Smach EFE 1500 User manual

SOFT-SERVE AND FROZEN YOGHURT FREEZER

SERVICE MANUAL

(SERVICE MANUAL)

for

MODEL: EFE 1500

Manual Number: V

001

-

17.05.2012

2

TABLE OF CONTENTS

1) Expansion Valve Adjustment

2) Refrigeration System Schematic

3) Control Functions

4) Air Adjustment

5) Electrical System

6) Troubleshooting (General, Inverter)

7) Inverter Control by a Laptop

8) Bacteria Troubleshooting

9) Exploded Views

3

1. EXPANSION VALVE ADJUSTMENT

Adjust the pressure higher or lower by turning the expansion valve adjustment screw. Clockwise turns will raise the

pressure and counterclockwise will lower the pressure.Bear in mind that In this model 3 0° turning is enough.

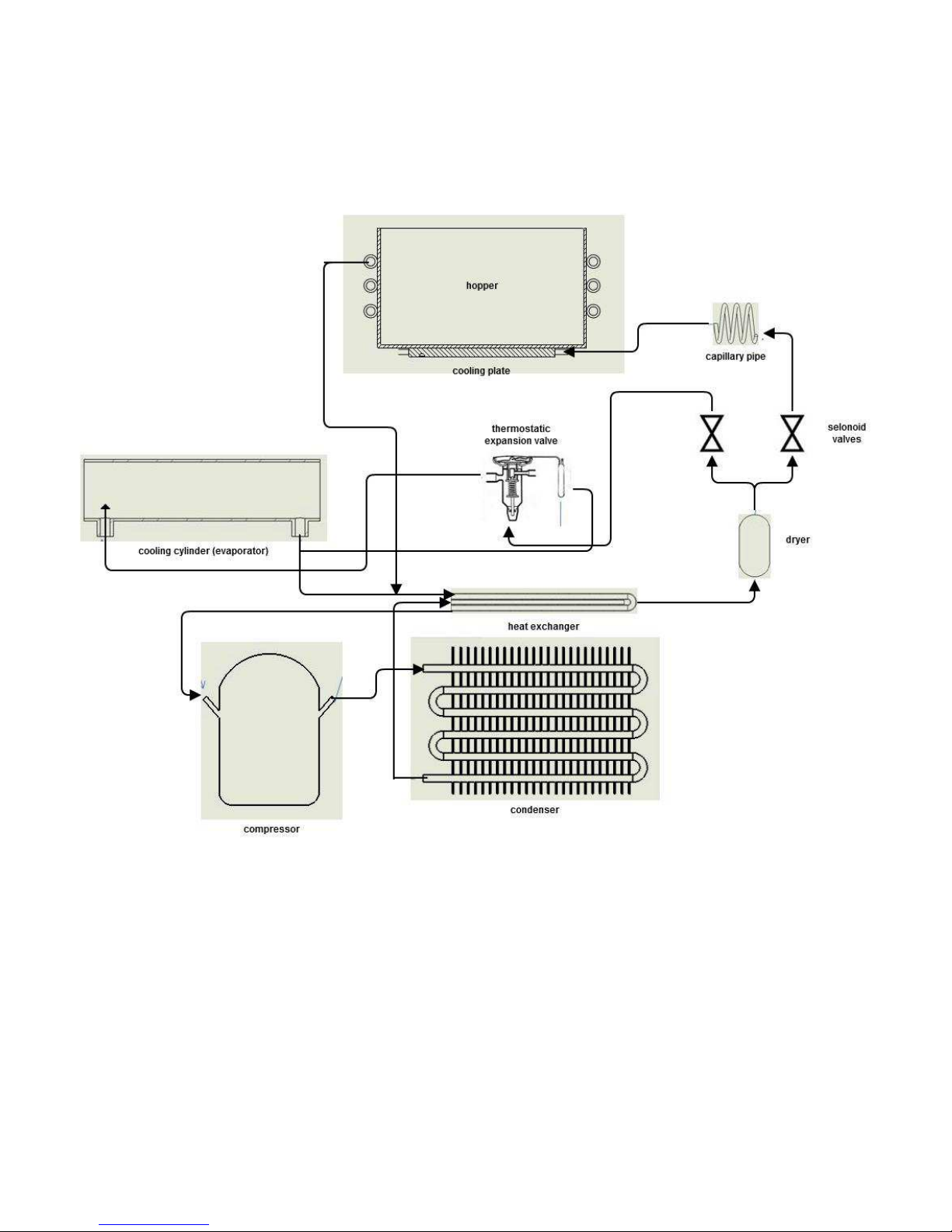

2. REFRIGIRATION SYSTEM SCHEMATIC

4

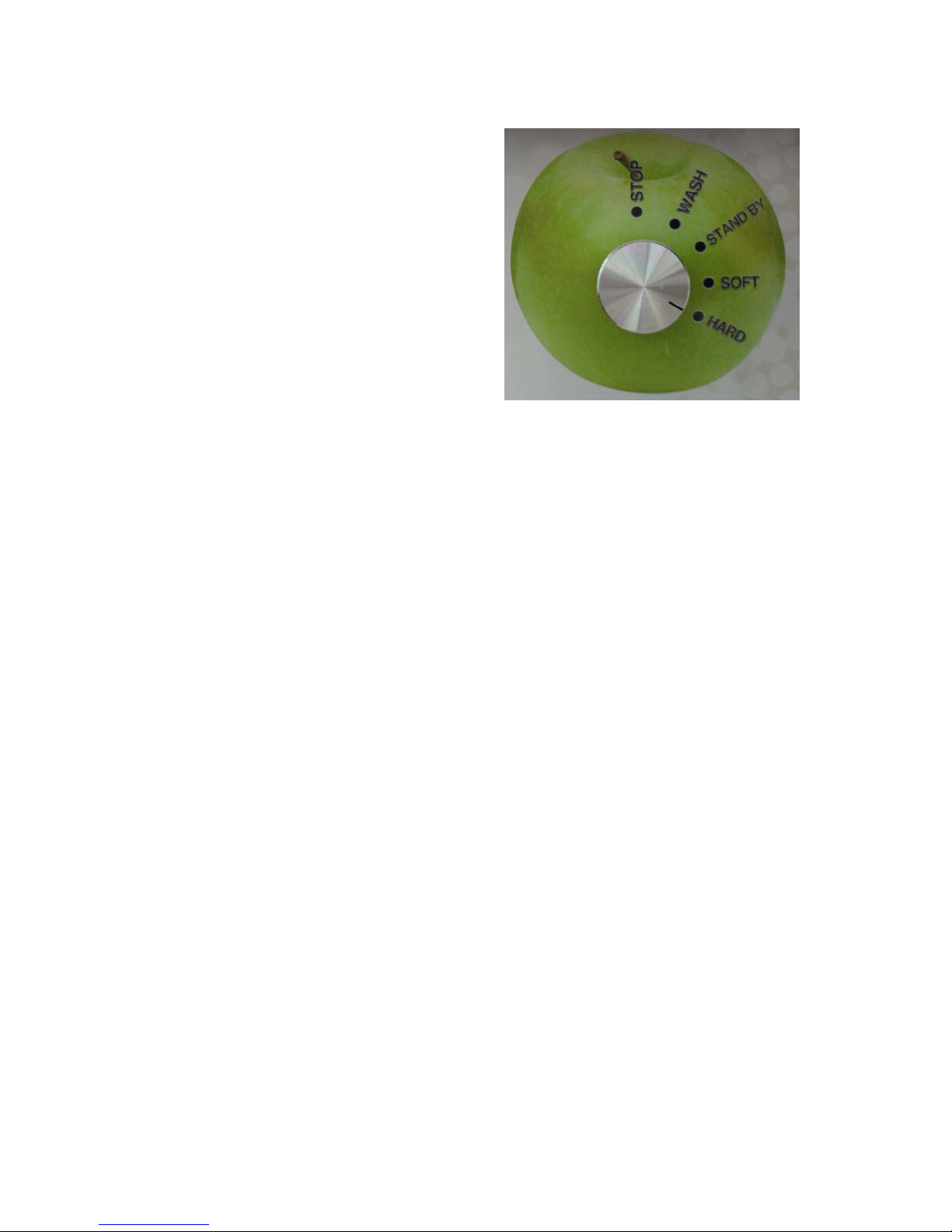

3. CONTROL FUNCTIONS

Stop

Machine operates keeping the temperature of the mix in the tankaround 4C. Therefore compressor runs at this

mode if the temperature is not mentioned above.

Wash

Machine operates cooling the mix in the tank and beater turns to blend the mix in the cylinder. Beater runs just

because to take the mix out of the cylinder in a short time.

Standby

Machine operates keeping the temperature of the mix in the tank and cylinder around 4C.

Soft&Hard

Machine operates keeping the temperature of the mix in the tank around 4C. Moreover, it cools down the mix in the

cylinder around - C when beater turns. Machine checks the current in the beater motor by an inverter when the

current is around 2. Amp for soft mode 2.8 Amp for hard mode, it stops cooling in the cylinder. However, beater

turns and cooling in cylinder starts if the motion sensor is activated by showing anything in front of them. This is

done normally when ice-cream is needed to dispense for serving. Otherwise, inverter tracks the time for 5 minutes

and then cooling in the cylinder starts and beater turns again. This goes on repeatedly. As it can be seen, soft and

hard modes are for turning the mix into ice-cream to be served. When the temperature in the cylinder goes down

the current need of the beater motor is increased.

5

4. AIR ADJUSTMENT

The AERATION TUBE has two parts ―OUTER and INNER

The OUTER has a large hole TOP and BOTTOM (These are constant)

The INNER tube has 3 different size holes TOP and BOTTOM

The INNER is turned inside the OUTER to select SMALL, MEDIUM or LARGE

The selection of the correct INNER hole-size depends on the product that is run through the Soft-Serve

Freezer and what amount of aeration is desired.

The setting can be changed during operations by simply turning the INNER aeration tube to the desired

size hole.

The SMALL HOLE will increase air percentage in the Soft-Serve and yield higher overrun.

The MEDIUM HOLE will result in an average air percentage and yield a medium overrun.

The LARGE HOLE for will decrease the air percentage and yield a lower overrun.

The LARGE HOLE setting may also be required for high-viscosity (thick) liquid mixes

TOP LARGE INNER TOP MEDIUM INNER TOP SMALL INNER

BOTTOM LARGE INNER BOTTOM MEDIUM INNER

BOTTOM SMALL INNER

5. ELECTRICAL SYSTEM

7

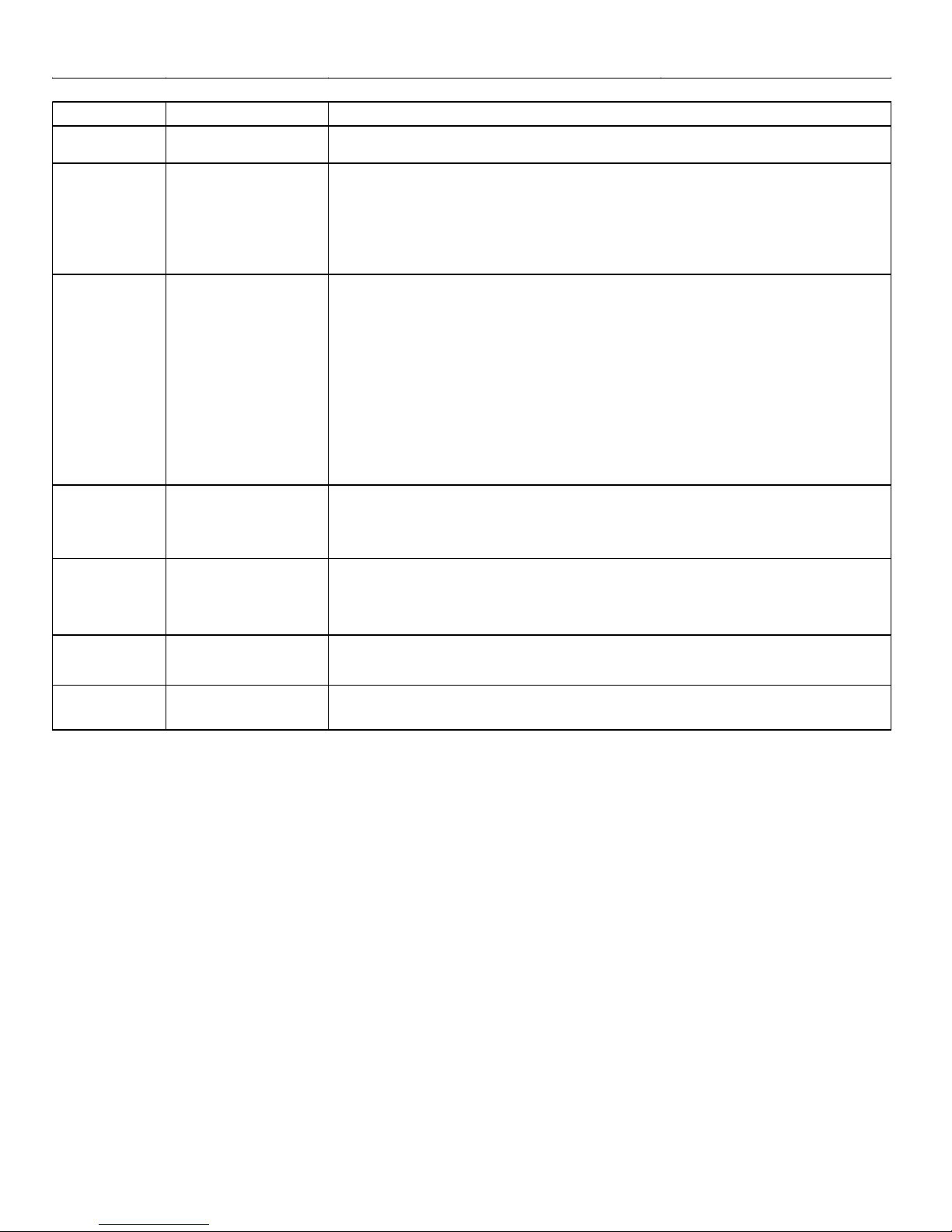

6.TROUBLESHOOTING

6.1. General

Troubleshooting

Problem CAUSE Solution

1 Machine does not run

Burnt Fuse Check&Replace.

Machine Unplugged Check&Plug the Machine

Selector mode is wrong Set the selector one of the soft-medium-hard

modes

2 Compressor starts then stops

after few seconds without

Air Not circulating Clereances should be 50 cm.

3 Machine fails to Cut-off when

running on ice cream

modes(soft-medium-hard)

Air circulation restricted Clereances should be 50 cm.

Too much air in cylinder Open tap&take off 1/2 litre of ice cream

No mix in Hopper(tank)or

just froth

Pour fresh mix

4 Machine works but no ice

cream comes out of tap

Frozen water in

spigot(piston)

All to thaw and take out 1 lt of mix/ice cream

before starting

No enough sugar in mix Replace with proper mix

5 Machine runs but ice cream

is too soft

Too much sugar in mix Replace with proper mix

Machine remained idle

without dispensing ice cream

Take out ice cream untill fresh mix is filled in

cylinder

Ice cream dispensed is too

fast

Do not exceed the production shown in the

capacity

6 Mix or ice cream comes out

from below or above the

closed tap/piston

Piston o-ring missing Putt the o-ring on piston

Piston with ruined o-ring Replace the o-ring with a new one

7 Mix comes from union drain Beater seal missing Put the beater seal

Beater seal ruined Replace the beater seal

8 Ice cream does not come out

of central tap

Cylinder(s) empty Add fresh mix

Too much air in cylinder(s) Add fresh mix

Ice cream frozen Run the machine on cleaning mode so that

frozen ice

cream will be melt

9 Ice cream comes out from

front lid/spigot

O-ring missing or not placed

properly

Place O-ring properly

Front knobs not tightened

properly/evenly

Tighten knobs evenlyand properly

10 Ice cream not increased

much in volume(overrun)

O-rings leaking Check and Replace, if necessary O Rings of

Pipe

Tighten knobs evenly

Improper mix Refill with proper mix(Proper fat&sugar)

8

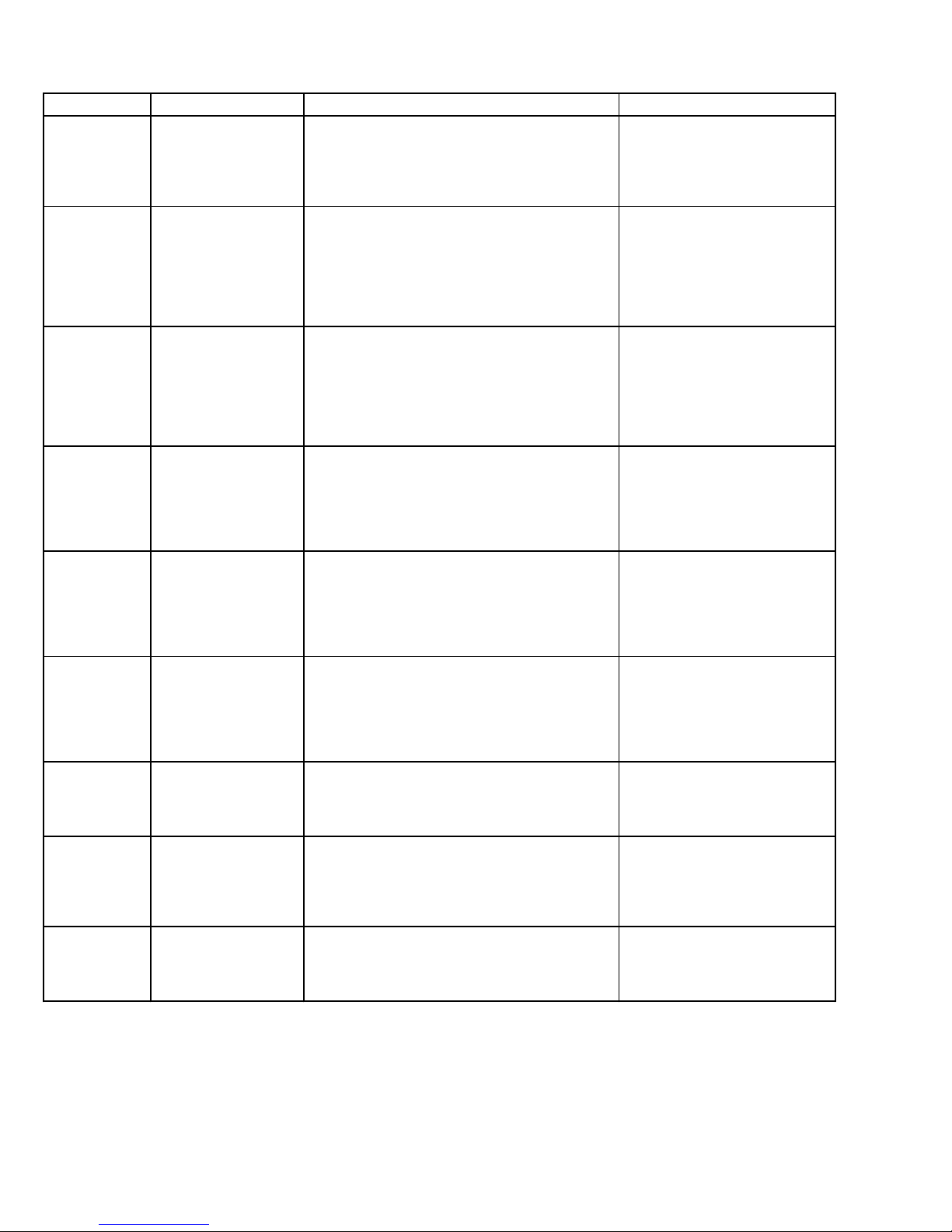

6.2.Inverter Troubleshooting

*Description of Terminals Troubleshooting in erter

SYMBOL

R\L1(L)

S\L2

T / L3 ( N )

P1

BR

P1/ P

U / T1

V / T2

W / T3

SYMBOL

R2A

R2B

R1C

Common contact

R1B

Normal close contact

R1A

Normal open contact

10V

AIN

24V

COM

FM+

SYMBOL

S1

S2

S3

S4

S5

S

Description

Main power input Single-phase: L/N

Braking resistor or connecting termina l: Used in cases where the inverter

frequently disconnects due to large load inertia or short deceleration time

(refer to specifications of braking resistor)

For

220V:1HP

DC rea ctor connecting terminals (bridging connection P1 – P must be

removed for connecting an DC rea ctor)

Inverter outputs

Description of Terminals of Tro bleshooting Inverter

Descriptions of main circ it terminals

Descriptions of SW f nction

Frequency knob (VR = Potentiometer ), when operating with optional LED keypad

power source terminal (pin 3) LEVEL SENSOR,ALARM BUZZER

Analog frequency signal input terminal or multifunction input terminals S7 (H

level:>8V, L level:<2V, PNP only) LEVEL SENSOR

Common contact for S1~S5 (S , S7)in PNP (Source) input. Short-circuit pin 2 and pin

3 (refer to SYNPLUS wiring diagram) of SW1 when used PNP input Rotary switch,optical sensor

Descriptions of SYNPLUS control circ it terminals

Description

Multifunctional terminal – Normal open ALARM BUZZER

L

Multifunctional output

terminals

HOPPER DIGITAL THERMOSTAT

CYLINDER VALVE

Common contact and analog input /output signal for S1~S5in NPN (Sink) input.

Short-circuit pin 2 and pin 3 (refer to SYNPLUS wiring diagram) of SW1 when used

NPN input optical sensor,ssr,alarm buzzer

The positive analog output for multifunction (refer to 8-00 description), the signal for

output terminal is 0-10VDC (below 2mA). SSR

Function Description

Multifunction input terminals(refer to 5-00 ~ 5-04 description)

(S5 = Encoder input terminal for integrated PLC functionality, the Encoder voltage

range: 19.2V~24.7V)

Wash-rotary switch 1

Stand by-rotary switch 2

Soft-rotary switch 3

Hard-rotary switch 4

optical sensor

Multifunction input terminals ( Digital terminal H level:>8V, L level:<2V, PNP only)

o r analog input terminal A I 2 ( 0 ~ 1 0 V d c / 4 ~ 2 0 m A ) ( refer to 5-05 description)

9

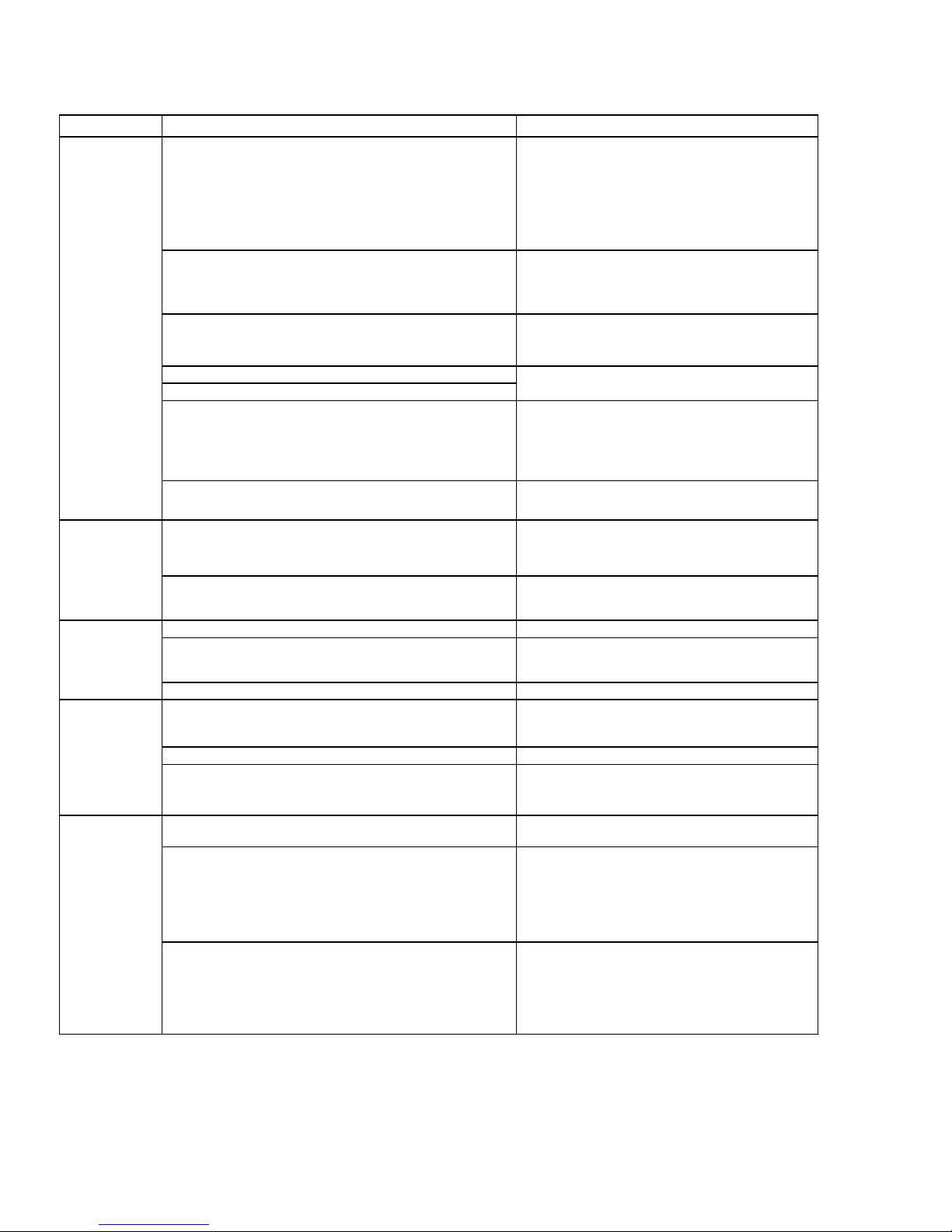

Display

CPF

EPR

-OV-

-LV-

OH

Display

OC-S

OC-D

OC-A

OC-C

OV-C

Err4

OVSP

Error Ca se Remendy

PROGRAM PROBLEM External noise interference

Connect a parallel RC burst

absorber across the magnetizing

coil of the magnetic conta ctor

that causes interference

Voltage too low

during stop

1. Power voltage too low

2. Restraining resistor or fuse

burnt out.

3. Detection circuit

malfunctions

1. Check if the power voltage

was correct or not

2. Replace the restraining

resistor or the fuse

3. Send the inverter back for

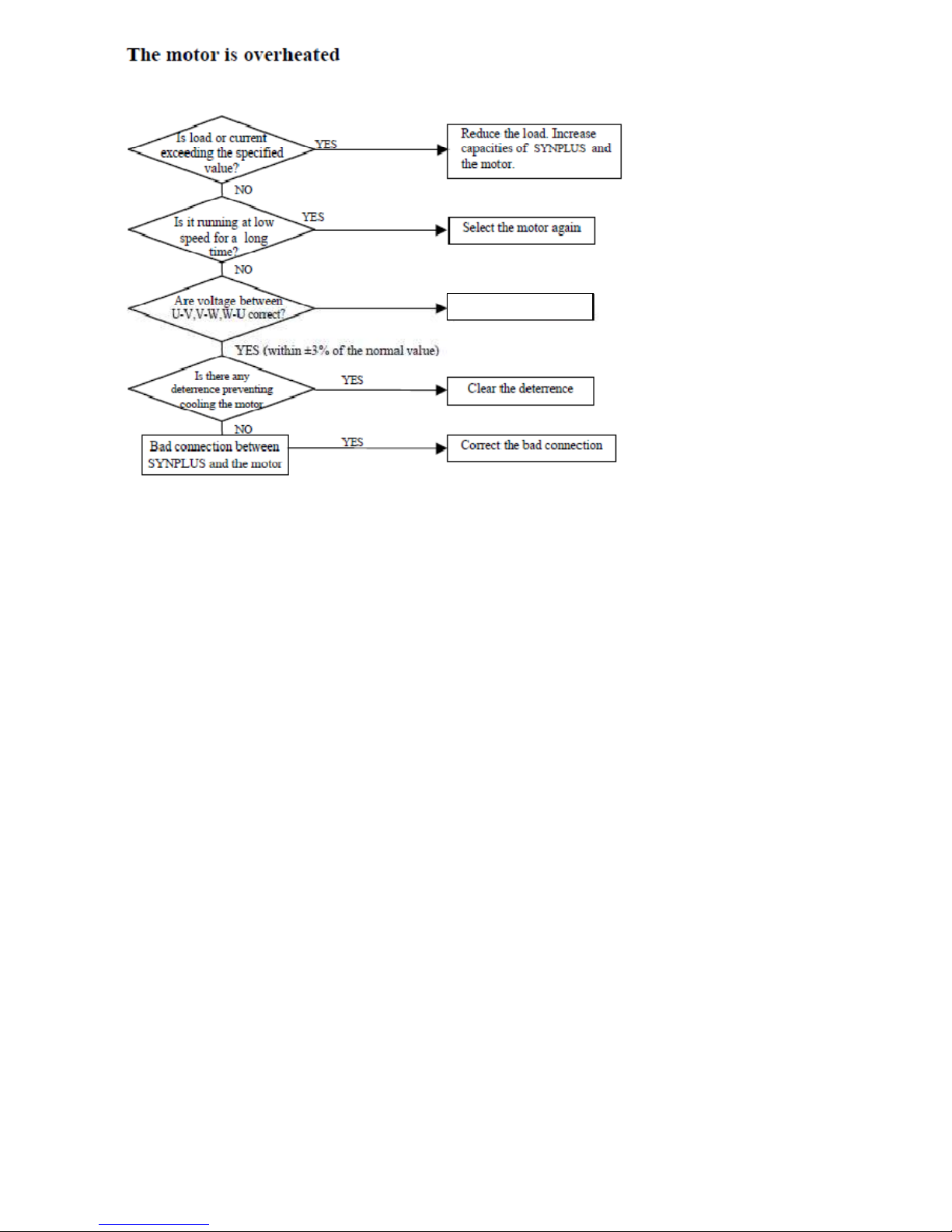

The inverter is

overheated

during stop

1. Detection circuit

malfunctions

2. Ambient temperature too high

or bad ventilation

1. Send the inverter back for

repairing

2. Improve ventilation

conditions

EEPROM

problem Faulty EEPROM Replace EEPROM

Voltage too high

during stop Detection circuit malfunction Send the inverter back for

repairing

Over current at

start

1. the motor wind and

enclosure short circuit

2. the motor contacts and earth

short circuit

3. the IGBT module ruined

1.inspect the motor

2.inspect the wire

3.replace the transistor module

Over-current at

deceleration

The preset deceleration time is

too short. Set a longer deceleration time

Errors which can be recovered man ally and a tomatically

Error Ca se Remendy

Voltage too high

during operation/

deceleration

1. Deceleration time setting too

short or large load inertia

2. Power voltage varies widely

1. Set a longer deceleration time

2. Add a brake resistor or brake

module

3. Add a reactor at the power input

side

4. Increase inverter capacity

Illegal interrupt

of CPU Outside noise interference Send back to repair if it happens

many times

Over-current at

acceleration

1. Acceleration time too short

2. The capacity of the

motor higher than the

capacity of the inverter

3. Short circuit between

the motor coil and the

shell

4. Short circuit between

motor wiring and earth

5. IGBT module damaged

1. Set a longer acceleration time

2. Replace a inverter with the

same capacity as that of the

motor

3. Check the motor

4. Check the wiring

5. Replace the IGBT module

Over-current at

fixed speed

1. Transient load change

2. Transient power change

1.Increase the capacity of the

inverter

2.Rerun parameter auto tuning

(0-0 = 1)

3. Reduce stator resistance (14-0)

if the above remedies are

helpless

Over speed during

operating

1. Motor load too big or Inverter

capacity too small

2. Motor parameter error

(vector mode)

3. The gain is too big during

vector mode operating

4. The Current detect circuit

fault

1. Increase acceleration /

deceleration time (3-02/3-03)

2. Input correct motor

Parameter

3.Cha nge stator Resistance gain

and Rotator resistance gain

(14-0/14-1), suggest tha t

decrease 50~100, until 0

4. Send back to SMACH.

Errors which can not be recovered man ally

*Error display and remedy

*Error which cannot reco ered manually

10

Display

OC

OL1

OL2

OL3

LV-C

OH-C

Voltage too l ow

during operation

1. Powe r volta ge too low

2. Power volta ge varies wi del y

1. Improve power qua l ity or

increa s e the val ue of 2-01

2. Set a l onger accelerati on time

3. Increas e i nve rter ca pa citor

4. Add a reactor a t the powe r

input

s i de

Hea tsi nk

temperature

too High during

operation

1. Hea vy l oa d

2. Ambi ent temperature too

high or ba d venti l a tion

1. Check if there a re a ny

problems wi th the loa d

2. Increa s e inverter capa city

3. Improve venti l a tion

conditi ons

Inverter overloa d Hea vy Loa d Increa se the inverter capaci ty

Over torque

1. Hea vy Loa d

2. Ins uffi cient s ettings of 9-14,

9-15

1. Increa s e the i nverter capa city

2. s e t 9-14, 9-15 properly

Over-current during

s top

1. Detecti on ci rcui t

ma l functi ons

2. Ba d conne ction for CT

si gna l cable

1.Check the noi s e between Power

l i ne and motor l i ne

2.Send the inverter ba ck for

rep ai ri ng

Motor overloa d

1. Hea vy l oa d

2. I nappropriate setti ngs of

0-02, 9-08~11

1. Increa s e the motor capaci ty

2. s e t 0-02, 9-08~11 properly

Errors which can be recovered man ally

Error Ca se Remendy

11

Display

STP0

STP1

STP2

E.S.

b.b.

ATER

PDER

Auto-tuni ng fa ults 1. Motor data error res ulti ng i n for a uto-tuni ng fai lure

2. Stop the i nverter emergently duri ng Auto-tuning

PID fe edback loss PID fe edba ck loss detect

Keypa d

emergency s top

1. If the inverter is s et a s externa l control mode (1-00=0001) a nd Stop

key i s ena bl ed (1-03=0000), the inverter will s top according to the

setting of 1-05 when Stop key i s press ed. STP2 fl a s hes after s top.

Turn the operati on s wi tch to OFF a nd then ON a gain to res tart the

inverter.

2. If the inverter i s i n communi cati on mode a nd Stop key is enabl e d (1-

03=0000), the inverter wi l l s top i n the wa y s et by 1-05 when Stop

key i s press ed during operation and then fl a s hes STP2. The PC has

to s end a Stop command then a Run comma nd to the inverter for it to

be restarted.

3. Stop ke y cannot perform emergency s top when 1-03=0001

Externa l

emergency s top

The inverter wi l l ramp stop a nd the n fla s h E.S., whe n i nput external

emergency s top s igna l via the mul ti functi ona l i nput termi na l (refer to

des cripti ons of 5-00~5-0 ).

Externa l ba s e

bl ock

The inverter s tops i mmedia tel y and then fl as hes b.b., when externa l

ba se block i s input through the mul ti functi ona l i nput termi na l (refer

to des cripti ons of 5-00~5-0 ).

Special conditions

Error DESCRIPTION

Zero s peed s top Ha ppene d when pres et frequency <0.1Hz

Fail to sta rt di rectly

1. If the inverter is s et a s externa l termina l control mode (1-00=1) a nd

di rect sta rt i s dis a bled (2-04=0001), the i nverter ca nnot be s tarted

and will fl a sh STP1 when ope ration s witch turned to ON after

appl ying powe r (refer to de s cripti ons of 2-04).

2. Direct s ta rt is pos s i bl e when 2-04=0001.

*Special Condition

12

Display

LOC

Err1

Err2

Err5

Err

Err7

Err8

EPr1

EPr2

Parameter a nd

frequency

reverse a l ready

locked

1.Attempt to modi fy frequency

/pa rameter whil e 3-17>0000

2.Attempt to revers e whil e 1-02=0001

1.Set 3-17=0000

2. Set 1-02=0000

Key

operati on error

1.Pres s _ or _whil e 1-0 >0 or

runni ng a t pres et s pe ed.

2.Attempt to modi fy the pa ra meter can

not be modi fied during ope rati on

(refer to the parameter l i st).

1.The _ or_ i s avai labl e

for modifyi ng the

pa rameter onl y when

1-0 =0

2.Modify the pa rame ter

whi l e STOP

Operation errors

Error Ca se Remendy

Communi ca ti on

fai l ed

1.Wi ring error

2 .Communi cati on pa rameter s etting

error.

3.Sum-check e rror

4.Incorre ct communica ti on protocol

1.Check ha rdwa rea nd wiring

2.Check Functi on 13-1~13-4

Para meter

confl i ct

1.Attempt to modi fy the function 15-0

or 15-7

2.Vol tage a nd current detecti on circui t

is a bnorma l

If Res et inverter i s not

avai l a ble, plea se send the

inverter ba ck for repai r

Paramete r s etting

error

1. 3-01in the range of 3-13 ± 3-1 or

3-14 ± 3-1 or 3-15 ± 3-1

2. 3-00≤3-01

3.The s etting e rror a s performing Auto

tuning(e.g. 1-00 ≠ 0_1-0 ≠ 0 )

1.Modify 3-13~3-15or 3-1

2. 3-00>3-01Set 1-00=0, 1-

0 =0 during Auto tuning

Modi fica ti on of

pa rame ter i s

not a vai la bl e i n

communicati on

1.Is sue a control comma nd during

communicati on di s abled

2.Modify the function 13-1~13-4

during communi ca tion

1.Iss ue ena ble command

before communicati on

2.Set the very pa rameter

of thefuncti onbefore

communication

Parameter not

match

Copy the para meter to inverter to

verify the pa rameter i s not ma tch.

1.Rewrite a gain

2.Repl a ce copy unit

Factory s etti ng

error

When PLC i s Runni ng, Perform

factory s etti ng

Plea s e perform factory

s etti ng be fore PLC s tops .

Paramete r s etting

error copy uni t

fai l ed

1.Set 3-18=1.2 wi thout connecting

copy uni t.

2. Copy uni t fa i l ed.

1.Modi fy 3-18

2.Repl a ce copy unit

*Operation Errors

13

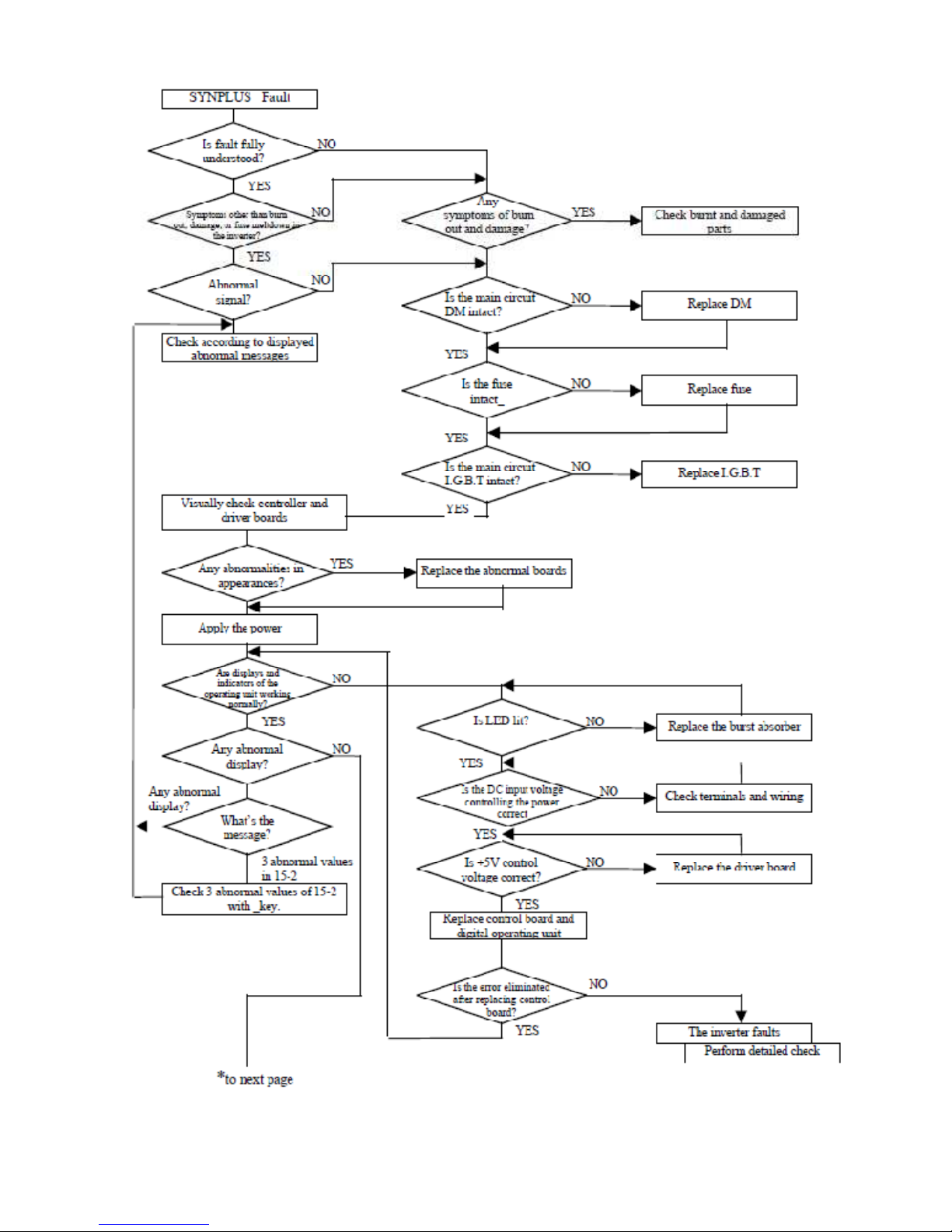

Stat s

General tro bleshooting

Checking point

Remedy

• Is a na l og frequency i nput s ignal wiri ng

correct?

• Is volta ge of frequency input correct?

Is operati on mode s etti ng correct?

• Opera te ope rati ons through the digital

pa ne l.

Motor runs

inversel y

Are wi ring for output termi nal s T1, T2, a nd T3

correct?

• Wi ring must match U, V, and W termi nal s of the

motor.

Are wi ring for forwa rd and reverse s ignal s

correct? • Check wiri ng a re correct if necess a ry.

Motor ca n not

run

Is power appl i ed to L1(L), L2, a nd L3(N)

termi nal s (is the cha rgi ng i ndica tor l i t)?

• Is the power appl ied?

• Turn the power OFF a nd then ON

aga i n.

• Make sure the power voltage is correct.

• Make sure s crews a re s ecured fi rmly.

Are there volta ge acros s the output termi na l

T1, T2, a nd T3?

• Turn the power OFF a nd then ON aga in.

Is overload ca usi ng the motor blocked?

• Reduce the load to l et the motor

running.

Are there any a bnormal i ti es i n the i nve rter?

• See error des criptions to check wiring

a nd correct if neces s ary.

Is forward or reverse runni ng comma nd i s s ued?

Motor s peed

varie s

unus ual l y

Is the l oad too hea vy? • Reduce the loa d.

Does the l oad va ry l a rgel y?

• Mi ni mi ze the variati on of the l oad.

• Increas e ca pa citi es of the inverter a nd

the motor.

Is the i nput power l a ck of pha s e?

• Add a n AC rea ctor a t the power i nput

side if us ing si ngl e-phase power.

• Check wiri ng if us ing three-phas e

power.

Motor

running

spee d too

hi gh or too

low

Are s pecifi cati ons of the motor (pol es ,

voltage…) correct? • Confi rm the motor’s s peci fica ti ons.

Is the ge ar ratio correct? • Confi rm the gea r ra tio.

Is the s etti ng of the hi ghes t output frequency

correct? • Confirm the hi ghest output frequency.

The motor

spee d can

not be

regul ate d.

Are wi ring for a na log frequency i nputs correct? • Check wiri ng are correct if necess a ry.

Is the s etti ng of operation mode correct? • Check the operation mode of the

operator.

Is the l oad too hea vy? • Reduce the loa d.

Has a na log frequency s ignal been input?

*General Troubleshooting of In erter

14

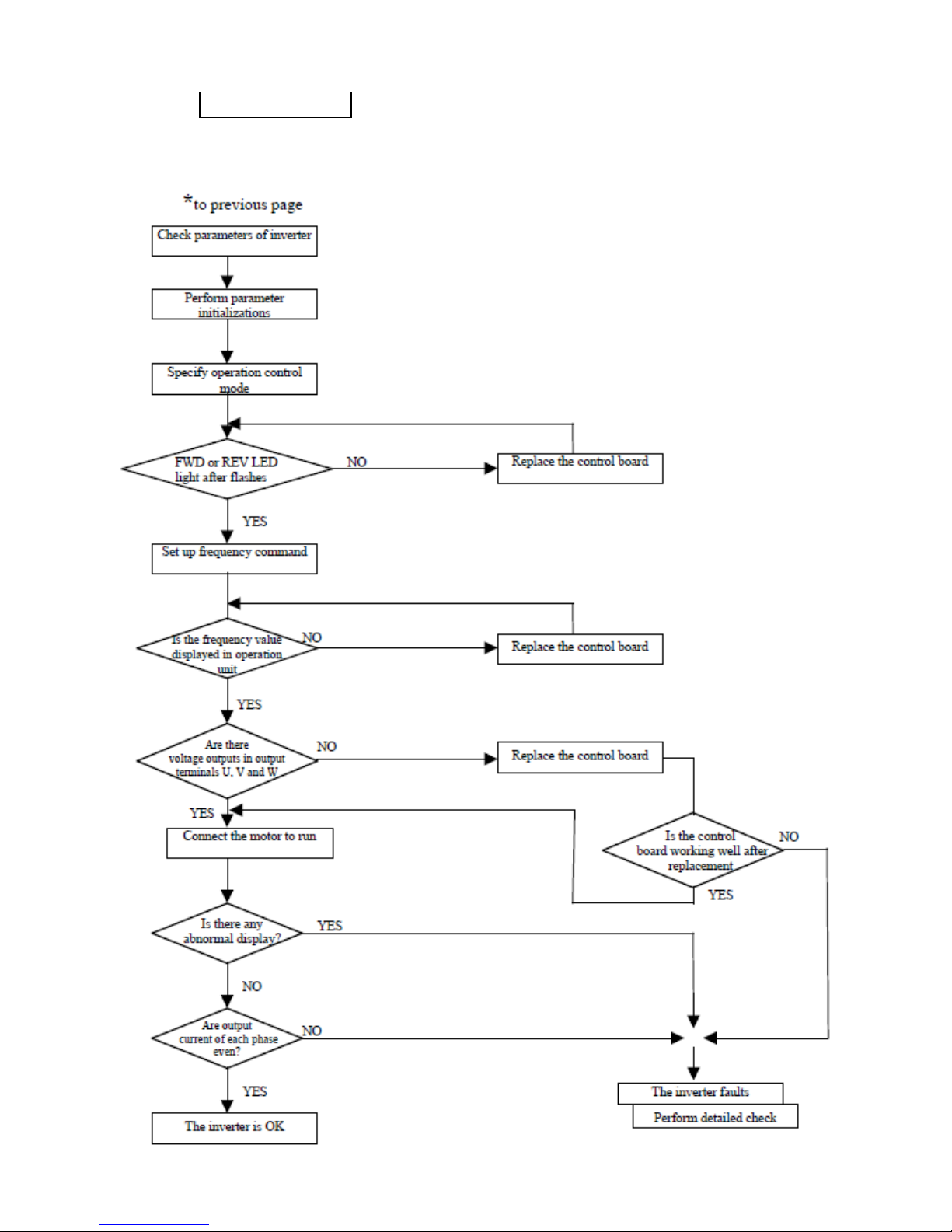

*Quick Troubleshooting of In erter

15

Inverter

Fault

1

17

Inverterfault

18

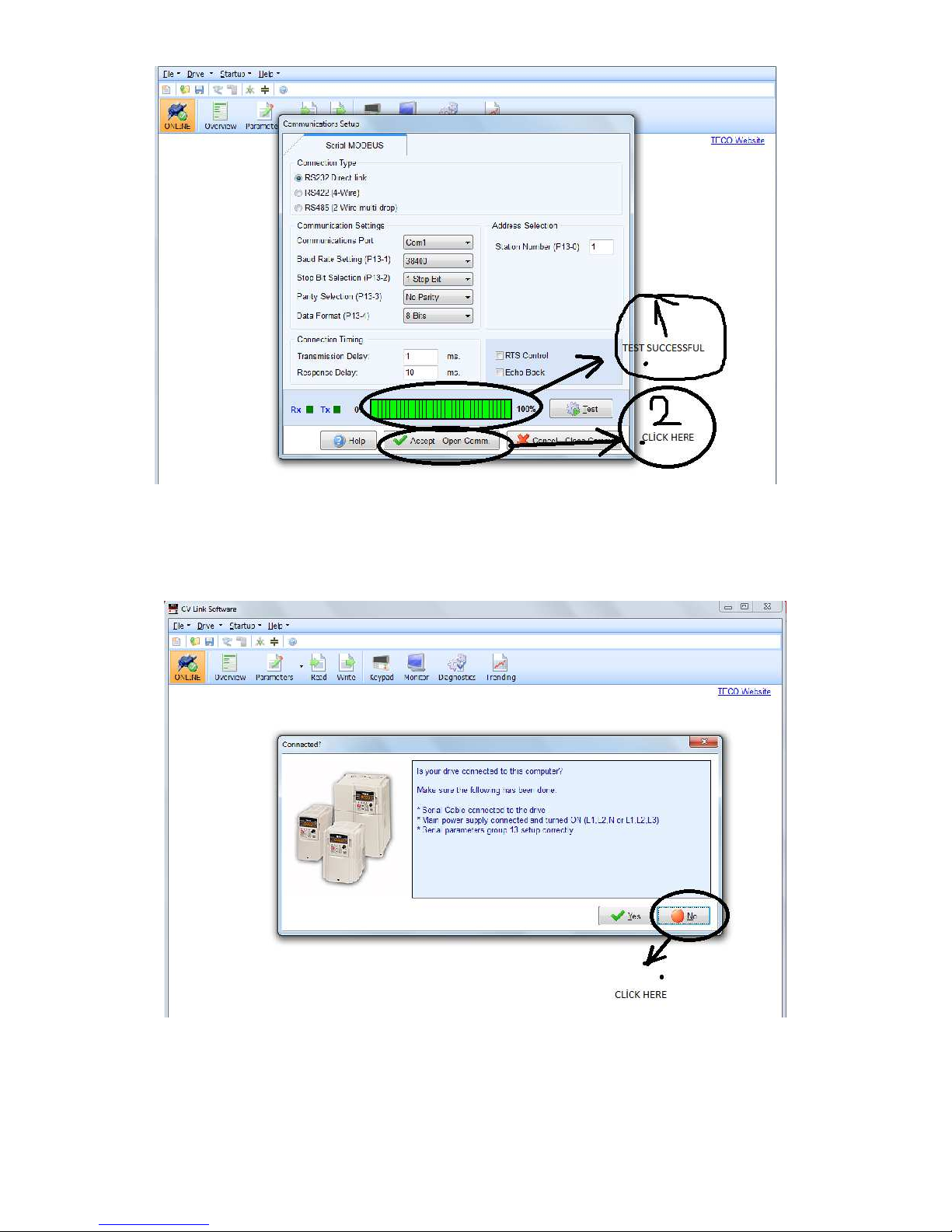

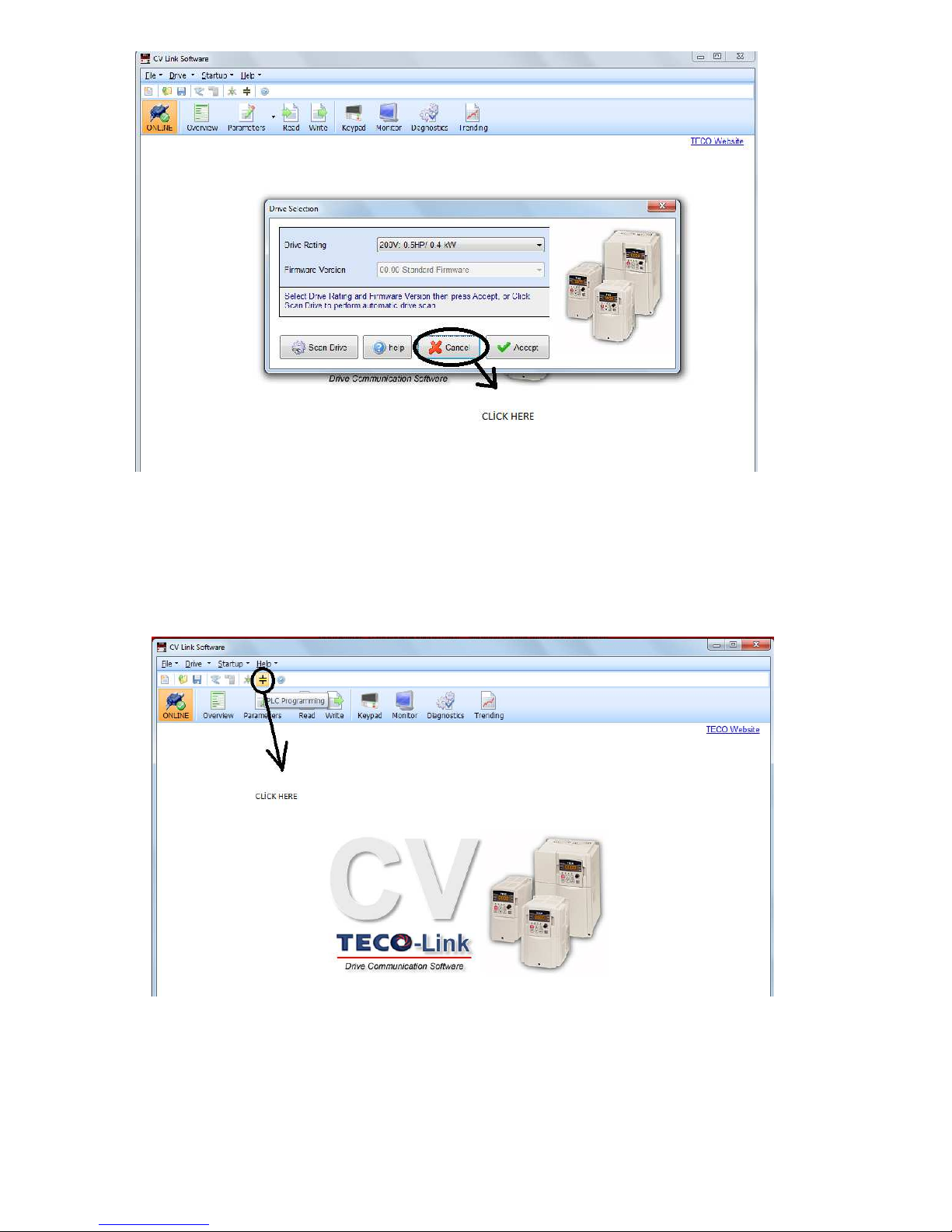

7. INVERTER CONTROL BY A LAPTOP

Inverter settings can be changed by the program named

SYNPLUS

and to connect to inverter over a laptop

RS232 cable is needed. Then follow the instructions to change settings.

19

20

Other manuals for EFE 1500

1

This manual suits for next models

1

Table of contents