SMC Corporation PFMB7201 User manual

No.PF※※-OMO0005-D

PRODUCT NAME

Digital Flow Switch

MODEL / Series / Product Number

PFMB7201

-1-

No.PF※※-OMO0005-D

Contents

Safety Instructions 2

Model Indication and How to Order 10

Summary of Product parts 13

Definition and terminology 14

Mounting and Installation 16

Installation 16

Piping 19

Wiring 21

Outline of Settings [Measurement mode] 25

Flow Setting (set value only) of OUT1 ·OUT2 [3 step setting mode] 26

Default settings 28

Function Setting [Function selection mode] 28

Default settings 28

F0 Reference condition ·Unit selection function 29

F1 Setting of OUT1 31

F2 Setting of OUT2 39

F3 Response time 44

F10 Display mode 45

F13 Reversed display mode 46

F20 External input 47

F22 Setting of analogue output 48

F30 Accumulated value hold 49

F31 Orientation correction function 50

F80 Display OFF mode 51

F81 Security code 52

F90 Setting of all functions 53

F98 Output check 55

F99 Reset to the default settings 56

Other Functions 57

Maintenance 61

Troubleshooting 62

Error indication 64

Specification 65

Specifications 65

Characteristics data 68

Dimensions 71

-2-

No.PF※※-OMO0005-D

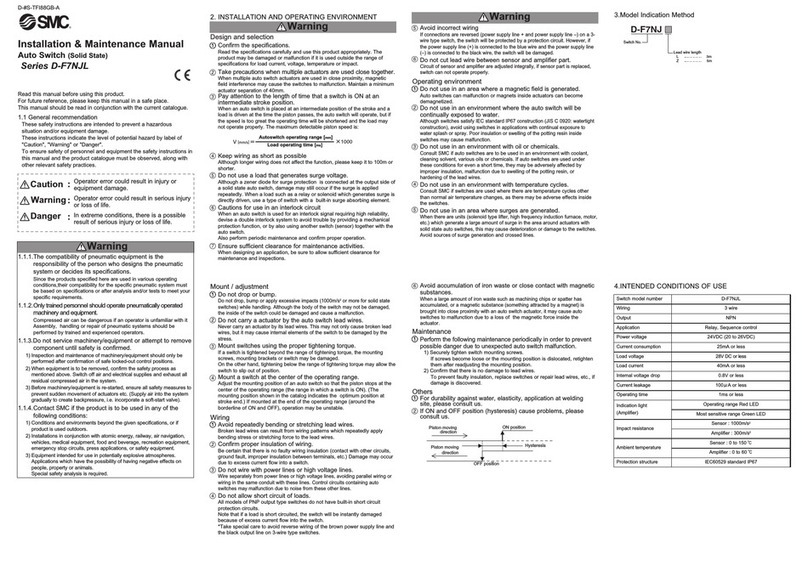

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or "Danger".

They are all important notes for safety and must be followed in addition to International Standards

(ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery -- Electrical equipment of machines .(Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -Safety.

etc.

Caution

Caution indicates a hazard with a low level of risk which, if not avoided, could

result in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk which, if not avoided,

could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will

result in death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications

based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person

who has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when

configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are

implemented and the power from any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the

product is to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place

exposed to direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special

safety analysis.

4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using

a mechanical protective function, and periodical checks to confirm proper operation.

-3-

No.PF※※-OMO0005-D

Safety Instructions

Caution

1.The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following "Limited warranty and Disclaimer" and "Compliance

Requirements".

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered, whichever is first.2)

Also, the product may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other

damage incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and

disclaimers noted in the specified catalog for the particular products.

2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the

vacuum pad or failure due to the deterioration of rubber material are not covered by the

limited warranty.

Compliance Requirements

1. The use of SMC products with production equipment for the manufacture of weapons of

mass destruction (WMD) or any other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are govemed by the

relevant security laws and regulation of the countries involved in the transaction. Prior to

the shipment of a SMC product to another country, assure that all local rules goveming that

export are known and followed.

Caution

SMC products are not intended for use as instruments for legal metrology.

Products that SMC manufactures or sells are not measurement instruments that are qualified by pattern

approval tests relating to the measurement laws of each country.

Therefore, SMC products cannot be used for business or certification ordained by the measurement laws of

each country.

-4-

No.PF※※-OMO0005-D

Operator

This operation manual is intended for those who have knowledge of machinery using pneumatic

equipment, and have sufficient knowledge of assembly, operation and maintenance of such

equipment. Only those persons are allowed to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling, operating or providing

maintenance to the product.

■Safety Instructions

Warning

■Do not disassemble, modify (including changing the printed circuit board) or repair.

An injury or failure can result.

■Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

■Do not operate in an atmosphere containing flammable, explosive or corrosive gas.

Fire, explosion or corrosion can result.

This product is not designed to be explosion proof.

■Do not use the product for flammable fluid.

Fire or explosion can result.

Only air and N2are applicable.

■Do not use the product in a place where static electricity is a problem.

Otherwise it can cause failure or malfunction of the system.

■If using the product in an interlocking circuit:

Provide a double interlocking system, for example a mechanical system

Check the product regularly for proper operation

Otherwise malfunction can result, causing an accident.

■The following instructions must be followed during maintenance :

Turn off the power supply

Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance work

Otherwise an injury can result.

-5-

No.PF※※-OMO0005-D

Caution

■Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the product can result.

■After maintenance is complete, perform appropriate functional inspections and leak tests.

Stop operation if the equipment does not function properly or there is a leakage of fluid.

When leakage occurs from parts other than the piping, the product might be faulty.

Disconnect the power supply and stop the fluid supply.

Do not apply fluid under leaking conditions.

Safety cannot be assured in the case of unexpected malfunction.

■NOTE

○Follow the instructions given below when designing, selecting and handling the product.

●The instructions on design and selection (installation, wiring, environment, adjustment, operation,

maintenance, etc.) described below must also be followed.

Product specifications

The direct current power supply used should be UL approved as follows.

Circuit (Class 2) of maximum 30 Vrms (42.4 V peak) or less, with UL1310 Class 2 power supply unit or UL1585

Class 2 transformer.

The product is a UL approved product only if it has a mark on the body.

Use the specified voltage.

Otherwise failure or malfunction can result.

Insufficient supply voltage may not drive a load due to a voltage drop inside the product.

Verify the operating voltage of the load before use.

Do not exceed the specified maximum allowable load.

Otherwise it can cause damage or shorten the lifetime of the product.

Data stored by the product is not deleted, even if the power supply is cut off.

(Writing time: 1000000 cycles)

The applicable fluids are air and Nitrogen.

The fluid temperature range is 0 to 50 oC.

Before designing piping confirm the pressure loss at the sensor from the pressure loss graph

(characteristics data).

For the details of compressed air quality, refer to ISO 8573-1, 1.1.2 to 1.6.2.

Use the specified measurement flow rate and operating pressure.

Otherwise it can cause damage to the product or inability to measure correctly.

Reserve a space for maintenance.

Allow sufficient space for maintenance when designing the system.

-6-

No.PF※※-OMO0005-D

●Product handling

Installation

Tighten to the specified tightening torque.

If the tightening torque is exceeded the mounting screws, the product may damaged.

If the tightening torque is insufficient, the product may be displaced and the mounting screws may come loose.

Do not apply excessive stress to the product when it is mounted with a panel mount.

Otherwise damage to the product and disconnection from the panel can result.

Ensure that the FG terminal is connected to ground when using a commercially available switch-mode

power supply.

Do not drop, hit or apply excessive shock to the product.

Otherwise damage to the internal parts can result, causing malfunction.

Do not pull the lead wire forcefully, or lift the product by the lead wire. (Tensile force 49 N or less)

Hold the product body when handling, to prevent damage, failure or malfunction.

For piping of the product, hold the piping with a wrench on the metal part (attachment) of the product.

Holding other parts with a wrench leads to may damage the product.

Any dust left in the piping should be flushed out by air blow before connecting the piping to the product.

Otherwise damage or malfunction can result.

Refer to the flow direction of the fluid indicated on the product label for installation and piping.

Do not mount the body with the bottom facing upwards.

Retention of air can cause inability to measure accurately.

Do not insert metal wires or other foreign matter into the piping port.

This can damage the sensor causing failure or malfunction.

Never mount a product in a location that will be used as a foothold.

The product may be damaged if excessive force is applied by stepping or climbing onto it.

If there is a risk of foreign matter entering the fluid, install and pipe a filter or the mist separator at the

inlet to avoid failure and malfunction.

Otherwise failure or malfunction can result, and it can cause inability to measure accurately.

It is possible to satisfy the air quality class indicated in the specification using the pneumatic circuit below.

Recommended pneumatic circuit example (Compressed air)

-7-

No.PF※※-OMO0005-D

Wiring

Do not pull the lead wires. In particular, never lift a product equipped with fitting and piping by holding the

lead wires.

Otherwise damage to the internal parts can result, causing malfunction or disconnection of the connector.

Avoid repeatedly bending or stretching the lead wire, or placing heavy loads on it.

Repeated bending stress or tensile stress can cause damage to the sheath, or breakage of the wires.

If the lead wire can move, fix it near the body of the product.

The recommended bend radius of the lead wire is 6 times the outside diameter of the sheath, or 33 times the

outside diameter of the wire insulation material, whichever is larger.

Replace any damaged lead wire with a new one.

Wire correctly.

Incorrect wiring can damage the product.

Do not perform wiring while the power is on.

Otherwise damage to the internal parts can result, causing malfunction.

Do not route wires and cables together with power or high voltage cables.

Otherwise the product can malfunction due to interference or noise and surge voltage from power and high voltage

cables.

Confirm proper insulation of wiring.

Poor insulation (interference from another circuit, poor insulation between terminals, etc.) can lead to excess

voltage or current being applied to the product, causing damage.

Keep wiring as short as possible to prevent interference from electromagnetic noise and surge voltage.

Do not use a cable longer than 10 m.

Wire the DC (-) line (blue) as close as possible to the power supply.

When analogue output is used, install a noise filter (line noise filter, ferrite element, etc.) between the

switch-mode power supply and this product.

-8-

No.PF※※-OMO0005-D

Environment

Do not use the product in an area that is exposed to water or steam.

Otherwise it can cause failure or malfunction.

Do not use the product in area that is exposed to oil, coolant, cleaning, solvent, sea water or chemicals.

Otherwise it can cause adverse effects (damage, failure, malfunction, or hardening of the lead wire, etc).

Do not use the product in an area where electrical surges are generated.

If there is equipment generates large electrical surges (solenoid type lifter, high frequency induction furnace, motor,

etc.) close to the product, damage or failure of the internal circuit may occur. Take measures against the surge

sources, and prevent the wires from coming into close contact.

Do not use a load which generates a surge voltage.

When a surge-generating load such as a relay or solenoid is driven directly, use a product with a built-in surge

absorbing element.

The product is CE marked, but not immune to lightning strikes. Take measures against lightning strikes

in the system.

Do not use the product in areas that are exposed to vibration or impact.

Otherwise failure or malfunction can result.

Do not use the product in the presence of a magnetic field.

This may lead to the malfunction of the product.

Prevent foreign matter such as wire debris from entering the product.

Otherwise failure or malfunction can result.

Do not use the product in areas subject to large temperature cycle.

Heating/cooling cycles other than ordinary changes in temperature can adversely affect the internal structure of the

product.

Do not expose the product to direct sunlight.

If using in a location directly exposed to sunlight, use a suitable protective cover.

Otherwise failure or malfunction can result.

Keep within the operating temperatures range.

The operating temperature range is 0 to 50 oC.

Operation below the minimum temperature limit may cause damage or operation failure due to frozen moisture in

the fluid or air.

Protection against freezing is necessary.

An air dryer is recommended for elimination of drainage and water.

Avoid sudden temperature changes even within the specified temperature range.

Do not operate close to a heat source, or in a location exposed to radiant heat.

Otherwise malfunction can result.

-9-

No.PF※※-OMO0005-D

Adjustment and Operation

Connect load before turning on the power.

Do not short-circuit the load.

Although an error is displayed when the product load is short circuited, excess current may cause damage to the

product.

Do not press the setting buttons with a sharp pointed object.

This may damage the setting buttons.

Supply the power when there is no flow.

There will be a drift on the display/analogue output of approx. 2 to 3% for 10 minutes after the power supply is

turned on.

The output is off for 3 seconds after power is supplied.

Use settings suitable for the operating conditions.

Incorrect settings can cause operational failure.

During the initial setting and any subsequent flow rate setting, the product will switch the output

according to the existing settings until the changes are complete.

Confirm the output has no adverse effect on machinery and equipment before setting.

Stop the control system before setting if necessary.

Maintenance

Perform regular maintenance and inspections.

There is a risk of unexpected malfunction of components due to the malfunction of equipment and machinery.

Turn off the power supply, stop the supplied air, exhaust the residual pressure and verify the release of

air before performing maintenance.

There is a risk of unexpected malfunction.

Perform drainage regularly.

If condensate enters the outside, it can cause failure of other pneumatic equipment.

Do not use solvents such as benzene, thinner etc. to clean the product.

They could damage the surface of the body and erase the markings on the body.

Use a soft cloth to remove stains.

For heavy stains, use a cloth lightly dampened with diluted neutral detergent, then wipe up any residue with a dry

cloth.

Other

When a flow adjusting valve is included, vibration may cause the flow adjustment valve to rotate and

change the flow rate.

Accuracy may vary by 2 to 3% if the customer removes or replaces the piping port.

-10-

No.PF※※-OMO0005-D

Model Indication and How to Order

-11-

No.PF※※-OMO0005-D

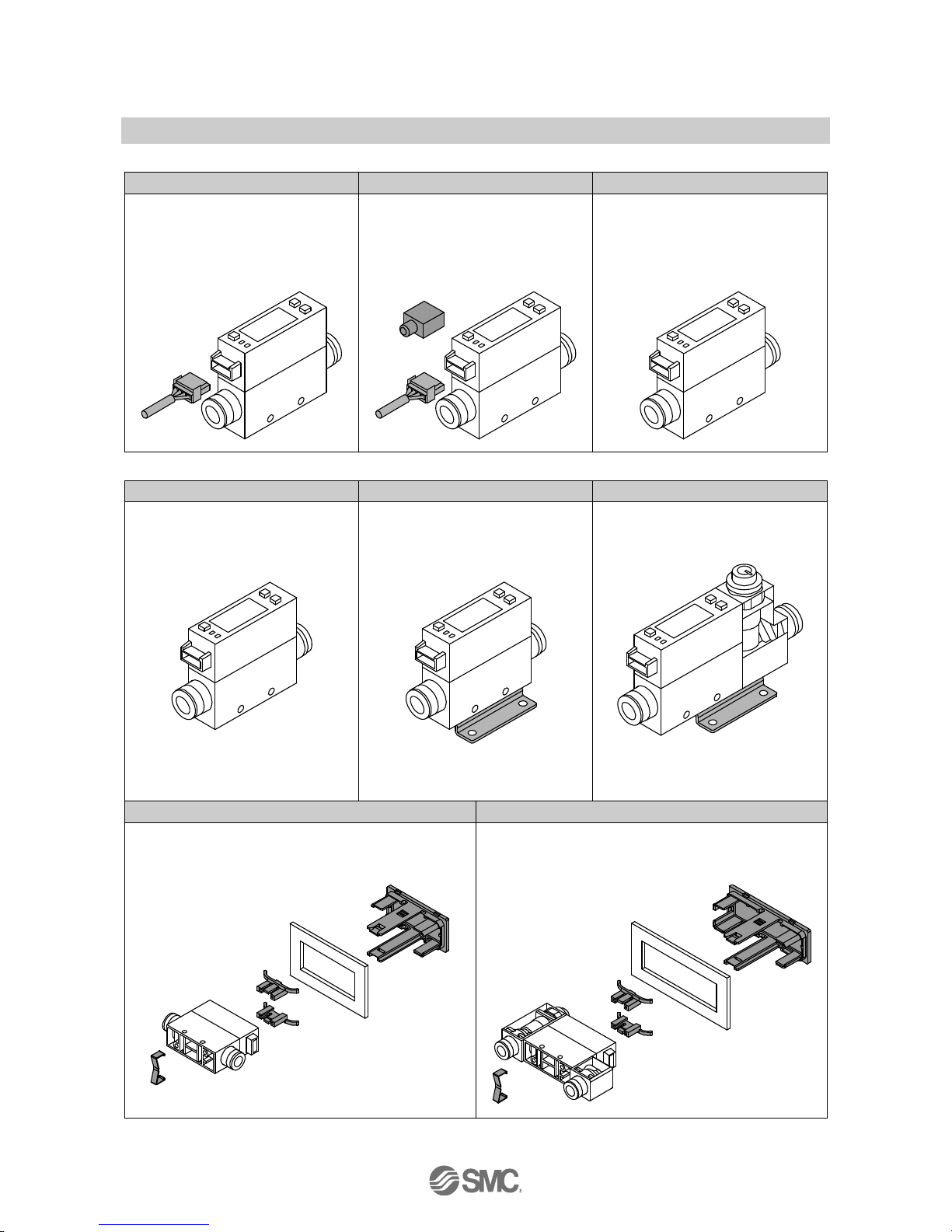

Option1

NIL

W

N

With lead wire with connector (2 m)

With lead wire with connector (2 m)

+

Connector cover

(Silicone rubber)

No lead wire

Option 2

NIL

R

S

No bracket

With bracket

(Without flow adjustment valve)

With bracket

(With flow adjustment valve)

Not suitable for bottom entry

piping type.

T

V

With panel mount adapter

(Without flow adjustment valve)

With panel mount adapter

(With flow adjustment valve)

: Each accessory is not assembled with the product, but shipped together.

-12-

No.PF※※-OMO0005-D

Accessories/Part numbers

If an accessory is required, order using the following part number.

Part number

Description

Note

ZS-33-D

Lead wire with connector

Length: 2 m

ZS-33-F

Connector cover

Silicone rubber

ZS-33-J

Panel mount adapter (without flow adjustment valve)

ZS-33-JS

Panel mount adapter (with flow adjustment valve)

ZS-33-M

Bracket (without flow adjustment valve)

With mounting screws

(2 pcs with nominal diameter of 3.0)

ZS-33-MS

Bracket (with flow adjustment valve)

With mounting screws

(3 pcs with nominal diameter of 3.0)

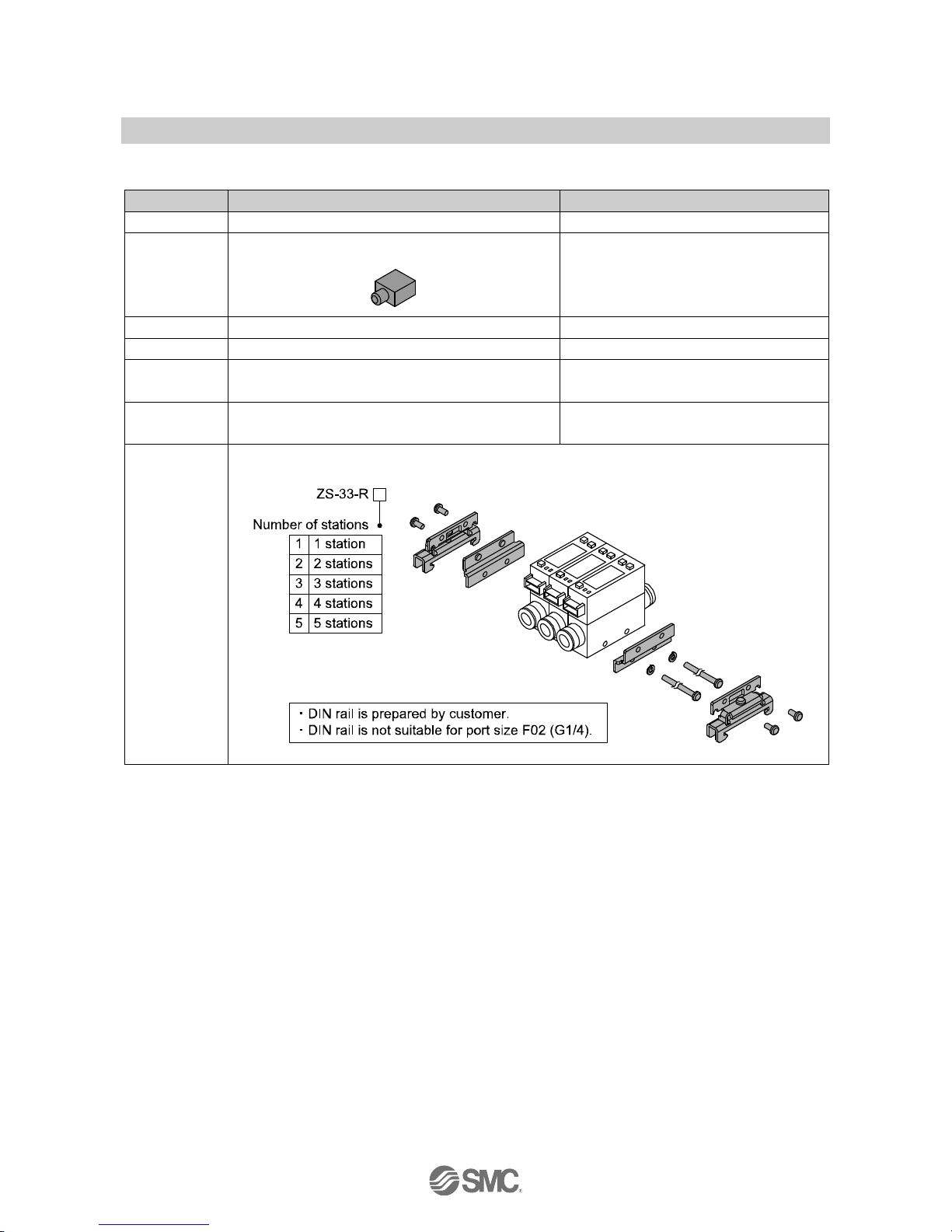

ZS-33-R□

DIN rail mounting parts

-13-

No.PF※※-OMO0005-D

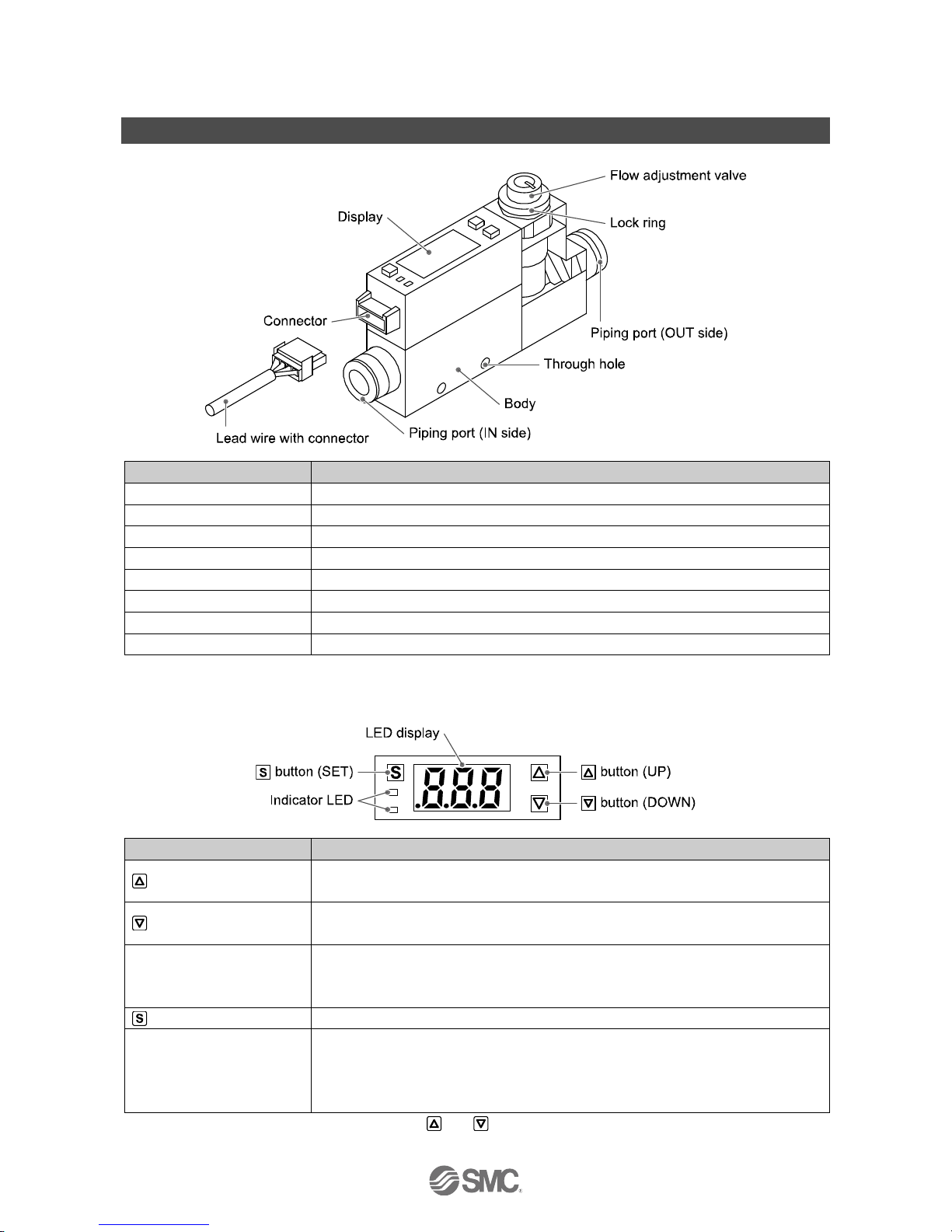

Summary of Product parts

Body

Name

Description

Display 1

See below.

Connector

Connector for electrical connections.

Flow adjusting valve 2

Orifice mechanism to adjust the flow rate.

Lock ring 2

Used to lock the flow adjustment valve.

Piping port

For piping connections. Connected to the fluid inlet at IN and to the fluid outlet at OUT.

Through hole

Used to mount the product on a DIN rail or directly to a panel.

Body

The body of the product.

Lead wire with connector

Lead wire for power supply and outputs.

1: Aprotective tape is affixed to the display. Please remove it before use.

2: The table lists the parts when a flow adjusting valve is included.

Display

Name

Description

button (UP) 3

Selects the mode and increases the ON/OFF set value.

Press this button to change to the peak display mode.

button (DOWN) 3

Selects the mode and decreases the ON/OFF set value.

Press this button to change to the bottom display mode.

LED display

Displays the flow value, setting mode and error codes.

The display colour is selectable from red and green depending on the output (OUT1)

condition.

button (SET)

Press this button to change the mode and to set a value.

Indicator LED

Displays the output status of OUT1 and OUT2.

When the accumulated pulse output mode is selected, the LED will turn OFF.

OUT1: LED is ON (Green) when the output is ON.

OUT2: LED is ON (Red) when the output is ON.

3: When the reversed display is used, the function of the and buttons is reversed.

-14-

No.PF※※-OMO0005-D

■Definition and terminology

Terminology

Definition

A

Accumulated flow

The total amount of fluid that has passed through the device. If an instantaneous

flow of 10 L/min continues for 5 minutes, the accumulated flowwill be 5 x 10 = 50 L.

Accumulated flow external

reset

A function to reset the accumulated flow to "0" when an external signal is input.

Accumulated pulse output

A type of output where a pulse is generated every time a predefined accumulated

flow passes. It is possible to calculate the total accumulated flow by counting the

pulses.

Accumulated value Hold

A function to store the accumulated flow value in the internal memory. The flow

value will be stored at a set time interval of either 2 or 5 minutes. When the power

supply is turned on, the stored accumulated flow value will be displayed and

accumulated flow will continue from that point.

Analogue output

A type of variable output that has a value proportional to the measured quantity.

When the analogue output is in the range of 1 to 5 V or 4 to 20 mA, it will vary

continuously, following the change of flow.

Attachment

A metal part on both sides of the product to connect piping.

Auto-preset

This function calculates and sets an approximate set value automatically based on

the on-going operation.

Auto-shift

A function where the switch output state is determined by the change in

instantaneous flow rate, relative to a reference value set when an external signal

is input.

Auto-shift zero

As the auto-shift function, but in addition the display is also reset to zero when an

external signal is input, and so the display shows the change of instantaneous

flow from the reference value.

C

Chattering

The problem of the switch output turning ON and OFF repeatedly around the set

value at high frequency due to the effect of pulsation.

D

Display flow range

The range which can be displayed by the product with a digital display.

F

F.S. (Full span, Full scale)

Stands for "full span" or "full scale", and indicates varied analogue output range at

rated value. For example, when analogue output is 1 to 5 V, F.S. = 5[V] - 1[V] = 4[V],

(ref. 1%F.S. = 4[V] x 1% = 0.04[V])

The maximum measuring range or change in analogue output over the maximum

measurement range.

H

Hysteresis

The difference between ON and OFF points used to prevent chattering.

Hysteresis can be effective in avoiding the effects of pulsation.

Hysteresis mode

Mode where the switch output will turn ON when the flow is greater than the set

value, and will turn OFF when the flow falls below the set value by the amount of

hysteresis or more.

I

Instantaneous flow

The volume of flow per unit of time. If it is 10 L/min, there is a flow of 10 L passing

through the device in 1 minute.

Internal voltage drop

The voltage drop across the product (and therefore not applied to the load), when

the switch output is ON. The voltage drop will vary with load current, and ideally

should be 0 V.

K

Key-lock function

A function that locks the set buttons so that no accidental setting changes can be

made.

-15-

No.PF※※-OMO0005-D

Terminology

Definition

M

Minimum setting unit

The resolution of set and display values.

If the minimum setting unit is 1 L/min, the flow can be displayed in 1 L/min units, i.e.

10, 11, 12.

O

Operating fluid temperature

The fluid temperature range within which the product will meet all published

specifications.

Operating humidity range

The ambient humidity range within which the product will meet all published

specifications.

Operating pressure range

The pressure range within which the product will meet all published specifications.

Operating temperature

range

The ambient temperature range within which the product will meet all published

specifications.

P

Part in contact with fluid

A part that comes into physical contact with the fluid.

Power saving mode

The condition in which the display is turned off to reduce current consumption.

Pressure characteristics

The amount of variation in the analogue output or display value when the supply

pressure is changed.

Proof pressure

The pressure beyond which the product will be damaged.

R

Rated flow range

The flow range within which the product will meet all published specifications.

Repeatability

Reproducibility of the display or analogue output value, when the flow is

repeatedly changing.

Response time

(switch output)

The time from when the flow is applied as a step input (when the flow rate

changes from 0% to 100% instantaneously) until the analogue output (voltage or

current) reaches 90% of the actual flow rate.

Response time

(analogue output)

The time from when the flow is applied as a step input (when the flow rate

changes from 0% to 100% instantaneously) until the switch output turns ON (OFF)

at 90% of the rated flow rate.

S

Set flow range

The range of ON/OFF threshold values that can be set for products with a switch

output.

Switch output

An output type that has only 2 conditions, ON or OFF. In the ON condition an

indicator LED will turn on, and any connected load will be powered. In the OFF

condition, there will be no indicator LED and no power is supplied to the load.

T

Temperature characteristic

The amount of variation in the analogue output or display value when the ambient

temperature is changed.

U

Unit selection function

Function to change the unit in which the value of flow is displayed. Only a product

with this function can change the unit. Aproduct with unit selection function cannot

be purchased if it is used within Japan. Flow is indicated only by SI units in Japan.

W

Window comparator mode

An operating mode in which the switch output is turned on or off depending on

whether the flow is within the range of 2 set values.

-16-

No.PF※※-OMO0005-D

Mounting and Installation

Mounting

Never mount the product in a place where it will be used as a mechanical support.

Mount the product so that the fluid flows in the direction indicated by the arrow on the side of the body.

■Installation

Panel mounting

Insert the panel mount adapter Ainto the panel mount adapter B.

Push the panel mount adapter B from behind until the adapter is fixed on to the panel.

The pin of the mounting bracket fits into the hook C of the panel adapter A to fix the product.

Refer to the dimensions (page 83) for panel thickness and panel mount cut-out dimensions.

-17-

No.PF※※-OMO0005-D

Bracket mounting

Mount the bracket to the product using the mounting screws.

Fasten the bracket mounting screws to a torque of 0.45 to 0.55 Nm.

Self tapping screws are used, and should not be re-used several times.

Without flow adjustment valve

(using ZS-33-M)

With flow adjustment valve

(using ZS-33-MS)

Mount the product with bracket using M3 screws (4 pcs) or equivalent.

Screws are prepared by customer.

Refer to the dimension drawing (page 84) for the bracket thickness and mounting hole dimensions.

Without flow adjustment valve

With flow adjustment valve

-18-

No.PF※※-OMO0005-D

Direct mounting

For direct mounting use M3 screws (2 pcs) or equivalent.

Screws are prepared by customer.

The tightening torque should be 0.35 to 0.45 Nm.

Refer to the dimension drawing (page 84) for the mounting hole size.

DIN rail mounting

Mount the bracket to the product using the joint screws.

Mount the DIN rail mounting bracket to the bracket with the DIN rail mounting screws.

The tightening torque for the DIN rail mounting screws and joint screws should be 0.35 to 0.45 Nm.

-19-

No.PF※※-OMO0005-D

■Piping

Never mount the product upside down.

The straight piping length shall be 8 cm or longer.

Otherwise, if a straight section of piping is not installed, the accuracy varies by approximately 2%F.S.

Refer to the straight inlet piping length and accuracy graph (page 70).

Avoid sudden changes in the piping size on the IN side of the product.

Do not release the OUT side piping port of the product directly to the atmosphere without the piping

connected.

If the product is used with the piping port released to atmosphere, the accuracy may vary.

Piping for the metal attachment

Tighten to the specified torque. Refer to the table below for the required torque values.

If the tightening torque is exceeded, the product can be broken.

If the tightening torque is insufficient, the fitting may become loose.

Avoid any sealing tape getting inside the flow path.

Ensure there is no leakage after piping.

When mounting the fitting, a spanner should be used on the metal part (attachment) of the fitting only.

Holding other parts of the product with a spanner may damage the product.

Specifically, make sure that the spanner does not damage the connector.

Nominal thread size

Required torque

Rc1/4, NPT1/4

12 to 14 Nm

Nominal thread size

Width across flats of

attachment

Rc1/4, NPT1/4

17 mm

G1/4

21 mm

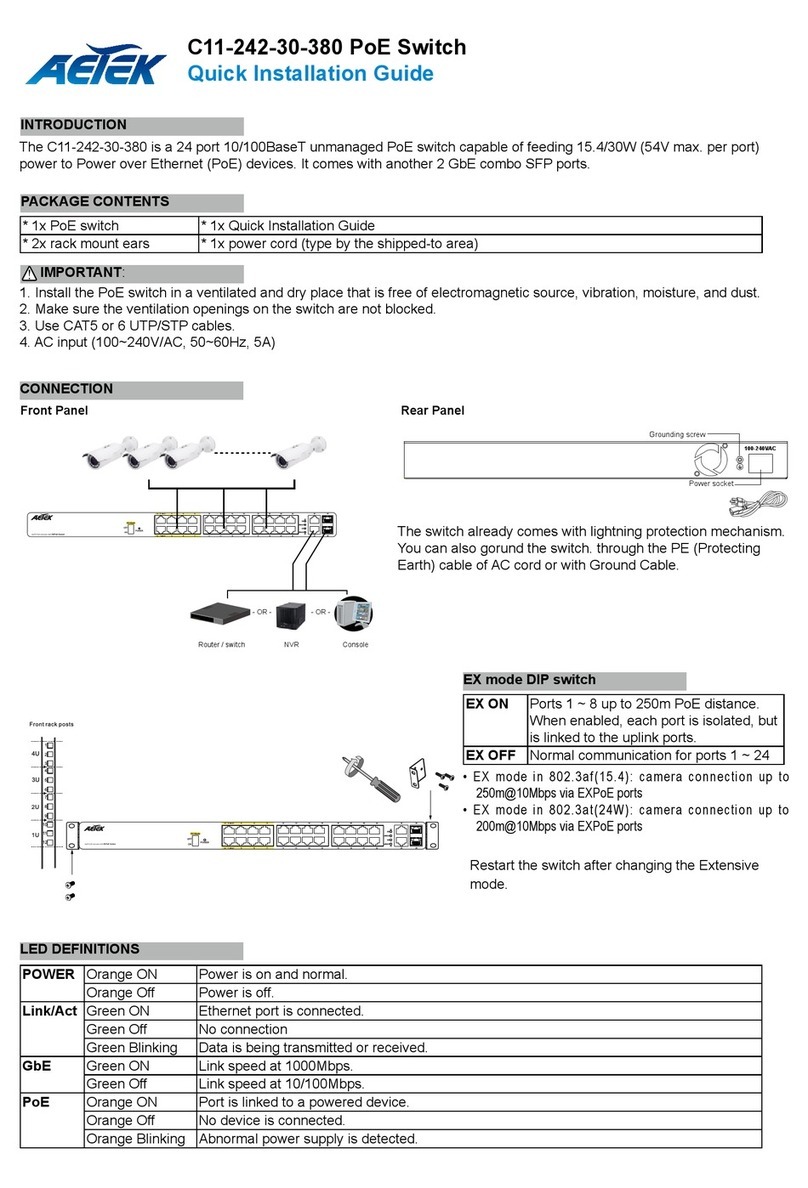

Table of contents

Other SMC Corporation Switch manuals

Popular Switch manuals by other brands

Allen-Bradley

Allen-Bradley 140G-R Series installation instructions

AETEK

AETEK C11-242-30-380 Quick installation guide

SIIG

SIIG 2x1 USB DisplayPort KVM Switch with Remote... Quick installation guide

steute

steute Ex 13 Mounting and wiring instructions

H3C

H3C S3600-28PSI Operation manual

Eusso

Eusso UGS5805-EMC Specifications