SMAR HI302 User manual

AGO / 02

FOUNDATION

HI 32FME

smar Specifications and information are subject to change without notice.

BRAZIL

Smar Equipamentos Ind. Ltda.

Rua Dr. Antonio Furlan Jr., 1028

Sertãozinho - SP 14170-480

Tel.: +55 16 645-6455

Fax: +55 16 645-6450

e-mail: [email protected]

ARGENTINA

Smar Argentina

Soldado de La Independencia, 1259

(1429) Capital Federal – Argentina

Telefax: 00 (5411) 4776-1300 / 3131

e-mail: smarinfo@smarperifericos.com

CHINA

Smar China Corp.

3 Baishiqiao Road, Suite 30233

Beijing 100873, P.R.C.

Tel.: +86 10 6849-8643

Fax: +86-10-6894-0898

e-mail: info@smar.com.cn

FRANCE

Smar France S. A. R. L.

42, rue du Pavé des Gardes

F-92370 Chaville

Tel.: +33 1 41 15-0220

Fax: +33 1 41 15-0219

e-mail: sm[email protected]r

GERMANY

Smar GmbH

Rheingaustrasse 9

55545 Bad Kreuznach

Germany

Tel: + 49 671-794680

Fax: + 49 671-7946829

e-mail: [email protected]

MEXICO

Smar México

Cerro de las Campanas #3 desp 119

Col. San Andrés Atenco

Tlalnepantla Edo. Del Méx - C.P. 54040

Tel.: +53 78 46 00 al 02

Fax: +53 78 46 03

e-mail: vent[email protected]

SINGAPORE

Smar Singapore Pte. Ltd.

315 Outram Road

#06-07, Tan Boon Liat Building

Singapore 169074

Tel.: +65 6324-0182

Fax: +65 6324-0183

e-mail: info@smar.com.sg

MIDDLE EAST

Smar Middle East

Al Sadaka Tower, Suite 204

P.O. Box 268

Abu Dhabi

Tel: 9712-6763163 / 6760500

Fax: 9712-6762923

e-mail: sm[email protected].ae

USA

Smar International Corporation

6001 Stonington Street, Suite 100

Houston, TX 77040

Tel.: +1 713 849-2021

Fax: +1 713 849-2022

e-mail: [email protected]om

Smar Laboratories Corporation

10960 Millridge North, Suite 107

Houston, TX 77070

Tel.: +1 281 807-1501

Fax: +1 281 807-1506

e-mail: sm[email protected]

Smar Research Corporation

4250 Veterans Memorial Hwy.

Suite 156

Holbrook , NY 11741

Tel: +1-631-737-3111

Fax: +1-631-737-3892

e-mail: sales@smarresearch.com

Introduction

III

Introduction

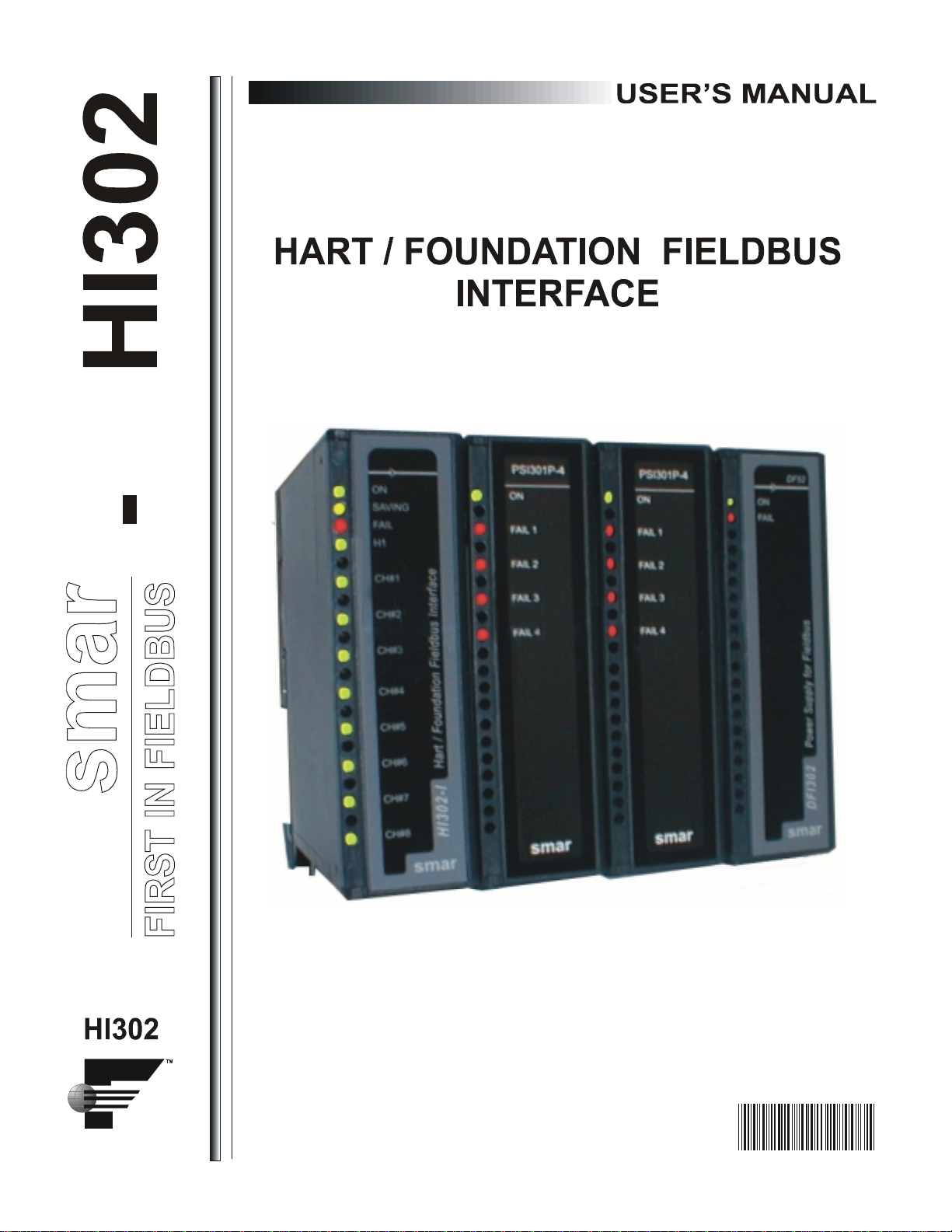

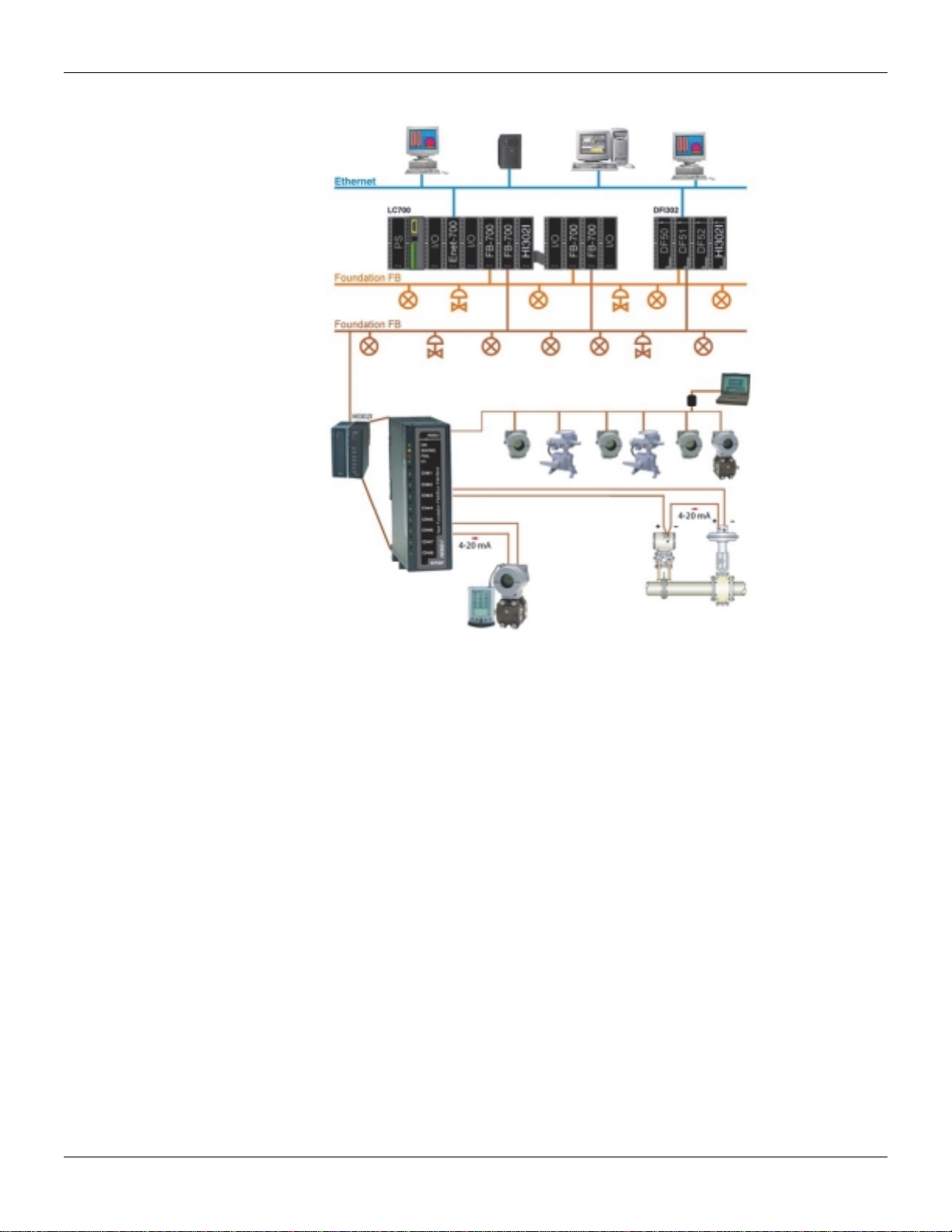

The HI302 is a hardware component integral to System 302 which main function is to interface

HART devices to Foundation Fieldbus Systems, allowing the user to perform maintenance,

calibration, sensor status monitoring, device status, among others information.

See below some HI302 features:

•Integral Part of System 302;

•Tight integration with different system manufactures due to the use of standard protocols such

as Foundation Fieldbus;

•8 HART master channels;

•Optional Analog Conversion (4-20 mA / Foundation Fieldbus – HI302-I and Foundation Fieldbus

/ 4-20 mA – HI302-O);

•Totally integrated to Asset View;

•Easy to operate due to a uniform system and tools;

•Not-multiplexed and independent HART channels;

•HART Configuration Commands located into the module and possibility to send HART

messages through parameters and bypass;

•Suitable for Asset Management System;

•Complete configuration of Smar devices embedded in HI302 module, thus no additional

configuration is required.

HI302 - User’s Manual

IV

Index

V

Index

INTRODUCTION..............................................................................................................................III

CHAPTER 1 - GENERAL VISION...................................................................................................1.1

General Characteristics..........................................................................................................1.1

Function Blocks......................................................................................................................1.2

Hart Transducer Blocks .........................................................................................................1.2

CHAPTER 2 – INSTALLATION.......................................................................................................2.1

Installation of the HI302 modules...........................................................................................2.1

Mechanical Installation...........................................................................................................2.1

Electrical Connection .............................................................................................................2.2

HART Device Installation.......................................................................................................2.4

Device Physical Types...........................................................................................................2.4

HART Installation Topology...................................................................................................2.5

Supply Voltage x Total Loop Impedance...............................................................................2.5

HI302-N..................................................................................................................................2.6

HI302-I....................................................................................................................................2.7

HI302-O..................................................................................................................................2.7

Maximum Cable Length.........................................................................................................2.8

Other devices in the Loop......................................................................................................2.8

Switching On the HI302 .........................................................................................................2.8

Updating the HI302 Firmware................................................................................................2.9

CHAPTER 3 - BASIC CONFIGURATION.......................................................................................3.1

Instruction on HI302 Configuration ........................................................................................3.1

Configuring the HCFG Block..................................................................................................3.1

HART Communication Operation Parameters.......................................................................3.2

HART Communication Diagnostic Parameters......................................................................3.4

Configuring the HIRT Block ...................................................................................................3.5

Configuring the HVT Block.....................................................................................................3.7

HI302-I – Configuring the MAI Block......................................................................................3.7

HI302-O – Configuring the MAO Block..................................................................................3.8

Starting the HI302 Operation.................................................................................................3.8

CHAPTER 4 – ADVANCED CONFIGURATION.............................................................................4.1

HART Command Definition with HCD and HWPC Blocks ....................................................4.1

Configuration for Specific HART Commands ........................................................................4.1

Commands.............................................................................................................................4.2

Configuring the HCD Block....................................................................................................4.4

HVT Allocation Map ...............................................................................................................4.4

Setting the Definition of the HART Commands in the HCD Block.........................................4.4

Request Parameters..............................................................................................................4.5

Response Parameters ...........................................................................................................4.5

Writing Parameters ................................................................................................................4.5

Setting the HWPC Block Configuration................................................................................. 4.6

HI302 - User’s Manual

VI

CHAPTER 5 - OPERATION ............................................................................................................5.1

Initialization ............................................................................................................................5.1

Leds Status ............................................................................................................................5.1

Understanding the HART Communication.............................................................................5.2

BLK_EXEC_STATE Parameter.............................................................................................5.2

BLK_ERROR and DEVICE_STATUS Parameters................................................................5.3

HIRT Block Operation............................................................................................................5.4

HART Variable Writing and Reading .....................................................................................5.5

Operating the HVT Block .......................................................................................................5.7

Sequence for HVT Reading Cycle.........................................................................................5.8

Writing Sequence in HVT Block Parameter...........................................................................5.8

HI302 versus Portable Programmers (Field Alterations)......................................................5.9

Behavior of the Static Revision (ST_REV) parameter..........................................................5.9

HART Response Code Conversion to Status FF ...............................................................5.10

Bypass Mode ......................................................................................................................5.10

Sequence for Sending a HART message through a Bypass.............................................. 5.11

CHAPTER 6 – BASIC FUNCTIONING THEORY............................................................................6.1

The HI302 Block Diagram......................................................................................................6.1

Hardware................................................................................................................................6.2

Power Supply, Operation Voltage and Protection .................................................................6.2

Hot Swap................................................................................................................................6.2

Regulators..............................................................................................................................6.2

Protection...............................................................................................................................6.3

Processing Core.....................................................................................................................6.3

HI302 Module Resetting.........................................................................................................6.4

H1 Fieldbus Communication..................................................................................................6.5

HART Communication ...........................................................................................................6.5

4-20 mA to Foundation Fieldbus Analog Conversion (HI302-I).............................................6.5

Foundation Fieldbus to 4-20 mA Analog Conversion (HI302-O)...........................................6.6

CHAPTER 7 – AN EXAMPLE OF HI302 USAGE...........................................................................7.1

Installation..............................................................................................................................7.1

Step by Step Configuration....................................................................................................7.1

Step by Step Operation..........................................................................................................7.3

CHAPTER 8 – TROUBLESHOOTING ............................................................................................8.1

Installation..............................................................................................................................8.1

Configuration..........................................................................................................................8.1

Operation ...............................................................................................................................8.1

APPENDIX A....................................................................................................................................A.1

APPENDIX B...................................................................................................................................B.1

APPENDIX C...................................................................................................................................C.1

Chapter 1

1.1

General Vision

This user manual contains instructions on how to configure and install the HI302.

General Characteristics

Among the main characteristics, the following may be mentioned:

•The HI302 supports up to eight peer-to-peer HART devices or 32 HART devices in the

multidrop mode (4 devices per channel);

•8 HART Master communication ports that can be configured as Primary or Secondary;

•1 Foundation Fieldbus H1 Channel;

•Feeding via backplane (5Vdc @500 mA);

•Device Feeding via outside source;

•Input circuits 4-20 mA on HI302 – I (current conversion to Fieldbus);

•Output circuits 4-20 mA on HI302 – O (Fieldbus conversion to current);

There are three models for the HI302, according to the analog conversion needs:

•HI302 – N: only HART communication;

•HI302 – I : HART communication and conversion of eight 4-2- mA analog inputs to FF;

•HI302 – O: HART communication and FF conversion to eight 4-20 mA analog outputs;

General Vision

1.2

Function Blocks

Several blocks were implemented to give the module the required functionality.

HART Transducer Blocks

HCFG (HART Configuration) – Concentrates general configuration parameters for

module working, in addition to parameters on HART Communication performance and

diagnostic.

HIRT (HART Identification and Real Time data) – This block contains the main

parameters, i.e., the most commonly used, besides dynamic variables. All parameters

related to universal commands and some main “Common Practice” commands are found

here. There should be one HIRT block for each HART device installed, up to 32 blocks. In

normal operation, the HIRT block parameters show the HART device variables, since

there are mechanisms to keep the HI302 database updated. See the Appendix A or the

Function Blocks handbook for details.

HVT (HART Variable Template) – This block is a large collection of variables for general

use arranged in arrays. It is now possible to access any HART instrument parameter. To

this effect, the module should get a configuration (HCD and HWPC blocks) to define the

specific instrument one wants to access, and how these commands will relate to each

parameter on the block. There is just one HVT block that should be shared among the

devices when accessing them through the HART_TAG. This configuration is already

configured in the Smar device’s memory.

Process View

(Workstation)

S

yscon

(Configuration Station) Asset View

(Maintenance)

Up to 15 devices per channel in multidrop mode.

(Only digital communication with fixed current)

Secondary Master

Multidrop Mode

Point to Point Device

(HART + 4-20 mA)

Primary Master

Up to 32 Devices

Power Supply

HI302 - User’s Manual

1.3

HCD (HART Command Definition) – It contains the HART command description for each

device type or version. This description stores information needed by the module to

communicate and the data read on the HIRT or HTV blocks. The HCD blocks defining the

universal and the common practice commands, as well as all commands specific to Smar

instruments, are already stored in the equipment’s memory and do not require any

configuration from the user. See the Appendix B for details.

HWPC (HART Writeable Parameter Command Correlation) – This block stores

information about all parameters to be written on the instrument and mapped on the HVT

block.

See table with detailed definitions on the Appendix A blocks.

In order to support the analog circuits on HI302-I and HI302-O modules, use the MAI or

MAO blocks, respectively, to convert the analog 4-20 mA standard to FF or FF to 4-20

mA. Inquire about our availability of AI or AO blocks.

MAI – Multiple Analog Input

The MAI block makes available to the fieldbus network 8 variables of the I/O subsystem

through 8 output parameters, namely, OUT_1 to OUT_8. These parameters correspond to

the current value, in percentage, on the 8 analog inputs.

MAO – Multiple Analog Output

The MAO block makes available to the I/O Subsystem 8 input parameters, IN_1 to IN_8.

These parameters correspond to the current value on the 8 analog outputs.

General Vision

1.4

Chapter 2

2.1

Installation

This chapter deals with the main physical installation features, namely: mechanical and

electrical elements.

IMPORTANT

All comments or considerations made in this manual refer to HART communication using

FSK modulation (Frequency Shift Keying).

Installation of the HI302 modules

Mechanical Installation

The HI302 modules are enclosed in the Smar standard plastic housing, like the LC700

and the DFI302. Therefore, they are fully interchangeable on the standard racks. The

picture below shows a typical HI302 installation set:

The HI302 requires just one 5V @ 500 mA power supply. We recommend the Smar PS-

AC or DF50 power supply modules. Besides providing a high quality feeding, they also

provide a “Power Fail” signal to prevent power failure or AC problems. However, the user

can use another power supply, provided it meets the minimum requirement of quality and

safety.

The other elements follow the same installation procedure as Foundation Fieldbus and

HART devices. For more information on installation procedures, visit our www.smar.com

site and download a Smar handbook copy free of charge.

BASIC SE

T

Installation

2.2

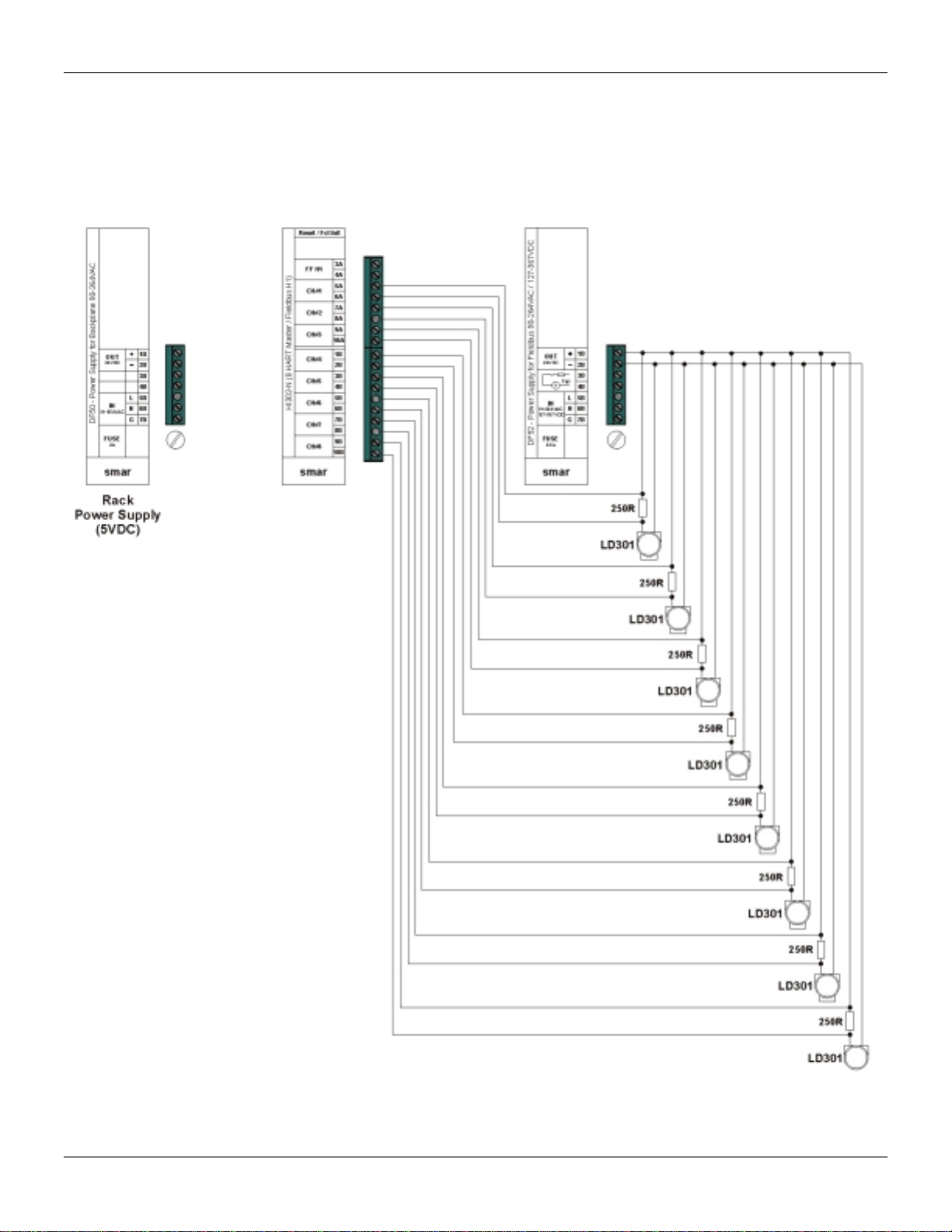

Electrical Connection

The minimum electrical connections for the HI302 relate to the power supply, normally

connected to the rack, to the connection with the H1 communication bus and to the

connection with HART devices. See the following picture for details. Since the HI302 does

not feed the devices, it is necessary to use a power supply for them.

IMPORTANT

Since the HI302 H1 channel is a passive channel, it is not necessary to use the bus

power supply. For instance, if the DF51 channel is connected to the HI302 channel, they

will communicate normally. However, impedance should be used.

The picture above shows the connection of devices fed by the same power supply

module. Remember that the HI302-I and HI302-O analog inputs and outputs are isolated.

smar

1B

2B

3B

4B

5B

6B

7B

FUSE

2A

L

G

IN

90-264VAC

OUT

24VDC

DF50-PowerSupplyforBackplane90-264VAC

N

smar

HI302-I(8HARTMaster+4-20mAInputs/FieldbusH1)

1B

2B

3B

4B

5B

6B

7B

8B

9B

10B

3A

FF H1

CH#4

CH#5

CH#6

CH#7

CH#8

CH#1

CH#2

CH#3

5A

4A

6A

7A

8A

9A

10A

Reset / Fct Init

smar

1B

2B

3B

4B

5B

6B

7B

FUSE

2.5A

L

G

IN

90-264VAC

127-367VDC

OUT

24VDC

DF52-PowerSupplyforFieldbus90-264VAC/127-367VDC

N

Fail

V

TT301/FY301

Rack

Power Supply

(5VDC)

HI302-I

or

HI302-O

TT301/FY301

TT301/FY301

TT301/FY301

TT301/FY301

TT301/FY301

TT301/FY301

TT301/FY301

HI302 - User’s Manual

2.3

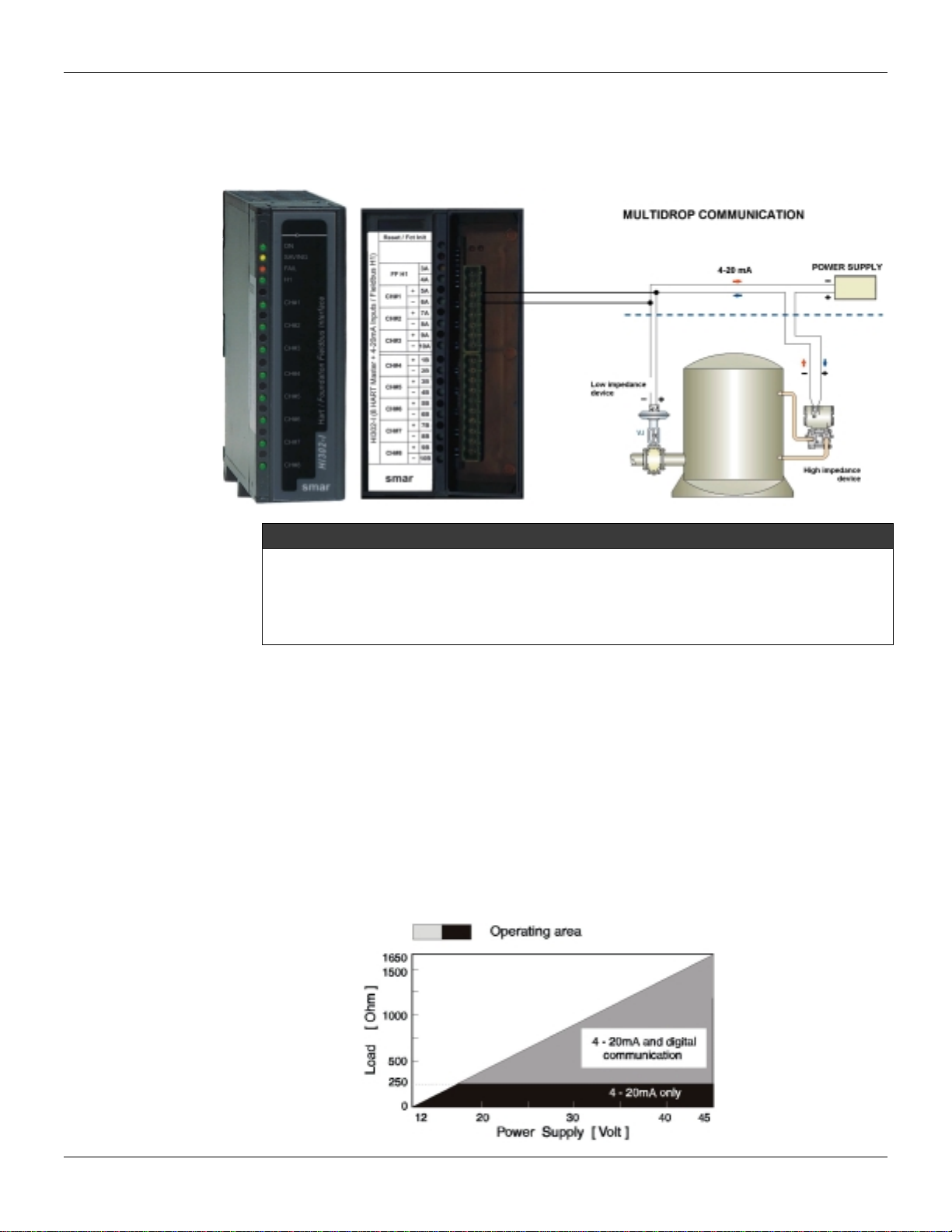

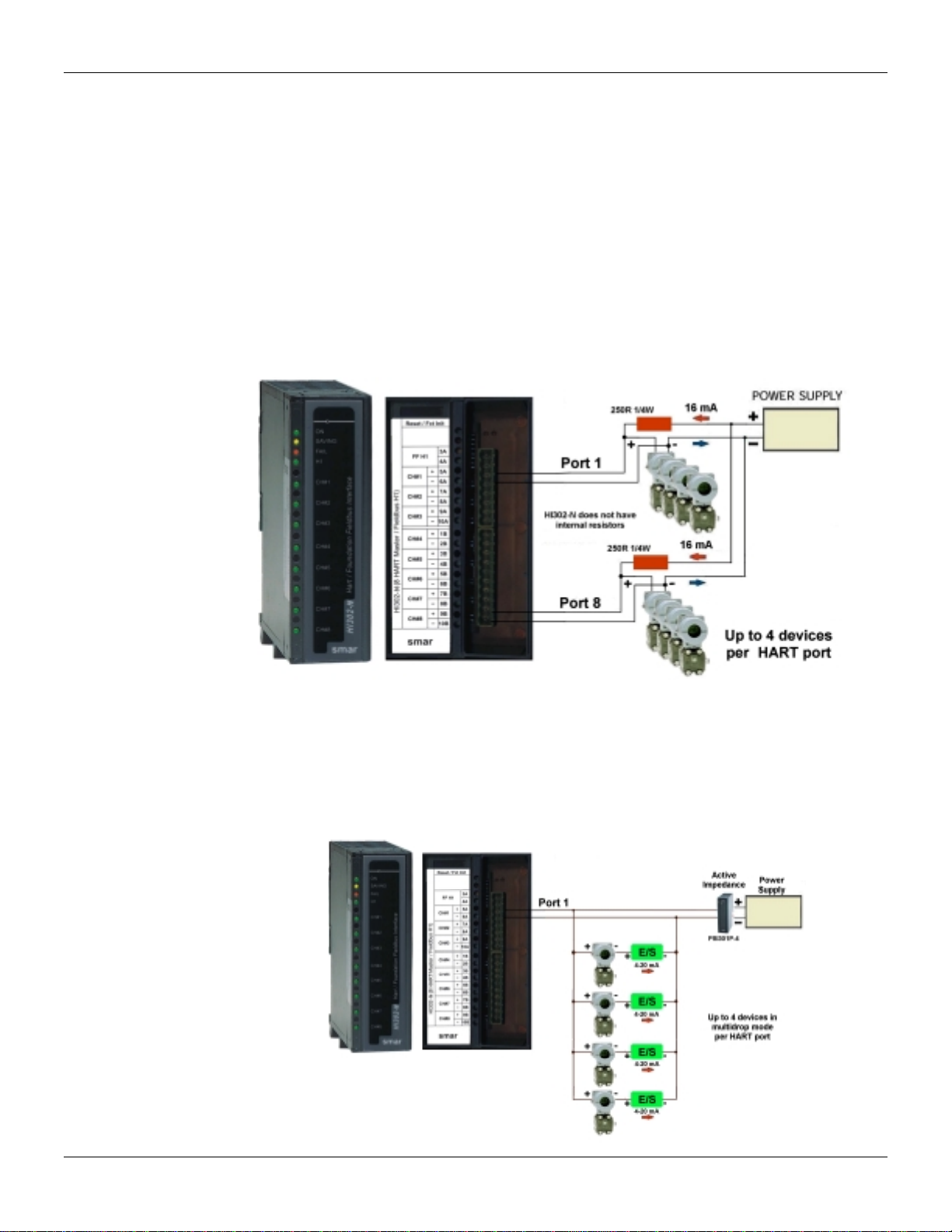

The following picture shows an example of an HI302-N connection focused on the HART

communication. In this case, connect more devices, up to 32, in parallel, to perform a

multidrop communication. In order to simplify the connection below, connect the HART

channel in parallel to the device, instead of connecting it in parallel to the resistor. Doing

so, a common grounding should be used to decrease the wiring length. The connection

below makes the channel independent from the device’s power supply.

Installation

2.4

NOTE

The 250Ωresistor (see the previous picture) in series with each equipment is the analog input

impedance, for example a PLC’s input, that reads the 4-20 mA signal. If the analog input

impedance is less than 250Ω, connect a lower resistor, so that the association of both

impedances is at least 250Ω.

For instance, suppose that a TT301 is connected to a PLC’s input with an impedance equal to

50Ω. So, connect a 200Ωresistor in series with the device’s feeding in order to enable the HART

communication. The user can also use a 250Ωinstead of a 200Ωresistor.

HART Device Installation

Now we will describe the main communication features regarding the device installation.

For more detailed information about the devices, please read the specific device manual.

Concerning the HART Communication, take into consideration that the superimposition of

a modulated signal on an analog current signal can deteriorate, if some precautions are

not taken. It is important to mention that the HART communication does not affect the 4-

20 mA analog signal, since the average value of a FSK modulated signal is zero. Thus, if

the HART device is already installed, make sure that the minimum impedance (25Ω) is

used and connect the HI302 channel in parallel to the device.

Device Physical Types

Low Impedance Devices

Low impedance devices are typically signaling elements intended to receive current

analog signals or serve as master for a multi-drop network. As an example of a low

impedance device we can mention the FY301.

High Impedance Devices

High impedance devices control current, either as a mean of analog signaling or at a fixed

level in a multi-drop environment. As an example of a high impedance device we can

mention the LD301 and the TT301.

HI302 - User’s Manual

2.5

These concepts are of fundamental importance when connecting different devices. For

example, in the connection shown below, depending on the internal actuator impedance, it

may be necessary to install a resistor in series with the power supply. This is done to

achieve the minimum impedance requirement (25Ω).

IMPORTANT

Whatever the topology used, it is important to keep a 25Ωimpedance. In the previous

picture, it is not necessary to connect an impedance in series with the power supply if

the impedance read by the HART channel is at least 25Ω. In case the impedance is

lower than 25Ω, improve its value to the minimum requirement. The connection above

allows the communication between the two devices.

HART Installation Topology

The HI302 comply with several applications, since the new ones to older installations,

where it is necessary to increase the HART device’s life span and preserve the

investment with the gradual introduction of the Foundation Fieldbus technology. Below are

some examples of connections. However, the applications are not limited to these

examples and should be considered separately.

Supply Voltage X Total Loop Impedance

The total impedance of the devices connected to a pair of cables and the cable

impedance should be between the operation limits complying with the loop supply voltage.

See the next graphic:

Installation

2.6

Notice that it is very important to keep the minimum impedance (25Ω) to allow HART

communication. Sometimes the voltage supply must be increased to ensure that the

system is in the operation area.

HI302-N (without Analog Conversion)

This HI302 option has only HART communication and no circuit for analog conversion.

The HI302-N does not have an internal resistor, so use an external resistor or an active

impedance (PSI301) if many devices are used.

•Typical Multidrop

There are two ways to perform this connection. The resistor can be installed in series with

the power supply or in parallel to the HART channel. The first way is shown below:

•Multidrop with 4-20 mA enabled

Be careful with this topology because some types of I/O devices do not accept the

connections presented below, for example, the SDCS’s that feed the devices via internal

power supply. The I/O device must receive external feeding, like PLC cards or field

devices. Besides its complexity, this connection allows an improvement in the use of the

HI302 channels and, as the current that flows in the loop is tenths of mA, use an active

impedance instead of a simple resistor. See the next picture:

HI302 - User’s Manual

2.7

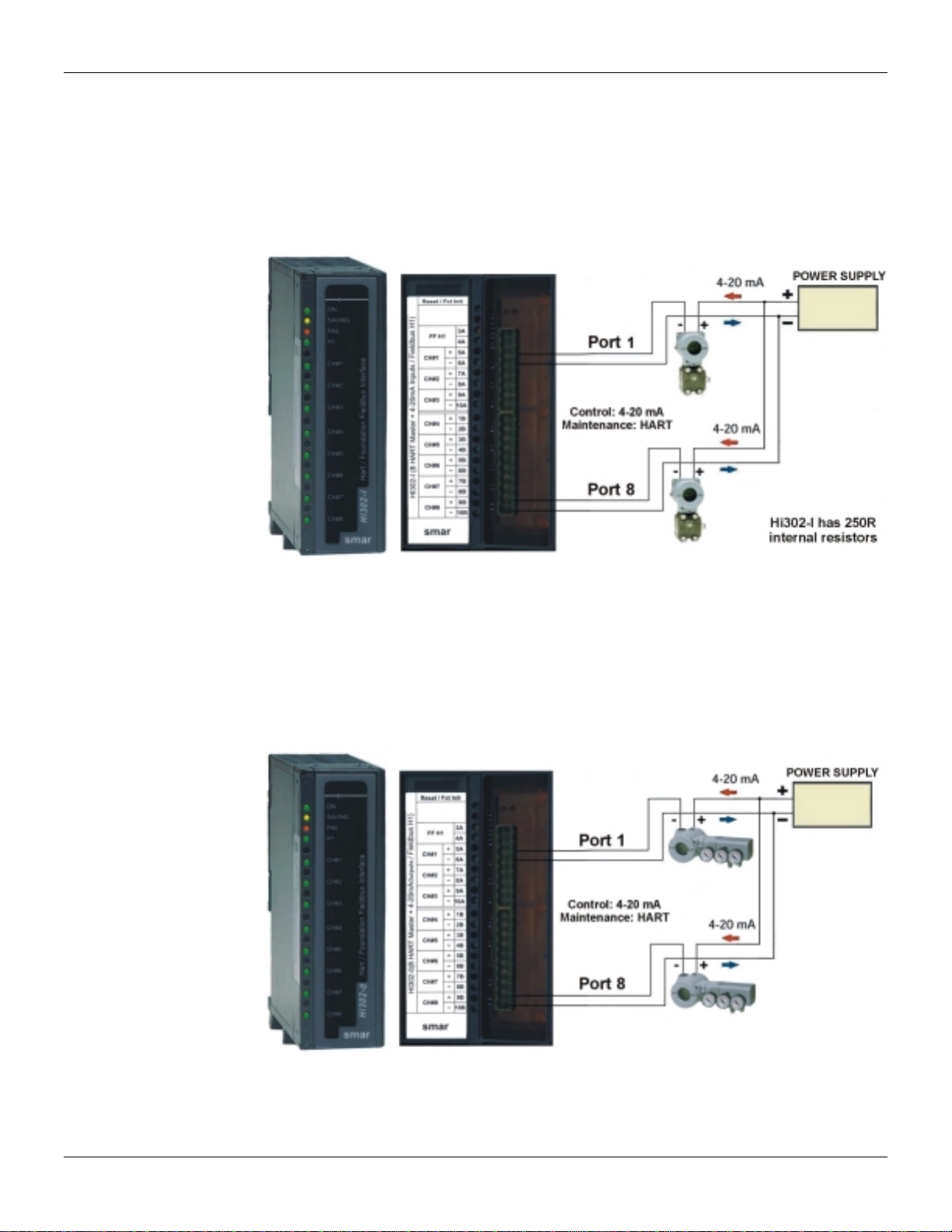

HI302-I (4-20 mA to FF Conversion)

This kind of topology doesn’t have necessarily the 250Ωexternal resistor connected in

series with each device, since there is a 4-20 mA sampling resistor on the HI302 analog

board serial to the loop. Be careful with a short-circuit in the loop, because the HI302’s

internal resistor may be damaged. The HI302 does not have internal protection against

short-circuit.

HI302-O (FF to 4-20 mA Conversion)

It is not necessary to use a resistor in series with the power supply in this topology,

because the device internal impedance and the actuator impedance ensures the minimum

requirement for HART comunication. However, the user should watch the minimum supply

voltage required for total impedance (including the wiring impedance). In this topology, the

HI302’s output is protected against short-circuit.

Installation

2.8

Maximum Cable Length

The user may choose from a shielded pair of twisted cables, a multi-pair of cables with a

single shield or a combination of these.

IMPORTANT

The shield can be overlooked if noise in the environment or any other interference do not

affect the communication.

Use a 24 AWG (0,5 mm) cable for lengths up to 5000 ft. For lengths in excess of 5000 ft

use at least a 20 AWG (0,8 mm) cable.

If a cable longer than 500 m is required, make a detailed analysis of the system to avoid

operation failures. According to HFC (HART Communication Foundation), the maximum

cable length depends on:

•The cable’s resistance and capacitance,

•The device’s resistance and capacitance on the HART channel, as well as the

additional equipment.

Due to the complexity of the subject, users should read the HART Foundation

Communication documentation, specially the FSK Physical Layer document.

Other devices in the Loop

The control loop may have additional devices, besides the HI302 and the HART devices.

See some common types as follow.

Portable Configurator

As we mentioned before, the HI302 operates as a master in most applications. So, there

is no problem in using a portable configurator, such as a HP301. Whatever the installation

topology, make sure to install a 25 Ohms impedance serial to the power supply. If no

active impedance or resistors are installed, the secondary master device will not

communicate.

Indicators and Converters in general

Indicators and converters are very common in industrial installations. They usually have

high impedance in the HART communication frequency (1200 to 2200 Hz). Sometimes

the introduction of such elements in the loop can prevent communication. However, there

is a simple and well known solution for this problem, by connecting a capacitor ranging

from 0.1 to 1µF (100v at least) parallel to the device. This capacitor supplies an

impedance of hundreds Ohms parallel to the device’s impedance, allowing the HART

communication.

Switching On the HI302

When you turn on the module, the system will check some important hardware and

software components. If any errors are found, the module will not operate and the

FAILURE LED (red LED) will light..The HART LEDs (green LEDs) will blink slowly around

¼ Hertz. This check takes approximately 1 minute, so you should wait before checking

the HI302 in the Live List or watch for any value.

HI302 - User’s Manual

2.9

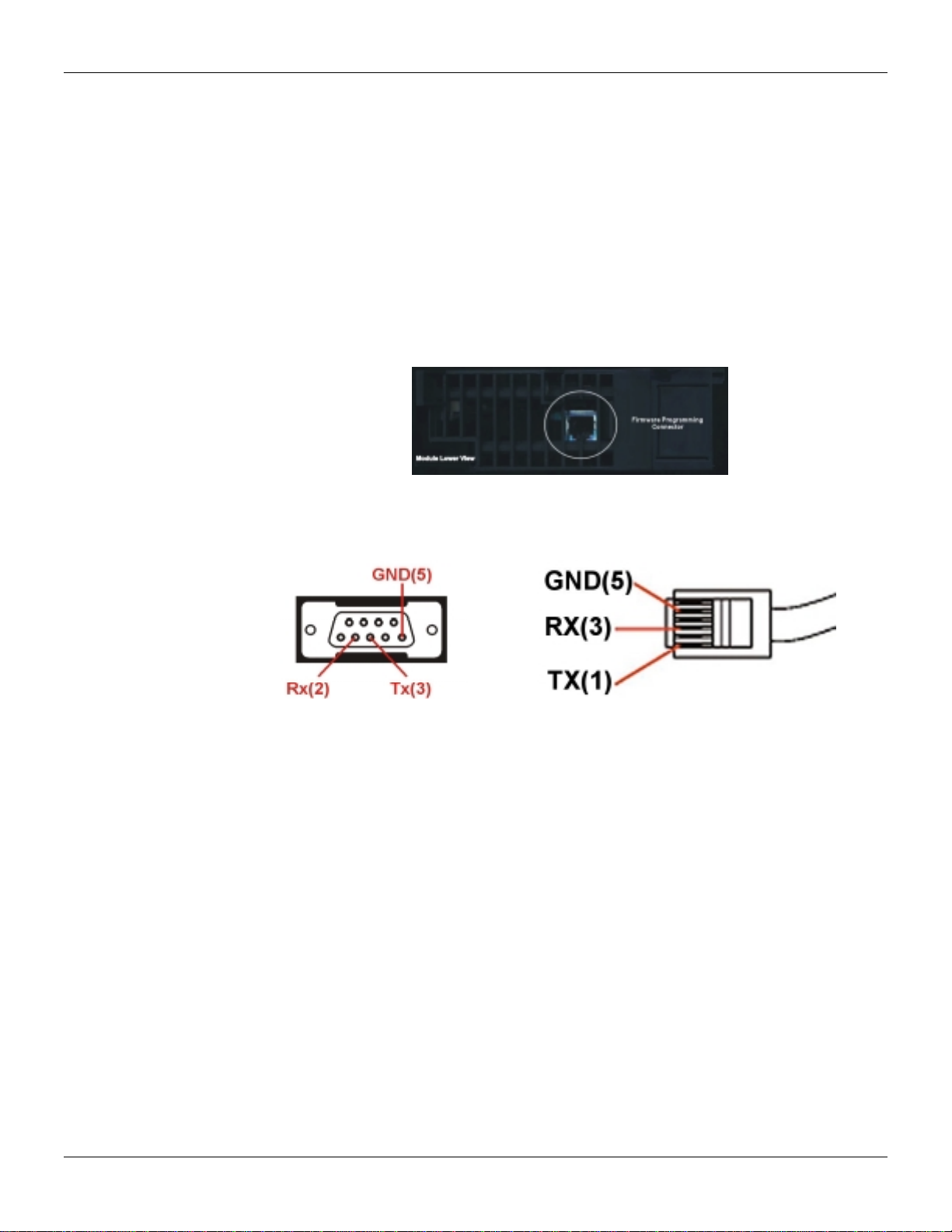

Updating the HI302 Firmware

To update the HI302 firmware you must use the FBTools program built in the System302

as an integral part of it. To do so, connect the RS232 serial cable to the firmware

download connector located behind the module.

Before you begin the update, the HI302 module must be set in the boot loader mode. To

do so, press the Reset button located at the upper right side in the front part of the

module. By pressing it, the FAILURE LED (red LED) will light. Then click the download

button in the Serial Download program and wait for the end of the process.

After the completion of the update process, press the Reset button again, in order to put

the module back in normal operation.

Firmware Programming Connector

RS232 Serial Cable Connector for Firmware Download, DB09F and RJ11M.

Installation

2.10

Other manuals for HI302

1

Table of contents

Other SMAR Recording Equipment manuals