Smart temp Viking SMT-920 Instruction Manual

SMT-920 Viking

Commercial multistage HVAC controller

User & Installer Manual

Ver 3.1

(Firmware 2.95+)

Page 2

Preface

The new SMT-920 “Viking” HVAC controller has been built by Smart Temp Australia using the best

components and design philosophy currently available. As a result, the Smart Temp SMT-920

“Viking” will provide your clients with many years of trouble free comfort control.

It is highly recommended that you take the time to read and understand these simple instructions

so that you can take full advantage of the many functions and capabilities that are offered in this

premium product.

The SMT-920 “Viking” product is under constant revision, upgrade and enhancement to meet the

new needs of the market. A table below provides a revision history of the manual –which in most

cases reflects product improvement.

Manual Revision History

Ver. 1

First Release.

Ver. 1.01

Some minor spelling and diagram errors corrected.

Ver. 2.0

Version II Hardware. Improved “Smart Sensor” hardware. Added BACnet MS-TP

communications. Improved AO functions. Added service Menu. Added Night purge.

Removed Modbus point data from manual –(separate communications manual provided).

Ver. 2.5

Removed outside air temperature sensor input. (outside temp only measured with Smart

Sensor) Added 0-10V input for IAQ function. Changed economy settings to better support

enthalpy control. Compressor call now suspends outside air function. Minor bug fixes and

performance enhancements.

Ver. 2.6

Some wording changes in the manual. Small spelling and diagram errors corrected. Stage down

for 4 compressor systems improved.

Ver. 2.7

Added hi / low temperature alarm function. Added PI control. Improved DST setting. Fixed night

purge bug. Increased holiday events to 30. Other minor enhancements and improvements.

Ver. 2.8

Additional wording and function description corrections. Added support for version II of the

Smart sensor with Display.

Ver. 2.9

Fixed bug that can cause loss of Smart sensor communication with change in communications

baud rate. Added Humidity Set point, added Hi/Low select function, added communications

parity select, added H, C & H&C output on aux relay menu, added basic/advanced mode in

installer menu layout, improved AH button logic, improved economy indication, clarified

information in the manual.

Ver 2.91

Minor spelling and manual layout changes

Ver 3.0

Updated Viking front label. Graphics in this manual to match.

Ver 3.1

Added “Master” function to Auxiliary relay functions (ver 2.95 firmware).

Removed BACnet

Great care has been taken in the preparation of this manual. Smart Temp Australia P/L takes no

responsibility for errors or omissions contained in this document. It is the responsibility of the

user to ensure this controller or equipment connected to it is operating to their respective

specifications and in a safe manner.

Due to ongoing product improvement Smart Temp Australia P/L reserves the right to change

the specifications of the SMT-920 “Viking” (or its components) without notice.

All rights reserved. © Smart Temp Australia P/L 2015.

Intellectual rights apply.

Page 3

Index

Preface.......................................................................2

Index..........................................................................3

Installation.................................................................4

Wiring Overview........................................................4

Powering the Viking...................................................4

Equipment Connections ............................................4

Communications Terminals .......................................5

0-10V Outputs ...........................................................5

0-10V Input................................................................5

Room Sensor Input (2 wire).......................................5

Auxiliary Inputs..........................................................5

Setting the 2 DIP Switches Functions.........................5

Commissioning Aids...................................................6

Info Window..............................................................6

Service Override ........................................................6

Service Mode.............................................................6

Relay Test Mode ........................................................6

Economy Test Mode..................................................6

Typical Wiring Diagrams ............................................6

0-10V Wiring..............................................................9

Sensor Wiring ............................................................9

Ancillary Input wiring.................................................12

Setting Installer Preferences......................................12

Operation ..................................................................23

The PIN Prompt .........................................................23

Setting the “Start” event or run temperatures..........23

Programming.............................................................23

Setting the Clock........................................................24

Setting Daily Schedules..............................................24

Set Holiday Schedules................................................25

Setting Daylight Savings Times ..................................26

Advanced Features ....................................................27

Economy Cycle...........................................................27

Economy Checklist.....................................................28

CO2 input...................................................................29

Valve Control .............................................................29

After Hours Timer......................................................29

Handover Relay .........................................................30

Compressor Lead Lag.................................................30

Tips &Tricks ...............................................................31

Communications Functions .......................................33

Faults .........................................................................35

Specifications.............................................................36

Page 4

Installation

Wiring Overview

The Viking is a DIN rail mounted device that has been designed to precisely control a wide selection

of HVAC systems in commercial applications. Great effort has been made to ensure the Viking is

very simple to set up and install ensuring reliable control of commercial HVAC systems.

A brief input / output explanation is provided below, further function specific detail is provided

through this manual.

Powering the Viking

The Viking can be powered from either 24VAC (+/-15%) or from 100 to 270 VAC.

Use one power input only.

The A&N input is used for powering the Viking from line voltage (270V max).

The terminal marked G is the 24V active terminal; the Go is the 24V common terminal.

Equipment Connections

A common input is provided for the main 5 equipment relays while a separate relay common is

provided for the 6th, auxiliary relay input. The 6th Auxiliary Function relay has multiple installer

selected functions so a separate voltage can be used with this relay if necessary. See page 17 for

more information on this relays capabilities.

A change over relay is provided for first stage heating and cooling should the Viking need control

drive open/drive closed valves. All other relays are single pole normally open.

All relays are rated at up to 300V, the Fan relay is rated at 12Amps resistive; all other relays are

rated at 5Amps resistive maximum. It is recommended that an external fuse be used to protect the

Viking relays or the equipment that the Viking is controlling.

Do not exceed the maximum current handling capacity of any of the Viking relays.

Page 5

Communications Terminals

The Viking is provided with hardware and firmware to provide MODbus RTU communications

capability. The “A” and “B” terminals are provided for communications.

The communications terminals “A” and “B” are close to the 24V input.

Take extreme care that 24V is not accidentally applied to the communications terminals or

damage to the communications capability of the Viking will result.

0-10V Outputs

2 x 0-10 Volt outputs have been provided. These 0-10V output functions are defined in the installer

manual on page 20 of this manual.

0-10V Input

1 x 0-10 Volt input has been provided. This 0-10V input function is defined in the installer manual

on page 19.

Room Sensor Input (2 wire)

The standard room temperature sensor provided with the Viking is wired to the Room and Com

(Common) terminal next to it. It is recommended that 0.25mm or larger screened pair cable is used

and the screen drain wire earthed in a suitable location. This is especially important where long

cable runs are expected (>15M) or where the sensor cable is run close to other electrical cabling.

It is recommended to use the 4 wire communicating room sensor if you have concerns about

problems associated with long cable runs or interference in the sensor wiring. As this sensor is a

digital sensor, screened cable is required on all cable runs with the screen drain wire earthed in a

suitable location.

Auxiliary Inputs

The Viking has two digital inputs. These inputs have a number of pre-set functions selectable by

the installer. A list of available functions for these inputs is provided in the advanced installer

options listed on page 19. These inputs are volt free and initiated by switching the auxiliary input

to the “COM” (common) terminal next to them.

These inputs are VOLT FREE. Do NOT apply any external voltage to these Auxiliary input terminals

or damage to the Viking WILL result. This is NOT covered by warranty.

Setting the 2 DIP Switches Functions

There are 2 DIP switches that are used to set core function of the Viking. A table outlining these

functions is provided below.

These switch functions do not require the Viking to be powered to be set.

Switch

Function

Off

On

1

If Sw 2 = Off HP - Reversing valve logic

If Sw2 = On HC - Heat Fan logic

Energise in Heat

Electric Heating

Energise in Cool

Gas Heating

2

Equipment control logic

Heat Pump

Heat Cool

Page 6

Commissioning Aids

To assist commissioning the Viking there are a number of

aids provided.

Info Window

Simply press and hold both the UP/DOWN buttons together to open the status window. This

window gives an overview of the Viking functions showing the output from both analogue outputs,

both the room and outside air temperature sensor as well as whether a relay is on or off.

AO1 & AO 2 show the 2 Analogue output values. RT shows the room temperature. OT shows

outside air temp. D1 & D2 shows the two digital input status (0=open 1= Closed). G, Y3, Y2, Y1, OB,

and Ax (aux) show the relay status (0=de-energised 1= energised). A1 shows the 0-10V input

voltage.

Service Override

Pressing both the <F1> and <F3> buttons together for 2 seconds brings up the service override

shortcut. This will permit you to lock the Viking OFF when

you wish to temporarily suspend control functions. Use the

UP/DOWN buttons to select either “Enable” or “Disable”.

This function is NOT intended to replace electrical isolation.

Service Mode

Service mode suspends all anticycle and minimum run timers built into the Viking. See the service

menu on page 22 of this manual. You can activate service mode so that it turns off automatically in

15 mins, or stays on until manually turned off again. The Viking will flash “Service Mode” on the

LCD when this mode is active to warn you that the function is active.

Relay Test Mode

Use the relay test mode with caution. The relay test will cycle all Viking relays and illuminates the

LED displays to prove relay operation. The Viking should NOT be connected to the AC equipment

whilst performing this test or damage to the AC system may be caused. See the service menu on

page 22 of this manual.

Economy Test Mode

Should you wish to test correct damper operation in Economy mode, enter the installer menu and

in the “Change Economy Settings?” menu select Economy = TEST. Exit the installer menu. The

Economy LED will be on and the LCD will show “Economy Test”. The fresh air damper will be held

at 10V and the return air damper will be held at 0v.

Typical Wiring Diagrams

A number of typical wiring diagrams are provided in this manual. This list does not represent all

possible wiring combinations and should not be used as an indication of the complete control

options provided by the Viking. There are hundreds of possible control combinations for the Viking

so not all can be uniquely shown here.

The wiring instructions shown in this section indicate generic equipment connections. They are to

be used in conjunction with the documentation provided by the Original Equipment Manufacturer

as well as other diagrams within this manual.

Care has been taken in the preparation of these drawings however responsibility falls on the

installer to ensure that the Viking or HVAC system is working correctly and in a safe manner.

Page 7

Typical Heat Pump System –4 Compressors

In this example the Viking

is running a heat pump

system with 4

compressors providing 4

stages of heating and 4

stages of cooling.

The Viking is being

powered via 240VAC in

this example.

DIP Switch Settings

Sw1 Off –Rev in Heat

On –Rev in Cool

Sw2 Off –HP Mode

Installer Options

For 4 compressor systems

Set Aux relay = Comp 4

2 Stage Cooling With Drive Open Drive Closed Hot Water Valve

The first stage heating and

cooling relays in the Viking

are a changeover type

permitting you to drive a

heating and/or cooling

valve open and/or closed.

DIP Switch Settings

Sw1 Off –Fan on with heat

Sw2 On –HC Mode

Installer Options

None required.

Page 8

2 Stage Heat With Modulating Cooling Control

In Valve Mode both the

relays and 0-10V outputs

work in tandem,

permitting the Viking to

modulate the 0-10V valve

and also call for the

circulating water pump on

a cooling demand if

required.

Belimo valve terminal

numbers are shown in this

example.

DIP Switch Settings

Sw1 Off –Fan on with heat

Sw2 On –HC Mode

Installer Options

Set Aux relay = Aux heat

SetY1= Cool

Single Stage Water Sourced Heat Pump

This is similar to a

standard single stage

heat pump except that

the auxiliary input is set

to shut the Viking down

on loss of water, thereby

protecting the system.

This fault input can be

used as a phase fail input

or any other safety

interlock.

The Viking LCD will

indicate when a fault (low

water) is detected.

DIP Switch Settings

Sw1 Off –Rev in heat

On –Rev in cool

Sw2 Off –HP Mode

Installer Options

Set AUX input 1 to Fault.

Page 9

0-10V Wiring

The Viking has 2 x 0-10 Volt outputs that can be set to perform pre-set functions that are selectable

by the installer. See the 0-10V options detailed in the installer menu shown on page 20 of this

manual.

Sensor Wiring

The Viking will accept two types of temperature sensors. The standard 2 wire sensor and the more

advanced “Smart” 4 wire sensor that are capable of performing additional control functions.

2 Wire Sensors

The standard 2 wire sensors are suitable for room temperature monitoring

only. There are a number of types of 2 wires sensors available, an overview

is provided below. 2 wire sensors connect to the “room sensor” and the

“common” terminal next to it on the Viking. 2 wire sensor are not polarity

dependent.

RS-1 –It uses 2 wires to communicate the room temperature to the Viking.

The RS-1S sensor is identical to the RS-1 described above except that it is

fitted with a switch that initiates the after-hours run timer incorporated into

the Viking controller. The RS-1S sensor is supplied as standard in the box with

each Viking controller.

The RS-A (S) additionally permits a +/- 4c adjustment of room temperature

from the installer defined set point. This sensor is perfect

for permitting the room occupants to ‘trim” the room

temperature without making large adjustments.

For projects that present difficulty in running wires for

sensors, Smart Temp also offer the RS-W (non-

adjustable), & RS-WA (+/- 4c adjustable) wireless room temperature sensor. This sensor is fitted

with an afterhours run switch. The RS-W has a typical indoor range of approximately 30 meters.

Duct sensors (RS-1D) and averaging sensors (RS-2) are also available that permit additional

temperature monitoring options.

Additional functions using the 2 wire sensor

Auto Off or Vent Mode

You can switch the Viking to Ventilation Mode (or OFF) by manipulating the sensor wiring by placing

an inline switch in the sensor cable. This works whether you use the standard (RS-01) room sensor

or the adjustable (RS1-A) sensor. The Viking automatically detects the 2 wire sensor and when

absent the Viking will behave in a number of ways as set in the Viking installer menu. See the

installer menu options on page 17 for additional information on this function.

Off –An open circuit room sensor turns the Viking OFF.

Vent –An open circuit room sensor will permit the indoor

fan only to operate during occupied “Start” periods.

Full Vent - An open circuit room sensor will run the indoor

fan for as long as the sensor open circuit exists –regardless

of current program.

Page 10

After Hours Run Function

By placing a normally open momentary press button anywhere on the

sensor line (or internally fitted in the RS-1S shown right) the Viking

after- hours run timer can be initiated or cancelled.

Smart Temp P/N RS-1S with red AH switch shown.

Combinations of the options above are possible. For example from a single 2 wire sensor it is

possible to measure room temperature, offset the room temperature thereby altering comfort

levels by +/-4c, initiate (or cancel) an afterhours heating or cooling call, shut the Viking down or

place it in fan only Ventilation Mode.

Averaging Room Sensors

When it is necessary to measure the room temperature in multiple

locations the Viking is capable of using a network of room sensors

and have the Viking control to an average of these temperatures

with the 2 wire sensor.

An example of averaging in 2, 3 and 4 places is shown using a

combination of Smart Temp RS-1 & RS-2 sensors. These averaging combinations can also take

advantage of the advanced sensor functions such as Vent Mode or After Hours start if necessary.

To use the “After-hours” function with averaging sensors the after-hours switch must be wired so

that it affects the entire sensor input on the Viking and not just one sensor. See the diagram for the

4 averaging sensors example below.

It is highly recommended that screened single pair cable of 0.2mm diameter or larger be used on

cable runs in excess of 10 meters or when the cable is run near high voltage / high frequency

cabling.

4 Wire Sensors

When you wish to use the outside economy function and/or provide a wall sensor with room

temperature and set temperature display and adjustment then the “Smart Sensors” may be used.

These are a 4 wire addressable “communicating” sensor that do not suffer from line losses or other

problems that cab normally be associated with 2 wire sensors.

Any 2 wire sensor or sensor network wired to the Viking is automatically disabled when the Viking

detects an indoor Smart Sensor fitted. You are not permitted to use 2 wire and indoor 4 wire “Smart

Sensors” simultaneously.

“Smart Sensors” are available with a LCD and buttons, or as a blind sensor without display or

buttons.

Page 11

Sensor with Display. (P/N RS-SSD)(SSD ver II –pictured requires Viking with firmware version 2.8 or greater)

Smart Temp Smart Sensors measure both humidity and

temperature and are used when economy cooling is required or

when you wish the occupants to be able to makes limited

adjustments to the Viking operation.

Two versions of Smart Sensors are available. The display version

of the Smart Sensor is fitted with a backlit LCD and buttons that

permit the set temperature to be adjusted within the Heating

and Cooling set limits as set within the Viking controller if

enabled. See setting heating & cooling limits on page 15 in the

installer menu “Change Temperature Control Limits”.

When displayed, pressing the “After Hours” button will start the after-hours run timer for the

period of time pre-set in the Viking installer menu. See after hours run timer on page 15.

If displayed, the On/OFF button permits you to turn the Viking OFF

manually, overriding any time clock schedules if set. Pressing the On/Off

button again will return the Viking to its previous state, (if the Viking is

set to manual control the Viking will be “ON”, if under time clock control

the Viking will run its schedule and be on or off based on that schedule)

Sensor without Display (P/N RS-SS)

The standard “Smart Sensor” simply measures temperature and humidity

without permitting local set point adjustment or display etc. This type of sensor is essential for use

as an outside air sensor and can be used for an inside sensor if required.

NOTE - this sensor is NOT water resistant and therefore should be mounted in such a way that

protects the sensor from rain.

Smart Sensors have their own set of “TT” terminals where you are permitted to connect a standard

2 wire dry bulb sensor for remote temperature monitoring. This input overrides the internal Smart

Sensor dry bulb sensor only. Humidity is still measured at the Smart Sensor.

Manuals are provided with the Smart Sensors that provide detail on the

functions and settings of the Sensors.

Smart Sensor Wiring

Terminals 1 & 4 power the Smart Sensor (12v DC +/- 4v is normal) while terminals 2 & 3

communicate data between each sensor and the Viking.

The sensors must be wired in series only and no two sensors should have the same DIP switch

address on the sensor network. If multiple room sensors are fitted, the Viking will control to the

average temperature / humidity of all these sensors. Alternatively if set under the installer menu

option “ Change Sensor Performance” menu shown on page 15, you are able to select High Heating

& Low Cooling when using multiple Smart Sensors(Version 2.9 Viking firmware required).

Note, when short of cabling you may power the Smart Sensor locally from a 12VDC power supply and simply

connect the Viking to the Smart Sensor using terminals 2 & 3.

Page 12

Ancillary Input wiring

The Viking has two digital inputs that have been provided to permit a digital signal (ON/OFF) to

override or compliment the various Viking functions. These inputs are very simple to use and setup.

A number of pre-set functions can be selected for either or both of these two inputs. The installer

menu provides details on these functions on page 19.

If two inputs contradict each other, input 1 has priority. Fire and fault

inputs have priority over all other functions regardless of what input

they are on.

Setting Installer Preferences

Great consideration has been given to ensure the Viking is “right for the job” out of the box,

however in rare circumstances some adjustment of the standard Viking parameters may need to

be completed to meet the specific needs of the project.

The Viking has a comprehensive advanced installer menu. This menu permits you to adjust

operational settings for the safe and effective operation of the HVAC equipment under control of

the Viking.

To enter the Installer menu, press the [F3]. If the key lock is enabled you will be given the option to

enter your 3 digit PIN before advancing to the next step. (See page 23 for instruction on doing this.)

The Viking has 3 function buttons directly under the LCD. The text above the buttons change

dynamically to indicate the function of each button in that window at that time and in conjunction

with other options selected elsewhere in the various Viking menus.

A typical installer menu window is shown here.

Selecting [NO] will move to the next option in the installer menu.

Selecting [YES] will permit you to edit the shown option,

the “After-hours“ run period in this example.

Selecting [BACK] will move you to the previous menu item or if you press and hold the [BACK]

button for 3 seconds you will be “short-cut” exited from the installer menu.

As you navigate through the various windows, the 3 main

function button’s names will change to indicate the

button’s new function for the current window.

The [SELECT] button advances you through the various functions that can be adjusted as shown by

the black box surrounding the menus, the cool set temperature in this example.

Page 13

The UP/DOWN buttons will permit you to change the currently selected option.

The [SAVE] button will save the changes and exit this window.

The [REJECT] button will exit this window discarding any changes made.

The table provided below provides a detailed description of the various menu items, their functions

and the range the values that can be set where appropriate.

A list of the Basic & Advanced Installer Menu with details

of the options within each menu is provided below.

(Basic menu shown in Ver 2.9 firmware or later)

Note - Entering the installer menu will shut down the HVAC system until you exit this menu. The

HVAC system will then restart again after having waited for any set time delays to expire once

you exit this menu.

To advance through the menu, simply press the <F1> button. (By answering “NO” to “Do you want

to enter the current menu”option will move you to the next menu option). The <F3> (Back) button

steps you backwards through the menu options.

Hint - Press and Hold the <F3> (Back) button to fast exit the installer menu.

Answering “YES” will enter the menu where you will be able to adjust the highlighted option with

the UP/DOWN buttons. Using the [SELECT] button (when displayed) will permit you to adjust other

options within the current window.

Basic Menu

Change Programming Options?

Change Auxiliary Relay Functions?

Change Auxiliary Input Functions?

Change Economy Settings?

Change Analogue Output Settings?

Exit Installer Menu?

Advanced Menu

Change System PIN?

Change Button Lock?

Change Programming Options?

Change Temperature Control Limits?

Change Setback Temperature?

Change After Hours Run Period?

Change Sensor Performance?

Change Compressor Staging Limits?

Change Compressor Control Options?

Change Compressor Timing Options?

Change Room Sensor Functions?

Change Auxiliary Relay Functions?

Change Indoor Fan Options?

Change Unoccupied Mode Settings?

Change Auxiliary Input Functions?

Change 0-10V Input Settings?

Change Analogue Output Settings?

Change Display Settings?

Change Analogue Output Settings?

Change Economy Settings?

Change Night Purge Settings?

Change PI Settings?

Change Network Override Settings?

Edit Communications Settings?

Enter Service Setting Menu?

Exit Installer Menu?

Page 14

1

Change System Pin?

Default Value = 021

The Viking has a 3 digit PIN from 000 to 199 that is used to access various menu items if enabled

by the installer. This menu permits you to see the current PIN and change it if desired.

Should you wish to change the PIN, you must enter it twice. If both PINs match, the new PIN is

updated and must be used on all future PIN requests.

NOTE: If you change and then forget this PIN the Viking must be returned to Smart Temp or an

authorised service agent for unlocking and resetting. There may be a fee for this service.

2

Change Button Lock?

Default = OFF

Use this menu item to set the security access for the various menus within the Viking controller.

Options

Off –No menu items are PIN protected - Unrestricted access to all functions.

Set Temp Only –The user can alter the Set Temperatures without requiring a PIN but will be

prompted for the PIN before entering the Schedule and Installer menus.

Set & Program Only –The user can edit the Set Temperature and Time Schedules menu but

must use a PIN to enter the Installer Options menu.

Full Lock –All menu items require a PIN to enter.

3

Change Programming Options?

Default = 7 Day 1 Event

Optimised Start = OFF

The Viking can be operated as either a programmable controller or manual controller (requiring

an external time clock or switch to turn it on or off).

Options

Always ON –If selected the Viking will turn on and run 24 hours per day, 7 days per week.

This setting is to be used when using the RS-SSD to turn the Viking On and OFF manually.

Manual –The Viking will rely on an external signal to turn it on or off. This external signal is

from the auxiliary inputs only (see Auxiliary Input Options on page 19) or the built in After-hours

Run function as described on page 19 of this manual. Also see the Handover Functions described

on page 30 of this manual. Do NOT use this function if using the RS-SSD sensor On/Off Function.

7 Day 1 Event –This option permits the Viking to turn on and off automatically as set by the

inbuilt time clock, once per day for the 7 weekly days. The On event is named “Start” and the

Off event is named “Stop”

7 Day 2 Event –This option is similar to the 7 day 1 event as described above however you are

permitted 2 starts and 2 stops per day. This is useful should you wish the air conditioning to be

off for part of the day (during a lunch break for example) or when you wish the Viking to start

during one day, run past midnight and stop the next day. (See tips & tricks on page 31 of this

manual for help on doing this).

365 Day 1 Event –This option permits you to additionally set up to 30 holiday schedules in the

Viking that will override the normal 7 day 1 event program. Useful for pre-programming the

Viking to be OFF for Christmas holidays for example.

365 Day 2 Events –Same as 365 day 1 event but with 2 events (start & stops) per day.

Optimised Start OFF / ON. ON will start the HVAC before the programmed start time to ensure

the HVAC system is at the set temperature BY the start time.

Page 15

4

Change Temperature Control Limits?

Default = Heat 49°C & Cool 6°C

If permitted, the user can have the ability to adjust the heating and cooling set points. The range

of the user adjustment can be limited if desired by setting the values below.

Options

Heat –The highest heating set point that can be adjusted. (6°C to 49°C)

Cool –The lowest cooling set point that can be adjusted. (6°C to 49°C)

Note: Regardless of where these set point limits are set, the Viking will ensure that at all times

the cooling set point is above the heating set point. If necessary, the Viking will “push” set points

apart to ensure the set points do not overlap.

5

Change Setback Temperature?

Default = Heat Off & Cool Off

Rather than shutting the heating and cooling system completely off during the STOP events, the

Viking can automatically maintain a more energy efficient set point during this time.

This value can also be used as a set temperature during Holiday events if desired. See “Setting

Holiday Schedule” on page 25 of this manual.

The Fan will run in “Fan Auto” mode to maintain any set back temperatures that are set.

Options

Heat –The setback heating temperature. (Range Off –then 6°C to 49°C)

Cool –The setback cooling temperature. (Range 6°C to 49°C then OFF)

6

Change After Hours Run Period?

Default = 2 Hours

The Viking has a built in after-hours timer that, when initiated will replace the current “Stop” or

“Holiday Event” set points with the “Start” heating and cooling set points and Fan Mode. This

override period is timed and at the conclusion of this timed period the Viking will return to the

programmed set points for the current date and time.

Information on initiating the after-hours timer can be found on page 27 of this manual.

Hint: To disable this function set this value to OFF

7

Change Sensor Performance?

Default = 0.0 & Nor& SS

The Viking has 3 temperature sensor inputs.

Room - The 2 Wire Room sensor input

O/A - Smart outside air sensor

Options

Calibration –adjust this value of the selected sensor by +/- 4.5°C.

This is used mostly to offset any temperature accuracy errors caused by long cable runs with

the 2 wire sensors. Adjusting any Smart Sensor readings should NEVER be necessary.

Response Speed - The Viking will permit you to select how rapidly it will respond to room

temperature changes.

Options are VFAST / Fast / Nor (Normal) / Slow / VSLOW

High / Low select (Ver 2.9 or later firmware) - (only applicable with multiple indoor Smart

Sensors)

SS = Standard HI = High Select LO= Low Select

Page 16

8

Change Compressor Staging Limits?

Default = 1.0°C

Each of the Viking’s primary 3 compressors outputs have their own settings to control how each

compressor performs as part of the overall system. The 4th compressor if enabled, uses the same

setting set for the 3rd compressor.

You can set in 0.5 degree increments how far away “this” compressor will start from the

previous compressor’s start point.

Options

Off to 5°C –When selecting OFF for any compressor, it and subsequent compressors are also

turned to off.

Note: Compressor 1 cannot be turned OFF.

If enabled, compressor 4 uses all compressor 3 settings.

9

Change Compressor Control Options?

Default = Various

This menu item permits you to fine tune the Viking’s compressor control settings.

Options

Lead / Lag –Default = OFF. This option attempts to even the wear on air conditioning systems

with multiple compressors. When all compressors are off (either due to the room temperature

being in the dead band or via time clock etc turning the system off) the compressor numbers

will rotate 1 value so that next time the system starts, compressor 2 will start first etc.

Important –The Lead Lag Function will use all compressors under

Viking control as indicated in the Compressor Control Options menu

as described above, so it’s vital that the number of fitted compressors

is correct.

See more details on the Viking Lead Lag Function on page 30.

Smart Upstaging –Default 5 mins. The Viking does not simply measure the difference between

the room temperature and set temperature to bring on various stages of heating or cooling.

The Viking will give a running compressor a chance to bring the room to temperature on its own

before starting additional compressors in an attempt to reduce energy consumption. The

“Smart Staging” settings will determine the minimum time the Viking will wait before bringing

on additional compressors.

Timed Upstage –Default 30 mins. This setting will bring on additional compressors regardless

of how close the room temperature and set temperature are to prevent a struggling compressor

attempting to bring a room to set temperature on its own.

10

Change Compressor Timing Options?

Default = 3 Mins & OFF

An adjustable compressor anti cycle and minimum run timer has been provided to improve

compressor protection.

The anti-cycle timer will prevent the compressor from restarting too soon after it has shut down

and when the Viking first powers up (soft starting).

The minimum run timer will keep the compressor running for a minimum period of time, again

to prevent short cycling but more so to reduce long term energy consumption of the system.

Options

Anti-Cycle Delay –Adjust this from Off to 3, 4 or 5 mins (Default = 3 Minutes)

Minimum Run Time –Adjust this from Off to 2, 3, 4 or 6 mins (Default = OFF)

Page 17

11

Change Room Sensor Functions?

Default = OFF

The room temperature sensor wiring can be used for additional functions other than just

measuring the room temperature. When this sensor is open circuited (or permanently short

circuited) and seen as missing by the Viking, additional functions can be performed.

Options

Force Off –When the room temperature sensor is absent, the Viking will shut down.

Ventilation –When the room temperature sensor is absent the Viking will keep the indoor fan

running during the “Start” event programmed time. There will be no heating or cooling.

Full Vent –When the room temperature sensor is absent the Viking will keep the indoor fan

running regardless of time or set schedules. There will be no heating or cooling –use this with

caution.

Note: A fire or fault input will shut down both Full Vent and Ventilation Modes instantly.

12

Change Auxiliary Relay Functions?

Default = OFF

The Viking is fitted with an ancillary volt free relay to which you are able to assign pre-set

functions. Many of these functions have an additional setting associated with them, such as

when selecting the high temperature alarm the Viking permits you to set the alarm value.

Options

Off –This relay is not used.

Time & After Hours –the auxiliary relay will close when the Viking is running the “Start”

program or when the after-hours timer is active. See Tips and Tricks on page 31 of this manual

for details on using one Viking as a master time clock.

After Hours Only –the auxiliary relay will close only when the after-hours timer is running. This

can be used to pass the after-hours run information to additional devices.

Time Clock Only –The auxiliary relay will close when the Viking time clock is running the “Start”

program. If the after- hours timer is initiated, this relay will remain inactive.

Compressor 4 –The auxiliary relay is assigned as compressor 4. Compressors 1 - 3 must be

active for this function to operate. See Compressor Staging Limits on page 16 of this manual.

Aux Heat –In this mode, the auxiliary relay is assigned as auxiliary heat relay, providing a

heating call after all compressors have finished calling for heat or as a 2nd stage of heating in

Heat Cool Mode (Sw 2 ON).

Heat and Cool –The auxiliary relay will close whenever the Viking is calling for heating or

cooling. (ver 2.9 or later)

Cool –The auxiliary relay will close whenever the Viking is calling for cooling. (ver 2.9 or later)

Heat –The auxiliary relay will close whenever the Viking is calling for heating. (ver 2.9 or later)

Low Alarm - The auxiliary relay will close when the room temperature falls below the low

temperature alarm limit. It will auto reset when the room temp rises more than 2°C above the

alarm set point. Note –if set, the Low Alarm will operate as long as the Viking is powered, even

when stopped or OFF. (ver 2.9 or later)

Hi Alarm –The auxiliary relay will close with the room temperature exceeds high temperature

alarm limit. It will auto reset when the room temp falls more than 2°C below the alarm set point.

Note –if set, the High Alarm will operate as long as the Viking is powered, even when stopped

or OFF. (ver 2.9 or later)

Economy - The auxiliary relay will close whenever the Viking calls for economy mode.

Humidity - This permits the Viking to control a humidifier if the indoor humidity becomes low.

You are also given the opportunity to set the alarm threshold. (ver 2.9 or later)

Network –The auxiliary relay can be controlled (opened or closed) via MODbus

MASTER –The Auxiliary relay will close whenever the Viking is running and open when the

Viking stops. This takes into account any axillary input calls that may override the Viking to Run

or stop outside of programmed hours. (ver 2.95 or later )

Page 18

13

Change Indoor Fan Options?

Default Locked ON & No Purge

The indoor fan in the Viking can be controlled by the user if desired (permitted to select Auto

Fan or Fan On Mode) or locked into On or Auto Mode as set by this menu.

Options

Unlocked –The user can select Fan Auto or Fan On Mode for the “Start”event without

restriction.

Locked Auto –The user cannot adjust the Fan Mode. When the “Start” event is running the fan

will be in Auto Mode where the fan will cycle on and off with the heating and cooling.

Locked On –When the “Start” event is running, the fan will be held on continuously regardless

of the need for heating or cooling. The fan will turn off at the ‘Stop’program.

Purge - A fan purge period of 0 (Off) to 10 minutes, in 1 minute steps, can be set. This will hold

the fan on for a purge period of time after the set point has been reached and the heating and

cooling has stopped.

14

Change Unoccupied Mode Settings?

Default Heat / Cool Off /A Fan

The Viking has an “Unoccupied” Mode. When in unoccupied mode the current active set points

and fan mode are replaced by the Heat, Cool and Fan settings in this menu. The Unoccupied

Mode can be initiated via the auxiliary inputs (see page 19) or via the Holidays Function (see

page 25).

Options

Cool –The cooling set point to use during the unoccupied period. (Default OFF)

Heat–The heating set point to use during the unoccupied period. (Default OFF)

Fan–The Fan Mode to use during the unoccupied period. (Default Auto)

Caution –If you set the Fan Mode to “ON” in this menu and then use the unoccupied mode for

a holiday event, then the fan will run continuously, 24 hours per day during that holiday event

period regardless of the need for heating and cooling. See Holiday Programming on page 25

for more detail.

Page 19

15

Change Auxiliary Input Functions?

Default = Not Used

Two auxiliary inputs have been provided. These are digital inputs and each of these 2 inputs has

the same list of options. In the event of a conflict, auxiliary input 1 will have priority. A fire or

fault input regardless of what input calls them has absolute priority over all Viking inputs.

Options

Not Used –This input is disabled.

Fire –Normally closed input. If this input is open the Viking will shut down all functions, all relays

will open and both 0-10V signals will be 0 volts. This is an instant shutdown; minimum run times

and fan purge periods will be cancelled. The LCD will show “FIRE” to indicate this mode is active.

Occupancy –Initiating this function will cause the Viking to replace the current set points with

the installer set Occupancy set points and Fan Mode for as long as this input is active.

AH Initiate –A short On/Off signal (Pulse) on this input will initiate or cancel the Viking’s after

hours run timer function. During the after-hours run time, the Viking will use the “Start” set

points and Fan Mode for the timed after hours run period.

Force On –When this input is active, the Viking will use the “Start”program’s temperatures and

Fan Mode for as long as this input is active.

Delay Start –Initiating a Delay Start is similar to the Force On Function described above except

that rather than starting immediately the Viking will wait a random period of time, up to 90

seconds, before starting the A/C system. This is useful if you have multiple Vikings running from

a single time clock to protect the building’s power system.

Fault NC –Closing this input will shut the Viking down. The LCD will show “System Fault”.

Fault NO –Opening this input will shut the Viking down. The LCD will show “System Fault”.

Fresh Air –When this input is active and Economy Mode is enabled, the Viking will open the

fresh air damper and close the return air damper to introduce fresh air into the building.

Typically this input is connected to an indoor air quality monitor.

Auto –When Auto mode is used, the Viking will run based on its time schedule only when this

input is closed and stop when the input is open. This mode fits standard Mechanical

Auto/On/off switch logic. (Ver 2.9 or later)

16

Change 0-10v Input Settings

Default = OFF

Off - This input is not used.

IAQ Threshold - The voltage seen at the 0-10V input below this value will not initiate any fresh

air introduction into the building. This is the normal “background” level that is acceptable.

Range is the amount the fresh air damper will open when the 0-10V input measures 10V.

For example, if using a 0-2000ppm CO2 sensor where you want the damper to open to a

maximum of 60% when full fresh air is required and want the damper closed when the indoor

CO2 is below 500ppm. Set the threshold for 2.5V ((2000/500ppm)=4 10V/4 = 2.5)) Set the

range to 60%

17

Change Display Settings?

Default = Deg C & 12 Hour

Set the default temperature and time format display for the Viking from this menu option.

Options

Display –Degree C or F format.

Clock –12 hour (am/pm format), 24 hour format or Off

(Note Setting the clock to OFF will force the Viking into Manual Mode )

Page 20

18

Change Analogue Output Settings?

Default = NOT USED

The Viking has two analogue outputs which can be assigned specific functions as detailed below.

Each of the two analogue outputs has the same functions.

Options

Not Used –The output is not used. Output is 0V

H & C –By selecting this option this single output will modulate for both heating and cooling.

This is mostly used by BMS systems for example to obtain feedback about how far the room is

from set point for both heating and cooling modes.

Cool –This sets the analogue output to control a 0-10 cooling valve. When you select “Cool”

you are then given the option to select the span for the cooling valve, i.e. how far above set

point the 0-10V output is at 10V.

Heat –This sets the analogue output to control a 0-10 heating valve. When you select “Heat”

you are then given the option to select the span for the heating valve, i.e. how far below set

point the 0-10V output is at 10V.

Return Air –This assigns the analogue output to control the inside economy cycle damper.

When economy is used, this damper will modulate closed as more outside air is used.

Fresh Air –This assigns the output to control the outside economy damper. Normally this is at

0V until economy air is used but can sit above 0V if the DVT function is set (see Change Economy

Settings below). The outside damper is also used for the Night Purge Function as described

below.

Type –0-10V or 2-10V type valves. Note - This applies to BOTH Analogue outputs.

19

Change Economy Settings?

Default = OFF

Please note, you must assign one of the 0-10V analogue outputs as described above before

being permitted to adjust the economy settings within this menu. The Viking will

automatically change this setting to “ON” when you assign at least one analogue output to

Fresh or return air.

When using outside air for free cooling (see Economy Function on page 27) the suitable

temperature range of outside air can be defined.

Options

DVT- Off to 90%. The Day Ventilation Time Function will open the outside air damper by this

fixed amount regardless of other economy function settings but only while the building is

occupied. This is to introduce a fixed amount of fresh air into the building to keep the indoor air

quality acceptable when the building is occupied. The damper will close when the building is

unoccupied to prevent heat loss overnight.

Off - Economy cycle is not used / required.

On - Economy Cycle is ready.

Test - Viking will behave as if 100% outside air is required.

RH Limit –When the outside Smart Sensor is used and the normal 2 wire sensor is used for

room temperature measurement the Viking will permit you to set a high outside relative

humidity limit. When the outside air is above this level outside air will not be used for cooling.

If both inside and outside Smart Sensors are used, then the economy settings window will show

“Enthalpy Based”. There are no adjustments required as this Viking will compare the inside and

outside air enthalpy and base the use of outside air on these values.

Note: When the outside air cannot adequately cool the room the Viking will suspend the use of

outside air and replace it with electric cooling.

Table of contents

Popular Controllers manuals by other brands

Community

Community ALC-404D Installation and user guide

PS Automation

PS Automation PSQ 103-AMS operating instructions

Kenwood

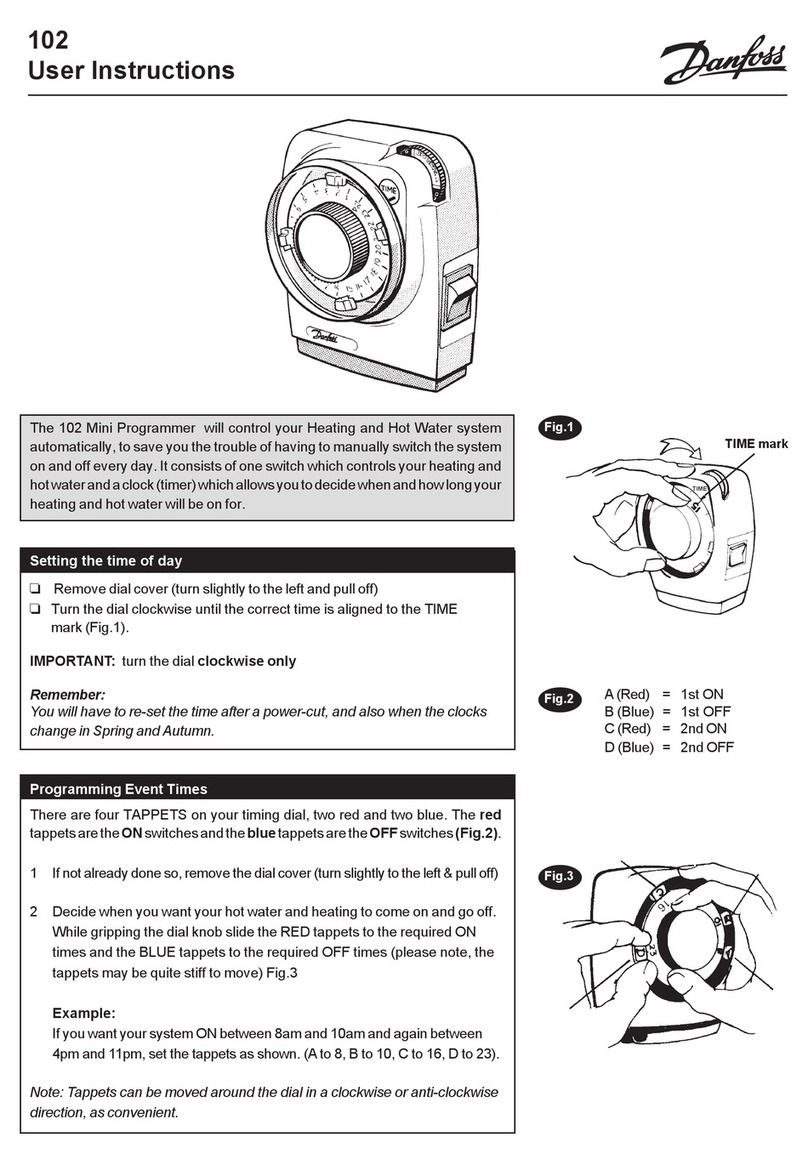

Kenwood KCA-CM50 instruction manual

Siemens

Siemens SIPLUS HCS3200 Compact operating instructions

Sunricher

Sunricher SR-2833T1 quick start guide

Taco Electronic Solutions

Taco Electronic Solutions iWorx HPU2 installation guide