Smacq Technologies Co., Ltd. USB-1000 Series User manual

USB-1000 Series Multi-Function

Data Acquisition Devices

USB-1252/USB-1252A

User Manual

Rev: C

Smacq Technologies Co., Ltd.

www.smacq.com

www.smacq.cn

2

Contents

1. Product Overview ..........................................................................................................................4

1.1. Overview .................................................................................................................................4

1.2. Block Diagram.........................................................................................................................4

1.3. Product Features ......................................................................................................................4

1.4. Product Specifications.............................................................................................................5

Analog Input ...................................................................................................................5

Digital IO ........................................................................................................................6

Counter............................................................................................................................6

Bus Interface ...................................................................................................................6

Power Requirements .......................................................................................................6

Other Specifications........................................................................................................6

2. Description on Appearance and Signal Connection....................................................................8

2.1. Appearance..............................................................................................................................8

2.2. Signal Connection .................................................................................................................10

Connecting Analog Input Signal ...................................................................................10

Connecting Digital IO Signals and Counter..................................................................12

2.3. USB Cable Reinforcement ....................................................................................................14

3. Installation and Testing ...............................................................................................................14

3.1. Driver Installation..................................................................................................................14

3.2. Hardware Installation ............................................................................................................15

4. Analog Input.................................................................................................................................16

4.1. Overview ...............................................................................................................................16

4.2. Input Range Description........................................................................................................17

Single-Ended Mode.......................................................................................................17

Differential Mode..........................................................................................................17

4.3. Description on Multi-Channel Scanning ...............................................................................17

Sampling rate ................................................................................................................17

Input Ranges .................................................................................................................17

4.4. Trigger Sources......................................................................................................................18

4.5. Analog Input Mode................................................................................................................18

4.6. Floating Signal Source...........................................................................................................19

Using Differential Connections for Floating Signal Source..........................................19

Using Non-Referenced Single-Ended (NRSE) Connections for Floating Signal Sources

......................................................................................................................................22

Using Referenced Single-Ended (RSE) Connections for Floating Signal Sources.......23

4.7. Ground-Referenced Signal Source ........................................................................................24

Using Differential Connections for Ground-Referenced Signal Source .......................24

Using Non-Referenced Single-Ended (NRSE) for Ground-Referenced Signal Sources

......................................................................................................................................25

Using Referenced Single-Ended (RSE) for Ground-Referenced Signal Sources..........26

5. Digital IO ......................................................................................................................................26

5.1. Overview ...............................................................................................................................26

3

5.2. Connecting Digital I/O Signal ...............................................................................................26

6. Counter .........................................................................................................................................27

6.1. Overview ...............................................................................................................................27

6.2. Event counter.........................................................................................................................28

6.3. Period/Positive/Negative Pulse Width Measurement ............................................................28

6.4. Connecting Counter Signals..................................................................................................28

7. Programming Instructions..........................................................................................................29

7.1. Overview ...............................................................................................................................29

7.2. Basic functions ......................................................................................................................29

FindUSBDAQ() ............................................................................................................29

OpenDevice()................................................................................................................30

CloseDevice()................................................................................................................30

ResetDevice()................................................................................................................30

7.3. Analog Input Related Functions ............................................................................................30

SetUSB1AiRange().......................................................................................................30

SetSampleRate()............................................................................................................31

SetChanMode().............................................................................................................31

SetChanSel() .................................................................................................................31

SetSoftTrig() .................................................................................................................32

7.4. Digital IO Related Functions.................................................................................................32

SetDioOut()...................................................................................................................32

7.5. Counter Related Functions ....................................................................................................33

SetCounter()..................................................................................................................33

StartCounter()................................................................................................................33

ClearCounter() ..............................................................................................................33

7.6. Read Data Control Functions.................................................................................................34

StartRead() ....................................................................................................................34

StopRead() ....................................................................................................................34

GetAiChans() ................................................................................................................34

GetDioIn().....................................................................................................................35

GetCounter() .................................................................................................................35

GetCtrTime().................................................................................................................35

ClearBufs()....................................................................................................................36

TransDioIn()..................................................................................................................36

7.7. Error Code.............................................................................................................................36

7.8. Instructions for LabVIEW Developecr..................................................................................37

7.9. Instructions for MATLAB Developer....................................................................................37

8. Ordering Information..................................................................................................................38

9. Service and Warranty..................................................................................................................39

10. Revision History...........................................................................................................................40

4

1. Product Overview

1.1. Overview

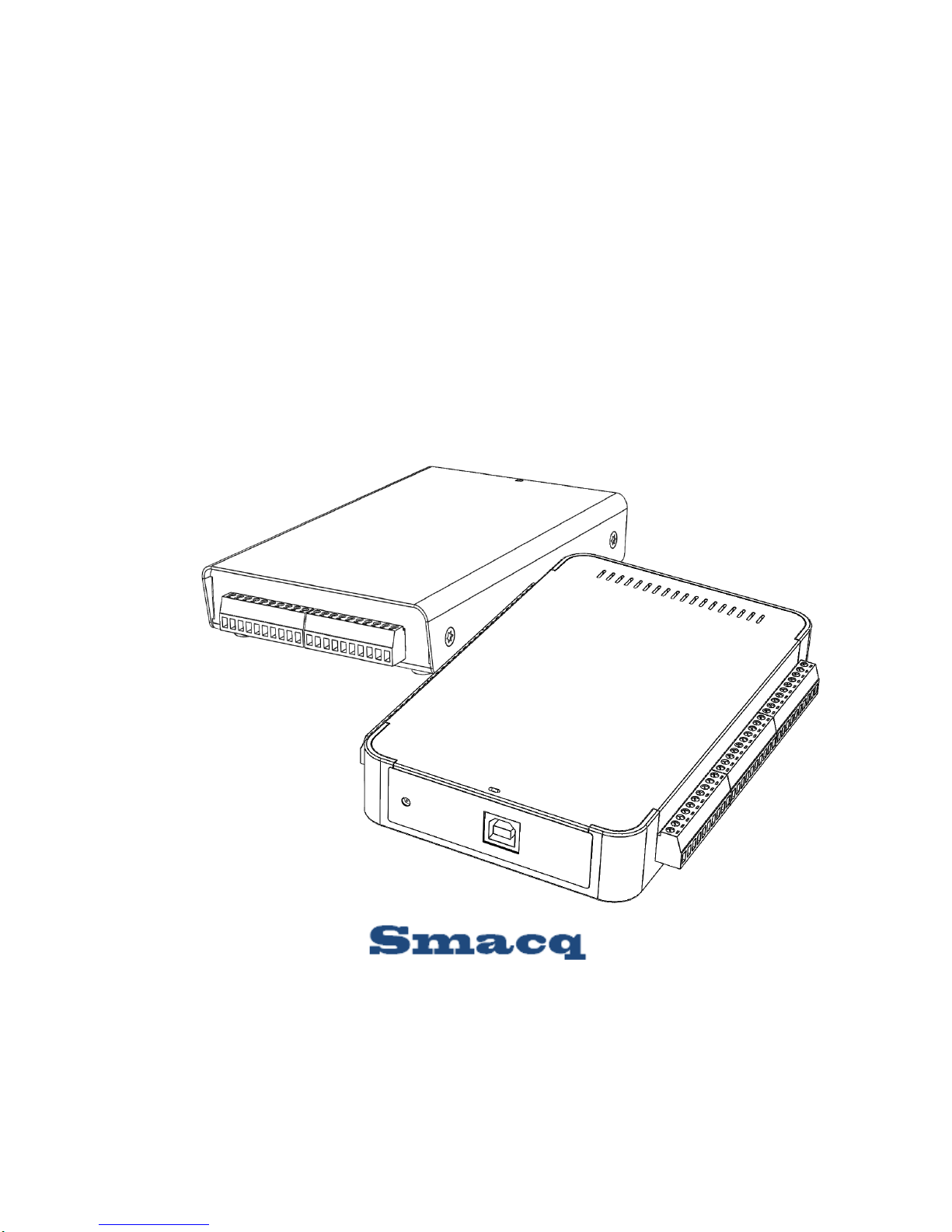

The new USB-1000 series multi-function data acquisition (DAQ) device provides a new option

for convenience and quick start of data acquisition application. Its exquisite shape provides super

portable and very flexible installation.

USB-1000 series DAQ devices provide 12-bit, up to 500kS/s sampling rate, and up to 16 analog

signal acquisition channels. You can set the range as 0~10V or ± 5V via software.

With 16 digital input/output channels and 4 counter channels, USB-1000 series DAQ device offers

you the flexibility to build automatic control system of any size.

1.2. Block Diagram

1.3. Product Features

12-bit analog input (AI) resolution.

Up to 500kS/s analog input (AI) sampling rate. (Up to 200kS/s with multiple channels

enabled.)

Sampling period configurable by steps of 20ns.

Up to 16 single-ended AI channels or 8 differential AI channels configurable via

software.

Figure 1. Block Diagram of USB-1000 series DAQ device

Digital IO

Counter

USB bus

AI

5

0~10V or ±5V configurable via software.

Onboard 16K sampling point FIFO buffer.

Up to 16 digital input (DI) channels and 16 digital output (DO) channels.

Up to four 32-bit counter channels.

LabVIEW, Visual Studio and MATLAB development support.

1.4. Product Specifications

The following product specifications, unless otherwise stated, are measured at the temperature of

25°C and the humidity of 40%.

Analog Input

Number of AI Channels

16 single-ended channels or 8 differential channels

configurable via software.

Synchronous Sampling

No

AI Resolution

12-bit

Converter Type

SAR

Sampling Rate

Single-channel acquisition: 500kS/s maximum

Multiple-channel acquisition: 200kS/s maximum

Timing Resolution

20ns

AI FIFO Buffer

16k sampling point

Range

0~10V or -5~5V configurable via software.

Safe Voltage

±15V, the DAQ device may be damaged if the input voltage

exceeds this safe voltage.

Input Impedance

>1GΩ (Power On)

Input Coupling Mode

DC

Trigger Mode

Software trigger

System Noise

NRSE 0~10V range: 0.15mVrms

NRSE ±5V range: 0.3mVrms

DIFF 0~10V range: 0.2mVrms

DIFF ±5V range: 0.4mVrms

AbsoluteAccuracy

NRSE 0~10V range: 2.8mV

NRSE ±5V range: 3mV

DIFF 0~10V range: 3mV

DIFF ±5V range: 4mV

6

Digital IO

Number of DO Channels

16

High Level Output Voltage

3.0~3.4V

Low Level Output Voltage

0~0.1V

Number of DI Channels

16

Low Level Input Voltage

3.3~5V

High Level Input Voltage

0~0.5V

Counter

Number Of Counters

4

Resolution

32-bit

Counter Measurement

Edge Count,

Counting Direction

Count Up

Maximum Input Frequency

1MHz

Bus Interface

USB Interface Specification

USB 2.0 High-Speed Interface

USB Interface Connector

USB Series Type-B Connector

Power Requirements

USB Bus Power Supply

4.75~5.25VDC

Current Consumption

About 300mA

Other Specifications

Dimensions (mm)

Without Connector: 156*102*26

With Connector:161*102*26

Weight

About 420g

Analog Channel Signal Connector

10-PIN Screw Terminal Connector

Digital IO and Counter Connector

40-PIN IDC Connector

Operating Environment

0°C ~55°C

5%RH~90%RH, Non-Condensing

Storage Environment

-40°C ~85°C

7

5%RH~90%RH, Non-Condensing

8

2. Description on Appearance and Signal

Connection

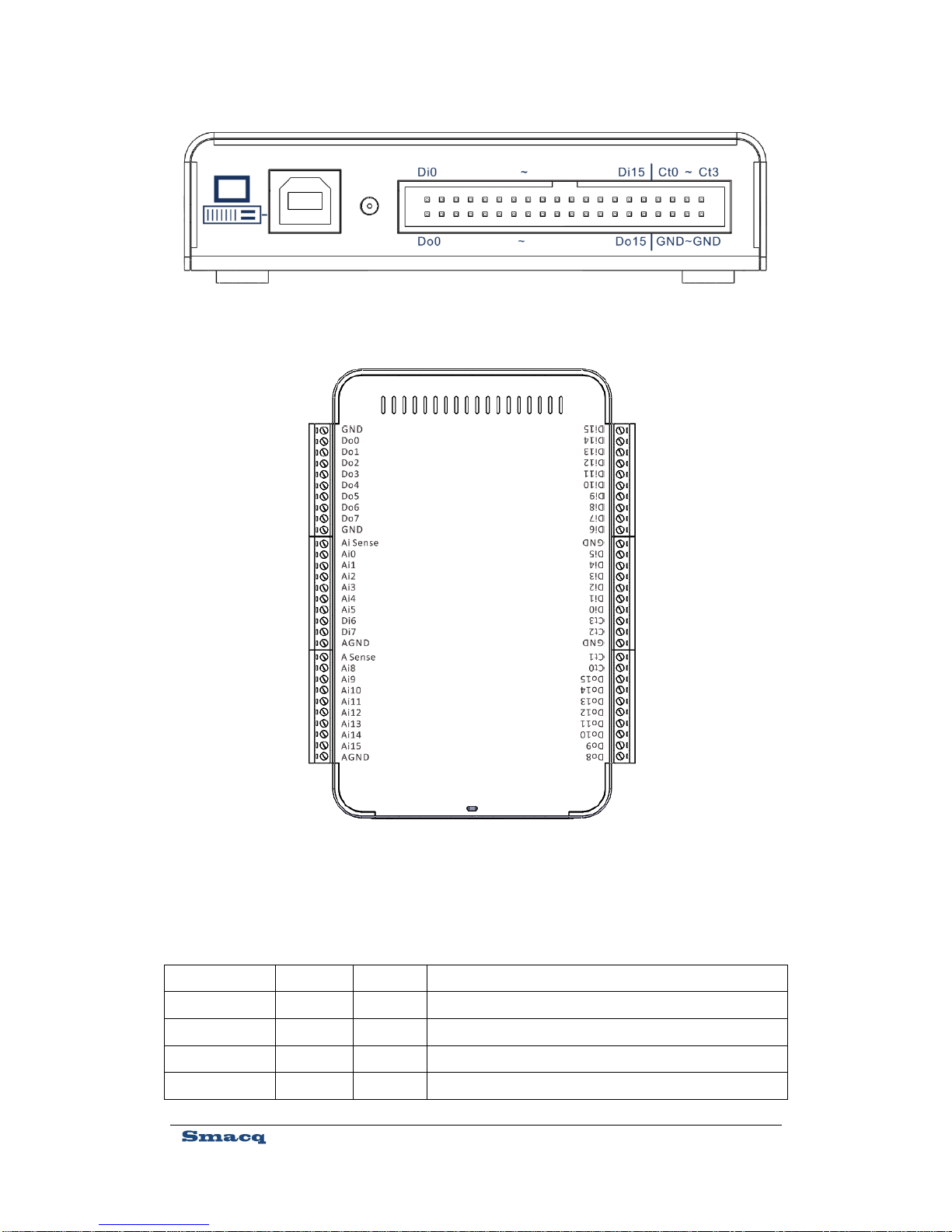

2.1. Appearance

USB-1000 series DAQ device uses metal shielding enclosure, with AI signals connected with

plug-in screw terminal connectors, digital IO signals and counter signals connected with 40-PIN

IDC connectors, and USB communication interface connected with USB series type-B connector.

Figure 2 shows the overall appearance and dimensions (in mm) of the product.

Sensors generate electrical signals to measure physical phenomena, such as temperature, force,

sound, or light. Strain gauges, thermocouples, thermistors, angular encoders, linear encoders, and

resistance temperature detectors (RTDs) are commonly used sensors.

9

Figure 2. External View of USB-1252 DAQ Device

10

2.2. Signal Connection

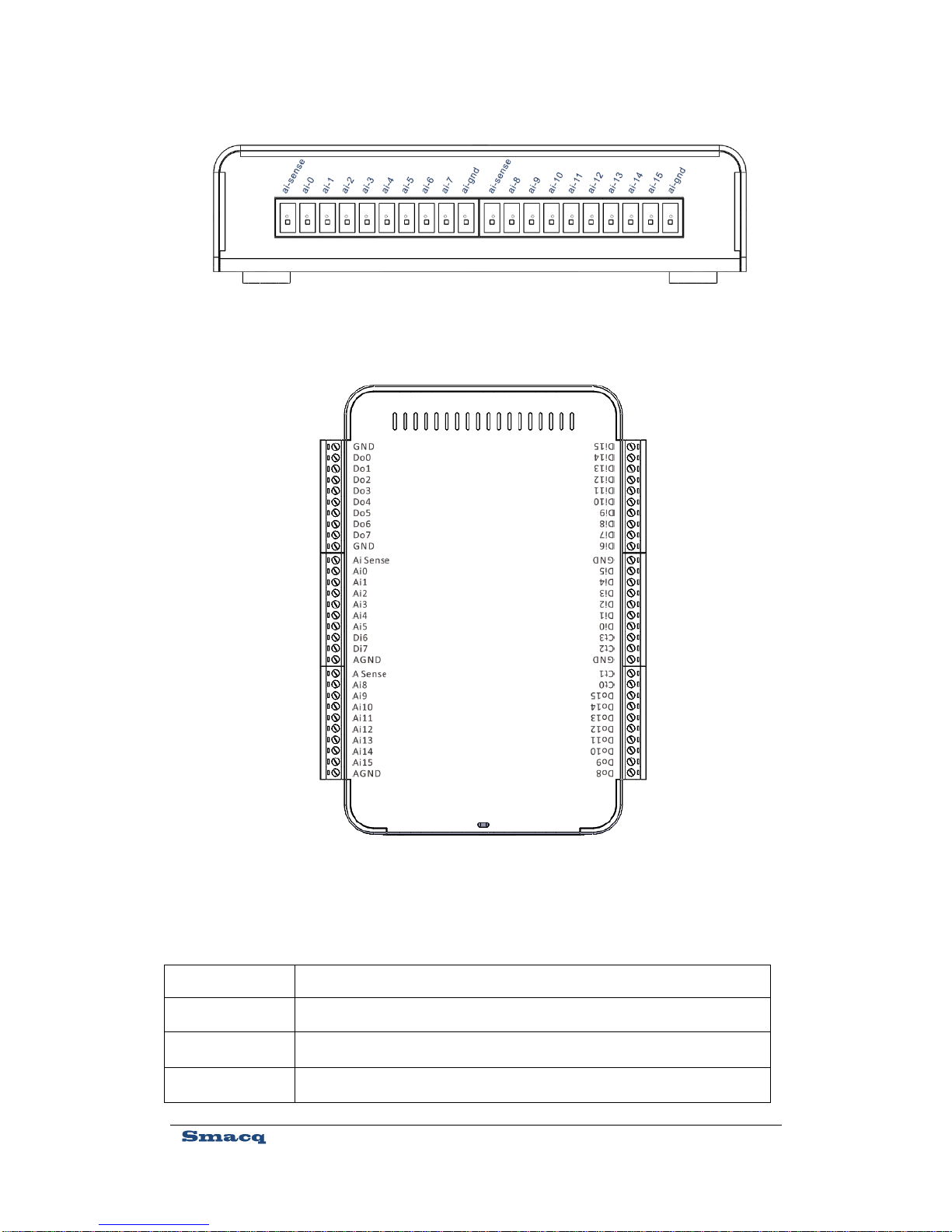

Connecting Analog Input Signal

The screw terminal connector, located in front of the DAQ device, is used for connecting AI

signals. Figure 3 and Table 1 show its pin distribution and corresponding signals. Unused AI

channels should be grounded so as to reduce system noise and achieve higher stability.

Figure 3. External View of USB-1252A DAQ Device

11

Table 1 Mapping of Pins and Signals of Screw Terminal

Name

Description

ai-sense

Reference end input for Non-Referenced Single-Ended (NRSE) signal

ai-gnd

Analog ground

ai-0

AI channel, ai0 for single ended, and ai0+ for differential

Figure 4. Pin Distribution and Corresponding Signals of Screw

Terminal Connector

Figure 5. Pin Distribution and Corresponding Signals of Screw

Terminal Connector

12

ai-1

AI channel, ai1 for single ended, and ai0- for differential

ai-2

AI channel, ai2 for single ended, and ai1+ for differential

ai-3

AI channel, ai3 for single ended, and ai1- for differential

ai-4

AI channel, ai4 for single ended, and ai2+ for differential

ai-5

AI channel, ai5 for single ended, and ai2- for differential

ai-6

AI channel, ai6 for single ended, and ai3+ for differential

ai-7

AI channel, ai7 for single ended, and ai3- for differential

ai-8

AI channel, ai8 for single ended, and ai4+ for differential

ai-9

AI channel, ai9 for single ended, and ai4- for differential

ai-10

AI channel, ai10 for single ended, and ai5+ for differential

ai-11

AI channel, ai11 for single ended, and ai5- for differential

ai-12

AI channel, ai12 for single ended, and ai6+ for differential

ai-13

AI channel, ai13 for single ended, and ai6- for differential

ai-14

AI channel, ai14 for single ended, and ai7+ for differential

ai-15

AI channel, ai15 for single ended, and ai7- for differential

Connecting Digital IO Signals and Counter

The IDC connector, located at the back of the DAQ device, is used for connecting digital IO

signals and counter signals. Figure 4 and Table 2 show its pin distribution and corresponding

signals.

13

Table 2 Mapping of Pins and Signals of Screw Terminal

Name

Reference

Direction

Description

Di0~Di15

GND

Input

DI channels

Do0~Do15

GND

Output

DO channels

Ct0~Ct3

GND

Input

Counter channels

GND

Digital ground

Figure 6. Pin Distribution and Corresponding Signals of IDC

Connector

Figure 7. Pin Distribution and Corresponding Signals of Screw

Terminal Connector

14

2.3. USB Cable Reinforcement

To prevent USB connectors from falling off accidentally, a binding band is provided to be used to

fix the USB cable to the body of the USB-1000 series DAQ devices. Refer to Figure 5 for

installation.

3. Installation and Testing

3.1. Driver Installation

If you intend to use USB-1000 series DAQ device on a PC running Windows, you need to install

the driver to make the OS recognize the DAQ device.

Here we take Windows7 operating system as an example. The driver installation steps are as

follows: (for Windows8, Windows8.1 and Windows10 operating systems, it is required to disable

the driver signature authentication during booting. For Windows XP operating system, it can be

used directly without any other settings.)

1) Open the Device Manager of the Windows operating system.

2) Right click on the device with an exclamation point

, and select Update Driver Software....

3) In the pop-up dialog box, select Browse my computer for driver software.

Figure 8. USB Cable Reinforcement

15

4) Then, choose Select from a list of device drivers on my computer.

5) Keep the default and click Next, and then click Have Disk.

6) In the pop-up dialog box, click Browse, go to the \USB-1000 Series DAQ\dirver folder

in the ResourceCD, find the Win7 folder, and then go to the x86 folder for 32-bit

operating system and x64 folder for 64-bit operating system, and finally select the

gusb.inf file, and click Open. (Windows8, Windows8.1, and Windows10 use the same

driver file as Windows7.)

7) Click OK in the Install from Disk dialog box.

8) Click Next. If a Windows security warning dialog box appears, you need to choose the

second option Always install this driver software.

9) The system starts the installation, which will take about 30 seconds. Upon the driver

installation is completed, you can see that the exclamation point in the Device Manager

disappears, as shown in Figure 6.

3.2. Hardware Installation

For connection of testing signals, refer to detailed description on connections of AI, digital IO and

counter in the subsequent sections.

After installing the driver and correctly connecting signals, you can run any one of the routines of

the USB-1000 series DAQ device in the ResourceCD. The acquired signals will be shown.

Figure 9. Device Manager Display with Driver Correctly Installed

16

4. Analog Input

4.1. Overview

With 16 AI channels, USB-1000 series DAQ device can be configured as 16 single-ended input

channels or 8 differential input channels. Figure7 shows the block diagram of analog input

function of the USB-1000 series DAQ device.

The AI block diagram of the USB-1000 series DAQ device includes the following main

components:

MUX: A multiplexer, routing and inputting the signal from the desired channel to the

instrumentation amplifier.

AI mode setting: Set AI to differential input (DIFF), Referenced Single-Ended (RSE), or

Non-Referenced Single-Ended (NRSE). Refer to Section 4.2 for detailed description on these

modes.

PGIA: Programmable gain instrumentation amplifier, used for setting input ranges.

ADC:An analog to digital converter.

AIFIFO:Data buffer FIFO.

Figure 10. Block Diagram Of Analog Input

Input Range

setting

AI mode

setting

17

4.2. Input Range Description

Single-Ended Mode

For single-ended input mode, positive input is connected to ai-n, and negative input to ai-gnd or

ai-sense. Its input range can be set to 0~10V or ±5V via the software.

Differential Mode

For DIFF Mode, positive input is connected to AI+, and negative input to AI-. Its input range can

be set to 0~10V or ±5V via the software.

The voltage from AI+ and AI- can vary in the range of -10V~10V. The actually measured voltage

value is the difference of voltage between AI+ pin andAI- pin.

When the input range is set to 0~10V, voltage range that can be measured in differential mode

shall meet the following conditions:

The voltages from both AI+ and AI- are in the range of -10V~10V, and the voltage in the range of

0V ≥ (AI+) – (AI-) ≤ 10V can be measured correctly.

When the range is set to -5V~5V, voltage range that can be measured in differential mode shall

meet the following conditions:

The voltages from both AI+ and AI- are in the range of -10V~10V, and the voltage in the range of

-5V ≥ (AI+) – (AI-) ≤ 5V can be measured correctly.

4.3. Description on Multi-Channel Scanning

Sampling rate

In multi-channel scanning applications, the PGIA will need enough settling time in switching

channels. In such case, the sampling rate can be set to 200kS/s at maximum.

Setting sampling rate higher than actually required sampling rate should be avoided, as lower

sampling rate makes the PGIA having more sufficient settling time, so that the accuracy of data

acquisition can be improved.

Input Ranges

The input range of the DAQ device should be set uniformly. In multi-channel scanning

applications, all the channels shall have a same range.

18

4.4. Trigger Sources

When USB-1000 series DAQ acquires signals via analog input, its trigger source can be set to

trigger by software or trigger by the rising edge or falling edge of digital IO input channel DIN0

port.

4.5. Analog Input Mode

The AI channel of USB-1000 series DAQ device can be configured as Referenced Single-Ended

(RSE), Non-Referenced Single-Ended (NRSE) or Differential Input (DIFF) mode. Table 3 shows

the recommended analog input modes for floating signal source and ground-referenced signal

source.

Table 3 Analog Input Mode

Analog Input

Mode

Floating Signal Sources (Not

connected to the building ground)

Ground-Referenced Signal source

Example

Ungrounded thermocouple

Isolated output signal

Battery-powered devices

Non-isolated output signal

Differential

Input

(DIFF)

Non-Referenced

Single-Ended

(NRSE)

Signal source

Signal source

Signal source

Signal source

19

Referenced

Single-Ended

(RSE)

4.6. Floating Signal Source

A floating signal source is not connected in any way to the building ground system, and instead it

has an isolated ground-reference point. Some examples of floating signal sources are outputs of

transformers, thermocouples, battery-powered devices, optical isolators, and isolation amplifiers.

An instrument or device that has an isolated output is a floating signal source.

Using Differential Connections for Floating Signal Source

Use DIFF mode for connections of floating signal sources when any of the following conditions

are met:

Two analog input channels, AI+ andAI-, are available for the signal.

The input signal is low level and a high accuracy is required.

The leads connecting the signal to the DAQ device are greater than 3m.

The input signal requires a separate ground-reference point or return signal.

The signal leads travel through noisy environments.

DIFF signal connections reduce noise pickup and increase common-mode noise rejection.

For floating signal source with impedance less than 100Ω, it is allowable to connect the negative

side of the signal to AI- and AI-GND, and connect the positive side of the signal to AI+, as shown

in Figure 8 below.

Signal source

Ground-loop

potential (VA –

VB) are added

to measured signal.

Signal source

When measuring a floating signal, make sure the negative input is

directly connected to the AGND, or indirectly through a resistor

connected to theAGND.

20

However, for floating signal source with larger impedance, this connection leaves the DIFF signal

off balance. Common-mode noise will couple onto AI+ signal instead of AI- signal. Such,

common-mode noise will appear in your measured data. In this case, connect AI- port and

AI-GND port through a bias resistor that is about 100 times the equivalent source impedance, as

shown in Figure 9. In such way, the resistor puts the differential signal nearly in balance, so that

about the same amount of noise couples onto both ends of the signal, yielding better rejection of

common mode noise.

However, for floating signal source with larger impedance, you can also use DIFF Mode using

two bias resistors, as shown in Figure 10. This fully balanced bias resistor connection offers

Figure 11 Differential Connection for Floating Signal Sources without Bias Resistor

Figure 12. Differential Connections for Floating Signal Source with Single Bias Resistor

This manual suits for next models

2

Table of contents

Popular Computer Hardware manuals by other brands

ATTO Technology

ATTO Technology FastStream SC 8500E Specification sheet

Freescale Semiconductor

Freescale Semiconductor MTRCKTSPS5604P quick start guide

Aaeon

Aaeon NEZHA-N97 user manual

D-Link

D-Link DUB-1320 Technical specifications

sparkfun

sparkfun DEV-14034 HOOK-UP GUIDE

Sony Ericsson

Sony Ericsson GC79 user guide

Crystal Vision

Crystal Vision TANDEM 3G user manual

Panasonic

Panasonic SH-AC300 operating instructions

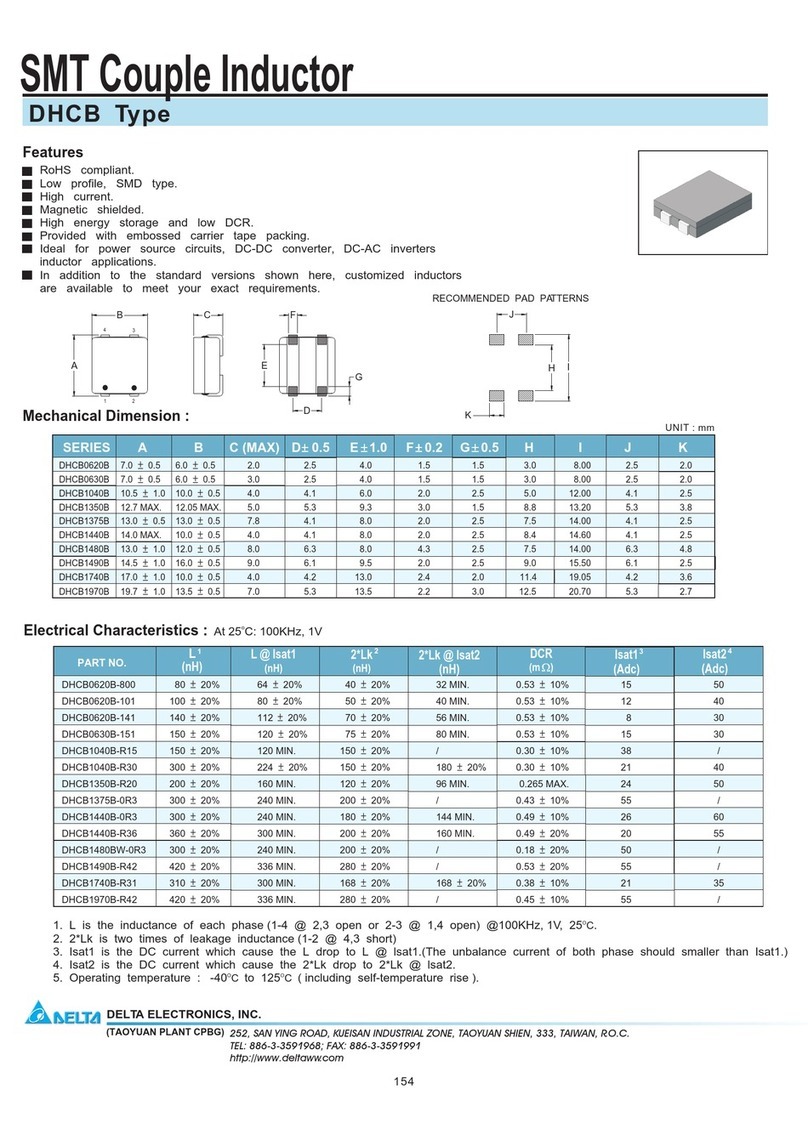

Delta Electronics

Delta Electronics SMT Couple Inductor DHCB Product specifications

Lumistar

Lumistar LS-3x Series user manual

ekwb

ekwb EK-FC590 GTX Installation and mounting manuals

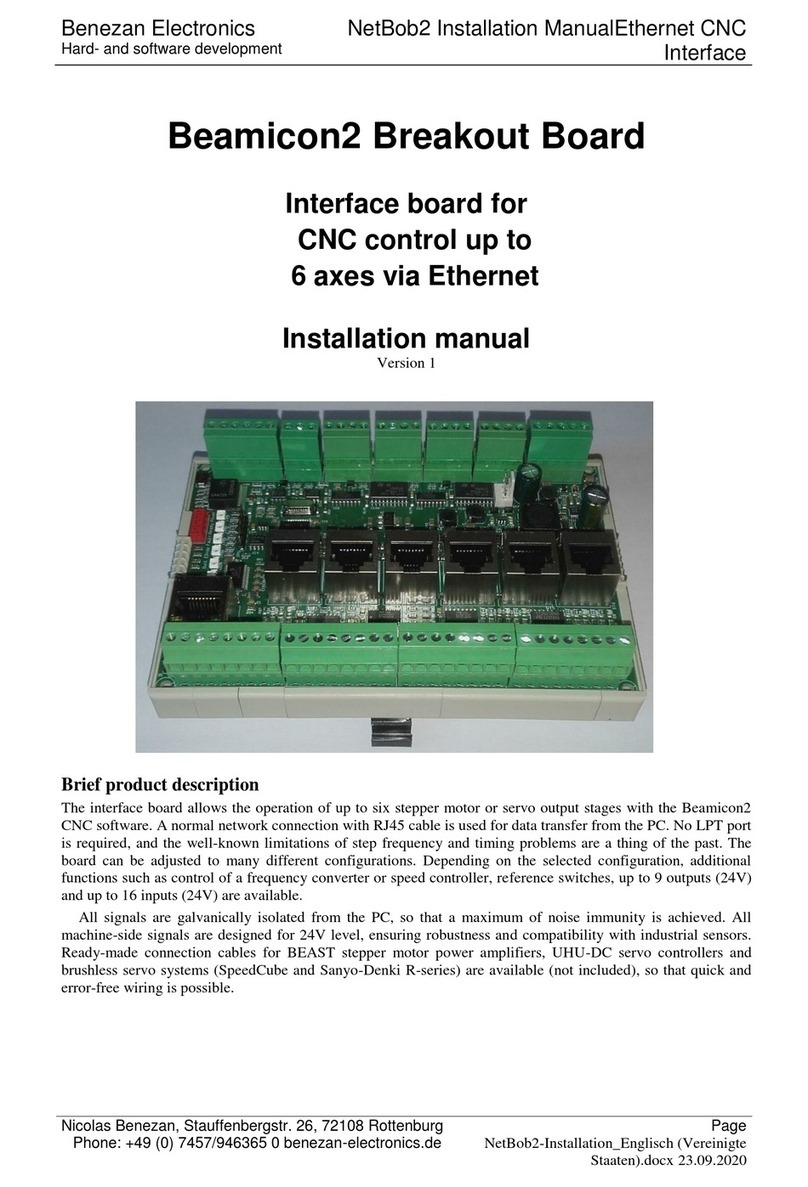

Benezan Electronics

Benezan Electronics NetBob2 installation manual