SMART 3D Multimaterial Dryer User manual

Multimaterial Dryer

User Manual

Important: Read this instruction manual. Failure to read, understand, and follow the

instructions in this manual may result in damage to the unit, injury to operating

personnel, or poor equipment performance.

Congratulations on your selection of the Smart3D Multimaterial Dryer! Please read

these operating instructions, user notes, and the warranty card thoroughly before the

initial operation of your Multimaterial Dryer. This will ensure proper operating

procedures and extended life for the unit. Please keep the operating instructions

together with the warranty card for easy access whenever you need them.

Caution: All internal adjustments and maintenance must be performed by

02

03

Liability statement

The information provided in this user manual is subject to change without notice, and

we reserve the right to modify the manual at any given time. We have made every

liability for any inaccuracies or omissions. We shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this equipment/material. We make no warranty of any kind with

regard to this equipment/material, including, but not limited to, the implied warranties

equipment/material purchaser to determine that any Smart3D product is safe, lawful,

and technically suitable for the intended application. Likewise, it is your responsibility

to identify the proper disposal (or recycling) method consistent with your local

environmental regulations. Except as provided in Smart3D's standard conditions of

sale, we shall not be responsible for any loss resulting from any use of any Smart3D

product described herein. Some hardware, software, user interface, and elements may

Copyright statement

Upon our written consent, you may download, view, print and reproduce this

reserved. This document and its contents are made available on an "as is" basis, and all

implied warranties are disclaimed. All drawings and information herein are the

property of Smart3D. All unauthorized use and reproduction is prohibited.

EMC Class A warning

Warning!

may cause radio interference in which case the user may be required to take

adequate measures.

!

MSDS (Material Safety Data Sheet)

Material Safety Data Sheets for the materials supported by this device are available for

download at: www.smart3d.tech/materials

04

Waste Electrical and Electronic Equipment Statement (WEEE)

This symbol on the Product or on its packaging indicates that the device

your responsibility to dispose of your waste equipment by handing it over

to a designated collection point for the recycling of waste electrical and

electronic equipment. The separate collection and recycling of your

waste equipment at the time of disposal will help to conserve natural resources and

ensure that it is recycled in a manner that protects human health and the environment.

or the shop where you purchased the product.

California Proposition 65

chemicals listed by the State of California that cause cancer, birth defects or other

reproductive harm. By requiring that this information be provided, Proposition 65

enables consumers to make informed decisions about their exposures to these

chemicals. Proposition 65 also prohibits businesses from knowingly discharging

INDEX

The importance of properly dryed material

Components

Requirements for installation

Handling warnings

Control panel

Operating instructions

01.

02.

03.

04.

05.

06.

07.

08.

05

06

08

09

11

13

16

18

19

Current solutions vs. Smart3D hybrid drying technology™

THE IMPORTANCE OF PROPERLY DRIED MATERIALS

06

Time

Moisture rate

hard or even imposible with such techniques

Performance

Since this method depends on contact with dry air, moisture may be found even

after a full drying cycle

Quantity

These solutions cannot process more than a few pounds of material

Versatility

Cost

Why are other current solutions suboptimal for engineering needs?

either ruin your filament by altering its physical properties or not dry it

properly.

Moisture, the silent enemy

Hydrolysis is a chemical reaction in which a molecule of water ruptures one or more

filaments that have a certain chemical structure,

resistance to impact, since the polymer chain is changed. This consequence is

What is hydrolysis?

07

on the place, but there is always, at least a small percentage of water in the

atmosphere.

source of a lot of issues like degradation or fragility.

prone to absorb moisture more easily than others. As a major rule, if you leave a

WET FILAMENT DRY FILAMENT

Moisture can affect the filament within only two hours of exposure. Since an

average print takes between 5 and 7 hours, the exposed filament can ruin the

entire print and may ruin your spool.

THE IMPORTANCE OF PROPERLY DRIED MATERIALS

IMPORTANT SECURITY INSTRUCTIONS

When using electrical appliances, basic safety precautions should always be followed,

including the following:

1. Please read all instructions carefully before using this appliance. Then keep them in

a safe place for future reference.

2. This product is not intended for use by people (including children) with reduced

physical, sensory, or mental abilities, or lack of experience and knowledge.

3. This product is not designed to be moved frequently. But if necessary, never move

or drag the appliance by pulling on the power cord. Make sure the cord is not caught,

crushed, lying on the edge of the Dryer, or in contact with hot surfaces.

4.

technical service for its revision, repair or adjustment.

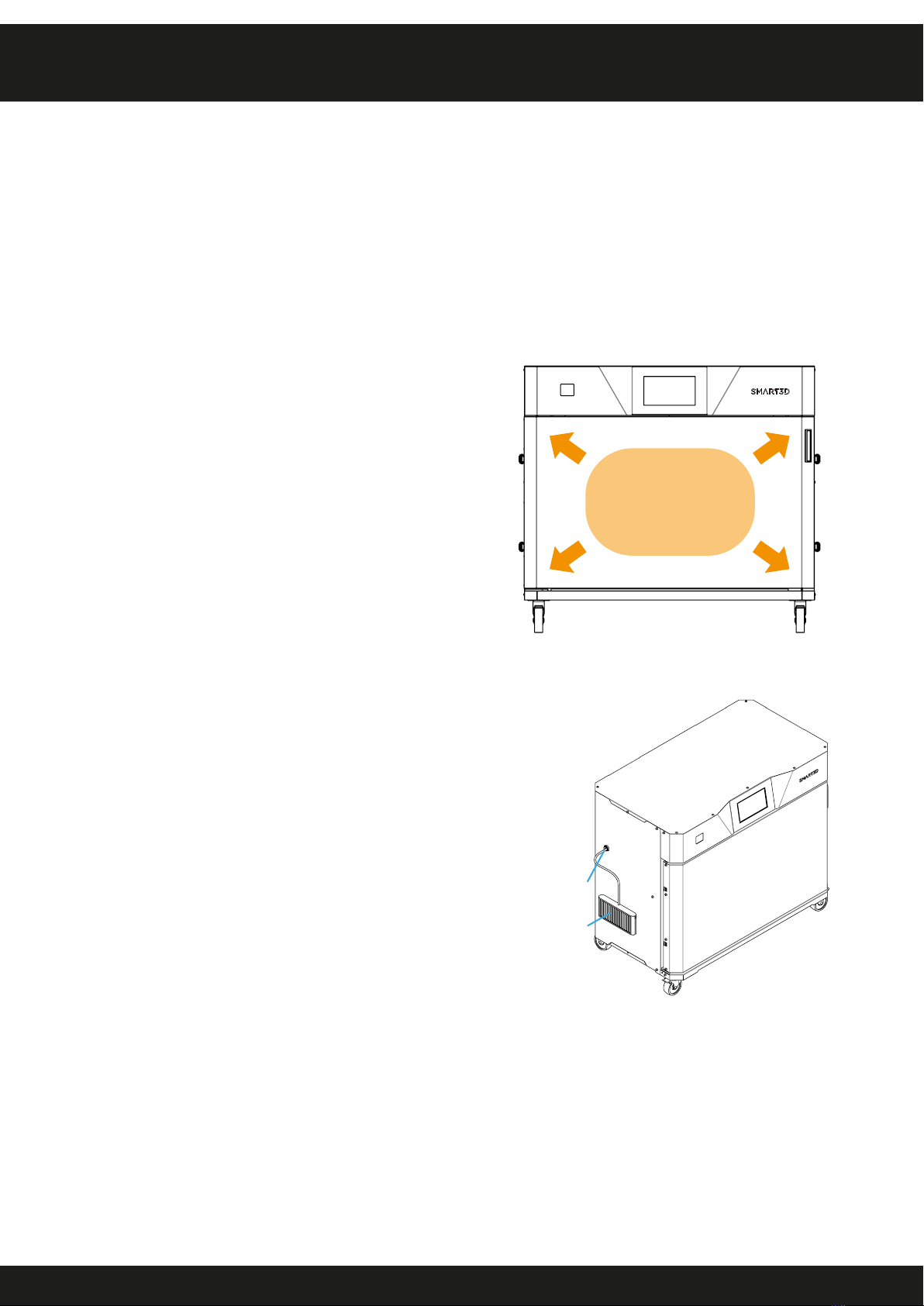

5. Leave at least a 30 cm clearance around the sides of the dryer and 25 cm between

the backside and the wall, allowing adequate air circulation.

6. The use of accessories not included in this manual by the manufacturer may result

7. Before plugging or unplugging the unit, check that it is OFF.

8. Unplug the unit by pulling from the plug and never from the power cord.

9.

10.

11.Do not use the Dryer cavity as a place to store items that do not correspond to the

unit.

12. ATTENTION: THIS UNIT MUST BE EARTHED. The manufacturer is not

responsible for the damages caused to people or things by an incorrect ground

13.

adequate thermal protection.

14.

authorized technical service.

15. This unit has a short power cord to reduce the risks that a longer cable can

produce. An extension can be used as long as the following care is taken:

• The cable extension must be carefully located avoiding excess on tables or grills that

can be hooked, crushed, or cut into accidentally.

08

major problem for low glass transition

temperature (Tg) materials.

The Smart3D Multimaterial Dryer manages

to dry all kind of materials simultaneously in

steady, controlled environment with a

Setting the temperature

Two cartidges of silica gel, one inside

the chamber and other at the exterior.

These manage to regulate the humidity

that comes from the outside during the

Controlling humidity

1. Generic drying

3. ABS drying

Then, there is the possibility that the user can make their own custom cycles.

Drying cycles

to dry a variety of materials at the same time, including TPU and PA simultaneously.

GENERAL SPECIFICATIONS

The Smart3D Multimaterial Dryer is the only current solution that integrates a hybrid

perfect conditions and ready to use.

09

45ºC - 113ºF

Pipe tubing

to the valve

Silica cartridge

GENERAL SPECIFICATIONS

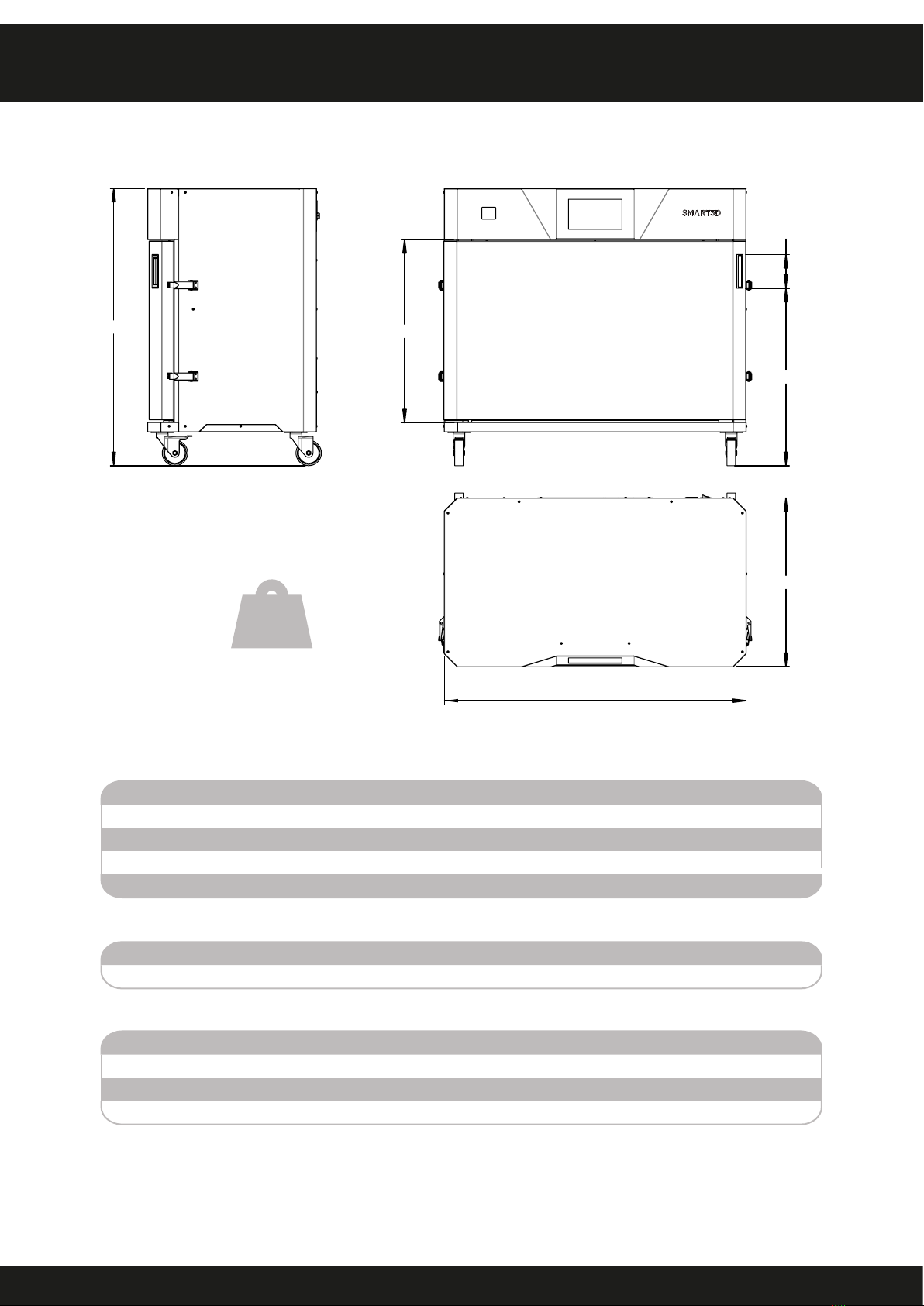

General dimensions

100

540

525

820

890

500

Performance

Cycle duration: <3h

Drying capacity: Up to 24 spools (depending on spool size)

Compatibility: Filament spools of any material and brand

Connectivity: WiFi, Ethernet, USB

Display: 7” full color touch screen

Electrical

Rated voltage: 110 - 240V / 50 - 60 Hz / 1500W

Auxiliary power outlet: 110 - 240V / 50 - 60 Hz / 4 - 2A

Software

Spool recognition: Through RFID tag

Reports and statistics: Temperature and drying cycles

Updates: Internet/Manual

I4.0 compliant: Yes

10

WEIGHT

175kg

COMPONENTS

3

1

2

4

7

8

9

10

6

5

11

12

COMPONENTS

Handle

Side locks (four in total, two on each side)

Power supply plug

Button switch

USB ports (two in total)

Access door to the Raspberry Pi

Ethernet port

Bars (four in total)

Heating system

Wheels with brake (two in total)

Wheels without brake (two in total)

This Dryer requires permanent connection wiring to a power source.

11

12 13

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

13

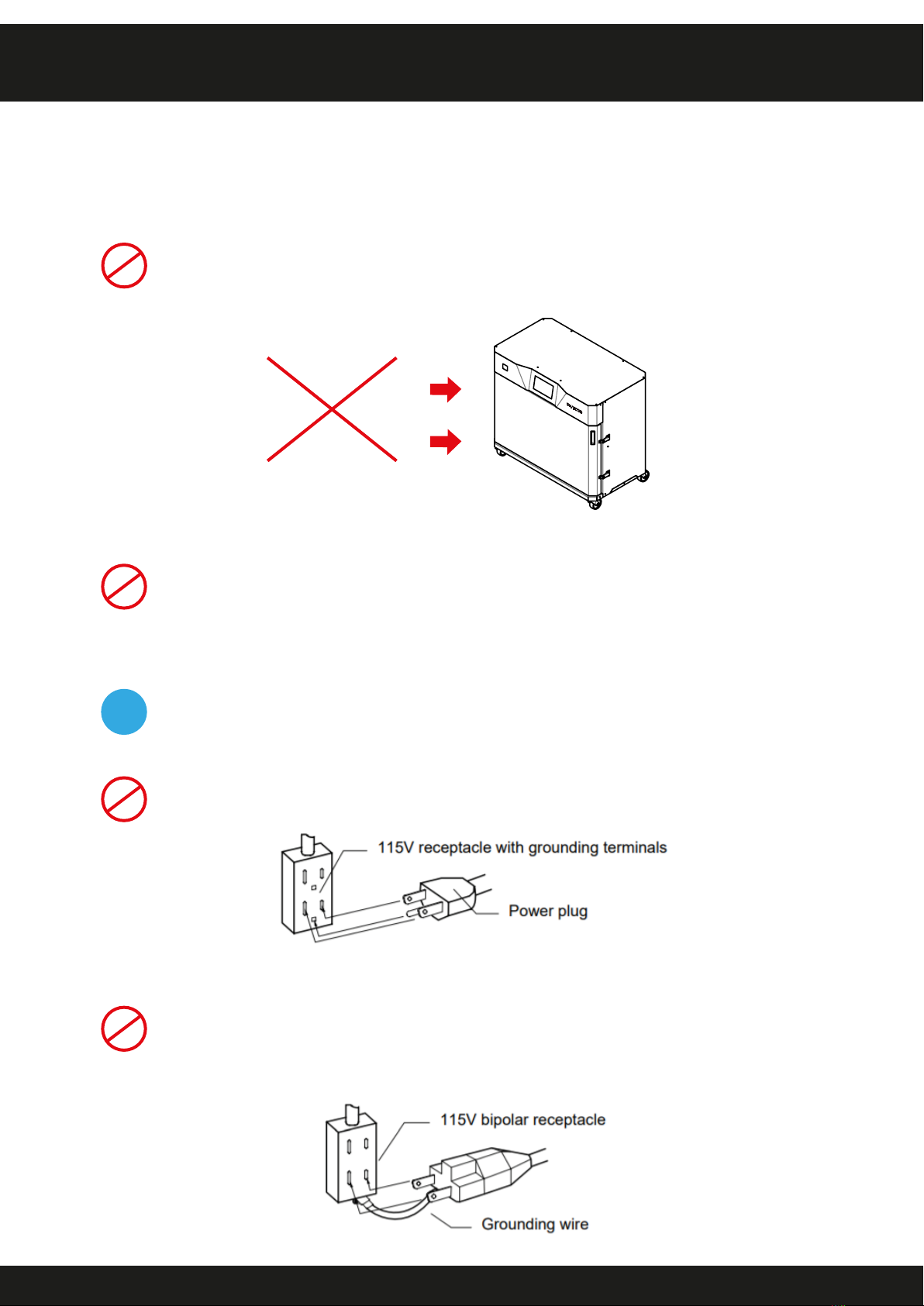

REQUIREMENTS FOR INSTALLATION

make sure you follow the following advice:

Do not use the unit in an area where there is a �lammable or explosive gas

operator and create problems during operation.

Install the Dryer on a level area

not forget to ground the Dryer, to protect you and the unit from electrical shock

in case of a power surge. Choose a receptacle with grounding connectors as

often as possible.

Do not connect the grounding wire to a gas pipe, or use a lightning rod or

receptacle before connecting the adapter to the receptacle. Connect the

our service center for additional information or assistance.

!

Always ground the unit

Explosive gas

Flammable gas

14

Multimaterial Dryer in a proper

press the brake with your foot. Make

sure the unit does not move at all.

Lock the wheels

REQUIREMENTS FOR INSTALLATION

Take measures to prevent the unit from falling in case of an earthquake, high

impact, etc. as it could lead to personal injury.

After installation

!

Do not process, bend, wring, or stretch the power cord forcibly. Fire or electrical

shock may result.

Do not put the power cord under or through an object. Otherwise, there is the

Do not run the power cord next to the heating equipment. When the power cord

and the main power. Contact customer service.

Handling of the power cord

Do not install the Dryer in a place where:

Choose a proper place for installation

More than

25 cm / 10 inches

More than

25 cm / 10 inches

More than

30 cm / 12 inches

More than 25 cm / 10 inches

!

Keep the following clearance around the Dryer

15

REQUIREMENTS FOR INSTALLATION

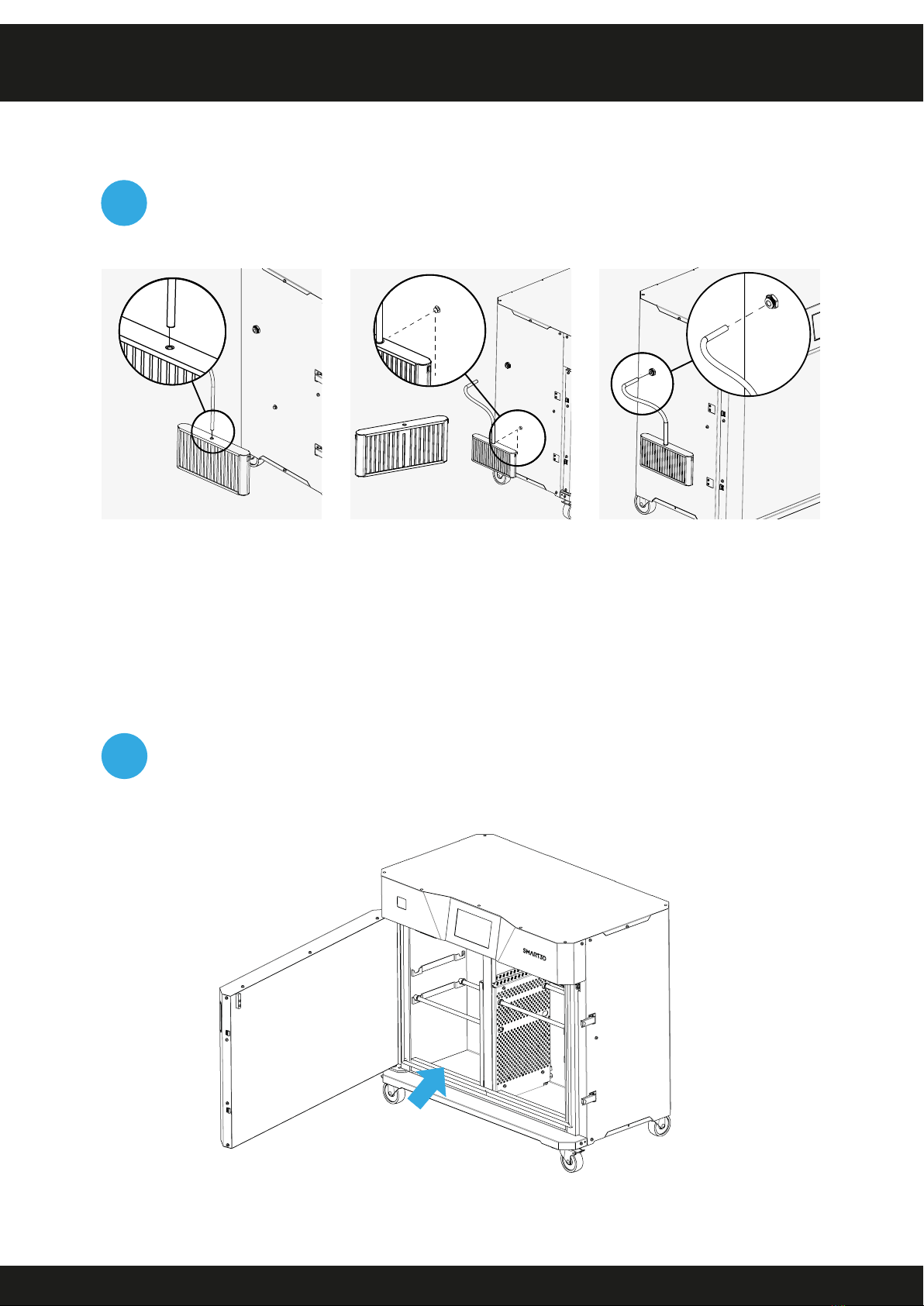

cartridge

. For perfect installation, you

shou

previous section,

you must replace the exterior cartridge with this one after

every drying cycle, ensuring the silica used is always dry.

Place the silica gel correctly

!

highly recommended to replace this cartridge after the drying cycle for the one

that was on the inside, ensuring the silica used is always dry.

Place the exterior silica cartridge

!

Finally, insert the tubing in

the connector on the left

lateral case.

hole. Apply some

pressure.

Slide the cartridge and

hang it to the two binding

barrels that the Dryer has

on its side.

Silica gel cartridge

16

HANDLING WARNINGS

n the bars or the base of the chamber.

WARNING!

compartment during the drying cycle. This surface may get very hot and could

Sort your �ilament spools

This central heating

compartment may

get hot. Please be

careful!

bars with two levels.

WARNING!

Heating and drying other objects may cause damage to the Multimaterial Dryer.

!

17

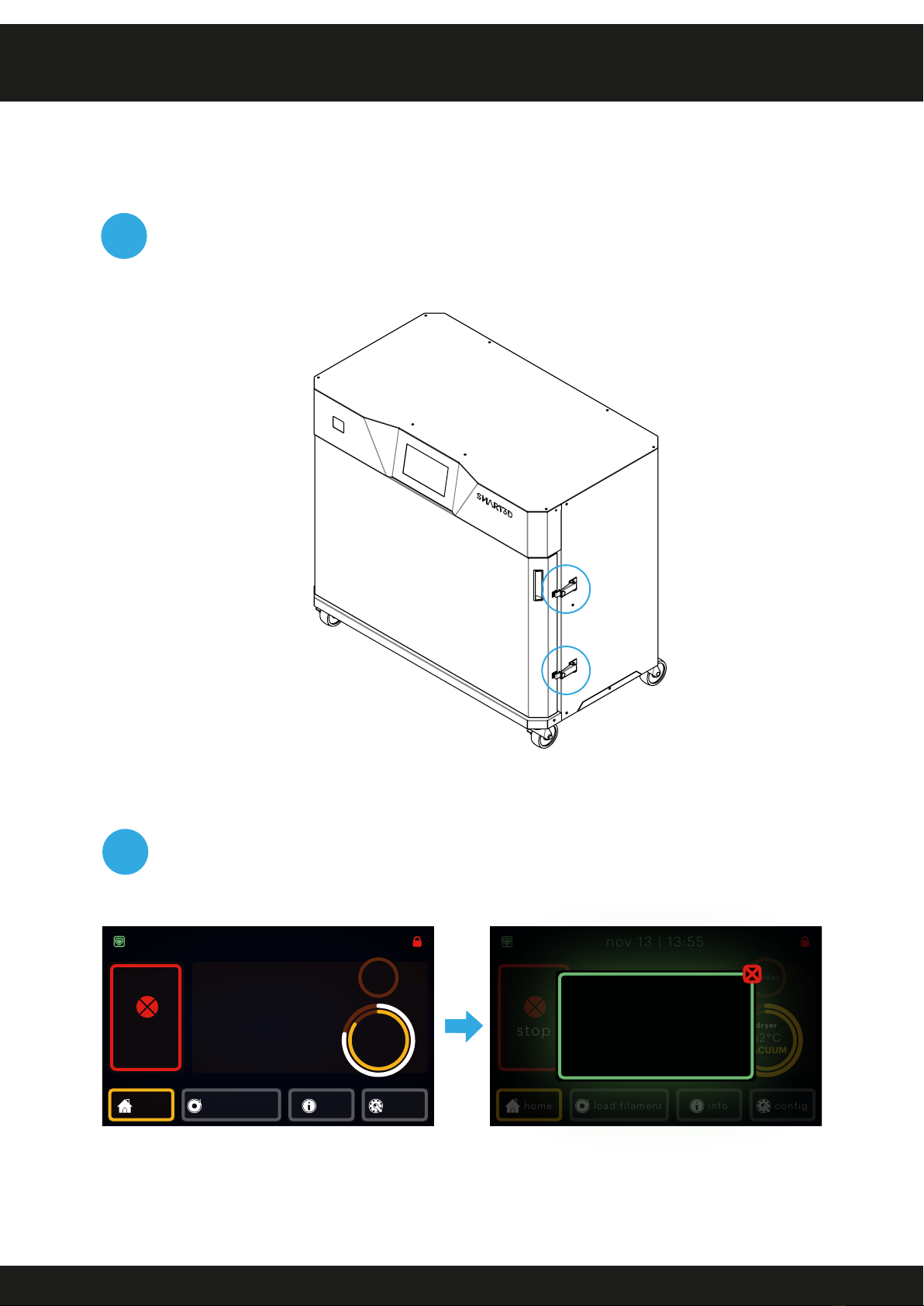

Before running any drying cycle, check the door seal for any debris which could

prevent proper closing and then secure the door with both locks. Remember to

take good care of the door seal as there can't be any leaks during the cycle's

vacuum process. Be sure to contact Customer Support if you encounter any

problems.

Lock the door during the cycle

!

HANDLING WARNINGS

icon must have turned green. Under no circumstance, open the door before it

is enabled on the screen

Do not open the door until the cycle is over

!

stop

00:35

elapsed time

00:55

remaining time dryer

DRYING

feeder

home info

nov 13 | 13:55

stop

00:35

elapsed time

00:55

remaining time dryer

VACUUM

feeder

home info

nov 13 | 13:55

Drying cycle

completed

successfully!

18

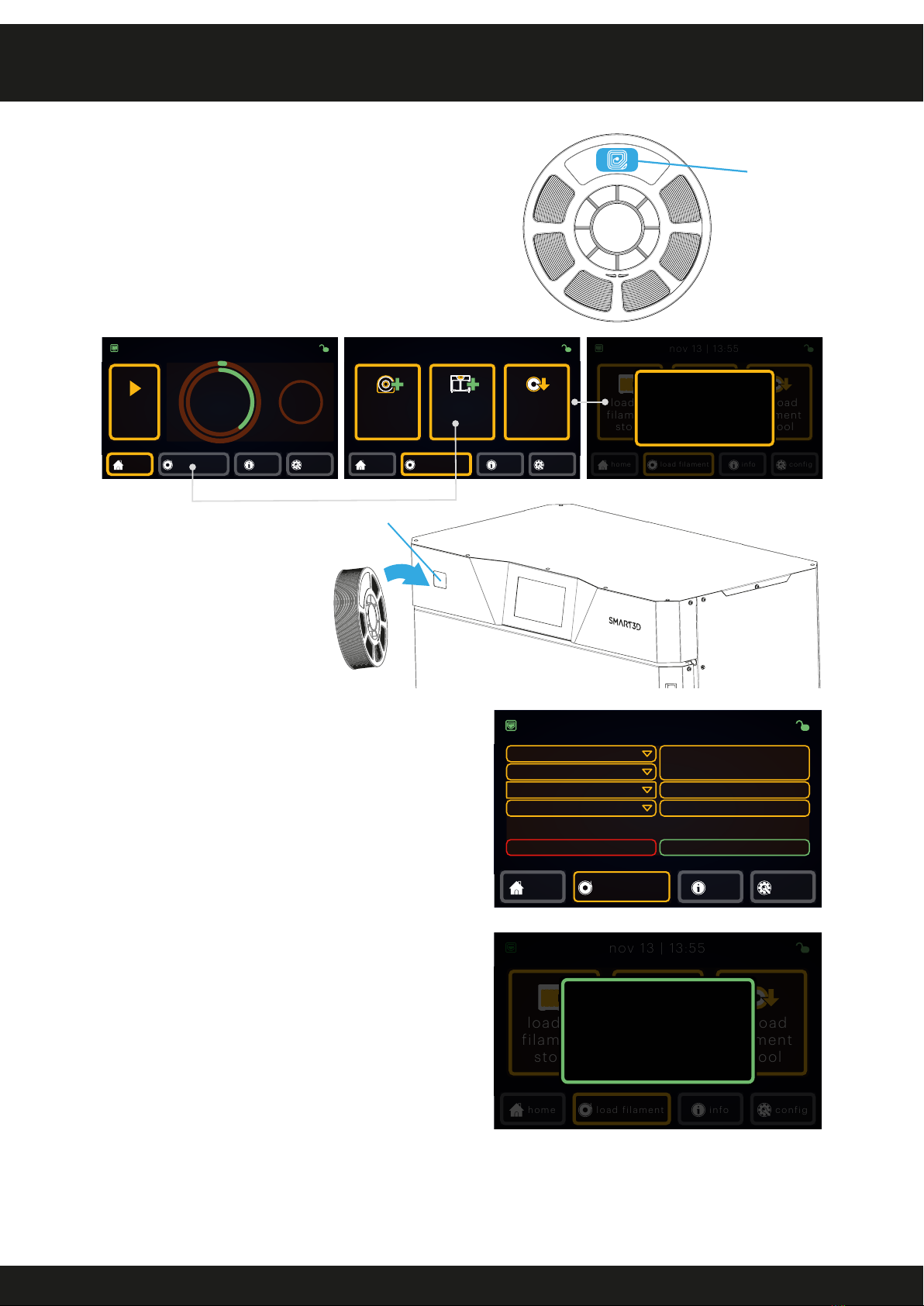

CONTROL PANEL

Multimaterial Dryer.

Network connection

Start drying

Pressing this button will start the drying cycle. Before starting the drying cycle, the door

must be properly closed and locked. The drying cycle will not start unless the chamber is

Home

Pressing this button while on any other screen, will lead you back to the home screen.

Load �ilament

Information

more details) you store inside the Dryer, as well as those that went through a drying cycle.

Con�iguration

and allows to create drying programs with customized values. Also, you may update the

software here and set up the network connection settings.

Door sensor

When the door is open the padlock is green and open. But once you close the door this

icon changes to red and closed.

feeder

dryer

READY

start

drying

home info

nov 13 | 13:55

2

17

3 4 5 6

2

3

4

5

6

1

7

19

OPERATING INSTRUCTIONS

The Smart3D Filaments have their own

When the screen shows

the scanning popup,

you can take the spool

near the scanner.

should show you this screen on the right.

Once you've completed all the data, press

Dryer.

NFC Recognition

NFC Tag

Scanner

home info

nov 13 | 13:55

add

in feeder

load

in dryer

unload

spool

feeder

dryer

READY

start

drying

home info

nov 13 | 13:55

home info

nov 13 | 13:55

load in

store

load in

dryer

unload

spool

Scanning

Put the label on the

scan and wait please

home info

label’s information

Brand

Spool size

Diameter

Material Colour

KODAK

|

750g

1.75 mm

ABS

Density

Black

1.04 g/cm3

okback

home info

nov 13 | 13:55

load in

store

load in

dryer

unload

spool

The spool load

was completed

successfully

code properly.

20

OPERATING INSTRUCTIONS

Drying programs

feeder

dryer

READY

start

drying

home info

nov 13 | 13:55

network

info

custom

drying

program

dryer

info

home

nov 13 | 13:55

info

at the same time. For example, TPU needs low heat

to be dried, unlike nylon that needs high exposures

to heat. With this program you can dry these two

materials together without damaging either of

them.

Duration of the cycle: 2 hours

Generic drying

is designed for ABS only, do not put other types of

material inside the dryer when using this cycle, as

can run the risk of them ruining them.

Duration of the cycle: 3 and a half hours

ABS drying

cycle you want for your materials. The one selected will change in color to green.

home

drying programs

info

Generic

ABS

Peek

Custom program 01

Custom program 02

Custom program 03

Custom program 05

home

drying programs

info

Generic

ABS

Peek

Custom program 01

Custom program 02

Custom program 03

Custom program 05

home info

Program material ABS chamber temperature 45°C

Drying pressure 500mb Pre heating time 10’

Drying duration 40’ number of subcicles 5

activatecancel

drying programs

home info

Program material ABS chamber temperature 45°C

Drying pressure 500mb Pre heating time 10’

Drying duration 40’ number of subcicles 5

activatecancel

drying programs

home info

Program material Generic chamber temperature 45°C

Drying pressure 450mb Pre heating time 10’

Drying duration 30’ number of subcicles 4

activatecancel

drying programs

Table of contents