SMAR RHP303 User manual

RHP303

PROFIBUS HUB REPEATER

USER´S MANUAL

R H P 3 0 3 M E

web: www.smar.com/contactus.asp

www.smar.com

Specifications and information are subject to change without notice.

Up-to-date address information is available on our website.

smar

RHP303 –Profibus Hub Repeater

3

AVOIDING ELECTROSTATIC DISCHARGES

NOTE

To ensure that our products are safe and without risk to health, read the manual carefully prior to

installation.

Installation, operation, maintenance and repair should only be performed by trained

personnel and according to the User Manual.

Updated information about the Smar products can be obtained directly on http://www.smar.com

ATTENTION

Electrostatic discharges may damage semiconductor electronic components in printed circuit

boards. They usually occur when touching components or connector pins from modules and racks,

without wearing the appropriate equipment to prevent discharges. It is recommended to take the

following precautions:

Before handling modules and racks, remove the electrostatic charge from your body by

wearing a proper wristband or touching grounded devices;

Avoid touching electronic components or connector pins from racks and modules.

RHP303 –Profibus Hub Repeater

4

RHP303 – PROFIBUS HUB REPEATER

Description

RHP303 is an active element serving as interface between segments on Profibus network and

ensures adequate signal levels, while guarantees the communication signal integrity. The repeater

prevents signal deterioration in long distances. Essentially it receives the signal from a network

segment, cleans, amplifies and transmits it to other segments. This way, the original message is

preserved for all network segments. The RHP303 executes this function bidirectionally. In addition,

serves to galvanically isolate the segments.

The PROFIBUS DP is a high speed communication bus that follows strict spur lines rules due to

possible reflections that disturb communications.

The RHP303 is the innovative solution for applications that need spur lines or star segments. It is

the most economical solution to install reliable spur lines on high speed DP networks. It has 5

insulated galvanic transparent repeaters, allowing network structures with extended spur lines,

which, individually, may include up to 31 devices and a length equal to the main bus. The RHP303

regenerates the electric signal in one channel and transfers it to all the others (chicken foot

topology).

As RHP303 creates insulated segments, the devices can be removed and inserted during the

operation. Likewise, electric bus problems and EMC disturbances on a spur do not spread to other

segments. The RHP303 smart circuits and its insulation do not electrically modify the

communication signal. These circuits also identify automatically the transmission speed.

The RHP303 has a differential feature that is to work in Modbus for two communication rates in

manual mode: 9.6 Kbps and 19.2 Kbps.

To help installation, a terminator is integrated and can be turned on or off. The RHP303 is powered

by 12 to 30Vdc voltage. For faults identification, maintenance and commission, it has LEDs that

indicate each channel status.

Main features

•IP 20 classification;

•5 insulated channels;

•Transparent for all PROFIBUS DP protocol versions;

•RS-485 specifications for each channel;

•Maximum 12 Mbps communication rate;

•Supports up to 31 devices per channel;

•Supports up to 1200 m length of spur line;

•No address required;

•Integrated terminator;

•Supports Modbus protocol in manual mode on 9.6 Kbps and 19.2 Kbps;

•Insertion and removal of slave equipment during the operation;

•Protection against short circuit and indication on each channel;

•Compact and robust construction;

•Status and error display per channel;

•Compatible with all DP cables;

•Provides more convenient arrangement for the network cables;

•Easily extensible installations;

•DB9 connector available for diagnostics;

•Cost savings with cabling and repeaters.

IMPORTANT

This equipment must only be used with devices or components complying with PROFIBUS and

RS-

485 standards. This product can only work correctly and safely if transported, stored,

adjusted, installed, operated and revised according to recommendations.

RHP303 – User’s Manual

5

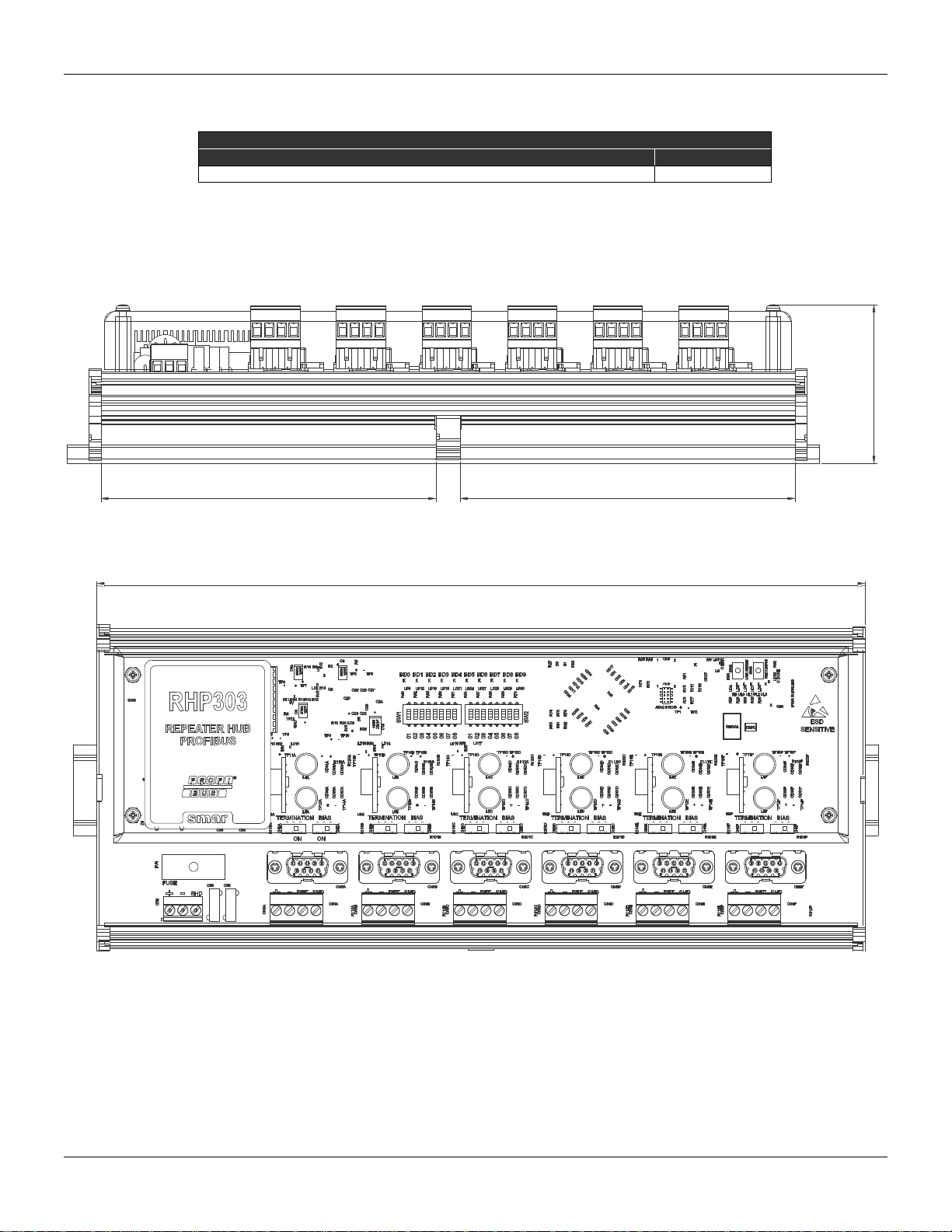

Figure 1 – RHP303

Areas of Application

•Dynamic spur lines for actuators, flow meters and pH analyzers;

•Inverters and motors;

•Motor control centers;

•Barrier for galvanic and non-insulated equipment;

•Large star/tree structured networks.

Examples of Application

The figure below shows a general RHP303 application. Each insulated channel prevents short

circuit propagation from one channel to another and allows expansion of up to 1200m per segment.

Figure 2 – General application

Profibus DP networks can be expanded in tree or star topology, without limits for RHP303 in

cascade. See the next figure.

RHP303 –Profibus Hub Repeater

6

Figure 3 – Expansion of Profibus DP networks

The RHP303 increases the network availability by filtering EMI noises so that one channel does not

interfere with the other or with the main trunk.

Figure 4 – Insulation between areas

PROFIBUS DP cable lengths

See on the table below the relation between the several communication rates and the allowed

lengths. Make sure the cables on the main channel (A) and the derived channels (B to F) comply

with the PROFIBUS DP cable specifications for the RS-485.

Baud rate (kbps)

9.6

19.2

45.45

93.75

187.5

500

1500

3000

6000

12000

Segment length (m)

1200

1200

1200

1200

1000

400

200

100

100

100

Segment length (feet)

3940

3940

3940

3940

3280

1310

656

328

328

328

RHP303 – User’s Manual

7

Baud Rate LEDs

The BD0 to BD9 LEDs blink in yellow to indicate the baud rate used by the Profibus DP Repeater

according to the next figure. The baud rate will be the same for every channel.

Figure5–BD0 to BD9 LEDs to indicate the communication rate

BDO BD1 BD2 BD3 BD4 BD5 BD6 BD7 BD8 BD9

9,6 Kbps ON

off off off off off off off off off

19,2 Kbps

off

ON

off off off off off off off off

45,45 Kbps

off off

ON

off off off off off off off

93,75 Kbps

off off off

ON

off off off off off off

187,5 Kbps

off off off off

ON

off off off off off

500 Kbps

off off off off off

ON

off off off off

1,5 Mbps

off off off off off off

ON

off off off

3,0 Mbps

off off off off off off off

ON

off off

6,0 Mbps

off off off off off off off off

ON

off

12 Mbps

off off off off off off off off off

ON

LEDS

Baudrate

Status LEDs (ST)

Each Profibus DP Repeater channel has a ST LED. The red ST LED indicates the channel status.

If the LED is off, the channel is good. If it is on, the channel has some fault. It can be caused by a

cable short circuit or any other problem that may degrade the signal until it is no longer recognized

by the RHP303.

Channel Status

ST LED

Good

Off

Faulty

On

RHP303 –Profibus Hub Repeater

8

Figure 6 – ST LEDs to indicate the channel status

RX LEDs

Each Profibus DP Repeater channel has a RX LED. The yellow RX LED indicates the reception by

the channel.

When turned off, the channel is not receiving a valid signal.

When turned on, the channel is receiving a valid signal.

Reception

RX LED

Invalid or non-existing signal

Off

Receiving a valid signal

On

Figure 7 – RX LEDs to indicate signal reception

Installation

The RHP303 can be installed anywhere in a non-hazardous area and on the specified temperature

range of 0 to 60ºC.

The RHP303 must be installed on DIN rail, with the connector cable on the bottom part. In this

position the cables go down and it is also easier to read the status LEDs.

RHP303 – User’s Manual

9

Figure 8 – RHP303 installed on a DIN rail

NOTE

The installation must be executed by qualified technicians with a PROFIBUS Installer or a

PROFIBUS Engineer certificate.

Power supply

The power supply connector, a 3-pin terminal block, is located on the RHP303 lower left corner. The

power supply must comply with the Technical Specifications topic.

Figure 9 – Detail of the power supply connector

Spur segments

Connect the spur segments on the channel B, C, D, E and F connectors, according to the table

below.

Pin

Signal

B (+)

Positive

A (-)

Negative

REF

GND

SHD

Shield

RHP303 –Profibus Hub Repeater

10

Figure 10 – Detail of spur segment connectors

Terminators

All RHP303 channels have configurable terminators. The main channel termination is adjusted in

OFF by default. If the RHP303 is the last or the first segment device, the termination must be

adjusted in ON.

The termination of the other channels is adjusted in ON by default because the new segment is

expected to be initiated on the RHP303.

Do not forget to turn on the switch at the other segment end.

NOTE

Non-used channels must have their terminators activated.

Figure 11 – Detail of channel terminators position

Baud Rate Configuration

The RHP303 recognizes the transmission speed by default. If necessary lock the RHP303 on given

transmission speeds, the SW1.1 to SW1.5 must be adjusted on the required value. To execute the

adjustment remove the top cover.

Figure 12 – Switches SW1.1 to SW1.5 for communication rate adjustment

The switches SW1.1 to SW1.5 are used to select the baud rate used by the Profibus DP Repeater

according to the next table. The baud rate selected will be the same for all channels. These baud

rates are standardized by the Profibus DP protocol.

RHP303 – User’s Manual

11

BAUD RATE

SW1.1

SW1.2

SW1.3

SW1.4

SW1.5

SW1.6

SW1.7

SW1.8

AUTO

OFF

X

X

X

X

X

X

X

MANUAL

9.6 Kbps

ON

ON

OFF

OFF

OFF

X

X

X

19.2 Kbps

ON

OFF

ON

OFF

OFF

X

X

X

45.45 Kbps

ON

ON

ON

OFF

OFF

X

X

X

93.75 Kbps

ON

OFF

OFF

ON

OFF

X

X

X

187.5 Kbps

ON

ON

OFF

ON

OFF

X

X

X

500 Kbps

ON

OFF

ON

ON

OFF

X

X

X

1.5 Mbps

ON

ON

ON

ON

OFF

X

X

X

3.0 Mbps

ON

OFF

OFF

OFF

ON

X

X

X

6.0 Mbps

ON

ON

OFF

OFF

ON

X

X

X

12 Mbps

ON

OFF

ON

OFF

ON

X

X

X

Note: The “X” on the table means “The switch position is irrelevant”.

To adjust the transmission speed, use a screwdriver.

NOTE

For the Modbus protocol, the available rates must be adjusted in “Manual”: 9.6 Kbps and 19.2

Kbps.

Technical Specifications

POWER SUPPLY

Power connector

3-pin terminal block

Voltage

12 to 30 Vdc (24 Vdc nominal)

Maximum current

270 mA @ 24 Vdc

Protection against reverse polarity

Yes

Cabling

< 2.5 mm2

FUNCTION SPECIFICATIONS

Supported Protocols

Modbus, DP-V0, DP- V1, DP-V2, FDL, MPI,

FMS, PROFIsafe, PROFIdrive and any other

FDL-based protocol

Communication Rates (kbps) 9.6; 19.2; 45.45; 93.75; 187.5; 500; 1500;

3000; 6000 and 12000

Communication Rate detection Self-detectable by default or switch

configurable

Communication rate selection switch

0 = Self-detectable by default

Communication rate detection time

< 5 s (if self-detection selected)

Data delay time

1 Tbit for all rates

Jitter delay time

±0.1 Tbit for all rates

Terminators

One on each spur

ENVIRONMENT CONDITIONS

Operation temperature

0 to 60 ºC

Protection degree

IP 20

DIMENSIONS AND WEIGHT

Dimensions (LxWxH)

296 x 125.4 x 65 mm

Weight

612 g

MOUNTING

Support

DIN rail

RHP303 –Profibus Hub Repeater

12

Spare part components

SPARE COMPONENTS LIST

COMPONENTS DESCRIPTION

CÓDE

5 x 20 mm Fuse – 500 mA (package with 10 pieces)

400-1241

Dimensional Drawings

The sizes are in millimeters and in brackets for inches.

65

(2.55)

138

(5.43)

138

(5.43)

CH A CH B CH C CH D CH E CH F

296

(11.65)

RHP303 – User’s Manual

13

RHP303 –Profibus Hub Repeater

14

Appendix

A.1

SRF – SERVICE REQUEST FORM

RHP303 – Profibus Hub Repeater

Proposal Nº:

COMPANY INFORMATION

Company:

_____________________________________________________________________________________________________

Unit: ________________________________________________________________________________________________________

Invoice: _______________________________________________________________________________________________________

COMMERCIAL CONTACT

Full Name:

____________________________________________________________________________________________________

Phone: _________ _________________________ _________ _________________________ Fax: _______________________

E-mail:

_______________________________________________________________________________________________________

TECHNICAL CONTACT

Full Name: ________________________________________________________________________________________________

Phone: _________ _________________________ _________ _________________________ Extension: ____________________

E-mail:

_______________________________________________________________________________________________________

EQUIPMENT DATA

Model:

______________________________________________________________________________________________________

Serial Number: ________________________________________________________________________________________________

PROCESS DATA

Process Type (Ex. boiler control): __________________________________________________________________________

Operation Time: ____________________________________________________________________________________________

Failure Date: __________________________________________________________________________________________________

FAILURE DESCRIPTON

(Please, describe the failure. Can the error be reproduced? Is it repetitive?)

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

OBSERVATIONS

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

USER INFORMATION

Company: _____________________________________________________________________________________________________

Contact: _______________________________________________________________________________________________________

Section: _______________________________________________________________________________________________________

Title: _________________________________________________ Signature:_______________________________________________

Phone: _________ _________________________ _________ _________________________ Extension: ___________________

E-mail: ________________________________________________________________________ Date: ______/ ______/ _________

For warranty or non-warranty repair, please contact your representative.

Further information about address and contacts can be found on www.smar.com/contactus.asp

RHP303 – Profibus Hub Repeater

A.2

Table of contents