Small Wonder Labs Retro-40 User manual

‘Retro-40’ Instructions July 11, 2011 Page 1

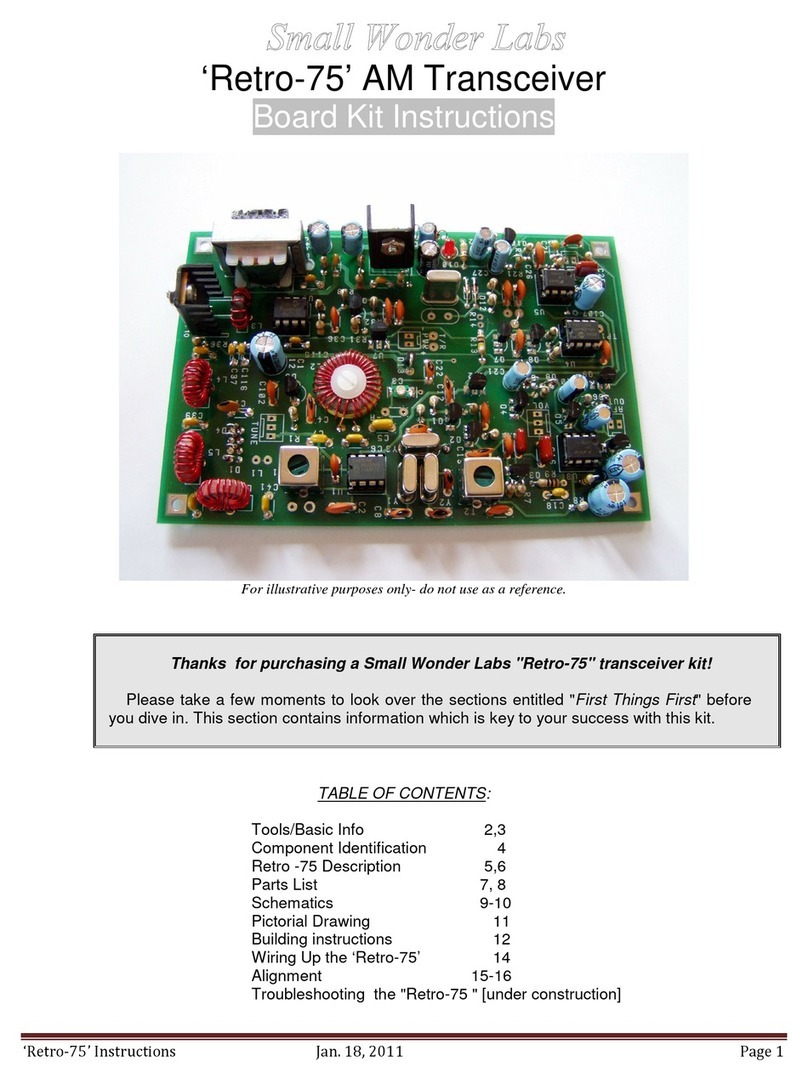

‘Retro-40’ AM Transceiver

Board Kit Instructions

For illustrative purposes only- do not use as a reference.

Thanks for purchasing a Small Wonder Labs "Retro-40" transceiver kit!

Please take a few moments to look over the sections entitled "First Things First" before

you dive in. This section contains information which is key to your success with this kit.

TABLE OF CONTENTS:

Tools/Basic Info 2,3

Component Identification 4

Retro -40 Description 5,6

Parts List 7, 8

Schematics 9-10

Pictorial Drawing 11

Building instructions 12

Wiring Up the ‘Retro-40’ 14

Alignment 15-16

Troubleshooting the "Retro-40 " [under construction]

‘Retro-40’ Instructions July 11, 2011 Page 2

THE FINE PRINT:

There are lots of small parts in this kit. I strongly

recommend a magnifying glass or close-up

glasses to check all solder joints and component

codes.

THE OTHER FINE PRINT:

If you encounter conflicts between various

sections of this document, contact me for a

resolution. The following order of precedence

applies:

•

Schematic (most trustworthy)

•

Parts list

•

Pictorial

TOOLS:

You'll need the following tools:

-Soldering iron- ~25W

- 60/40 solder, small diameter

-Diagonal cutters

-Needle-nose pliers

-Small slot screwdriver

TEST EQUIPMENT:

- Multimeter

- 50-ohm dummy load

RETRO-40 Power Requirements

.

The RETRO-40 is designed to operate with a

minimum supply voltage of approximately 10V. A

power supply capable of delivering a minimum of

1 Amp at 12-14 Volts DC is recommended.

Maximum recommended supply voltage is

16VDC.

A low-cost supply suggestion: Jameco's #319920,

15V regulated 'wall-wart'. They're at

www.jameco.com. Note: the less expensive

unregulated 'wall-warts' will not provide

adequately filtered DC- don't waste your

money! 'Filtered' is not sufficient- you need to

see the word ‘Regulated' on the description.

FIRST THINGS FIRST -

-Stuff worth knowing!

COLOR CODES:

Resistor color codes are given in the parts list.

Radio Shack's Color-Code Guide, #271-1210, or

the ARRL Handbook will help. If you're not sure,

verify the resistor values with a multimeter before

installing.

For what it's worth, roughly 8% of the male

population is red/green color-blind. If you're one of

these, you should be verifying all resistors with a

multimeter before installing them.

The RETRO-40 board is double-sided and all

holes on the board are plated-through. This

means that you do not need to solder on the top

side of the board.

SOLDERING SKILLS

Hopefully this isn't your first experience with a

soldering iron. If it is, though, or this is your first

solid-state project, here are some tips to ensure

your success:

- Soldering Iron:

Use a small iron in the 25-watt class (such as a

Radio Shack #64-2070) and keep the tip clean.

Use a moistened sponge or paper towel to clean

the tip periodically as you work.

Apply only as much heat as is needed to get a

good joint. A small vise to hold the printed-circuit

board may make soldering easier.

Touch the soldering iron tip to the PC board

trace and the component lead simultaneously.

Within a second or two, apply solder and you'll

see the solder flow onto the junction. Withdraw

the solder and then the soldering iron.

Avoid the temptation to load solder onto the joint

until no more will fit! This is an invitation for

trouble, as solder bridges may form across the

closer trace separations. Here's what the correct

and incorrect joint treatments look like:

‘Retro-40’ Instructions July 11, 2011 Page 3

.

PLEASE READ THE SECTION BELOW

BEFORE REMOVING ANY PARTS FROM THE

BOARD

Uh-oh! Sooner or later, you may need to remove

a part installed in the wrong location, or perhaps

pull a component for troubleshooting purposes.

Get yourself a roll of desoldering braid (Radio

Shack #64-2090B). Lay the end of the braid

down on the joint to be cleaned and press the

soldering iron tip over the braid. Within several

seconds you'll see the braid begin to wick up

solder from the joint. Remove the braid and

reapply a new section as needed until the joint is

clean. It may be necessary to pull the component

out from the top side of the board while heating

the joint. Leave the iron tip on the board only as

long as necessary to do the job- the PC-board

traces will eventually delaminate (peel off) if

overheated.

If that still doesn't do the job, it may be necessary

to cut the offending part off on the top side and

pull the remaining leads through with pliers.

If you need to remove a transistor, I'd highly

recommend sacrificing the part by snipping it off

on the top side of the board. The leads are best

pulled out singly to minimize the risk of lifting

pads. Contact me for replacement parts if

necessary.

After removing a component from the board, the

through-hole will probably still be blocked with

solder. Use a dissecting needle or dental probe

(explorer), apply heat to the probe and the board

trace simultaneously until the tool pushes through.

Lacking either of these tools, a round wooden

toothpick works well also!

WINDING TOROIDS:

-Count as you go. Draw each turn snug against

the core to ensure a trim and tight winding

-Double-check the turns count when you're

finished. Use your fingernail or small screwdriver

to "bump" over each turn as you count- this is

easier than counting by eye.

- Trim the excess wire off to about 3/8" (1cm) and

strip the insulation off the ends with a knife-edge

Counting the turns:

If the wire passes through the toroid center

hole, it counts as a turn. Here's an example:

MATERIALS-

You'll find the following items with your Retro-40

kit:

1- bag of parts, miscellaneous

1- antistatic bag (contains semiconductors)

1- poly bag (resistors/capacitors)

1- printed circuit board

- (these instructions )

GOOD

SOLDER FILLET IS CONCAVE AND 'WETS'

SMOOTHLY TO COMPONENT LEAD

BAD

SOLDER FILLET IS CONVEX OR DOES NOT

ADHERE TO COMPONENT LEAD

This toroid is wound with 8 turns

Turns must be uniformly distributed around

the circumference of the toroid.

‘Retro-40’ Instructions July 11, 2011 Page 4

REFERENCE DESIGNATORS:

Each component is uniquely identified with a

reference designator. Bypass capacitors are

identified as C101 and up. Reference

designators are shown in blue on the schematic

pages. Component values are shown in magenta.

C

OMPONENT IDENTIFICATION

:

•

Resistors and RF chokes

This manual describes the color coding for all

resistors. Only the first three bands are described,

the fourth band is a tolerance code, typically gold

(=5%) and is not listed. All resistors are 1/4W 5%

carbon film types, RF chokes are also an axial

(leads on each end) component but are shaped

differently.

•

Capacitors:

Electrolytic caps. The black band

denotes the negative end of the capacitor.

•

NPO Disk Caps

NPO disk caps may be distinguished from

other types of disk caps- they have a black

band at the tip of the ceramic disk.

•

Extra information on components

There's often extraneous information marked on

components. Examining a sample IC, I find

"MC1458P1 KKJK 8949". You care only about

the '1458' or other markings I've specified If I've

specified a capacitor '104' and you find the

correct number of parts, but marked "104M', for

instance, those are them!

Here's the general rule for capacitor

nomenclature:

If 3 digits are printed on the capacitor, the first two

are significant figures and the third is a multiplier.

Examples:

'471' = 47 x 10

1 =

470 pF

'103' = 10 x 10

3 =

10,000 pF = .01 uF

Letter suffixes: J=5%, K=10%, M=20%.

Please: If you're looking for a '104' monolithic

cap, be sure to inspect both sides of the caps

before concluding we gave you the wrong value!

Monolithic caps.

Poly Cap

D5- MV1662 Diode

‘Retro-40 Instructions July 11, 2011 Page 5

‘Retro-40 ‘ Description

Note: The text which follows describes the original (75M) Retro version. For the 40M

version , the IF is changed from 6 MHz to 4.915 MHz, and tuned circuits and the output

low-pass filter values are changed. The operating frequency is in the 7.0-7.3 MHz range.

Inspirations:

I’ve long been intrigued by relatively simple voice radios. The BC-611/SCR-536 [at right] was widely used

during WW II as a platoon-level radio. It had a ‘bare-bones’ crystal-controlled superhet receiver and an

AM transmitter with 350 milliwatts of output power. It had an effective range of about a mile with its built-

in whip antenna. Although pressed into service in the postwar years by enterprising hams, its lack of

selectivity limited its usefulness under crowded band conditions. As I extrapolated from this radio’s

highly inefficient whip antenna to a full-sized dipole, I realized that the effective range would be upwards

of 50 miles. In my book, that’s a usable communications distance for keeping in touch with friends! That

served as a challenge and as the inspiration for this project.

Although AM has long been supplanted by more effective modes of communication, AM activity is largely

channelized into ‘watering hole’ frequencies

.

See www.AMwindow.org . It’s therefore pretty easy to find

activity on the air. 7290 kHz is the standard ‘hot spot’ for 40M; this may vary by Region.

Receiver:

The receiver front end is entirely conventional. A series L-C T-R switch and bandpass transformer feed the SA612 first

mixer. The SA612’s internal oscillator is used to save component count by eliminating the need for a separate local

oscillator (LO) transistor. The varicap diode-tuned LO covers about 50 kHz of the 75M band. It operates at approximately

2.1 MHz and the 1

st

mixer up-converts to the Intermediate Frequency (IF).

In the interest of tradition, I initially used 455 kHz IF transformer in an IF design. A double-tuned filter using these

transformers proved woefully inadequate in keeping close-by SSB stations out of the detector stage. In light of the BC-

611’s lack of selectivity, this was largely a case of ‘reinventing the wheel’. Rather than wrestle with more stages of

filtering or the use of ceramic filters, I reverted to a tried-and-true crystal filter. I chose an IF of 6.00 MHz to keep both the

filter bandwidth and the LO frequencies reasonable. With the filter values shown on the schematic, pass bandwidth is 3.5

kHz with adequate skirt characteristics. I found it necessary to ground the case of crystal Y3 to eliminate pickup of strong

AM signals from the 49M shortwave broadcast band.

The IF amplifier uses the so-called ‘cascode’ configuration. Although the MC1350 IC is often used here, it’s been around

for an uncomfortably-long number of years. Parts cost was a factor, too- the discrete cascade amp has a parts cost of

about 15 cents. This amplifier is terminated by R6, whose value was chosen as a compromise between stage gain and

consistently stable operation.

The following stage is a peak detector which serves to recover the modulation envelope from the received signal. Q3 is

an ‘infinite-impedance detector’- a JFET biased near cutoff. I’d always wanted to say I’d used one- the phrase has a

nice ‘Hitchhiker’s Guide’ ring to it. I found it more sensitive in practice than an unbiased 1N34 Germanium diode.

U3- an LM386, is a widely-used AF Amp IC, and provides plenty of speaker volume. The transistors around it serve

several functions, Receiver audio needs to be firmly shut off during transmit. The transistor switch in series with the

LM386 output is important. That IC’s output voltage is dependent on supply voltage. As the power supply ‘pulls’ on voice

peaks, it yields an unwanted feedback path to the speaker.

The audio output waveform is also peak-detected by D6 and C20 and applied back to the gate of Q4 as a form of

Automatic Gain Control (AGC). Without it, nearby ‘Big Gun’ stations are easily capable of saturating this amplifier stage,

yielding harsh-sounding clipped audio. The AGC threshold is nominally 6 volts peak-peak, depending on the individual

characteristics of Q4. With this feedback path in place, even the strongest of stations sounds fairly clean in the receiver.

courtesy of N6GCE

www.prc68.com

‘Retro-40 Instructions July 11, 2011 Page 6

Transmitter:

The RF strip consists of a crystal-controlled Colpitts oscillator, a FET-driver IC, and a MOSFET Power Amplifier stage.

The PA stage runs class-C to keep the transmitter efficiency reasonably high. Generating an amplitude-modulated output

is done using one of the oldest tricks in the book: the transmitter’s supply voltage is varied by superimposing audio on it

through transformer T3. This is an inexpensive 48Ω:3.2Ωaudio output transformer. In this application, the transformer is

run ‘in reverse’ to step up the voltage output from U6. With no audio applied, the transmitter outputs a steady carrier. At

full (100%) modulation, the PA supply voltage swings to a minimum of 0V and to a maximum of twice the nominal supply

voltage.

In theory, this method is simplicity itself. When it’s extended to higher power levels, though, a pitfall becomes evident.

The necessary modulation transformers become rather formidable in size, and they were fondly referred to as ‘Big Iron’ by

the AM fraternity. The more modern term is, invevitably ‘Heavy Metal’. I considered heating in T3 (a maximum specified

output of 475mW) to be a design constraint and elected not to push it too hard. The transmitter runs about 2W of carrier

power and 6-7W peak output. I ran key-down tests of up to a half-hour duration- they showed minimal transformer

warming.

The ‘Big Iron’ approach is still in use, but it sees action mainly in vintage equipment. The necessary transformers have

largely gone the way of the hoop skirt and whale-oil lamps. More recent practice uses pulse-width (class-D) modulation to

directly form a varying power supply voltage, with a resulting improvement in transmitter efficiency, Other modulation

classes improve further on efficiency. The interested reader is invited to see Steve Cloutier- WA1QIX’s web site

,

www.classeradio.com for a treatment of the topic.

The FET driver, U8, is one of a family of devices with various peak drive-current ratings. The TC1412 can source/sink 2

Amps peak; other versions can supply up to 8 A. Its output is a 3.8 MHz square wave varying between 0V and 6V. I

selected the device for its small (8-pin DIP) footprint, but other builders have used CMOS hex inverters (for instance) with

all gates connected in parallel for higher drive current capability.

The choice of a microphone can often be problematic. I’d initially planned on using an HT speaker/mic to do the job, but

their typical shared mic/PTT line led to considerable complexity in T/R switching and AGC ‘gating’. I reverted to the classic

approach - a manually-operated switch- to do the job. This is more in line with the relaxed AM ‘ethos’ and lends more

flexibility to the choice of microphones. I settled on a Radio Shack

®

dynamic microphone, largely because of its modest

cost and wide availability.

U6 is a 10-Watt automotive AF amplifier in a 5-pin package. This device was attractive both for its output power capability

and for its ‘beefy’ heat sink tab. Voltage gain (40dB) and frequency response are established by the R-C networks

between pins 2 and 4 of this device.

A sample of the AF Amplifier’s output is peak-detected and applied back to an attenuator at the stage’s input. The

attenuator is formed by the series resistor between AF stages and a shunt to ground provided by Q10. The series diode,

LED and turn-on voltage of Q10 provide a fairly consistent AGC threshold at about 75% modulation. The 3.3K resistor in

the path is there to slow the AGC response time for ‘pop-free’ operation. . The AF amplifier is easily capable of

overmodulating the carrier, so it was gratifying to ‘close the loop’ and observe its effect on modulation percentage.

Transistor Q9 is turned on during receive intervals to mute the transmit audio strip.

Receiver ‘Test’ function:

One of the impediments to building an L-C oscillator (here used as the receiver LO) is that component tolerances make

the resulting operating frequency somewhat uncertain. CW/SSB projects can usually count on a borrowed signal from a

‘big rig’ in the shack to locate and adjust the local oscillator to frequency. With AM, though, there’s no ‘beat note’, and

you’ll probably hear an ‘in-shack’ AM signal everywhere you tune. The circuit block labeled ‘Test’ provides a built-in

frequency adjustment tool. At its heart is an 8-pin microcontroller coded as a frequency discriminator. It outputs a duty-

cycle modulated waveform which a digital multimeter will interpet as a DC voltage. Based on the DC reading, the builder

can compensate with a ‘select’ capacitor to bring the oscillator on frequency. See the ‘Alignment’ section of these

instructions for further details.

‘Retro-40 Instructions July 11, 2011 Page 7

‘Retro-40’ Parts List

Qty. Ref. Designator Description Identification

2 C3-A,C22 22 pF NPO disk ‘22’

1

C3 6-30 pF trimmer Green

4

C8-C11 33 pF NPO disk ‘33J’

3 C1,C2,C3-B 47 pF NPO disk ‘47J’

1 C3-C 68 pF NPO disk ‘68J’

7 C3-D, C4,C12,C13,C34-C36 100 pF NPO disk ‘101J’

1 C3-E 120 pF NPO disk ‘121J’

1 C3-F 150 pF NPO disk ‘151’ or ‘151J’

2 C38,C41 270 pF mono. cap ‘271’ or ‘271J’

1 C26 330 pF disk ‘331’ or ‘331J’

2 C39,C40 680 pF mono. cap ‘681’ or ‘681J’

1 C15 .001 uF poly ‘102J’, or ‘1n0’

2 C6,C7 2200 pF mono

. cap

‘222’

1 C5 6800 pF mono. cap ‘682J’

10 C14,C23,C101-104,106,109,C113,C114 .01 uF disk ‘103M’

1 C25 .015 uF poly ‘153’ or .’015’

1 C16 .033 uF poly ‘333’ or ‘333J’

9 C18,C24,C29,C31,C37,C108,C111,115,116 .1 uF mono. ‘104’

4 C21,C27,C28,C32 1 uF electrolytic ‘50 v 1 uF’

2 C17,C20 10 uF electrolytic ’35 v 10 uF’

3 C33,C107, C110 100 uF electrolytic ’16 v 100 uF’

3 C19,C105,C112 220 uF electrolytic ‘25V 220 uF’

1 C30 470 uF electrolytic ‘470 uF 10v’

10 D1-D4, D6-D9, D11,D12 1N4148 diode glass body

1 D5 MV1662 varicap diode 2 leads, banded

1 D10 LED red plastic, 2 leads

1 D13 1N5818 rectifier diode ‘1N 5818’

1 L1 10 uH RF choke btown-blk-blk-gold

1 L2 T68-6, add 32 turns #24 wire

Use 30” (75cm) of wire to wind

yellow toroid, large

1 L3 FT37-61, add 10 turns #24 wire

Use 8” (20cm) of wire to wind

dark grey toroid

2 L4, L6 T44-2, add 16 turns #24 wire

Use 12” (30 cm) of wire to wind

red toroid

1 L5 T44-2, add 18 turns #24 wire

Use 14” (35 cm) of wire to wind

red toroid

6 Q1,Q2,,Q7,Q8, Q10, Q11 2N4401 transistor

1 Q3 2N5485 transistor

4 Q4-Q6,Q9 2N7000 transistor

1 Q12 IRF530A power transistor

1 R26 1 ohm resistor brn-blk-gold-gold

2 R8, R25 2.2 ohm red-red-gold-gold

2 R9, R17 10 ohm “ brn-blk-blk-gold

2 R5, R23 47 ohm “ ylw-viol-blk-gold

1 R24 220 ohm “ red-red-brn-gold

4 R11, R14, R33, R36 1K ohm “ brn-blk-red-gold

2 R2, R16 1.5K ohm “ brn-grn-red-gold

2 R29, R30 2.2K ohm “ red-red-red-gold

1 R27 3.3K ohm “ org-org-red-gold

5 R3, R4, R6, R17-A R21 4.7K ohm “ ylw-viol-red-gold

3 R18, R19, R22 10K ohm “ Brn-blk-org-gold

‘Retro-40 Instructions July 11, 2011 Page 8

‘Retro-40’ Parts List (cont’d)

2 R31,R32 47K ohm “ Ylw-viol-org-gold

7 R10, R12, R13, R15, R20, R28, R35 100K ohm “ Brn-blk-ylw-gold

1 R34 220K ohm “ red-red-ylw-gold

2 R1, R7 1M ohm “ Brn-blk-grn-gold

2 T1,T2 IF transformer metal can-‘42IF123’

1 T3 Audio transformer ‘TU048-R’

1 U1 SA612AN IC

2 U2, U7 78L06 – 6V voltage regulator IC

1 U3 LM386 IC

1 U4 12C508A IC preprogrammed

1 U5 LM1458/MC1458 IC

1 U6

TDA2003V IC

1 U8 TC1412N IC

3 Y1-Y3 5.185 MHz crystal

1 Y4 7.290 MHz crystal

5 - 8-pin IC socket

2 - 4-40 x ¼” machine screw

2 - 4-40 nut

2 - Heat sink

1 - 4-40x ½” nylon machine screw

1 - 4-40 nylon nut

1 - 4-40 nylon shoulder washer

1 - 6’ (1.8m) #24 magnet wire

‘Retro-40 Instructions July 11, 2011 Page

Dave Benson, K1SWL 7/11/2011

40M AM Transceiver - p.1 of 2

.001

V

4.7K

2N7000

AF Out

V

4

6

2.2 220 uF

2

35

.1

10

50K

LM386

V

100K

Vsw

Q4

Q5

Q6

U3

18

2N7000

10 uF

220 uF

.033

A

U1

1

2

3

8

4

6

.01 Vr

L1 T1 SA602

68

7

2

.

1 Mhz

6800

NPO 2200

NPO

(2 pl)

4.7K

.01

1.5K

V

T2

4.7K

22

.01

5.185 Mhz

47

47 10 uH

L2

Q1

Q2

Q3

100

pF

50K

Vr

1M

RX TUNE

GAIN

D1

D2

100

C3

1M

100K

1K

-

10 uF

D3

D4

U2

78L06

V

.01

.01

1K .01

100K

22 pF

100K

1.5K

Vr

1

8

5

TP1

'TEST'

C

D

CLK IN Vss

Vdd

12C508A

2

GP2 GP1

6

C1

C4

C5

C6 C7

D5

C2

C8

C9 C10

C11

Y1 Y2 Y3

*

*

ground case

R2

R5

R3

R4

C12

R1

C102

C103

C104

C13

C14

R6 R7

C15

C16 R8 C105

C17 C18

R9

C19

D6

R10

R11

D7

D8 C20

R12

C22

R14

R16

R13

C23

R15

Q7 Q8

U4

C101

L2: 32 turns #24

on T68-6

E

n/c

.01

1 uF

C21

C106

C3-A

22

22 22

150

‘Retro-40 Instructions July 11, 2011 Page 10

7.122

MHz

40M AM Transceiver - p.2 of 2

7/11/2011

.01

MIC

Vsw

1

2

ANT.

21

3

Vr

10K

.1 4

V

10

8

.1

V

A

100

uF

Dave Benson, K1SWL

1.38 uH

HDBK

#97

DC power

12-15V ( )

U5

1N5818

330 pF

1K

.1

.1

Pri. Sec.

1.70 uH

270 270

680

B

78L06

IRF530A

100 uF

U7

Q12

S1

(T)

(R)

R17

R18

C107

C108

C109

C26

C24

T3

L3

L4 L5 L6

C37

C38

C116

C39 C40 C41

1 uF

100K

4

1

100 uF V

.1

5

U6

100K

1 uF

R20 C110 C111

Q9

B

2

.1 uF

1

220

2.2

470

uF

47

.1

4.7K

10K

3

1 uF

100

100K

1K

Y4

(Y5)

47K

47K

.1

100

220K

TC

1412N

2

1,8

6,7

4,5

U8

Q11

V

2.2K

2.2K

.01 .01

C113 C114 D11 D12

C115

D

C

E

3.3K

Q10

220

uF

R19

10K

C25

.015

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R32

R31

R33

R34

R35

R36

C27 C28

C29

C30

C31

C33

C32

C34

C35

C36

C112

D9

D10

D13

100 680

1.38 uH

T44-2, 16T T44-2, 16T

T44-2, 18T

R17-A

4.7K

‘Retro-40 Instructions July 11, 2011 Page 11

- +

220 uF

U1

U3 L1

7/12/2011

U5

U4

T1

D1

D2

D3

D4

TP1

.01

C106

U6

100K

R10 Y1

Y2

Y3

C101

.01

47

C2

C8

C9

C10

33

33 33

T2

C1

47

GND

ANT.

- +

- +

T3

C33

C110 100 uF 100 uF

U8

C115

.1

TC

1412N

LM

386

12C

508A

LM

1458

2N7000

Q6

220 uF

+

-

R8

2.2

C105

C19

220 uF

+

-

C112

Q12

R36

1K

Q2

Q1

Q3

C13

100

Q8 Q7

U2

78L06

2N

4401 2N

4401 Q11

U7

78L06

2N7000

Q9

Q5

Q4

2N7000

2N7000

R7

1M R6

4.7K

C104 .01

R9

10

C18 .1

+

-

C17

10 uF

+

-

C20

AF

OUT VOL.

10 uF

D6 R11

1K

+

-

R17

10

C107

100 uF

D12

D11

C108

.1

.

015 uF

.01

C25

R19

10K

C109 C24

.1

10K

R18

MIC.

.033 uF

C16

C15

C14

.001

.01

.01

.01

C113/114

Y4

Y5

R29/30

2.2K

2.2K

R14

1K

R13

100K

.01

C23

100K

R16

1.5K

R15

+

-

+

-

D9

D10

R27

3.3K

C28

1 uF

R22

10K

C30

470 uF

T/R

- PWR +

.1

C111

R26

1

.1

C31

R24

220

R25

2.2

.1

R23 C29

47

C26

330

R20

100K

+

-

+

-

C32

1 uF

R28

100K

Q10

C27

1 uF

R21

4.7K

D13

1N5818

C11

33

6800

C5

L2

C3-A

C6 C7

2200 2200

R2

R3 1.5K

47

R5

R4

4.7K

4.7K

22

C22

100

C12

C103

.01

TUNE

R1

C4 D5

100

1M

C102

.01

+

-

C21

1 uF

R12

D8 D7

100K

2N5485

C34/35

Note: Q1, Q2, Q10, and Q11 are 2N4401s

100 100

R32

R31

47K

47K R33

1K

100

C36 R34

220K

100K

R35

C38 270

C116

.1 .1

C37

L3

C39

C40

680

C41

270

680

L4

L5

L6

10 uH

'P'

C3

R17-A

4.7K

‘Retro-40 Instructions July 11, 2011 Page 12

General building instructions:

Before you get started, it’s a good idea to do an complete inventory of the parts in the kit. Why?... so you don’t

discover a shortage when assembly’s nearly complete. Worse yet, repeated requests for shortages discovered

‘piecemeal’ during building delay your progress and take time to fulfill.

You can empty the contents of the plastic packaging into cereal bowls or other study containers to begin the sorting

process. If you encounter shortages, please be sure the missing components aren’t still stuck in the packaging material.

I supply replacement parts promptly and without question, Please, though- if you lost the parts in the carpet or the cat took

them, you can tell me! That lets us know if it’s something separate from a parts-list or quality-control issue.

We appreciate feedback on the instructions- we incorporate corrections and new material to make the experience more

enjoyable for everyone!

All parts installed on the PC board should be fully seated unless otherwise noted.

Static-sensitive Components:

•

Keep these parts in the antistatic bag until you're ready to install them and handle them no more than necessary.

•

Ideally, you've got a grounded-tip iron, but if not- after the part is installed on the board and before soldering, touch

the iron tip to shack ground (if available) or to a PC-board ground point.

Diode Installation:

Some of the diodes are bent for "upright" or 'hairpin' installation on the board.

Installation polarity is as shown below. Be sure to note the orientation of the circle on

the pictorial illustration and install the diode to match this orientation. The banded

(cathode) end of the diode is always at the top. For diodes which are installed

'lying down', match the banded end to that shown on the silkscreen and pictorial

illustration.

•

Resistor installation:

Pictorial

Diode-

Schematic

Banded end

Is cathode

Pictorial or

Silkscreen

Outline

(Plan view)

‘Retro-40 Instructions July 11, 2011 Page 13

Many resistors are likewise installed in 'hairpin' fashion. As with the diodes, try to match the mounting orientation shown

on the drawing. (If mounted as shown you've got better troubleshooting access to circuit points from the top side of the

board.) Orientation of color bands on resistors and other non-polar devices is not critical.

•

Installing IC sockets:

The "notch" or dot at one end should be oriented as shown in the pictorial drawings. Doublecheck orientation before

soldering. A suggestion- solder down two opposite corners of each socket, and then go back and press a fingertip on the

socket from underneath while reheating both connections in turn. You may then solder the remaining pads. This

precaution ensures that the socket is well-seated on the PC board.

ASSEMBLY INSTRUCTIONS:

Do not install any capacitor in location C3-A until assembly is complete- see “Alignment”

Recommended Assembly sequence:

There is no critical assembly sequence for this kit. In general, it’s best to start at one corner of the board and work

your way across. It’s helpful to leave large components, e.g., the power semiconductors, T3 and the toroids until the last

steps. This minimizes the weight of the board and parts you’ll flip over repeatedly during assembly. It also minimizes the

risk of component damage when you drop the board.

Stuff only a few parts at a time (3-4 pieces). If you try to add too many parts at once between soldering operations, you

may lose track and wind up with missing solder joints! Once you've stuffed the parts on the board, bend the protruding

leads slightly outward to keep them in place while the board is inverted for soldering.

Mount all components on the silkscreened side of the board. Solder components into place and trim leads after

installation unless otherwise noted .

Before you begin assembly, you may want to organize the parts supplied with this kit. If you’ve got room to spread out,

it’s helpful to organize components by value and set them aside. If you find shortages, contact us for prompt shipment of

missing parts.

READ and HEED!

•Electrolytic capacitors and all semiconductors must be installed with the orientations shown in the pictorial

diagram. If you inadvertently install an IC socket backwards, leave it! Simply install the IC itself with the ‘notch’ or

pin 1 ‘dot’ oriented as shown on the pictorial diagram.

•Crystals Y1-Y4 should be installed with a slight (1mm) gap between the crystal case and the board surface. A

narrow strip of thin cardboard under the crystals serves as a good temporary spacer.

•Crystal Y3 requires a short jumper wire to ground from its case to a ground pad immediately to its left. Use a

leftover piece of resistor-lead for this connection.

•It’s important to make sure the wire leads on toroids have been stripped before installing the toroids on the board.

You cannot count on the heat of a soldering iron to burn through the enamel wire coating.

•The ‘flat’ on diode D10 must be oriented as shown on the assembly pictorial

•Transformer T3 is installed with the side with the letter ‘P’ facing toward L3 and the PA transistor. The

green side of the plastic winding bobbin faces the front edge of the board

•This kit includes a pair of heat sinks and 4-40 steel hardware- install these on the power semiconductors and

tighten down.

‘Retro-40 Instructions July 11, 2011 Page 14

•Toroidal inductor L1 should be restrained on the printed-circuit board using the nylon screw, nut and shoulder-

washer supplied with the kit. This improves mechanical stability and reduces the chance of ‘microphonics’.

Wiring up the Retro-40:

ANTENNA

L1

U5

TP1 Q8

Q5

Q4

+

-

R19

Y4

47

TUNE pot

50K or 100K

Linear('B') taper

DC POWER

12-15V

AF OUT

(speaker)

AF GAIN pot

50K or 100K

Audio('A') taper

If only one crystal

(Y4) is used

(OPTIONAL)

Channel Select

SPDT Switch

T/R Switch

SPST

Closed= Transmit

Open = Receive

Microphone

2/27/2010

Note: Wire colors are non-critical

-Colors shown for illustration purposes only

Note:

Do not 'bundle' these

wires with other

control functions.

Frequency selection:

The inset in the illustration above shows the crystal select function hard-wired to the ‘Y4’ position. Once a second crystal

is installed, remove the hard-wire jumper. Wire the ‘common’ on an SPDT switch to the topmost pin of the trio and the

two remaining switch leads to the two lower pads on the trio. Lead length to the SPDT switch is not critical.

Checkout instructions:

If you have not done so already, install all ICs in their respective IC sockets with the orientations shown on the pictorial

drawing.

Connect a 50-ohm dummy load to the antenna connector.

‘Retro-40 Instructions July 11, 2011 Page 15

Alignment Instructions:

There are 3 alignment steps for the Retro-40- these should be performed in the order given below.

1) Local Oscillator frequency

2) Receiver IF peaking

3) Receiver RF peaking

The tolerances on analog oscillator components (typically +/- 5%) mean that after assembling the oscillator, its operating

frequency is uncertain. The oscillator must be calibrated for operation at the proper receiver frequency. If you have a

frequency counter, you may use it instead of the DC voltage table (below) to set the correct local oscillator (LO)

frequency.

The local oscillator frequency is (7.290-5.185) MHz or about 2.1 Mhz. The frequency alignment procedure uses an on-

board microcontroller (U4) which is coded as a frequency discriminator. Its output is a waveform whose DC average

varies with frequency. [Higher LO frequencyhigher voltage.]

1) LO Frequency Adjustment

Connect DC power to the PWR +/- points indicated on the pictorial drawing. If you’ve installed D13 correctly, a

reverse-polarity supply situation will not cause harm.

Set the tuning pot to mid-scale (50% rotation).

Set the T/R switch to the closed (Transmit) position. Using a digital multimeter, measure the DC voltage at TP1

(left edge of board next to U4).

Temporarily install- but do not solder- a sample value of C3-A from the assortment supplied in the kit. Leave the

capacitors leads long for the moment. This should change the indicated value of DC voltage from the step above.

Use a fingertip to push the capacitor over slightly to ensure good contact with the board pads. Select the value of

C3-A which yields a DC reading closest to 2.646 volts. Adjust capacitor C3 to fine-tune the DC reading. The

adjustment range of C3 is 18-20 kHz. Adding higher values of capacitance lowers the operating frequency

and decreases the voltage at TP1.

This puts the center of the receiver’s tuning range at 7290 kHz.

Here’s a more extensive set of values for tuning the receiver to other center-frequencies. Use the supplied

7290kHz crystal at Y4 and set the ‘TP1’ DC voltage as follows:

Operating Frequency LO Frequency Application DC Voltage at TP1

7100 kHz 1915 kHz

2.559

7150 kHz 1965 kHz

2.582

7200 kHz 2015 kHz

2.604

7250 kHz 2065 kHz

2.627

7290 kHz 2105 kHz

U.S. Calling Freq

2.646

7295 kHz 2110 kHz

U.S. Calling Freq

2.650

Note: the current firmware version responds predictably to LO frequencies between the range of 1700 to 3400 kHz.

Beyond those limits, it yields erroneous results. If the LO is not working or the signal into U4 is missing, adjustments to

C3 or changing values of C3-A will not affect the DC voltage reading. This reading will be approximately 2.48 Volts.

This is a one-time adjustment. When this step is completed, set the T/R switch to Receive mode (switch open).

Remove DC power. Install the selected value of C3-A. Remove and save U4 (12C508A) for future use. This ensures that

U4 doesn’t modulate the supply voltage with its varying current demand, inducing an audio ‘whine’ during normal

operation.

‘Retro-40 Instructions July 11, 2011 Page 16

2) IF peaking

Set the AF gain pot for maximum gain. Touch a fingertip to R2 (1.5K), found just below Y3. Using a small slot

screwdriver, adjust the slug in T2 for maximum shortwave broadcast reception. AM signals which do not

response to tuning slug travel are probably AM (medium-wave) broadcast signals and should be ignored. There’ll

be a distinct response peak for 6 Mhz signals. Remove fingertip…..(from R2).

3) Receiver RF peaking

Replace the dummy load with a 75M/80M antenna and using the tuning pot, tune for an amateur signal. Using a

small slot screwdriver, adjust the slug in T1 for maximum received signal strength. Re-peak T2 as needed.

Transmitter adjustments: None

AF gain is controlled by a built-in ALC function. For the recommended dynamic microphone (Radio Shack

#33-3019

)*, ‘close-talk’ the microphone at approximately ¼” from your mouth. If you’re hitting the audio hard

enough, LED D10 will just flicker faintly on voice envelope peaks.

Note: this is not what you’d call a ‘good’ microphone- it’s simply inexpensive and widely available. If you need

more audio ‘highs’ in your signal, decrease the value of R19 and scale the value of C25 upward by the same

factor.

The Retro-40’s carrier output power is 2 Watts. With audio modulation, the peak envelope power

is 7-8 watts. The Retro-40 complies with current FCC requirements for waveform spectral purity.

•

Additional transmit crystals are available from www.af4k.com – see ‘HC-49/U crystals’

.

*“This just in”- I’ve been advised that the recommended microphone is a ‘Web-only’ item, They carry the following

dynamic mics in most of their stores:

Audio-Technica ATR-1100 RS # 55036964 $9.99

Sony FV 100 RS# 55032942 $9.99

If not, consider the following sources:

Audio-Technica ATR-30 (from online music stores)

Behringer XM-8500 (Amazon.com)

Both of those are in the $20 ballpark.

‘Retro-40 Instructions July 11, 2011 Page 17

Further Thoughts on Microphones:

Amateurs being what we are, the temptation to use other than the recommended microphones is probably irresistible. If

you go this route, please be aware of the following:

Dynamic Microphones:

Dynamic mics described as ‘high-level’ or ‘preamplified’ contain active internal circuitry. As such, they need a bias source

to provide working voltags. Add a 2.2K ohm resistor from the mic input signal to a stable source of voltage. U5 pin 8

would be a good choice. [Connecting to the power supply voltage will yield distortion due to power supply pulling on voice

peaks.

Further, the microphone signal levels will be too high with a preamplified mic. Replace R20 (100K) with a 10K resistor and

C26 (330 pF) with a 3300 pF (.0033 uF) capacitor. This cuts the audio level to the modulator by a factor of 10 (20 dB) and

reduces the resulting distortion.

Ceramic Microphones:

The ceramic (piezoelectric) microphones provide high-level audio but require no working bias voltage. The classic D-104

microphone is the most familiar example of this type. Add a 100K-220K resistor in series with the microphone input. This

reduces the Retro-40 audio gain to comfortable levels.

Electret Microphones:

Not recommended. These microphones require a working bias, and their capacitive nature ‘emphasizes’ audio highs.

If you must use one of these, a JFET buffer is a good idea, along with the series input resistance (above) to attenuate the

high signal levels.

Check this out: there’s now a user group at http://groups,yahoo.com/group/SWLRetro75/ A good source of advice for

both the 75 and 40M versions of the Retro- (and often quicker to respond than I am)

Dave Benson, K1SWL

k1swl@earthlink.net

July 12

th

, 2011

(Mail:)

Small Wonder Labs

P.O. Box 187

Newport, NH

03773 USA

Table of contents

Other Small Wonder Labs Transceiver manuals

Small Wonder Labs

Small Wonder Labs Retro-75 User manual

Small Wonder Labs

Small Wonder Labs SW-30+ User manual

Small Wonder Labs

Small Wonder Labs PSK-30 Manual

Small Wonder Labs

Small Wonder Labs PSK-40 User manual

Small Wonder Labs

Small Wonder Labs PSK-20 User manual

Small Wonder Labs

Small Wonder Labs PSK-20 User manual

Small Wonder Labs

Small Wonder Labs DSW-II-80 User manual