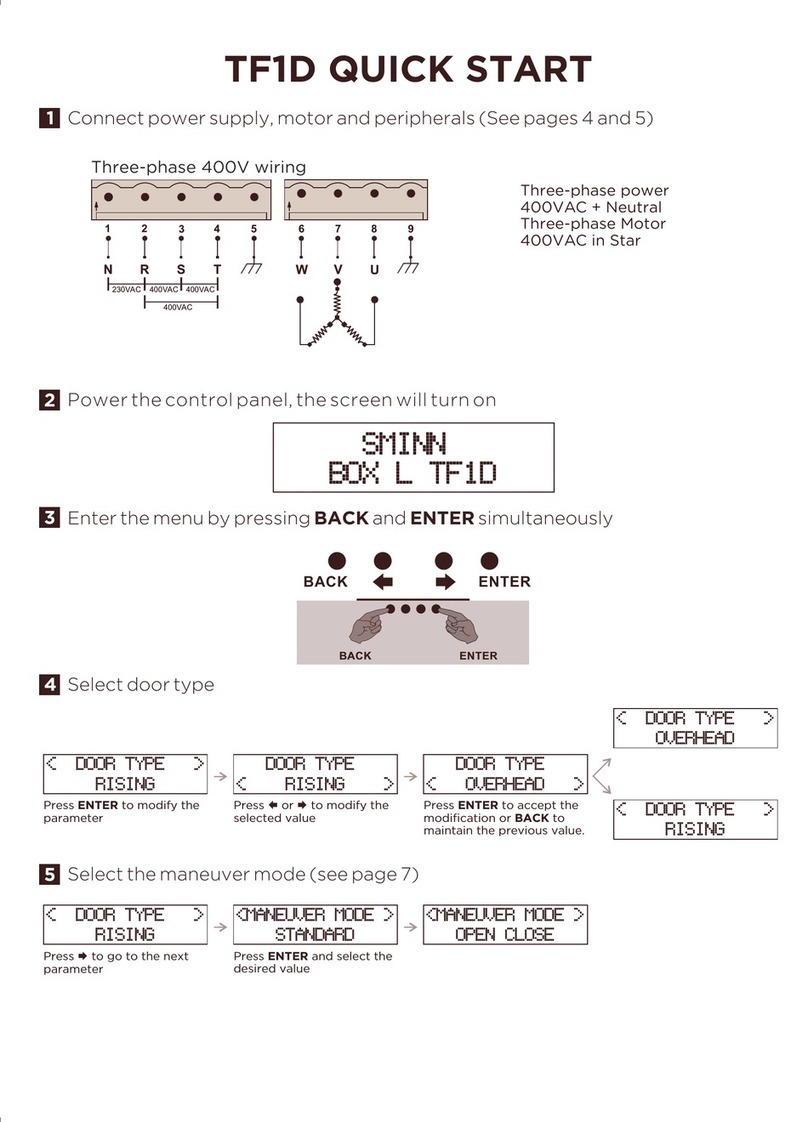

OPERATION

Once the motor controller is installed and congured correctly, it will start the maneuver

every time an operation request is received via radio, by pressing the test button or by

activating the P1 or P2 input.

The motor controller will stop the maneuver when the programmed time finishes or the

external limit switches are detected and will interrupt it when any security is activated.

OPERATING MODES

The motor controller has three maneuver types that are easily selectable via the option

selector (see fig. 1-4):

ŸAutomatic (dual channel)

in this mode the P1 input or the rst or third buttons of a transmitter will start an

opening maneuver. The P2 input or the second or fourth buttons of a transmitter will

start a closing maneuver.

If a maneuver is ongoing any of those inputs will stop the maneuver.

To select this mode set the switch with: DIP1 - OFF

DIP2 - OFF

Ÿ Semiautomatic (Alternating stop)

This mode works the same way the automatic mode does, but it only uses the P1

input or the rst transmitter button.

If a maneuver is ongoing any of those inputs will stop the maneuver.

Once stopped the next activation will invert the maneuver direction.

To select this mode set the switch with: DIP1 - OFF

DIP2 - ON

ŸDead-man in opening and closing

While holding P1 the door will open and while holding P2 the door will close. In this

mode only the security C.SEG and the opening light barrier (if set in BND) that stops

the maneuver are taken into account.

To select this mode set the switch with: DIP1 - ON

DIP2 - ON

ŸDead-man in opening and semiautomatic closing

The P1 input will open the door like in AUTOMATIC mode and while holding P2 the

door will close. In this mode only the security C.SEG and the opening light barrier (if

set in BND) are taken into account.

To select this mode set the switch with: DIP1 - ON

DIP2 - OFF

MANEUVER CONTROL

The board controls the movement of the motor through the P1 and P2 inputs (terminals

10/11) as described in the selected operating mode.

Light barrier (C.SEG)

Normally closed input (NC) between terminals 9 and 12 that stops and inverts the

maneuver when closing.

Opening light barrier (BND)

The BND input (terminals 8, 12) can be congured as a normally closed input for use with

an opening light barrier that stops and inverts the maneuver when opening.

To select this mode set the switch with: DIP3 - ON

Safety edge (BND)

8K2 safety edge input (terminals 8, 12) that stops and inverts the maneuver when closing

and stops and inverts for 2 seconds when opening.

To select this mode set the switch with: DIP3 - OFF

Automatic closing

Even though automatic closing is not normally used on blinds, this controller allows it as a

feature.

To select this mode set the switch with: DIP4 - ON

Peripheral power supply

With this connection, the motor controller supplies power to the external devices, such as

light barriers. This output is protected with a 200mA resettable fuse.

Receiver module

The controller includes an SMINN radio receiver, supporting activation via radio for up to

35 transmitters (see Fig. 1-1)

PROGRAMMING THE MANEUVER TIME

These instructions should be followed to program the maneuver time. The motor

controller must be powered on, the door/rolling shutter closed.

ŸPress and hold the programming button (PROG) for 8 sec. until the RUN/PROG led is

on (See fig. 1-2)

ŸRelease the programming button (PROG).

ŸPress the button of a TRANSMITTER or activate the P1 input to start opening.

ŸWait some seconds until the door is completely open and then press again the

programming button (PROG).

ŸThe relays should switch off; the maneuver time is saved.

ŸIf the motor controller is configured in automatic cycle (DIP 4 = ON, see fig. 1-4) the

RUN/PROG led will blink. After the desired “waiting time” has passed, press again

PROG button.

ŸFinally, a validation beep is heard.

The times of opening, closing and optionally, automatic cycle, have been programmed.

The opening and closing times are the same, and they can vary from 15 seconds up to 2

minutes.

1OFF

ON

1OFF

ON

1OFF

ON

1OFF

ON

1OFF

ON

1OFF

ON

1OFF

ON

ERASE MEMORY

SMINN transmitters’ codes stored in the memory can only be deleted completely erasing

the memory. To do so, follow these steps:

ŸPress and release the PROG button waiting 1 sec. between presses and upon the 5th

press hold the button 8 sec. until the RUN/PROG led powers on.

ŸRelease the PROG button for 2 seconds.

ŸPress and hold again the PROG button. RUN LED will switch off.

ŸWait 8 secs until the RUN LED blinks.

ŸRelease the PROG button. Wait for a validation beep.

This procedure completely erases the system memory and leaves it in a default factory

state.

TRANSMITTER PROGRAMMING

SMINN UNIVERSAL motor controllers can store up to 35 compatible transmitters. PIN

compatibilty must be ensured to register a transmitter.

If this is the first installation, the receiver memory must be customized.

Customizing the receiver

ŸPower the board and wait for 5 seconds.

ŸPress and hold the transmitter's 1st and 2nd buttons at the same time (5 sec.) until its

led switches on.

ŸRelease the buttons (the led remains on).

ŸEnsure you are close to the receiver to guarantee communication (2 to 10m).

ŸPress and hold the PROG button of the motor controller

ŸPress and hold the transmitter's 1st button (customization)

ŸWait for the valid registration beep.

ŸRelease the transmitter's button. Release the PROG button.

MANUAL PROGRAMMING

Follow these steps to register transmitters manually :

ŸTurn on the motor controller and wait for 5 seconds.

ŸPress and hold the programming button (PROG).

ŸPress and hold the button of the transmitter’s channel that you want to register.

ŸCheck that the PROG led is blinking (SCAN mode).

ŸWait for the valid registration beep.

ŸRelease the transmitter's button.

ŸRelease the PROG button.

Repeat the process for as many transmitters as you want to register. If you try to register

more than 35 transmitters, the receiver will answer with a long beep, indicating that the

memory is already full.

The first registered transmitter will indicate the operation channel of the motor controller;

the rest of transmitters will be registered using the same channel as the first one.

RADIO PROGRAMMING

Only a registered transmitter can invite or grant self-registration capabilities to other

SMINN transmitters with the same PIN.

Registration by invitation.

ŸPress and hold the already registered transmitter's 1st and 2nd buttons (MASTER

transmitter).

ŸPress and hold the new transmitter's 1st and 2nd buttons (must have the same PIN).

ŸWait for 5 seconds until the led is on in both transmitters.

ŸRelease both transmitter's 1st and 2nd buttons (the leds remain on).

ŸTake the Master transmitter's led near the new transmitter's SYNC area.

ŸPress and hold the Master transmitter's 1st button.

ŸWait until the new transmitter's led blinks 5 times.

ŸRelease the Master's button.

ŸEnsure you are close to the receiver to guarantee communication (2 to 10m).

ŸPress and hold the new transmitter's button that corresponds to the channel that

you want to register.

ŸWait for the valid registration beep.

ŸRelease the button of the new transmitter.

CODE REPLACEMENT DUE TO LOSS

This function allows the replacement of a transmitter code stored in the motor controller

with a new one, be it due to loss or mislaying.

The replacement of a transmitter code is only possible with a SMINN programming

console. Knowing the PIN of the installation and the code number of the lost transmitter is

required.

8K2 SAFETY EDGE

COMMON

DOWN

UP

TX RX

KEY SWITCH

(OPTIONAL)

LIGHT BARRIER

M

R8K2

MOTOR

230V AC