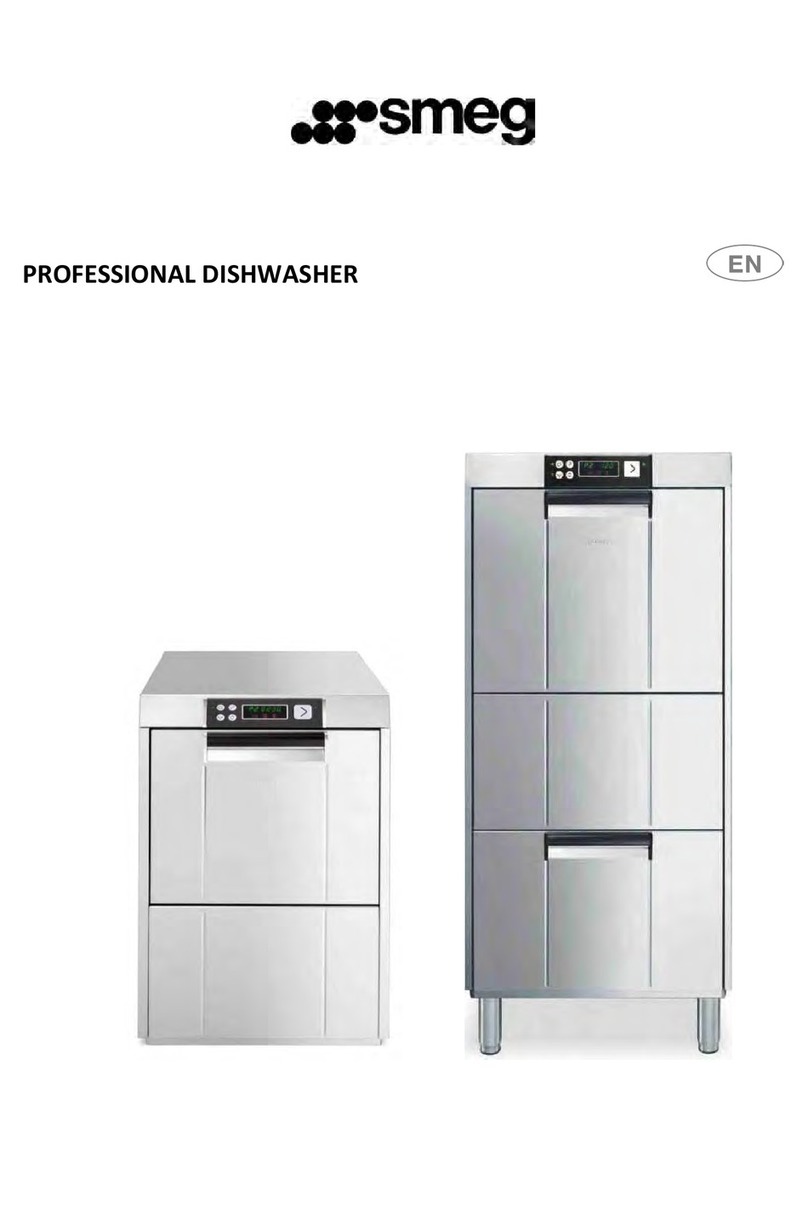

CW/CWH–511MDA

8

3 INSTALLATION AND POSITIONING

BringtheWAREWASHERtotheinstallationsite,removethepackagingandchecktheapplianceand

componentsfordamage;anydamagefoundmustbereportedtothetransporterinwriting.

Thepackagingcomponents(plasticbags,expandedpolystyrene,nails,etc.)mustnotbeleftwithinreach

ofchildrenandpetssincetheyarepotentiallydangerous..Allpackagingmaterialsusedare

environment‐friendly.Theycanbekeptwithoutconstitutinganyhazard,ormaybedisposedofata

specialistwastedisposalcentre.Theplasticcomponentssuitableforrecyclingaremarkedasfollows:PE

polyethylene:externalpackagingfilm,bagcontainingtheinstructions,protectivebags.PP

polypropylene:straps.PSexpandedpolystyrene:cornerguards,topofpackaging.Woodenand

cardboardcomponentscanbedisposedofinaccordancewiththerelevantregulations.Whenthe

productisdecommissioneditmustnotbedumpedintheenvironment;itmustbedisposedofin

accordancewiththerelevantregulations.Allmetalpartsareinstainlesssteelandcanberemoved.The

plasticpartsaremarkedwiththesymbolidentifyingthematerialused.

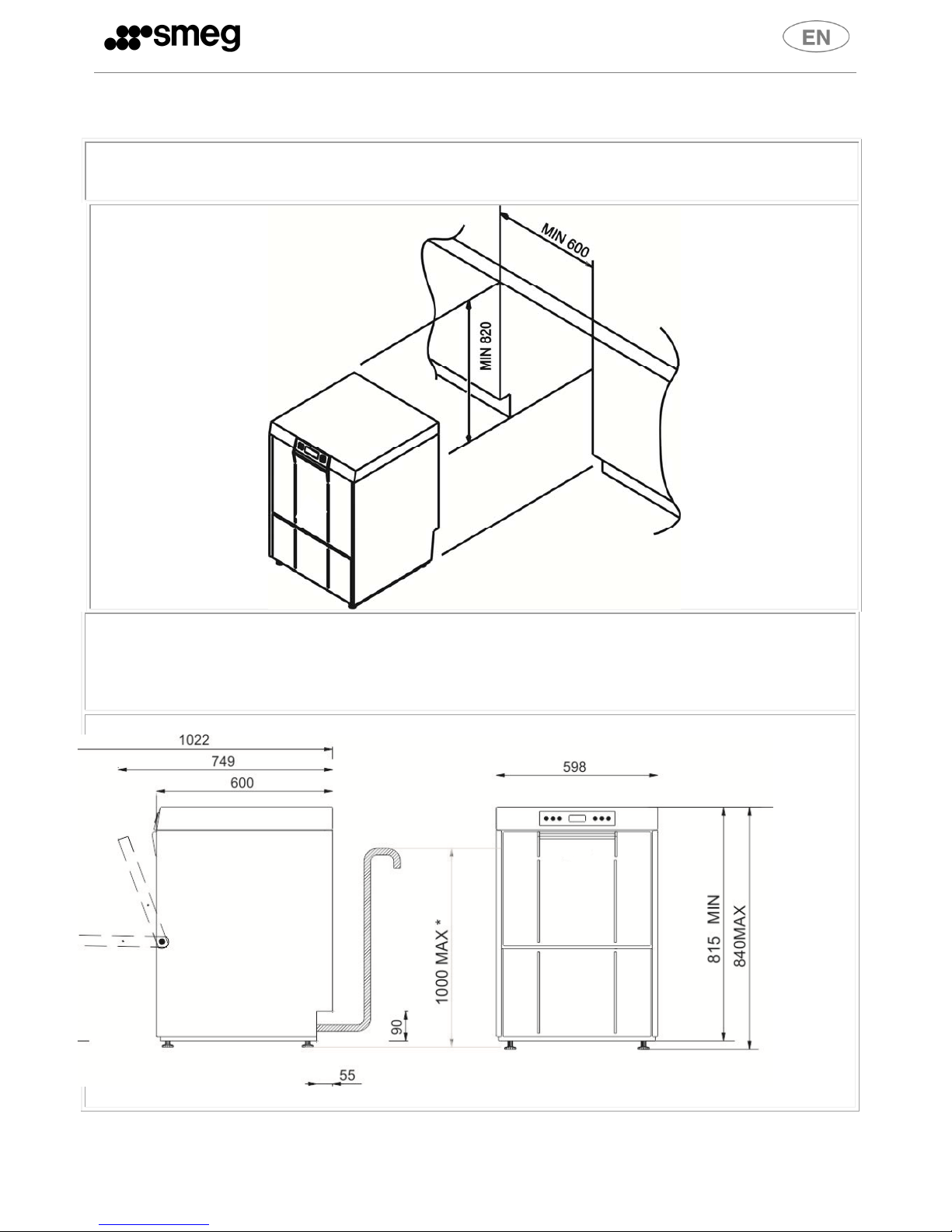

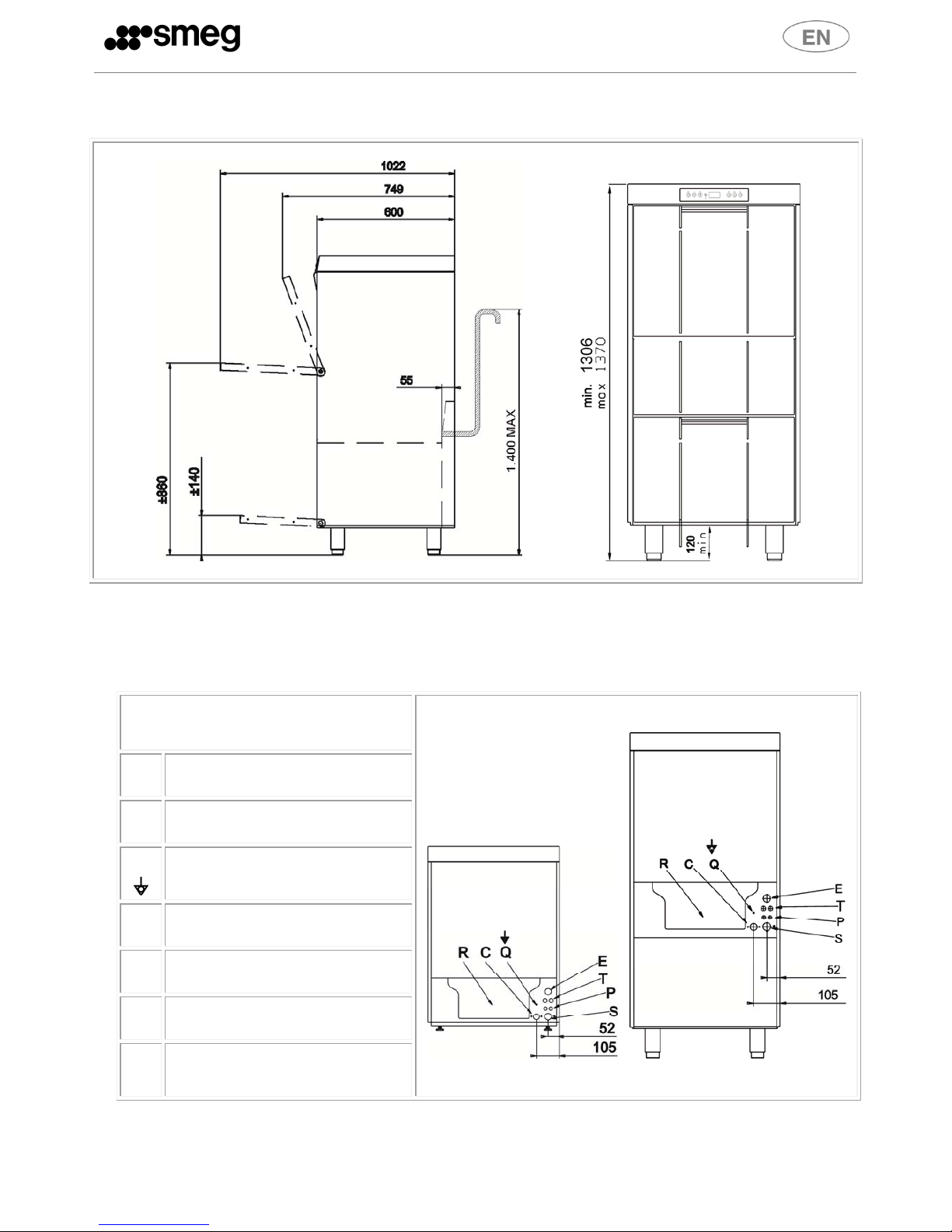

POSITIONING:

4 INSTRUCTIONS FOR TECHNICAL STAFF

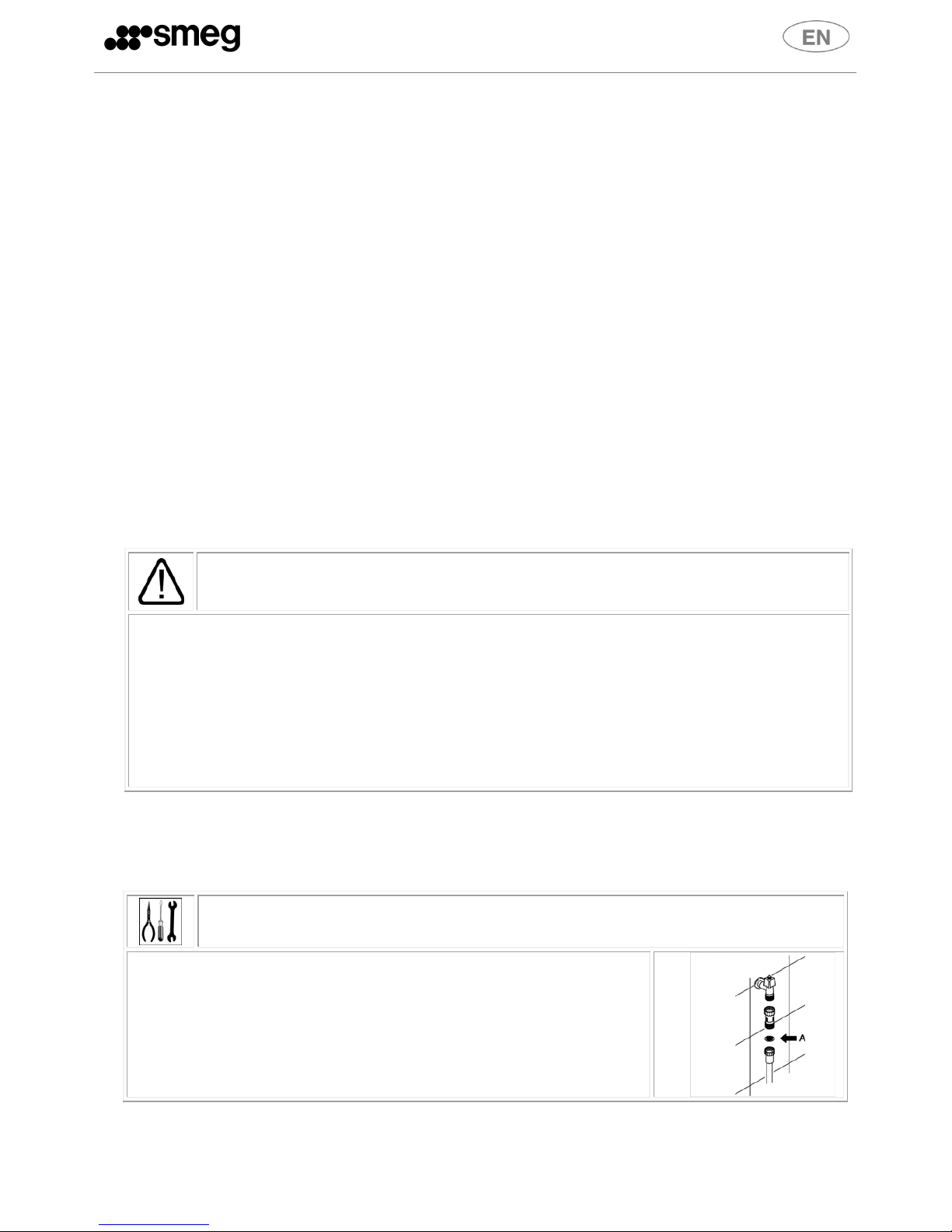

4.1 Plumbingconnection

Watersupplyanddrainconnection

Thewaterpipelinesandelectricitysupplycableleadoutofthebottom

right‐handcorneroftheappliance.Connectthewaterintakehosetoa

connectorwith¾”threadedfitting,fittingthefilterAprovided(in

modelswithacquastop,thefilterandring‐nutformasingleunit).

Theconnectiontothewatermainsmustonlybemadewithnew

hoses;theuseofoldorwornhosesisnotpermitted.

Caution:theindoorsystemandpremisesinwhichequipmentforinstitutionsisinstalled

mustcomplywiththerelevantregulations.

Themanufacturerdeclinesallliabilityfordirectorindirectinjuryordamagederivingfromfailure

tocomplywiththeseregulations.

Beforeinstallation,checkthattherearenoobjectsormaterialsinthevicinitywhichmaybe

damagedbysteamorsplashesofwashingsolution,orthatanysuchitemsaresuitablyprotected.

Placethewarewasherinthechosenpointandremovetheprotectivefilm.

Levelthewarewasher(withtheaidofaspiritlevel)onitsadjustablefeettoensurethatitis

stable;allothermountingsolutionsmustbeapprovedbythemanufacturer.