Sullair SAR 003 User manual

MODELS:- SAR 003 TO SAR 175

DESICCANT DRYERS

MAINTENANCE MANUAL

DATE : 24Mar2000 REV: 1

Page 2 of 30

FOREWORD

The compressed air dryer systems have been designed and manufactured to ensure that maximum

safety and performance is achieved. It is expected that users of these systems will employ safe

working practices and ensure that when installing, commissioning, operating or maintaining the

equipment, any legal requirements are fulfilled. For example, in the UK, users should refer to the

Health and Safety Act, 1974.

All ancillary equipment such as pipework, valves, fittings etc., must be suitable for the pressures and

capacities involved.

Replacement parts are available from your distributor or the manufacturers ( see back page for

information). The adoption of a regular servicing policy is strongly recommended and will result in

ensuring that a high performance is achieved. Serial numbers and customer order numbers should

be referred to in any communication. (Serial numbers can be found on the identification plate

attached to the dryer). The figure number and the appropriate diagram in this manual and the item

number (shown in circle,) will also assist in part identification.

Any warranty will be invalidated if the dryer is not installed in accordance with the manufacturers

recommendations or non-approved parts substituted. Substitute parts could reduce the performance

or service life in addition to creating potential hazards.

The manufacturers reserve the right to modify the contents of this manual without notice. The data

given is a guideline to users and in no way binding on the manufacturers.

BEFORE SERVICING OR DISMANTLING ALL PRESSURE MUST BE RELEASED

FROM THE SYSTEM AND ITS ASSOCIATED PIPEWORK AND ANY ELECTRICAL

SUPPLY ISOLATED.

Page 3 of 30

RECOMMENDED ROUTINE MAINTENANCE

Weekly

1. Ensure drain function / operation on all filters.

2. Ensure the change-over occures approximately every 2 mins.

3. Check all gaskets, control valves, pipes and fittings for air leaks.

4. Ensure moisture indicator paper is blue.

Inlet / Outlet elements should be changed every 6000 / 8000 hrs.

Page 4 of 30

Section

A1

A2

A3

A4

A5

A6

Description

Outlet Head Assembly.

Column Assembly.

Inlet Head Assembly.

Cam-Timer Replacement.

Fault Finding Guide.

Piping Schematic Diagrams.

Page No

Page 5 of 30

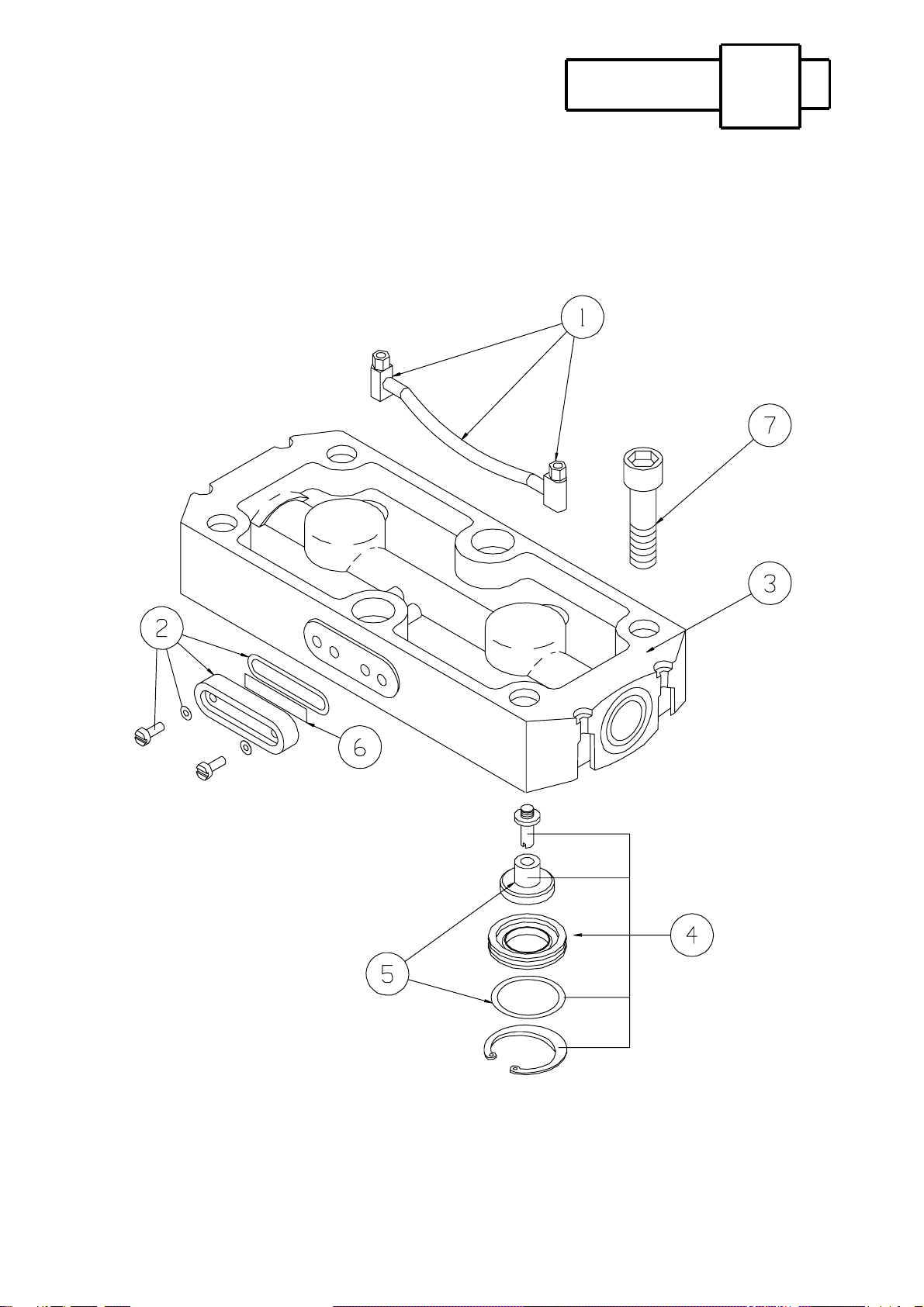

SECTION A1

OUTLET HEAD ASSEMBLY

A1.1

A1.2

A1.3

A1.4

Upper Gasket Replacement

Moisture Indicator Removal

Check Valve Replacement

Adjustment of variable purge

OUTLET HEAD ASSEMBLY SECTION A1

A1.1 UPPER GASKET REPLACEMENT

Disconnect outlet pipework. Remove head bolts, lift head clear.

A1.2 MOISTURE INDICATOR REMOVAL

Remove two screws from sight glass. Change indicator paper and refit, ensuring gasket is in

good condition and the air holes are clear.

A1.3 CHECK VALVE REPLACEMENT

Remove outlet head as above. Remove circlip and valve seat with o-ring. Remove check

valve.

SAR065 - SAR 088

Check the valve is accesible when the head and purge plate are removed. Valve discs can be

changed by securing the valve stem and removing the retaining nut. Valve guides can be

removed by unscrewing from the head.

For re-assembly, follow the reverse procedure always fitting new gaskets.

TORQUE HEAD BOLTS TO 25lbf ft

TORQUE SEQUENCE

Page 6 of 30

OUTLET HEAD ASSEMBLY SECTION A1

GENERAL

A1.4 ADJUSTMENT OF VARIABLE PURGE

The variable purge needle valves are situated in the top or rear of the outlet head on the dryer.

NOTE:

The dryer purge needle valves are factory set for 20% of rated flow of the dryer at 7

barg (102 psig) inlet pressure (18% actual @ 6 barg) The purge needle valves only

require adjustment if the inlet pressure to the dryer is not 7 bar g (102 psig).

TO ADJUST THE PURGE

A.

B.

C.

D.

E.

F.

G.

H.

Turn both valve adjusting screws clockwise until they are fully closed .

DO NOT OVER TIGHTEN THESE SCREWS.

The 4mm or 6mm plastic pipe which connects both valves together should be removed

from the push in connections on the valves by pressing on the face of the connection to

release the collet.

A flow meter (not supplied) which is capable of measuring the amount of purge air

required should be fitted to either one of the purge needle valves.

Allow the column, on which the purge needle valve functions to pressurise. Turn the

adjusting screw in an anticlockwise direction until the desired purge flow setting is

obtained. If the flow meter does not register after THREE TURNS, the adjacent

column is pressurising, wait for the desired column to pressurise and continue.

The operating pressure must be maintained throughout in order for the purge flow

setting to be correct.

When the above operation is complete and the correct purge flow is obtained, wait until

the adjacent column pressurises. Remove the flow meter from the previously adjusted

valve and attach to the unadjusted valve. Turn the adjusting screw anticlockwise until

the desired purge flow setting is obtained.

After adjustment has been carried out, remove the flow meter from the previously

adjusted valve. Replace the 4mm or 6mm plastic pipe. A proportionate amount of

purge air will exhaust when this pipe is being fitted, relative to the capacity of the

dryer.

The correctly adjusted unit is now ready for use. For settings other than 7 bar g, consult

the manufacturer.

NOTE: The maximum rated capacity of the flow meter as recommended by the

manufacturers instructions should be checked before use.

Page 7 of 30

OUTLET HEAD ASSEMBLY SECTION A1

PURGE FLOW

Page 8 of 30

SAR 5 - 10 bar CFM 5 - 10 bar L/M

003

006

013

024

065

088

106

129

175

4.8

6.4

8.4

10.6

12.99

17.58

21.2

26.0

35.1

136

181

238

300

368

498

600

736

996

OUTLET HEAD ASSEMBLY SECTION A1

SAR003 to SAR 013 OUTLET HEAD

Page 9 of 30

OUTLET HEAD ASSEMBLY SECTION A1

OUTLET HEAD SAR 024 to SAR 088

Page 10 of 30

OUTLET HEAD ASSEMBLY SECTION A1

SAR 106 to SAR 175

DUPLEX OUTLET HEAD

Page 11 of 30

Page 12 of 30

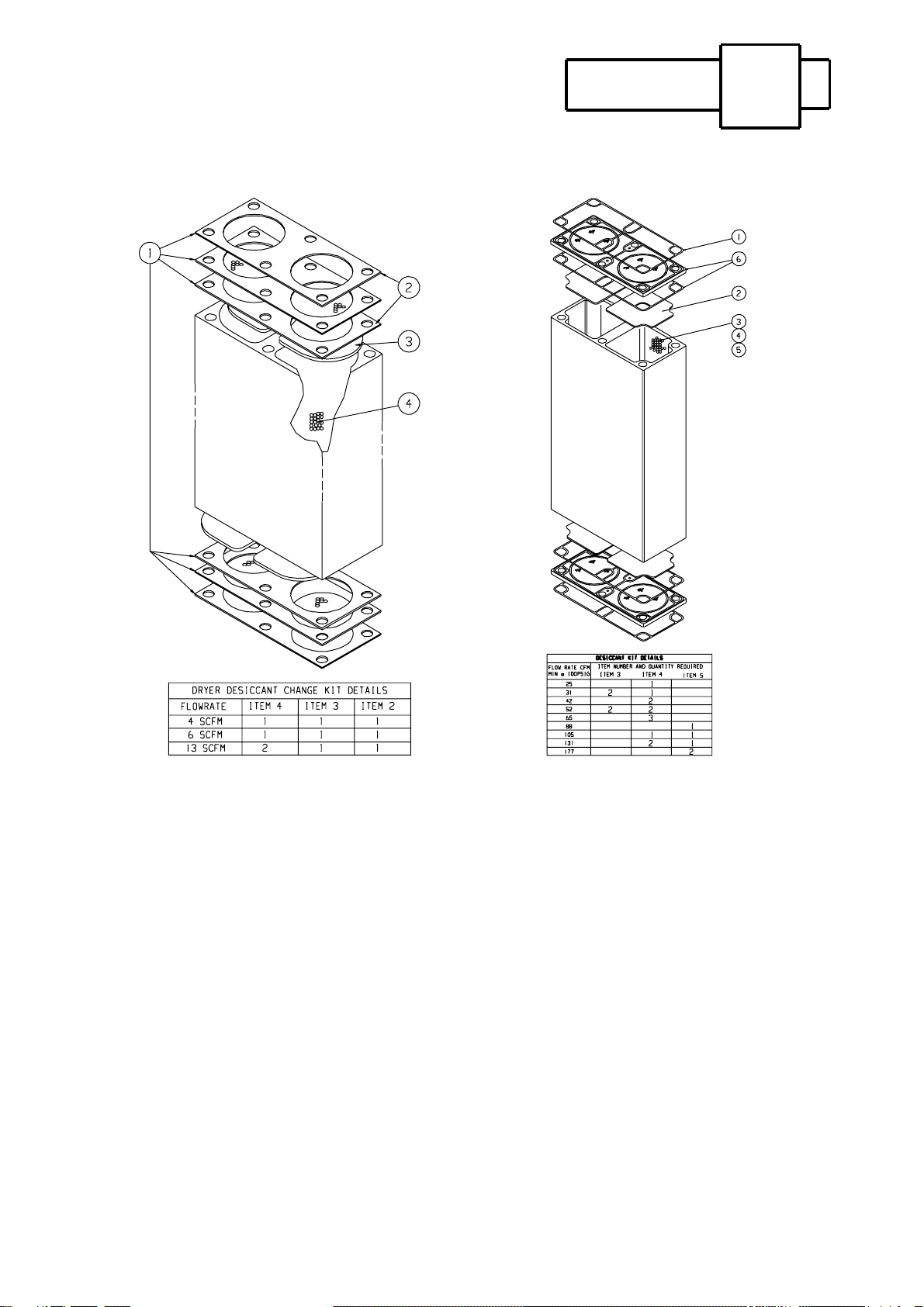

SECTION A2

COLUMN ASSEMBLY

A2.1

A2.2

A2.3

Column/Desiccant Removal

Desiccant Replacement

General

COLUMN ASSEMBLIES SECTION A2

SAR 003 TO SAR 013 SAR 024 TO SAR 088

A2.1 COLUMN / DESICCANT REMOVAL

Remove outlet head assembly and upper gasket. Remove upper column pads and remove

desiccant by either inverting dryer or by means of an industrial vacuum cleaner. The bottom

column bolts can be removed and the column lifted clear although complete removal of the

column is not always necessary.

NOTE : DESICCANT IS NOT REUSEABLE AND MUST BE DISCARDED.

A2.2 DESICCANT REPLACEMENT

Ensure the columns are free from dust, fit new lower column pads and check lower gasket is in

good condition. Refilling can now take place. In order to maintain dryer performance, the

columns must be refilled using a snowstorm filling device which will achieve maximum

packing density. The best results are obtained by using a smooth continuous operation.

A2.3 GENERAL

Each extrusion consists of 2 chambers filled with desiccant material. The manufacturer

suggests a performance life of 10,000 - 30,000 hours, many factors can influence this nominal

figure which should only be used as a guide. Accurate dewpoint monitoring with a hygrometer

is the only true indication of the desiccant material contition. (Consult the manufacturer).

Page 13 of 30

Page 14 of 30

SECTION A3

INLET HEAD ASSEMBLY

A3.1

A3.2

A3.3

A3.4

Bottom Gasket Replacement

Silencer Replacement

(SAR003 to SAR 013)

Control Valve Replacement

Exhaust Valve Replacement

(SAR 024 to SAR 175)

INLET HEAD ASSEMBLY SECTION A3

A3.1 BOTTOM GASKET REPLACEMENT

Disconnect the inlet and outlet pipework. Invert dryer if possible ensuring the purge regulators

are not damaged during this operation. Remove base plate or control panel by removing 4

screws from the control box. This will give access to the column bolts, remove these from sub

plate and lift column clear.

A3.2 SILENCER REPLACEMENT (SAR 003 TO SAR 013)

Remove control box as above, this will give access to exhaust silencer.

SILENCER REPLACEMENT (SAR 024 TO SAR 088)

Unscrew silencer from exhaust valve.

A3.3 CONTROL VALVE REPLACEMENT

Remove control panel or base plate from control box, remove bolts from control valve and lift

clear. Ensure o-rings are in place before refitting.

A3.4 EXHAUST VALVE REPLACEMENT (SAR 024 TO SAR 088)

Remove control panel from control box, control pipe from valve, unscrew silencer from valve

then unscrew valve from sub plate pipework. The exhaust valve can now be lifted clear.

For re-assembly follow the reverse procedure always fitting new gaskets and o-rings.

TORQUE SUB-PLATE BOLTS TO 25lbf ft

Page 15 of 30

INLET HEAD ASSEMBLY SECTION A3

SAR 003 TO SAR 013 INLET HEAD

Page 16 of 30

INLET HEAD ASSEMBLY SECTION A3

SAR 024 TO SAR 088 INLET HEAD

Page 17 of 30

INLET HEAD ASSEMBLY SECTION A3

SAR 106 TO SAR 175

INLET HEAD

Page 18 of 30

Page 19 of 30

SECTION A4

CAM-TIMER REPLACEMENT

A4.1

A4.2

SAR 003 TO SAR 013

Pressure Gauge Replacement

SAR 024 TO SAR 175

CAM TIMER ASSEMBLY SECTION A4

A4.1 CAM TIMER REPLACEMENT

ISOLATE ELECTRICAL SUPPLY

SAR 003 TO SAR 013

Disconnect inlet and outlet pipework and invert dryer, remove base plate, disconnect wires

from terminal block and earth wire. Remove cam profile and locating bolts, lift cam

motor/gearbox free. To change pilot valve, remove control pipes and screws.

SAR 024 TO SAR 175

Remove control panel from control box. Disconnect pneumatic control pipe from cam-timer

and pilot valves. Remove 4 screws from box lid, which will give access to 2 screws holding

cam-timer box to the control panel.

A4.2 PRESSURE GAUGE REPLACEMENT (SAR 024 TO SAR 175 ONLY)

Remove control panel from control box, disconnect pipe from gauge, remove clamp nut and

clamp, remove gauge.

For re-assembly follow reverse procedure.

SAR 024 TO SAR 175 CAM TIMER

ASSEMBLY

Page 20 of 30

This manual suits for next models

1

Table of contents

Other Sullair Dryer manuals

Sullair

Sullair SAR 180 User manual

Sullair

Sullair SR-5 User manual

Sullair

Sullair SR-250 User manual

Sullair

Sullair SR-125 User manual

Sullair

Sullair RH Series Troubleshooting guide

Sullair

Sullair SRV-250 User manual

Sullair

Sullair 02250201-297 R01 User manual

Sullair

Sullair DEX Series Troubleshooting guide

Sullair

Sullair SRS-125 User manual

Sullair

Sullair DMD Series Troubleshooting guide