Smart power SP-SWG-ARM-350 User manual

Swing Gate Opener Manual

Warnings

Please read this instruction manual carefully before the installation of gate-automated

system.

This manual is exclusively for qualified installation personnel. We are not responsible for

improper installatio and failure to comply with local electrical and building regulations.

* Be aware of the hazards that may exist in the procedures of isntallation and operation of

the gate-automated system. Besides, the installation must be carried out in conformity with

local standards and regulations.

* If the system is correctly isntalled and used following all the standards and regulations, it

will ensure a high degree of safety.

* Make sure that the gates work properly before installing the gate-automated system and

confirm the gates are appropriate for the application.

* Do not let children operate or play with the gate-automated system.

* Do not cross the path of the gate-automated system when operating

* Please keep all the control devices and any other pulse generator away from children to

avoid the gate-automated system being activated accidentally.

* Do not make any modifications to any components except that it is mentioned in this

manual.

* Do not try to manually open or close the gate before you release the gear motor.

* If there is a failure that cannot be solved and is not mentioned in this manual, please

contact qualified installation personnel.

* Do not use the gate-automated system before all the procedures and instructions have been

carried out and thoroughly read.

* Test the gate-automated system weekly and have qualified installation personnel to check

and maintain the system at least every 6 month.

* Install waring signs ( if necessory) on the both sides of the gate to warn the people in the

area of potential hazards.

1. Technical Characteristics

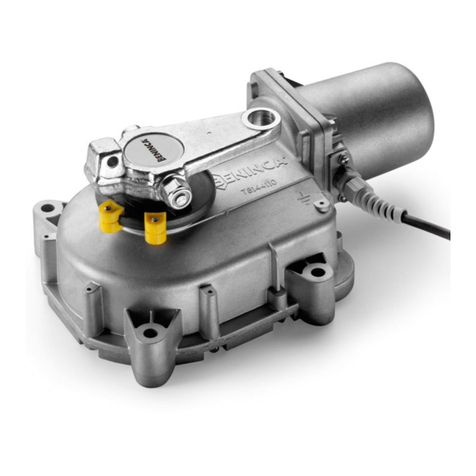

Motor: 24VDC motor with mechanical release

Gear type: Worm gear

Max absorbed power: 144W

Peak thrust: 3500N

Nominal thrust: 3000N

Stroke length: 300mm

Power supply: 24VDC

Nominal input power: 2A

Maximum operating current: 5.5A for maximum 10 seconds

Maximum gate weight: 300kg per leaf

Maximum gate length: 3meters

Duty cycle: 20%

2. Product Description and Applications

2.1 Applications

This model is applied for residential automation of single or dual leaf gate. It has to be operated

with electricity and it’s forbidden to be operated by back-up batteries for normal use. Back up

batteries are only allowed for emergent operation when there is a power failure, and the gear

motors can be released by special keys to move the gate manually.

2.2 Description of the Automation

The following diagram of typical installation describes some terms and accessories of a gate

automation system.

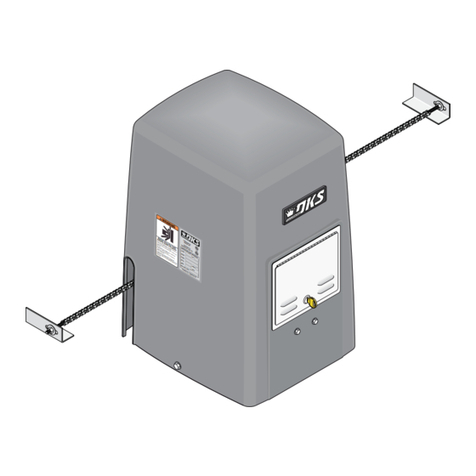

3. Motors, Components and Its Installation in Illustraion

The isntallation procedure maybe changed due to various accessories and quantities installed. The

basic wiring diagram is shown in below photo.

3.1 Power connection

The swing is required to connect two cores wires, which requires very low voltage that no

professinally trained personnel is required in installation; however, the users are advised to read

the installtion manual carefully before going for it. After getting to know all accessories and

their positions, suggest starting from cable conduit arrangement to prevent the cables from being

broken or damaged.

3.2 Notes for Power Connection

A. The installation of power supply cable to the motor should be carried out by a qualified

professional electrician.

B. The power supply cable of the motor should be equipped with short circuit protection and

leakage protection. Please make sure to shut off the power before going installtion or maintenance.

4. Installation

4.1 Preparation for Motor Installation

The gate motor is not applicable to a gate which is ineffcient or unsafe, neither to solve the defects

due to incorrect installation nor poor maintenance.

Check the following items before going for installtion:

1) Make sure the weight and dimension of the gate conform to the operation range of the gate

motor. Don’t use the gate mootr if the gate specifications do not meet the requirements.

2) Make sure the gate structure conform to the criteria of automatic operation and force

regulations.

3) Make sure there is no serious friction existing in the opening or closing travel of the gate

leaves.

4) Make sure the gate is at horizontal level that the gate will not move aside at any position.

5) Make sure the gate can bear the impact of the motor torque when it is installed on any hole of

the bracket which the surface is sufficiently sturdy.

6) Make sure the photo sensors are installed on flat surfaces to ensure the two ends of receiving

and transmitting corresponded to each other.

7) Check the dimensions of the motors as below:

8) Make sure to leave enough space when the gate is opening.

4.2 If the gate is OPENED OUTWARD, please leave at least 70mm between the post

brackets and the gate.

4.3 Using the leaf-opening angle as criteria to make sure all criteria in Figure 17 can be met

FIGURE 17

1) “C” value is 139mm

2) “D” can be measured from the gate easily

3) “A” = “C” + “D”

4) The value of “B” can be calculated from the value of “A” and the leaves opening angle. Ex. If

“A” =160mm with the leaves opening angle of 100 degrees, then the value of “B” is approximate

190mm

NOTE: Please make sure “ B” and “A” are similar or the same in value that the leaves can be

operated smoothly . Also to reduce the burden of the motor.

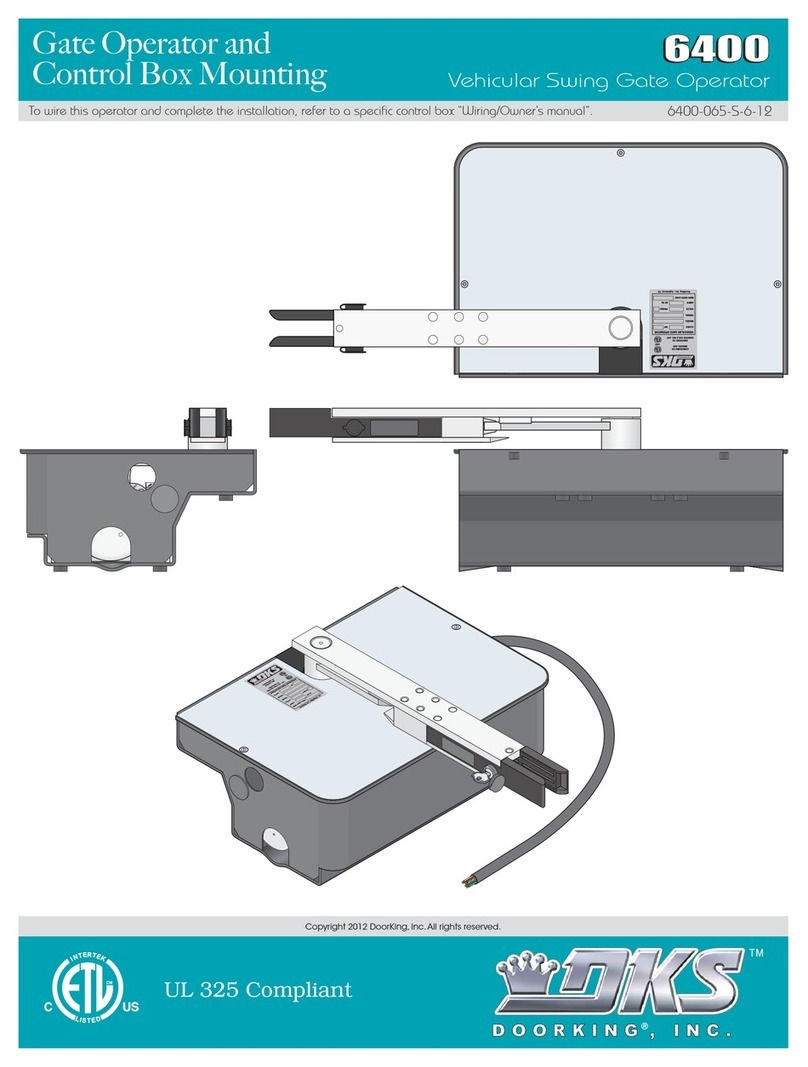

4.4 Installation of the Gear Motors

1) Choose the correct dimensioins of the motors and position to be installed.

2) Check if the mounting surface the brackets to be installed is smooth, vertical and rigid.

3) Arrange the cable conduit for power supply cable of the motors.

4) In order to obtain the optimal supporting from the rear plate, please assemble two post brackes

and one rear metal plast according to below photo

5) Loosen the two screws and remove the back cover of the motor as shown in photo

6) Place the leaves in the closed position.

Figure 18 Figure 19 Figure20

7) Refer to the distance of “B” in figure 17, place the rear plate in the coorect position on the

mounting surface. Inspect if the distance is proper as shown in Figure 23 i.e. the position the front

plate of the motor to be installed.

8) Place two post brackets on the surface to be installed and mark the drilling points, then drill

minimum diameter of 8mm holes by four on the mounting surface to be installed and fasten up the

brackets with screws and washers

9) Please make sure the front plate is completely installed horizontally.

Figure 21

10) Refer to Figure 23, the distance between front plate of the motor and rear plated is 798mm,

the difference in height is 22.5mm

11) Clamp and fix the motor front plate on the door temporarily

12) Lift up the motor and insert the screws into the front plate.

13) Open the gear motor cover and release the screws, then take out the bolt as below Figure 25.

Lift the motor overhead and push the gate to the end until the screw holes of the motor end

matches the holes on the rear plate as shown in Figure 25.1 and fasten the motor to the rear plate

with bolt and screw as shown in Figure 25.2

Figure 25 Figure 25.1 Figure 25.2

14) Fasten the nut tightly and loosen if for half round for motor supporting in rotating

15) Fasten the motor front end to the front plate with the bolt (A) and nut (B) tightly. Fully tighten

the screw.

16) Connect the motor power cable as shown in Figure 27

17) Close the gear motor cover by tightening the two screws as shown in Figure 28

Figure 27 Figure 28

18) Gear Motor Release

A. Turn the round plate on the release part to “OPEN” position, See Figure 29

B. Push out the release part to the end. See Figure 30

C. Use the release key to turn the pin ani-clockwise to the end. See Figure 31

Figure29 Figure30 Figure31

Gear motor release (fork series)

Table of contents

Other Smart power Gate Opener manuals