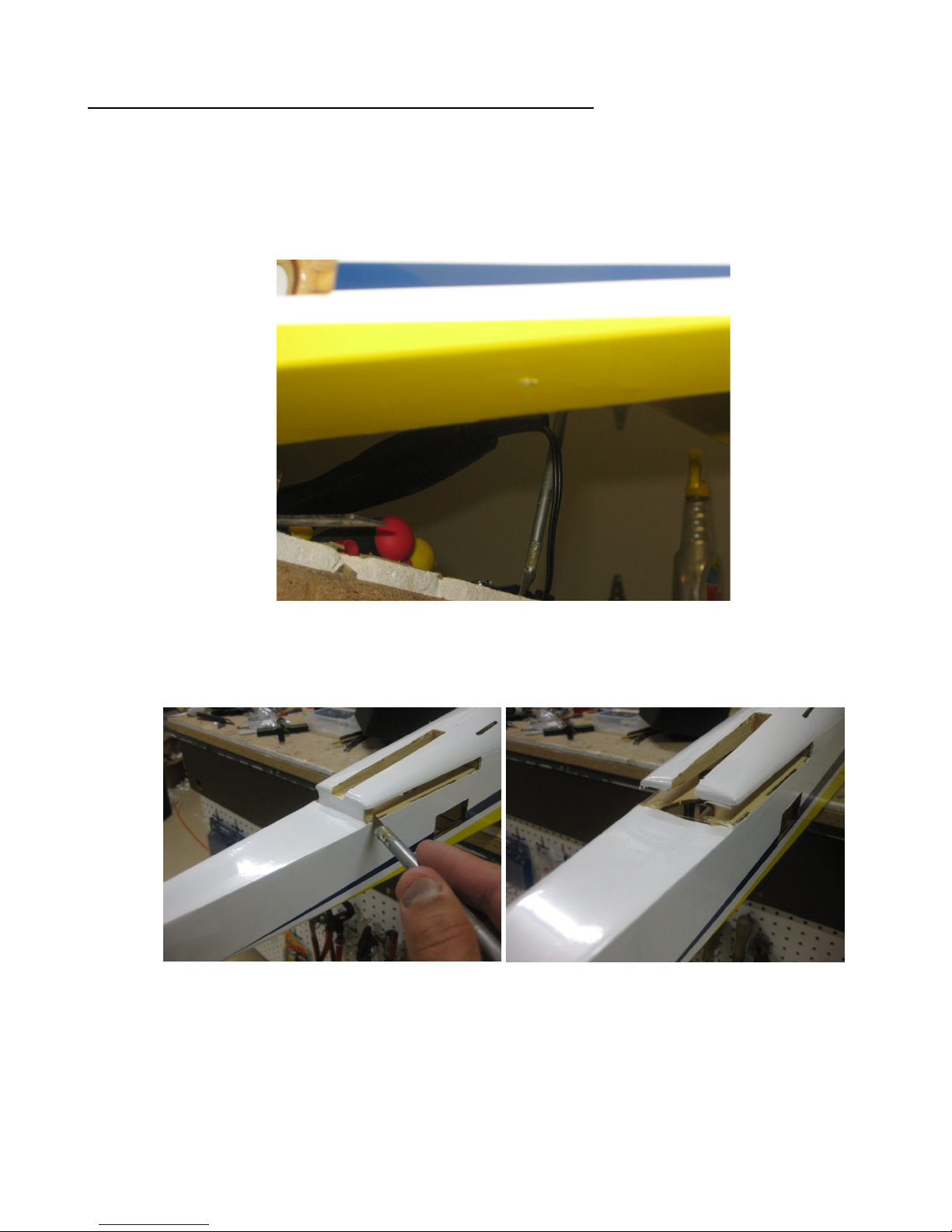

2. Cut off the supporting tabs where the horizontal stabilizer will slide in. See picture

below.

3. Cut the covering away where the horizontal stabilizer will seat as shown below.

4. Locate the horizontal stabilizer and slide it in the slot as shown in the picture below.

5. Use a ruler (or any of your favorite method) to check for square-ness. Once satisfied,

mark the top and bottom of the horizontal stabilizer to cut away the covering as shown

in the pictures below.

6. Carefully cutaway the covering where the glue will be applied. See pictures below.

7. Prepare some 30 minutes epoxy and apply it to the exposed section of the stabilizer

and install it onto the fuselage. Carefully check the alignment of the stabilizer. Once

satisfied, wipe off the excess epoxy with a paper towel soaked in rubbing alcohol.

8. Locate the tail wheel assembly and prepare it for assembly as shown below.

9. Insert the plastic guide tube as shown in the pic below.

10.Install the tail wheel through the bottom of the fuselage. See picture below.

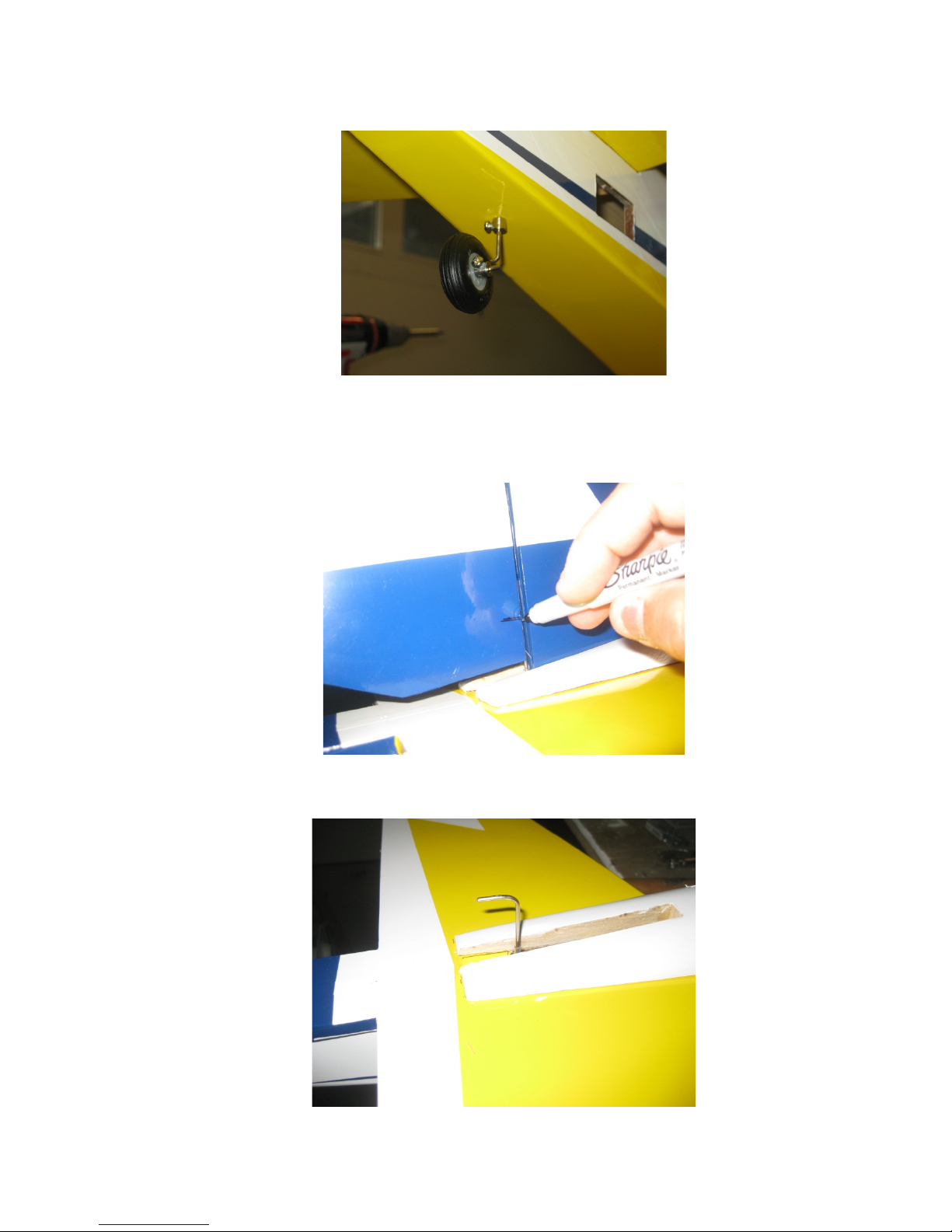

11.Locate the vertical stabilizer and rudder. Mount the vertical stabilizer onto the fuselage.

Trial fit the rudder onto the vertical stabilizer and mark the spot where the tail wheel rod

will be bent. See pictures below.

12. Bend the rod at the spot you marked above. See pic below.

13.Prepare the rudder by cutting a slot to recess the tail gear wire. Also drill a hole the

size of the tail gear wire. Harden the cut and drilled area with thin CA.

14.Prepare the vertical stabilizer for gluing onto the fuselage. Cut off the covering as

shown below.

15. Mix some 30 minute epoxy and glue the vertical stabilizer onto the fuselage. Use a

right angle triangle to make sure that the vertical stab is perpendicular to the horizontal

stabs.

16.Locate the vertical stabilizer extension and prepare the fuselage for installation.

Remove the covering as shown in the pictures below. Glue it on with either medium CA

or epoxy.

17.Locate the rudder and hinges and prepare it for installation. Use a little epoxy in the

hole where the tail wheel tiller will reside to strengthen it. Install the rudder as shown

below and use thin CAto glue the hinges in place.

18. Locate the elevators and the hinges to glue in the elevators onto the horizontal

stabilizers. Glue it in using the same method as was used in the rudder installation

above.

19. Locate the control horns for the elevators and prepare for installation. See pictures

below for the locations for the control horn. You will need two servos on either side of

the fuselage.

Tip: Measure both sides of the elevators and drill a small pilot hole. Once it is squared

use a right drill bit and drill trough. You can use a countersunk bit on the top of the

elevators to provide a cleaner look. Once the hole is made, wick it with thin CA to

harden it.

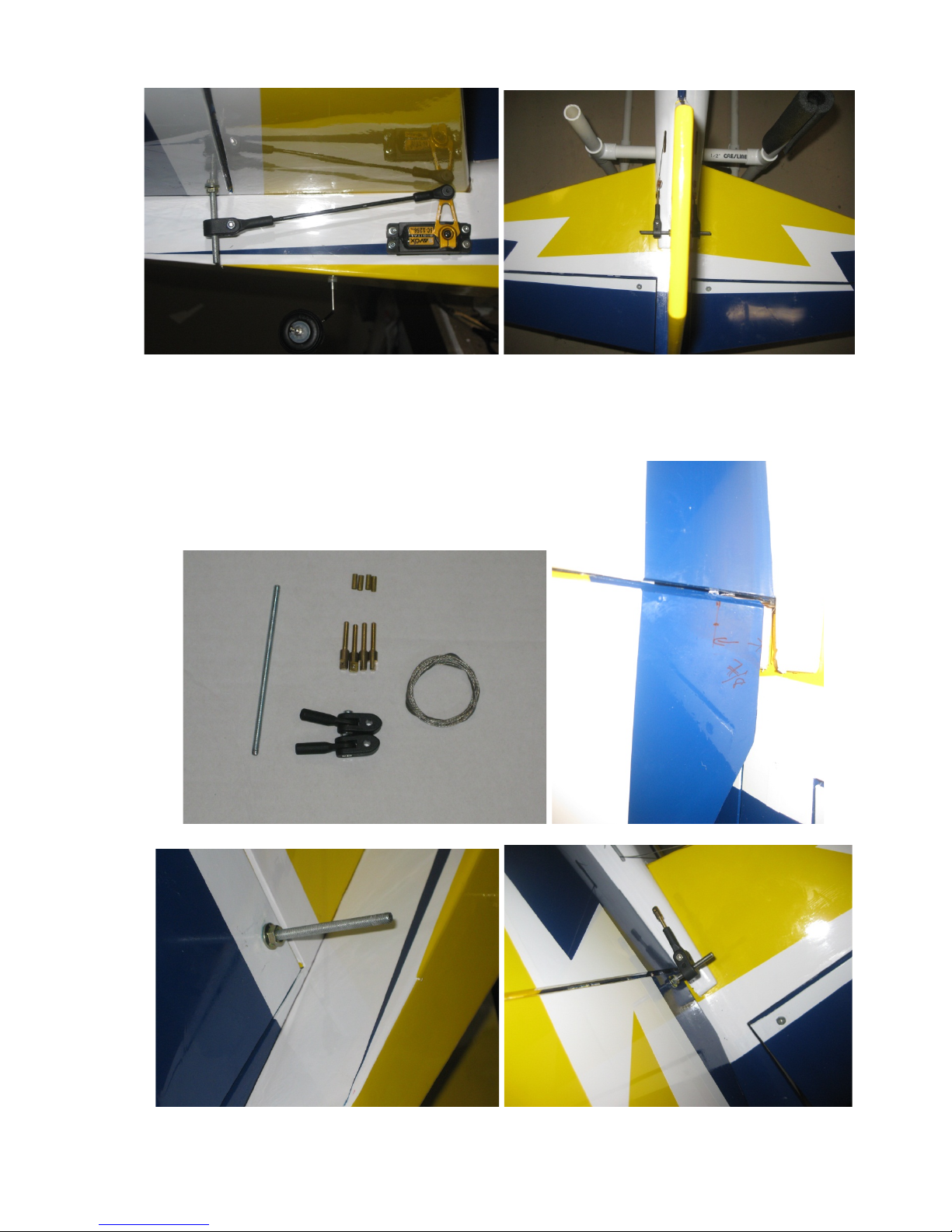

20.Locate the rudder control horn assembly. See pictures below for installation of the

control horns. Ensure that the rudder cables running through the slots do not rub the

fuselage.

ENGINE INSTALLATION

1. Look at the firewall and you will see the lightly scribed centerline marked for the center

of your engine mount. You can darken it with a pen for visibility.

2. Mark the location of mounting bolts (Here, a DLE 30 is used). Drill out the mounting

holes for your mounting hardware.

3. The distance of the firewall to the back plate of the spinner is about 7-31/4”. The

standoff length required will be 3-1/8”, which will give about a 1/8” clearance between

the back plate and the cowl. See pictures below for mounting the engine.

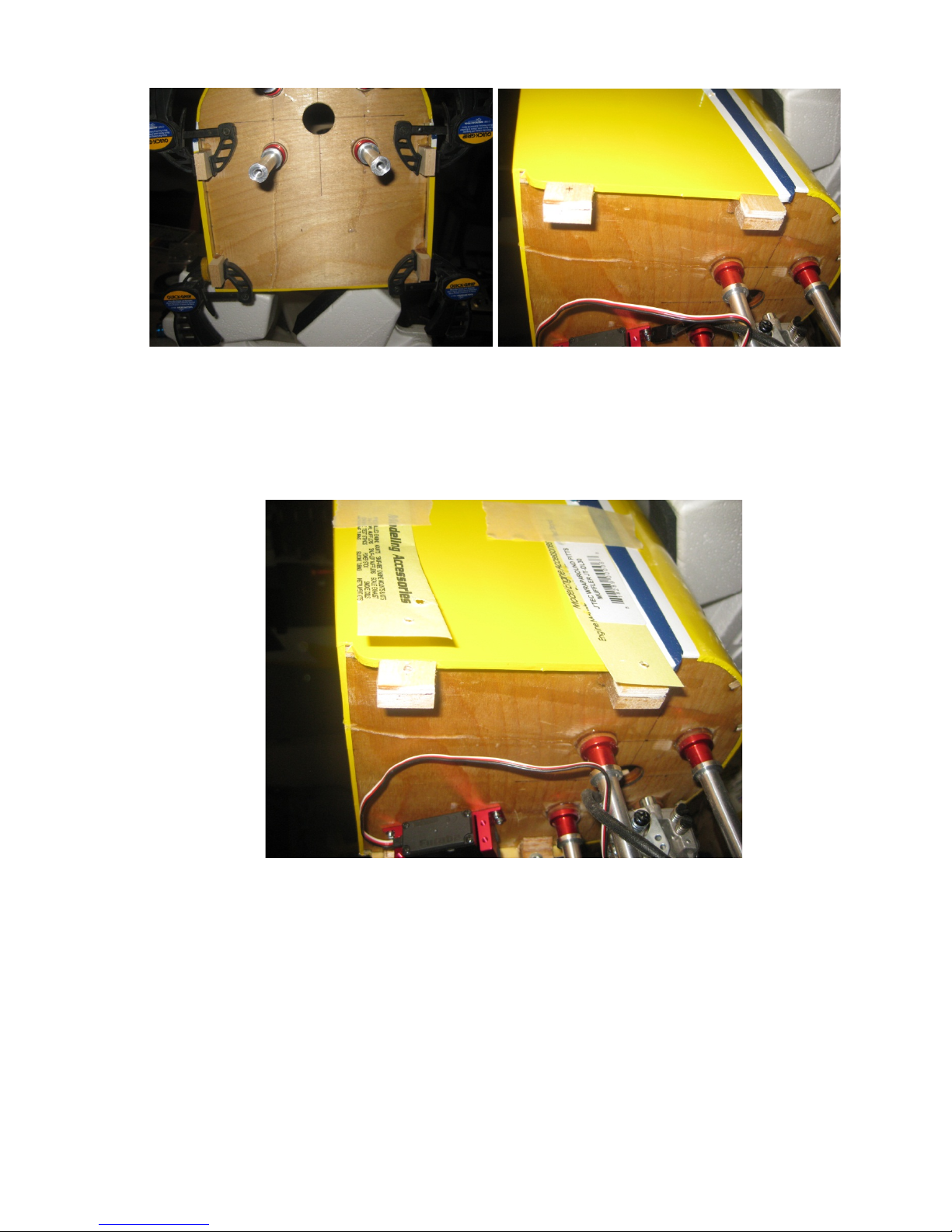

4. Locate the 4 mounting blocks for the cowl and install them as shown in the picture

below. Use 30 minute epoxy for the step. Place some scrap shims as shown in the

second pic below. The scrap shims will prevent cowl from being squeezed in and

damaging it.

.

5. Now prepare to mark the cowl for installation. You will want to mount the engine and

use a 3” spinner back plate for use as a guide. Make some paper strip and tape them

to the fuselage as shown below. Drill a hole that will be big enough to accept a 4-40

screw (or you can use the wood screw provided which the author does not

recommend). You can install a blind nut on the other side of the mounting block.

6. Line up the cowl and drill out the holes for the 4 mounting bolts. It should look like the

picture below.

7. Cut out appropriate openings in the cowl for engine and muffler. Also make cuts in the

bottom of the cowl for cooling purposes.

CANOPY INSTALL

1. Locate the canopy and align it on the fuselage as shown below. You will need

canopy glue for this step. Once you are satisfied with the alignment, apply the

canopy glue. Tape down the canopy with making tape so that it won’t move while it

is curing. Wipe off the excess glue with a damp paper towel.

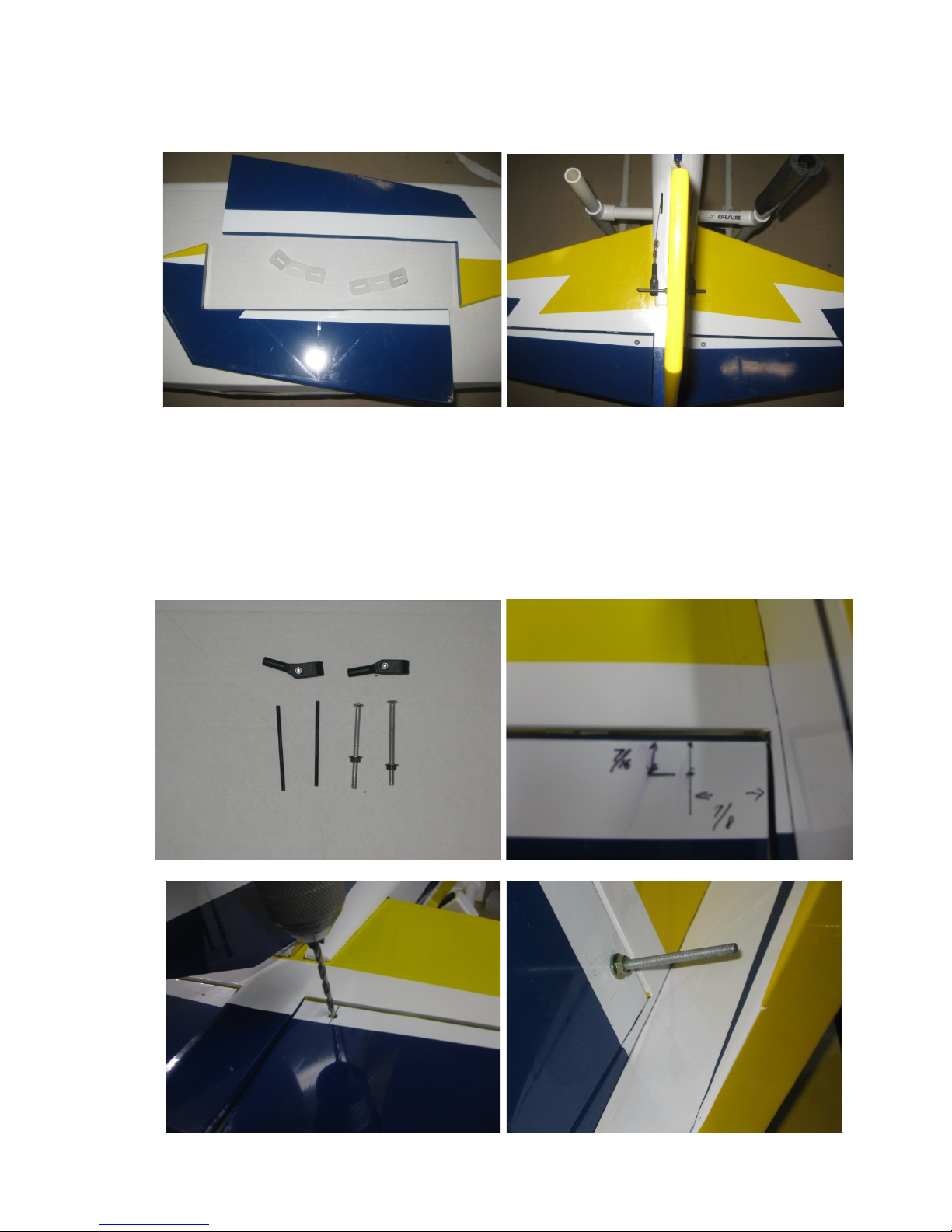

WINGS AND MAINLANDING GEAR:

1. Locate the wing joiner and trial fit the joiner onto the wings to ensure a smooth fit. Also

mark the joiner as it has a dihedral on it.

2. Use a hot soldering iron and carefully remove the covering where the servo wire will

come out of.Also use the soldering iron to remove the covering for the wing bolts.

3. Mix some 30 minute epoxy and apply it on the wing joiner and exposed ribs and glue

the two wing halves together. Use masking tape and clamps to hold the wing halves in

place while the epoxy cures.

4. Locate the wing bolt reinforcement plate. Remove the covering where the wing bolts

will come through. Use the wing bolts and align it onto the bottom of the wings and

mark the area where the covering needs to be removed. Mix some epoxy and glue

down the wing bolt plate. See pictures below.

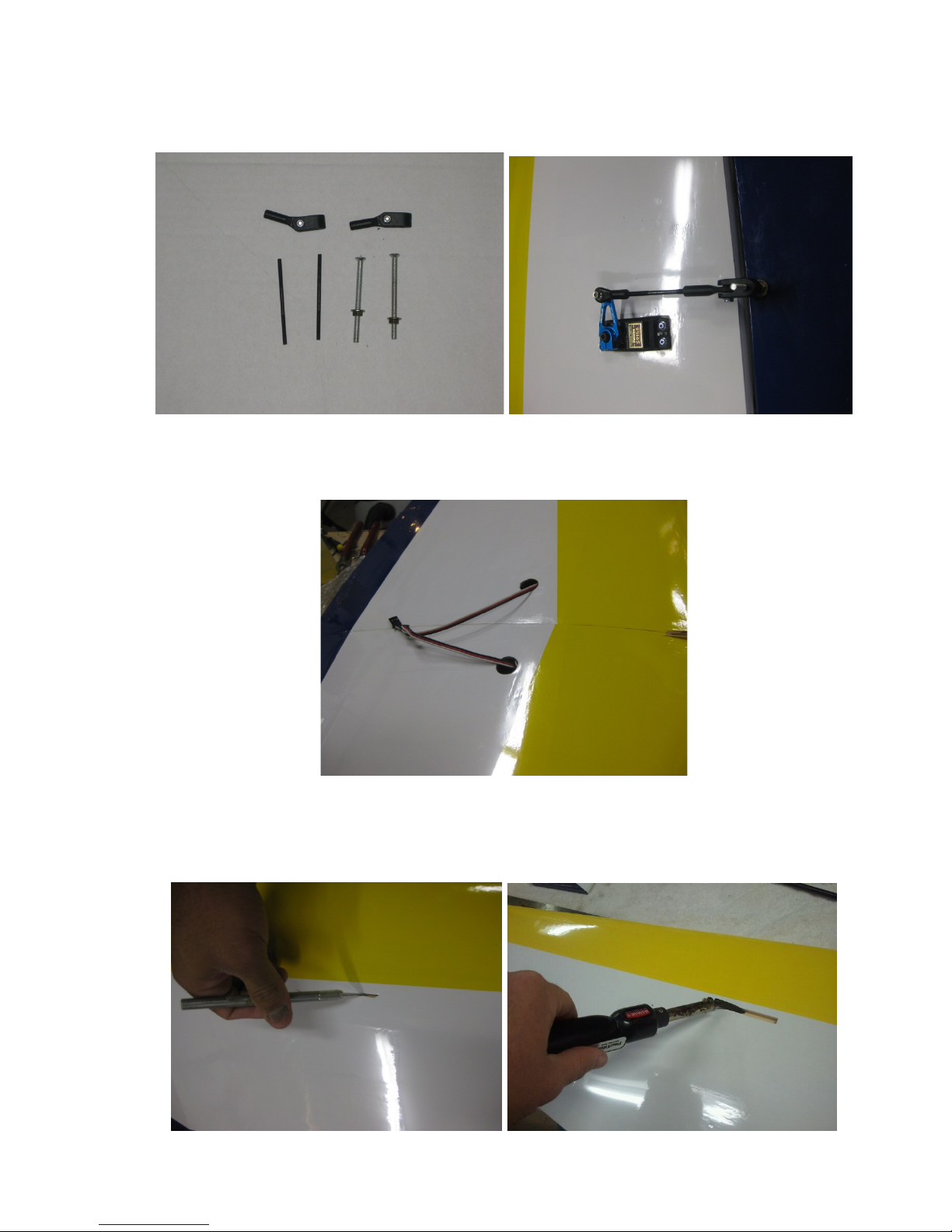

5. Locate the ailerons and prepare for installation onto the wings. Use thin CA and to glue

the aileron hinges in place.

6. Locate the control horns and install them as shown in the pictures below. You can use

the same method as was used in the installation of the horns for the elevator.

7. Route the extensions lead out as shown below. There is a guide thread pre-installed in

the wings to help thread the servo wires.

8. Locate the slots on the bottom of the wings for the landing gear. Use a sharp Xacto

knife and cut the slot open carefully. Use a trim iron and iron down the covering as

shown in the pictures below.

Table of contents

Other SlipStream Toy manuals

Popular Toy manuals by other brands

Yookidoo

Yookidoo CRAWL 'N' GO SNAIL Instruction leaflet

Vollmer

Vollmer 42553 Mounting instruction

Horizon Hobby

Horizon Hobby HobbyZone Apprentice S 2 1.2m instruction manual

iKarus

iKarus Rumpler Taube Building Instruction

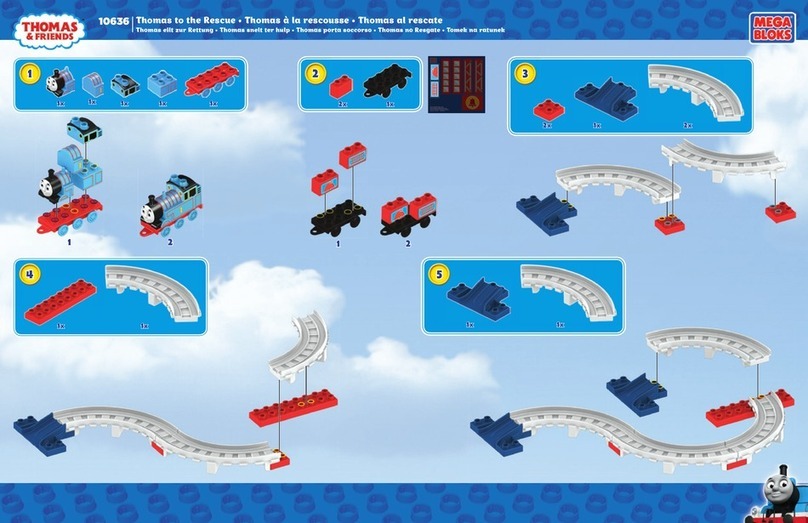

Mega Bloks

Mega Bloks Thomas & Friends Thomas to the Rescue Instruction

Aeromax

Aeromax 40 Easy Stik ARF Assembly instructions

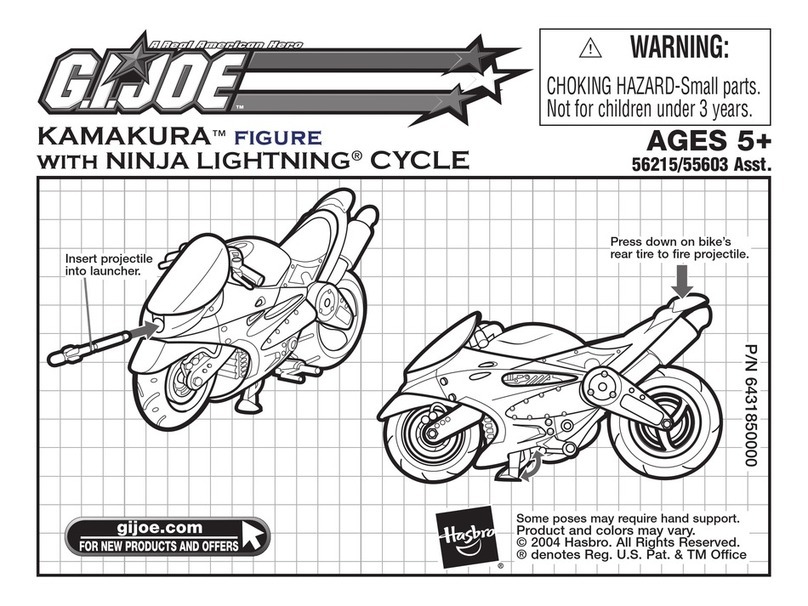

Hasbro

Hasbro Kamakura with Ninja Lightning Cycle... datasheet

ROBBE

ROBBE Amica Assembly and operating instructions

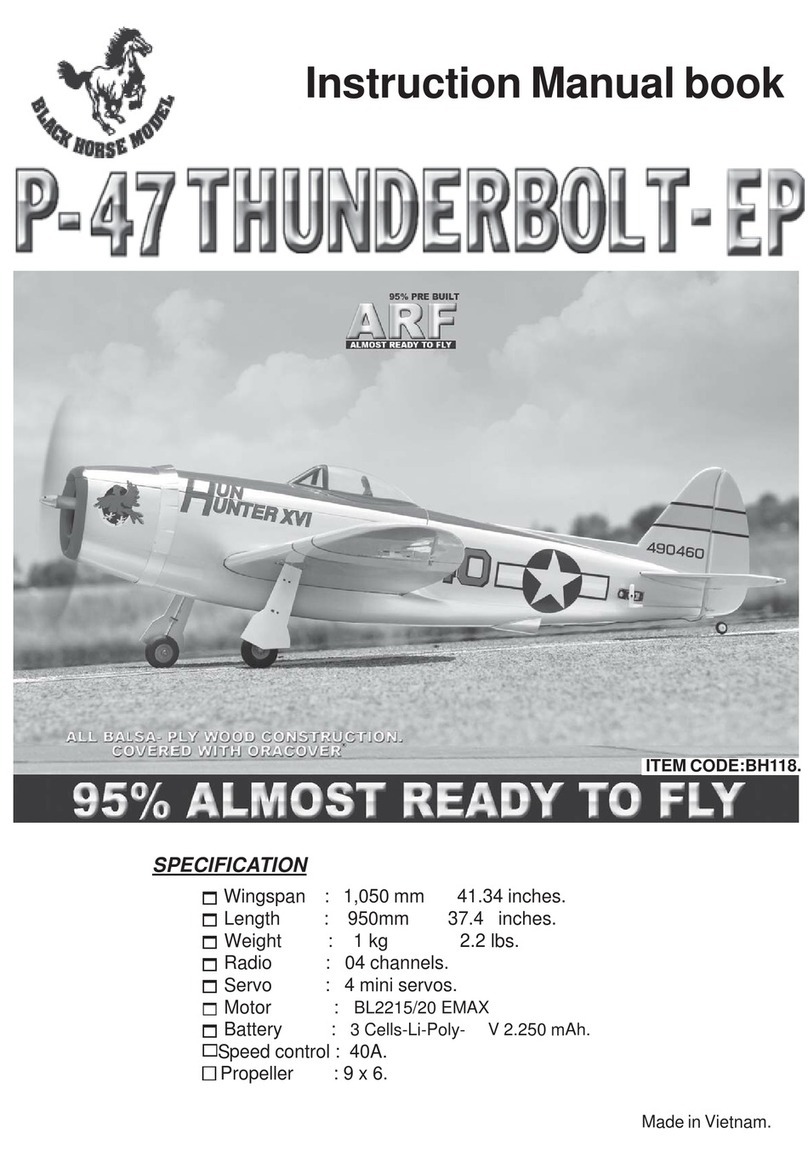

Black Horse Model

Black Horse Model P- 47 THUNDERBOLT- EP Instruction manual book

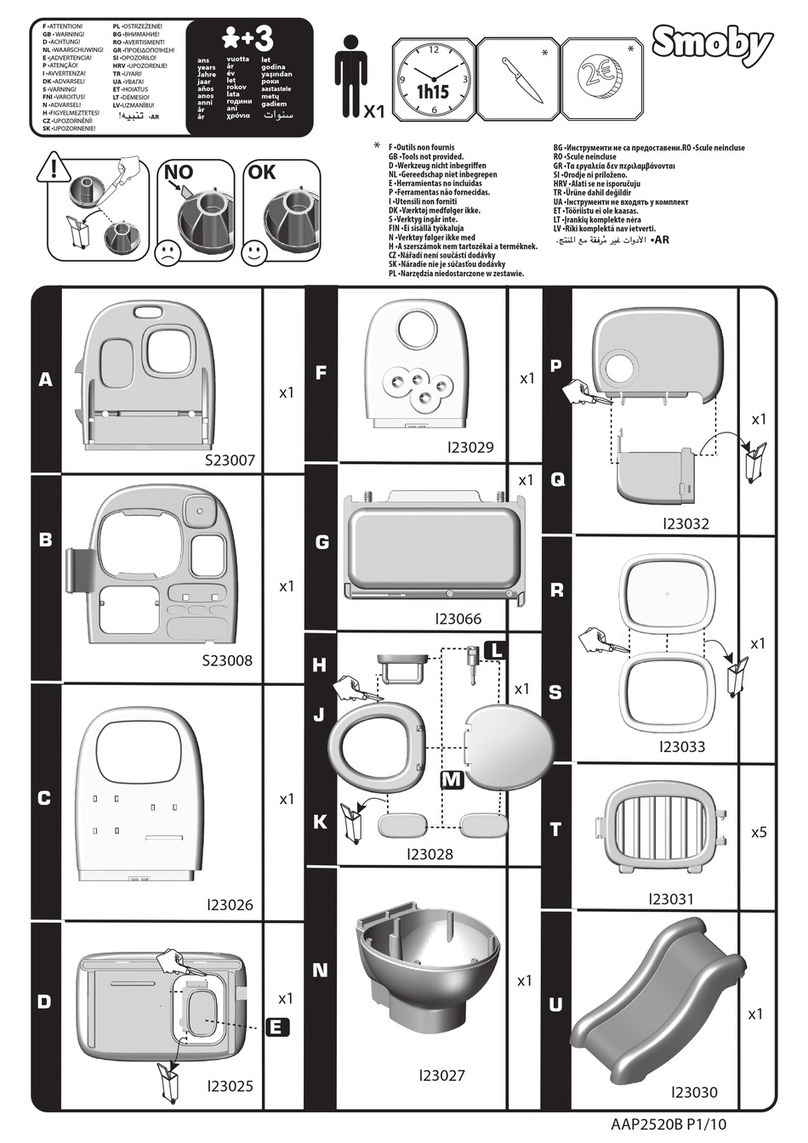

Smoby

Smoby 240307 manual

Mega Bloks

Mega Bloks Collector Series instructions

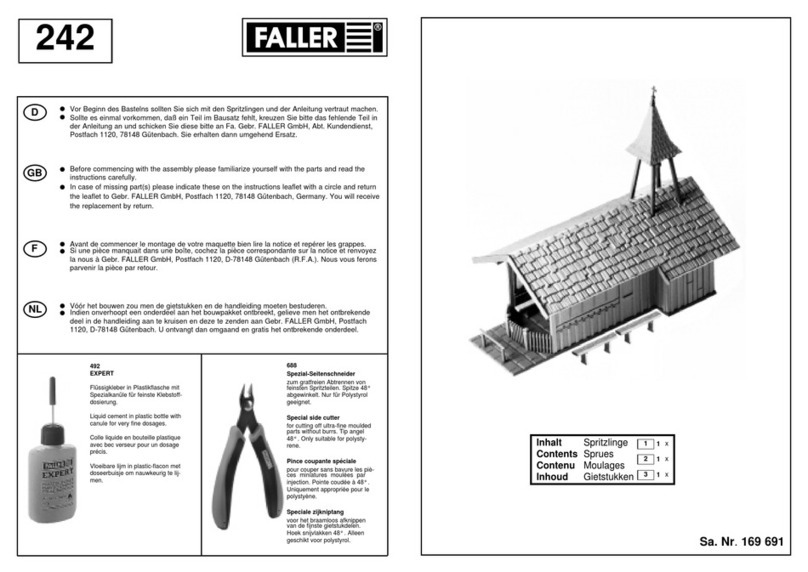

Faller

Faller 242 quick start guide