‐CW510/D/SD

CW510M/MD/MSD

2

CONTENTS

1PRECAUTIONSFORSAFETYANDUSE.............................................................................4

2TECHNICALDATA...........................................................................................................6

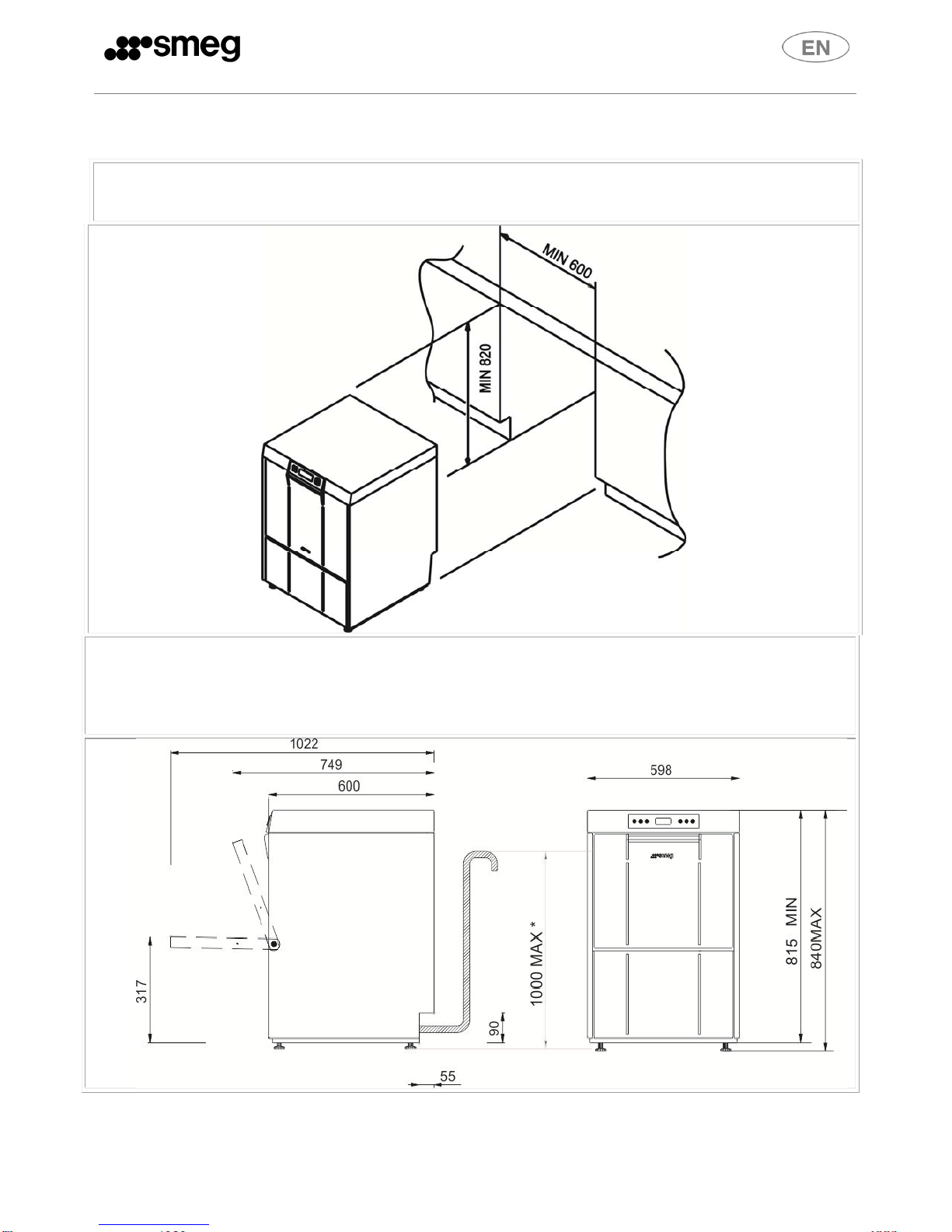

3INSTALLATIONANDPOSITIONING.................................................................................8

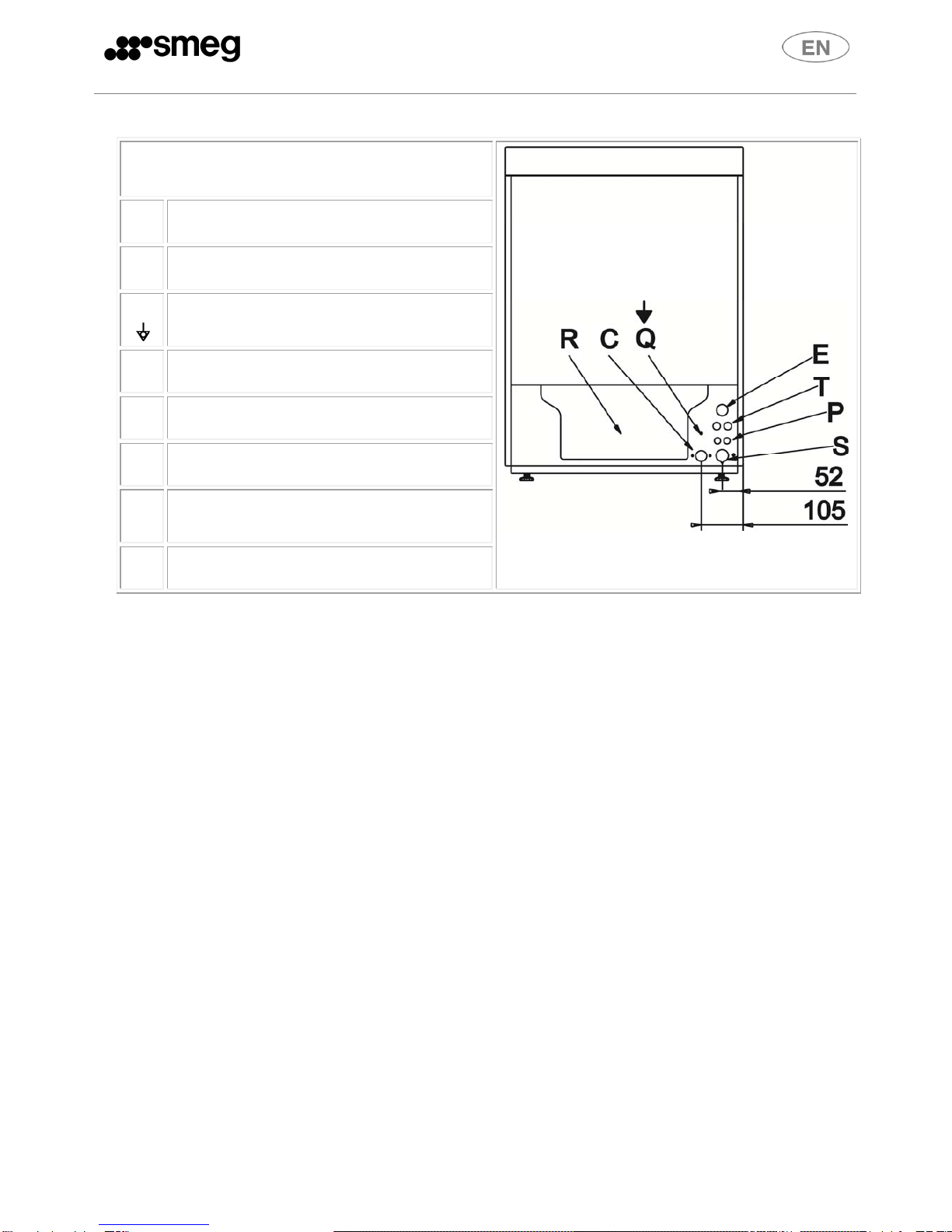

4INSTRUCTIONSFORTECHNICALSTAFF..........................................................................9

4.1Plumbinghookup.....................................................................................................9

4.2Electricalconnection.............................................................................................10

4.3Usingthewatersoftener(onmodelswiththisfeatureonly)...............................14

5SET‐UP.........................................................................................................................16

5.1DisplayContents...................................................................................................16

5.2Noteondisplayoftemperatures..........................................................................16

5.3Parameterprogrammingprocedure.....................................................................16

5.4Modifiableparameters.........................................................................................17

5.5Alarmtriggertimethresholds...............................................................................17

5.6Adjustingdetergentandrinseaiddispensing.......................................................18

5.7Adjustingtheregenerationfrequency(modelswithsofteneronly).....................19

5.8Memorisationprocedure......................................................................................19

5.9Tableofparameters..............................................................................................19

6MALFUNCTIONSSHOWNONTHEDISPLAY(FORTHETECHNICIAN)...........................20

7INSTRUCTIONSFORTHEUSER....................................................................................21

7.1Controlpanel........................................................................................................21

7.2Beforewashing.....................................................................................................22

7.3Firstuseeachday(tankandboilerempty)...........................................................23

7.4Choosingtheprogram..........................................................................................24

7.5Changingtheprogram(notpossibleoncetheprogramhasstarted)...................24

8MAINTENANCEANDCLEANING..................................................................................26

8.1Dailycleaningoffilters..........................................................................................27