450336-1 www.adclaundry.com 5

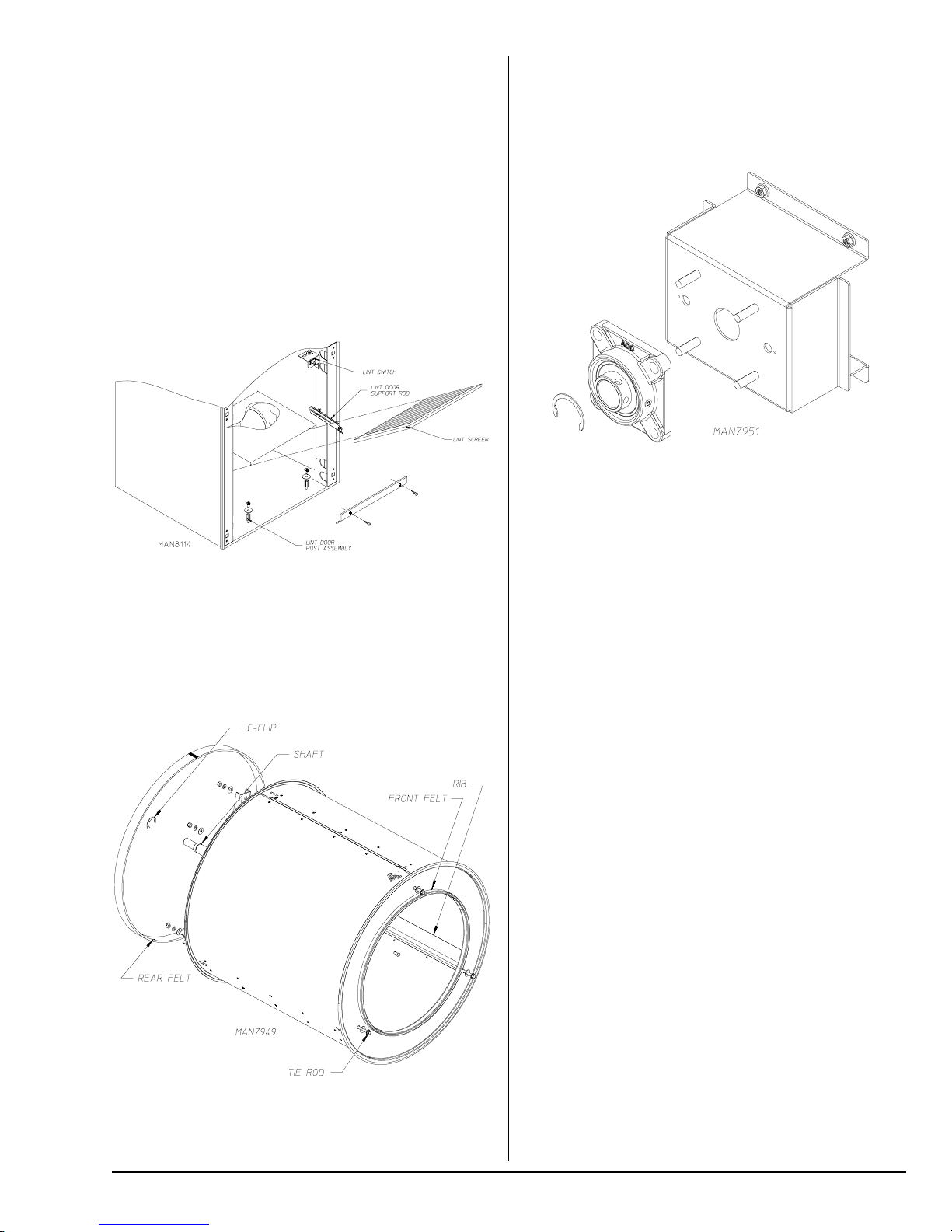

Adjustments

7 Days After Installation and Every 6 Months Thereafter

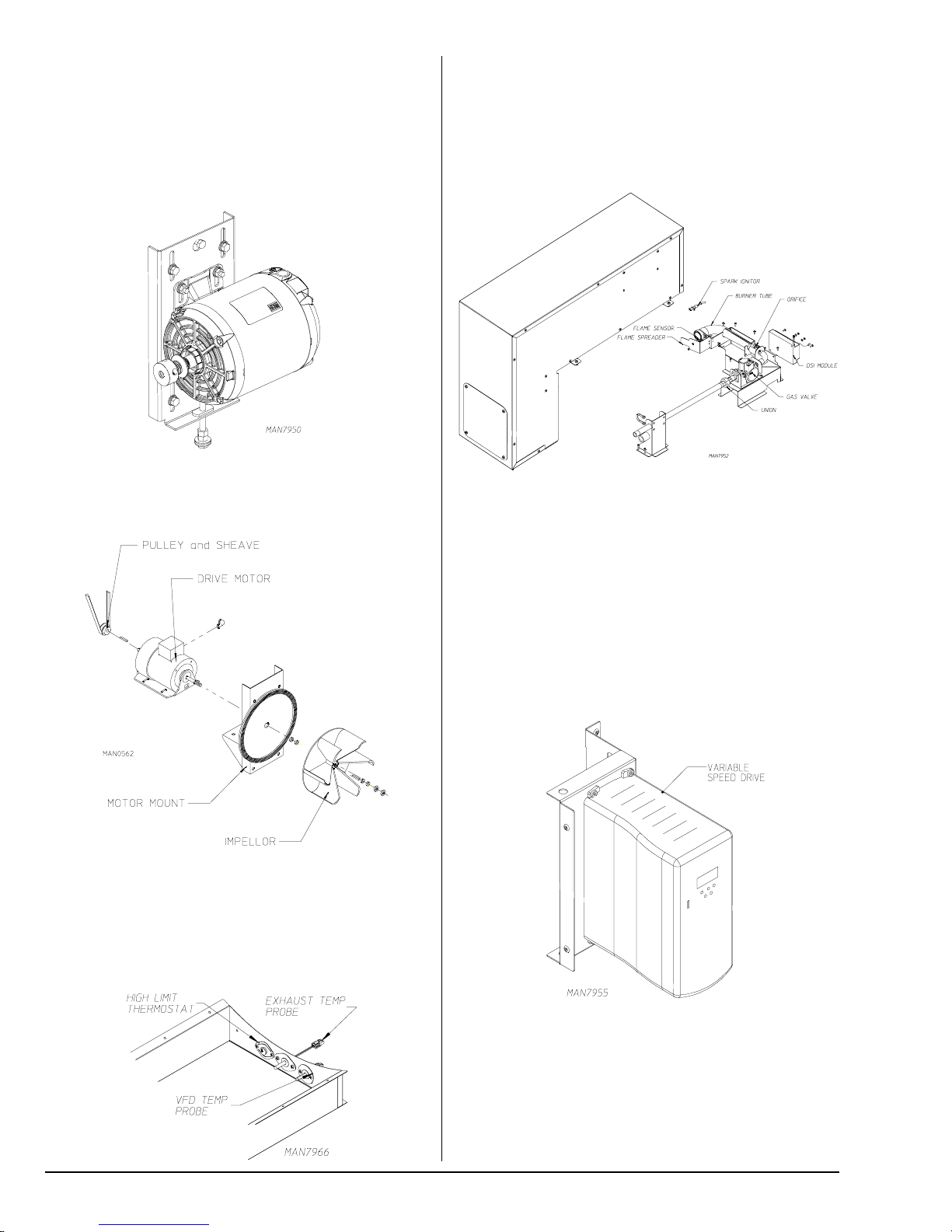

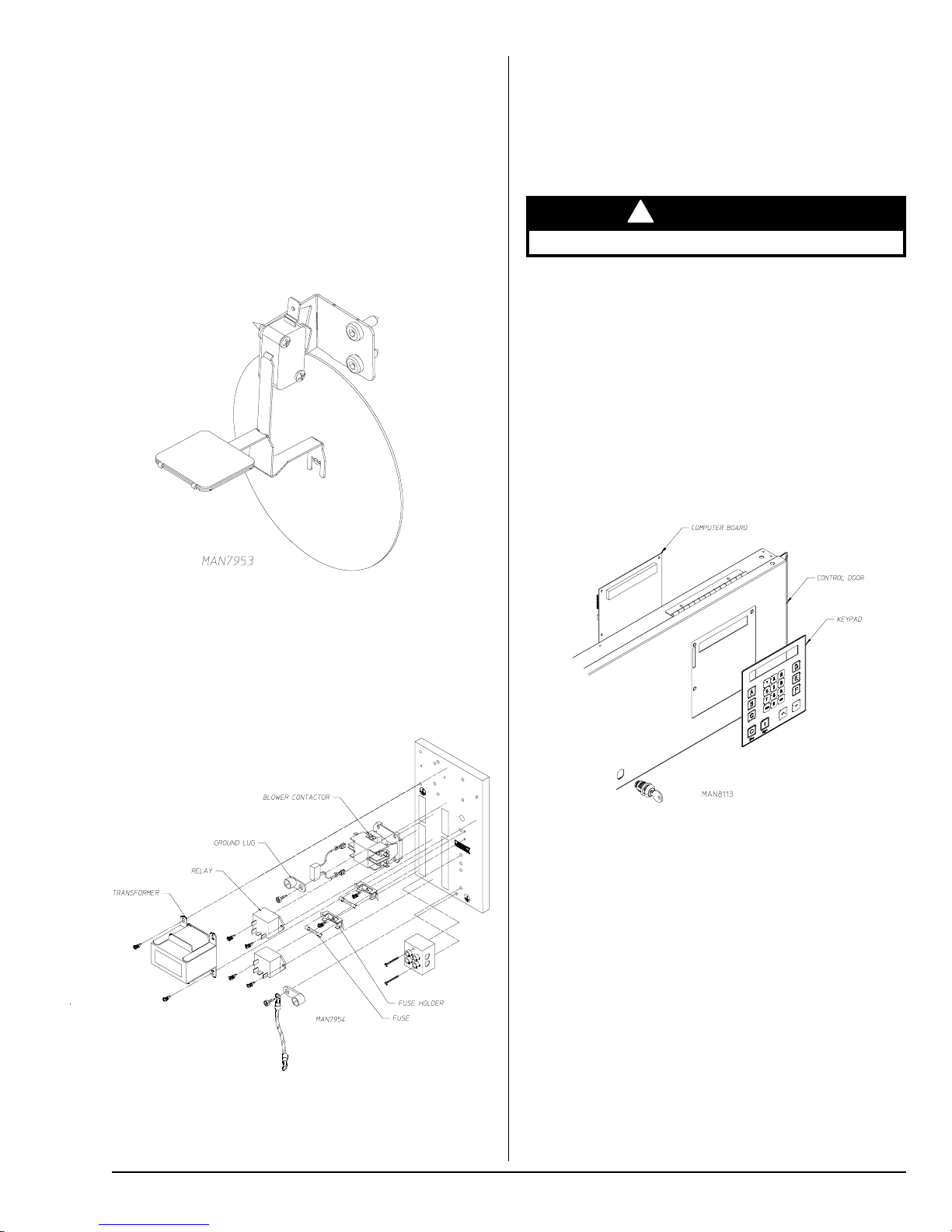

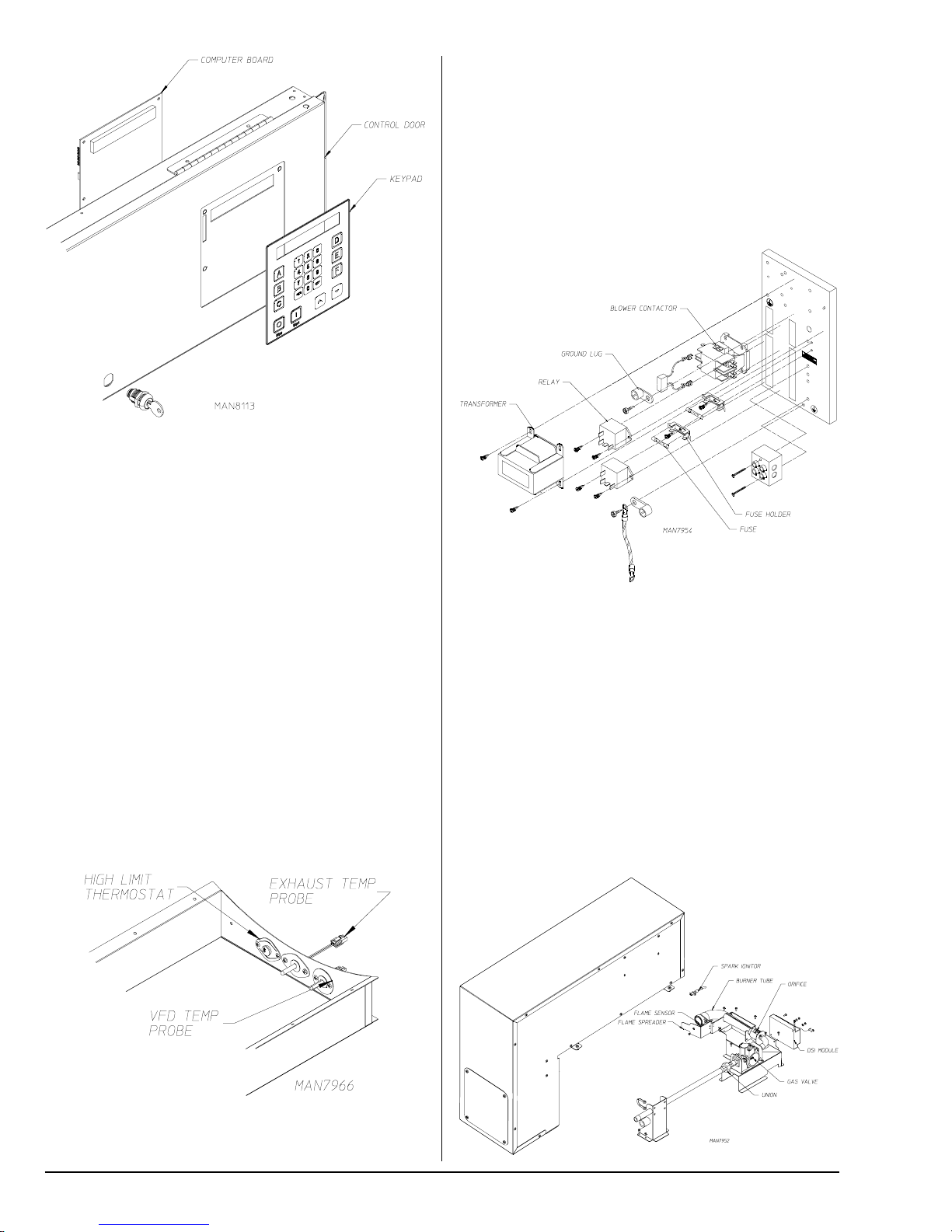

Inspectbolts, nuts,screws (bearing setscrews),nonpermanent

gas connections, and grounding connections (unions, shutoff

valves,and orifices). Motorand drive beltsshouldbe examined.

Cracked or seriously frayed belts should be replaced. Tighten

loose belts when necessary, and check belt alignment.

Complete operational check of controls and valves. Complete

operational check of all safety devices (door switches, sail

switch, burner and lint chamber thermostats).

Lubrication

The motor bearings, idler bearings and tumbler bearings are

permanently lubricated, and no lubrication is necessary.

Installation Requirements ____________

Installation should be performed by competent technicians in

accordancewith local and statecodes. In the absence of these

codes, the installation must conform to applicable American

National Standards: ANSI Z223.1-LATEST EDITION (National

Fuel Gas Code) or ANSI/NFPA NO. 70-LATEST EDITION

(National Electrical Code) or in Canada, the installation must

conformto applicable Canadian Standards:CAN/CGA-B149.1-

M91 (Natural Gas) or CAN/CGA-B149.2-M91 (L.P. Gas) or

LATEST EDITION (for General Installation and Gas Plumbing)

or Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or

LATEST EDITION (for Electrical Connections).

Enclosure, Air Supply,

and Exhaust Requirements

NOTE: The following information is very brief and general.

For a detailed description refer to the installation booklet for

non-coin dryers.

Bulkheads and partitions around the dryer should be made of

noncombustible materials. Allowances should be made for the

opening and closing of the control door and lint door. Also,

allowancesshould bemadein therearfor easeof maintenance.

(Refer to installation manual for recommended distances and

minimum allowances required.)

Whenthe dryeris operating,itdraws inroom air,heatsit, passes

the air through the tumbler, and exhausts it out the building.

Therefore, the room air must be continually replenished from

the outdoors. If the make-up air is inadequate, drying time and

drying efficiency will be adversely affected. Ignition problems

and sail switch “fluttering” problems on gas dryers may result,

and you also could have premature motor failure from

overheating. On electric dryers, premature electric element

failure may result. Air supply must be given careful

consideration to ensure proper performance of each dryer.

IMPORTANT: Make-up air must be provided from a source

free of dry cleaning solvent fumes. Make-up air that is

contaminated by dry cleaning solvent fumes will result in

irreparable damage to the motors and other dryer

components.

Exhaust ductwork should be designed and installed by a

qualified professional. Improperly sized ductwork will create

excessive back pressure, which will result in slow drying,

increased use of energy, and shutdown of the burner by the

airflow (sail) switch.

CAUTION: IMPROPERLY SIZED OR INSTALLED OR

MAINTAINED (CLEANED) EXHAUST DUCTWORK CAN

CREATE A POTENTIAL FIRE HAZARD.

Electrical and Gas Requirements

Electrical Requirements

It is your responsibility to have all electrical connections made

by a properly licensed and competent electrician to assure that

the electrical installation is adequate and conforms to local and

state regulations or codes. In the absence of such codes, all

electrical connections, materials, and workmanship must

conformto theapplicable requirementsof theNational Electrical

CodeANSI/NFPANO. 70-LATEST EDITION or in Canada, the

Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or

LATEST EDITION.

IMPORTANT: Failure to comply with these codes or

ordinances, and the requirements stipulated in this manual,

can result in personal injury or component failure.

It is your responsibility to have all plumbing connections made

by a qualified professional to assure that the gas plumbing

installation is adequate and conforms to local and state

regulations or codes. In the absence of such codes, all

plumbing connections, materials, and workmanship must

conform to the applicable requirements of the National Fuel

Gas Code ANSI Z223.1-LATEST EDITION, or in Canada, the

Canadian Installation Codes CAN/CGA-B149.1-M91 (Natural

Gas)orCAN/CGA-B149.2-M91(L.P.Gas) orLATESTEDITION.

Gas Supply

The gas dryer installation must meet the American National

Standard...National Fuel Gas Code ANSI Z223.1-LATEST

EDITION, or in Canada, the Canadian Installation Codes CAN/

CGA-B149.1M91 (NaturalGas) orCAN/CGA-B149.2-M91 (L.P.

Gas) or LATEST EDITION, as well as local codes and

ordinances and must be done by a qualified professional.

NOTE: Undersized gas piping will result in ignition problems

and slow drying and can create a safety hazard.

The dryer must be connected to the type of gas (natural or

L.P.) indicated on the dryer data label. If this information does

not agree with the type of gas available, do not operate the

dryer. Contact the dealer who sold the dryer or contact ADC.

The gas input ratings shown on the dryer data label are for

elevations up to 2,000 feet (609.6 meters), unless elevation

requirements of over 2,000 feet (609.6 meters) were specified

at the time the dryer order was placed with the factory. The

adjustment for dryers in the field for elevations over 2,000 feet

(609.6 meters) are made by changing the burner orifices. If

this adjustment is necessary, contact the dealer who sold you

the dryer or contactADC.

NOTE: Any burner changes must be made by a qualified

technician.