Smith Manufacturing X3 User manual

X3 Hydraulic

Heavy duty triple head remover

User Manual

(954) 941-9744

www.SMITHMFG.com

MANUFACTURING

Cutters / Removers / Parts / Support

1-800-653-9311

www.SmithMfg.com

Phone: 954-941-9744 • Fax: 954-545-0348

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

INTRODUCTION

2

Congratulations on purchasing the

X3™from SMITH Mfg. Company.

Page Contents

2 Index / Introduction

3 Safety Guidelines

4 Your X3 Heavy Duty Remover

5 Controls Descriptions / Attaching to Skid Loader

6 Safety Guidelines

7 Substrate Removal

8 Storage, Ordering, and Warranty Claims

9 Troubleshooting

10 Maintenance Check List

11-12 Cutter Head Installation and removal

13 Depth and Width of Cut

14-15 Belt Removal

16-17 Bearing Replacement

18-19 Maintenance Log

20 Limited Equipment Warranty

21 Warranty Activation

INDEX

The X3™ (patent pending) is an triple head

Eraser that attaches to most skid loader,

tractor or truck body for removing striping, curing

compounds, and more while leaving the road in

a natural condition. Powered by gas, diesel, or

hydraulics, the X3™ allows a single operator to

remove from 8” - 20” wide (when engaging the

swivel attachment with outboard wheel

assembly). The X3™ is a versatile, full-featured

eraser that grows as your needs grow, with

additional units: inline for faster removal, or

offset for wider removal. Designed to remove with

a unique swivel wheel sweeping removal method

pattern, the X3™ feathers the substrate edges to

eliminate the grooving pattern or "ghost line".

Select your style of removal tool: from our

gentle action set of 3 steel pin cutters, to our

aggressive, 72 pin tungsten carbide, or our 144 pin

carbide gentle abrading and NEW, 216 pin

tungsten carbide pin cutter for concrete.

Diamond Cup Wheel, Wire Brushes, or

Tungsten Carbide Mini-Pick Heads are

available for your other surface preparation and

line removal needs..

You will obtain years of satisfying service when

your machine is properly used and maintained.

Please read completely this guide and parts list

manual to assure your REMOVAL SUCCESS.

If you have any questions about the operation of

your machine or would like to order replacement

parts, please contact your SMITH Dealer directly,

or call SMITH at 1-800-653-9311 or

(954) 941-9744 for the name of your local dealer.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

3

UNCRATING EQUIPMENT

When you uncrate your equipment, make certain

that the machine has not been damaged and that

all fasteners and guards are properly tightened.

Battery, oil, and fuel (if non-hydraulic) were not

included in shipment. No hose ttings were

included on hydraulic models. Please note that

some assembly of your X3™ may be required

before use to include the bobtach plates. .

Your machine may not have been shipped

assembled with cutters and other accessories.

Assembly may be required.

BEFORE START-UP,

READ THIS..

REMEMBER: Only authorized, experienced and

properly trained personnel should operate this

equipment. Operating personnel should

practice safety at all times and ear protective

gear (gloves, goggles, safety vests, ear plugs,

steel-toe shoes, etc.)

Please read all operating instructions, and be

completely familiar with your equipment before

operating. When in doubt, please contact SMITH

Manufacturing Customer Service for operational

details. This Owner’s Manual will guide you

through the removal process, from start to

nish, and show you how to care for your

machine. Hydraulic Systems must have

adequate pressure and volume to operate

correctly.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

YOUR X3TM HEAVY DUTY REMOVER

Please take time to familiarize yourself with the X3™’s

controls, as well as some of the features of your new machine.

Read the engine manual before preparing the engine for starting.

4

C

E

G

H

H

I

J

K

L

M)

D

B

A

F

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

CONTROLS DESCRIPTIONS

5

• A) TANK RETURN LINE - Female quick

connect

• B) SUPPLY LINE - Male quick connect

• C) BOBTACH PLATE - Attachment to skid

steer. Machine may be located anywhere

along bar. Loosen clamp bolts (2) to adjust

the unit side to side.

• D) DIAGNOSTIC PORT - Contains 3

pressure indicating ports for diagnostic

purposes

• E) CUTTER SPEED CONTROL - Do NOT

exceed MAX of 2200 RPM.

• F) YOKE - Should be perpendicular to the

ground during operation.

• G) TACH/HOUR METER - Check before and

during operation to make sure safe running

speeds are being maintained.

• H) CUTTER HEIGHT CONTROL - 1 of 3,

adjust together.

• I) BOBTACH FIELD LEGS - Support

machine when not attached to skid steer.

May be located anywhere along bar. Loosen

clamp bolts (4) to adjust the legs side to side.

• J) SIDE MOUNT LOCATION - Wheels may

be mounted on the sides to avoid build up

from debris.

• K) DEBRIS SKIRT - Protects from ying

debris.

• L) YOKE SPRING - Check skid steer down

pressure here.

• M) TENSIONING SCREWS - Located under

the plate, adjust belt tension here.

ATTACHING TO SKID

LOADER

1. Complete pre-operational check and

complete and return warranty card.

2. Conrm skid-loader has proper mounting

brackets to t the supplied Bobtach plate. If

not, obtain for your local ski loader supplier and

replace plate on supplied with your X3 with the

plate for your skid loader.

3. If you are going to front mount to a truck,

contact SMITH for mounting instructions. The

unit can also be mounted ot the side of your

equipment as well.

4. Check the levelness of the 4 sets of caster

wheels and the bobtach assembly. Add spacers

to align, if required.

5. Make certain the machine is off the ground

and/or cutters are off the ground before start-up.

6. Get familiar with the drive system, how to

maintain and replace the drive belt and cutters.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

6

SAFETY GUIDELINES

• Never start the machine with cutters in down

position.

• Never operate machine without Rubber Skirt.

• Never operate machine without Belt Cover.

• ·· Do not operate in an explosive atmosphere,

near combustible materials or where gas fumes

may not be properly dispersed.

• Never leave the machine running unattended.

SAFETY GUIDELINES

The X3 requires a hydraulic supply

source capable of 3000 psi and delivering a

MINIMUM of 28 gpm.

Cutters should never exceed 2200 RPM

• Always wear safety glasses, steel toed shoes,

work gloves, earplugs, respirator.

• Always check to be sure all fasteners and

cutter assemblies are locked tight.

• Keep hands and feet clear of Cutter Assembly.

• Make certain the two Weights are fastened

securely before operation.

• Repair any fuel leaks immediately (Hydraulic

and Gas Models)

• Never operate machine with the unit off the

ground in an unsafe position.

• Never let anyone near Cutting Assembly

during operation. Under no circumstances may this machine be

modied from its original design without the

permission of the manufacturer in writing.

Non-authorized modications can lead to serious

injury or death.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

7

SUBSTRATE REMOVAL 6 STEPS FOR LONGER

CUTTER LIFE

1) Protect the bearings with clean, oiled felt

Seals*.

2) Do not pinch felt seals when installing

cutters*.

3) Replace bearings and felt seals when worn*.

4) Change rubber bushings on engine plate

and spindle assembly after 50 hours use.

5) Never drop cam lever during grinding

operations.

Lower cutters gently onto road surface.

6) Purchase a second spindle mount with

removal tools outtted and rotate out daily.

*Pin cutter only

BEGINNING REMOVAL OPERATION: Move

your skid loader (vehicle) in the direction

of removal before lowering the unit on the

ground. It is recommended that to avoid

damage to the cutters, that they be lowered

gently to the road surface while moving

forward/backwards. This will insure that you

will achieve best nish (eliminate “crop-circle”

appearance) and not damage the cutters.

IMPORTANT NOTE ON REMOVAL DEPTH:

It is also recommended that the cutters be

lowered to contact the road surface just

enough to compete the removal process.

Excess downpressure creates excess wear

on all the moving parts. The unit weighs

approximately 600 Lbs. This should be

sufcient weight to hold the cutter heads

against the work surface. Should the desired

results not meet your expectations, consider

resetting the engine speed (RPM’s) to the

correct speed or reducing forward motion

speed to an acceptable level.

ENDING REMOVAL OPERATION: Raise

the unit above ground prior to stopping. The

X3 “hard-stops” so make certain everyone is

clear when shutting down.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

STORAGE

Store machine upright in a cool, dry, and

well-ventilated area. Make sure not to

damage the hydraulic connections which

could allow air or water into the system.

ORDERING

To ensure product safety and reliability,

and to maintain your warranty, always use

genuine replacement cutters and partsfrom

SMITH when making repairs to equipment.

When oredering please specify the model and

serial number of the machine. In addition, give

a part number, description, and quantity as

listed on your parts list.

If you have any questions about the operation

of your machine or would like to order

replacement parts, contact your SMITH

Manufacturing representative directly.

Contact 1-800-653-9311 (954-941-9744)

for information.

Visit our website at

www.smithmfg.com

WARRANTY CLAIMS

The manufacturer reserves the right to

change or improve the machine design with-

out assuming any obligation to update any

products previously manufactured before

this manual. It is the customer’s responibility

to complete the warranty card and mail it to

the seller within 10 days from date of pur-

chase. If a failure occurs during the warranty

period, the customer must contact the seller

to determine the appropriate action.

Any and all transportation charges are to

be borne by the purchaser.

8

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

TROUBLESHOOTING

PROBLEM

Possible Reason(s)/Solution(s)

CUTTERS WEARING

UNEVENLY/PREMATURELY

Cutter head is too low

Material Build-up

Bearings may be worn

Wrong cutters for

application

CUTTERS SHAFT BREAKAGE

UNEVENLY/PREMATURELY

Cutter head is too low

End plates or bushings worn

Over 40 hours service-life

EXCESS VIBRATION

Bearing worn

Cutter head contacting ground

Wheels worn out

MACHINE JUMPS

ERRATICALLY

Cutter head is hitting ground

RPM is too low

Surface is severely uneven

DRIVE BELT WEARING

PREMATURELY

Pulley is misaligned

Wrong belt

*Motor repair and warranty issues

are handled directly

by your local engine service center.

For any other problems or questions,

please contact your local representative

or

SMITH Mfg today at 800-653-9311

or

(954) 941-9744.

9

Cutter head is hitting ground

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MAINTENANCE CHECK LIST

• Keep a coating of grease on the drive shaft

and threads for easy installation or removal,

and for longer hex bushing life.

• Check all fasteners and re-tighten, since the

machine will vibrate the fasteners loose if they

are not secured. Use locktight.

• Check the Drive belt for wear, and adjust

(tension), or replace as required.

After replacing belts, check for proper tension:

• Adjust Idler to tension belt. Do not over

tighten.

• Check that the pulleys are aligned properly

to ensure the belts are running true.

10

• The inside housing must be clean, and

remove any build-up from inside the cage so

cutters and drum rotate freely.

MAINTENANCE SCHEDULE

DAILY

Oil felt seals

Clean dirt from equipment

WEEKLY

Clean caster wheels

Grease slide bar

Inspect guards

EVERY 16 HRS OF OPERATION

Check cutter bearings

Check drive bearings

Check rubber bushings

EVERY 50 HRS OF OPERATION

Check springs

Check meters

Order spare parts

Before beginning servicing on any

X3 unit, DISCONNECT FROM

HYDRAULIC SUPPLY SOURCE

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

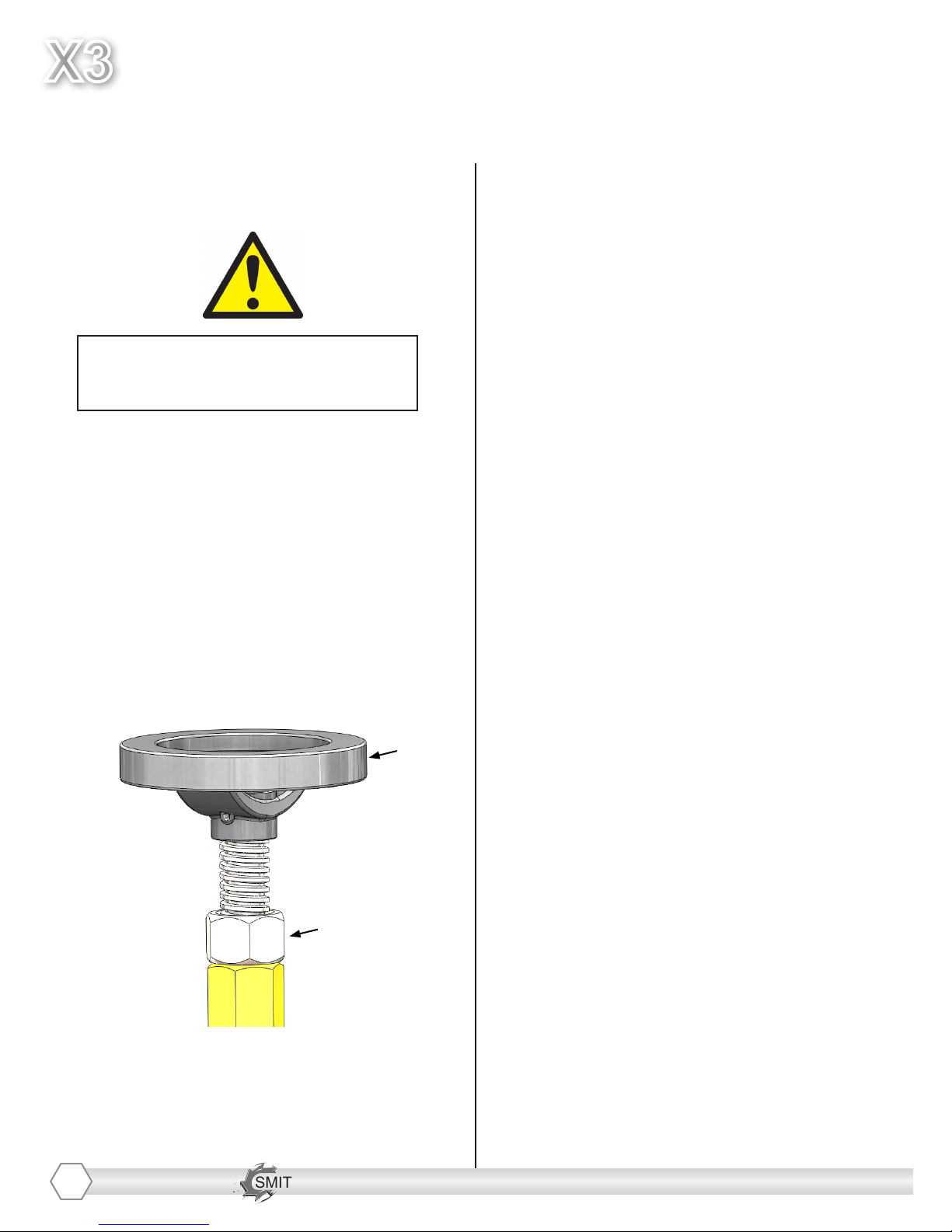

REMOVING

CUTTER HEADS

The X3 (patent pending) machine utilizes

multiple (maximum of 3) rotary heads to

increase forward speed or width in removal

of trafc lines or surface preparation. Re-

gardless of the type head chosen, correct

head installation and adjustment will ease

removal and ensure long cutter life.

Excess pressure increases wear on the

removal heads, belt and bearing,

and yields short life cycles.

Before beginning servicing on any

X3 unit, DISCONNECT FROM

HYDRAULIC SUPPLY SOURCE

1. Raise the X3 to a height where the cutters

are easily accessible.

2. Use a wooden block or something similar

to lock down the rotation to one of the cutter

heads (this will lock down rotation to all).

3. Use an impact gun with a 24mm socket to

remove the three hex head bolts from one

head and slide cutter head downward, off of

shaft. Repeat for remaining cutter heads.

4. It is recommended that the rubber

bushings that cushion the backplate and

hub connector to the hub heads be replaced

everytime the cutter head is removed.

*TIP: SMITH recommends owning

an extra drum loaded with cutter for

rapid job-sight

11

3)

Rubber Bushings

CAUTION: DO NOT DROP CUTTERS ON

SURFACE, DOING SO WILL POSSIBLY

DAMAGE PINS, BEARING AND BODY!

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

12

INSTALLING

CUTTER HEADS

1. Install the number of heads desired (from

one to three) on the spindles using either a

24mm socket or wrench. It is recommended

to use an impact gun if available.

2. Adjust the cutter heads by loosening the

jam nuts on the Acme elevation screws

located on both ends of the machine.

3. Turn the elevation knobs up about two

turns to ensure the Cutter heads do not hit.

Before beginning servicing on any

X3 unit, DISCONNECT FROM

HYDRAULIC SUPPLY SOURCE

5. Begin adjusting the heads downward and

using a piece of thick paper, adjust until the

heads are touching the paper evenly on all

sides.

6. Next you may lower the unit about 1 line

on the knobs so that the cutters touch by

a slight amount. Be sure to lower all cutter

heads evenly.

7. AT THIS POINT RECONNECT THE

SPARKPLUGS BEFORE CONTINUING.

8. Raise the X3™ off the ground slightly (½”

or so) to ensure the cutters do not put

grooves in the road surface when starting

the engine. Allow the engine to warm

up for a minute or two and then set to the

correct RPM for the cutters you have

installed (Rotary cutters = 2000-2200 RPM

(engine)). Incorrect setting of RPM will

damage cutters or drive belt so be sure it is

correct before proceeding.

9. After sufcient warm up time, begin

forward motion and lower the X3™ at the

same time. Remember: if you stop the

forward motion, the unit should be raised

again to prevent road surface damage. If

you cannot elevate the unit initially to start

the engine, you may put a couple of pieces

of ¼” plywood or some other suitable shim

under the wheels to raise the cutters off the

ground. This way the unit can be started

above the surface, then rolled off the wood

to begin erasing the line.

2)

4. For the initial installment, fold the rubber

skirt upwards and tape it to the frame. This

will allow you to view the cutters when

initially setting the height.

3)

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

SETTING DEPTH OF CUT

Lower cutters in a downward motion just

enough to do the job. Too much pressure

will wear the cutters out faster and leave a

much more severe cut on the surface.

Ideally, you should add slightly more

pressure to the rear cutters than the front.

This will allow the front cutters to remove

the material and the rear will nish the job.

Observe the tachometer to ensure

speed with cutters in use matches the

recommended speed for best cutter life.

Adjust as required using the speed control

knob.

13

IMPORTANT NOTE

Excess down pressure creates excess wear

on all the moving parts. The unit weighs

approximately 600 Lbs. This should be

sufcient weight to hold the cutter heads

against the work surface. Should the

desired results not meet your expectations,

consider resetting the engine speed (RPM’s)

to the correct speed or reducing forward

motion speed to an acceptable level.

RECOMMENDED SPEEDS

SETTING WIDTH OF CUT

The X3™ allows the unit to be swiveled up

to 30° either left or right to increase the

cutting path width. Move the caster wheel

assembly from inboard to outboard when

removing at wider paths.

1. Loosen the center swivel bolt at the end

of the attachment arm and then loosen the

outer two bolts using two 3/4” sockets or

wrenches. Swivel the unit either right or left

to the desired angle and retighten the bolts.

1)

You may wish to elevate the leading edge

side of the cutters just slightly to increase

erasing capacity.

The hydraulic model X3 best performs at

2000-2200 RPM.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

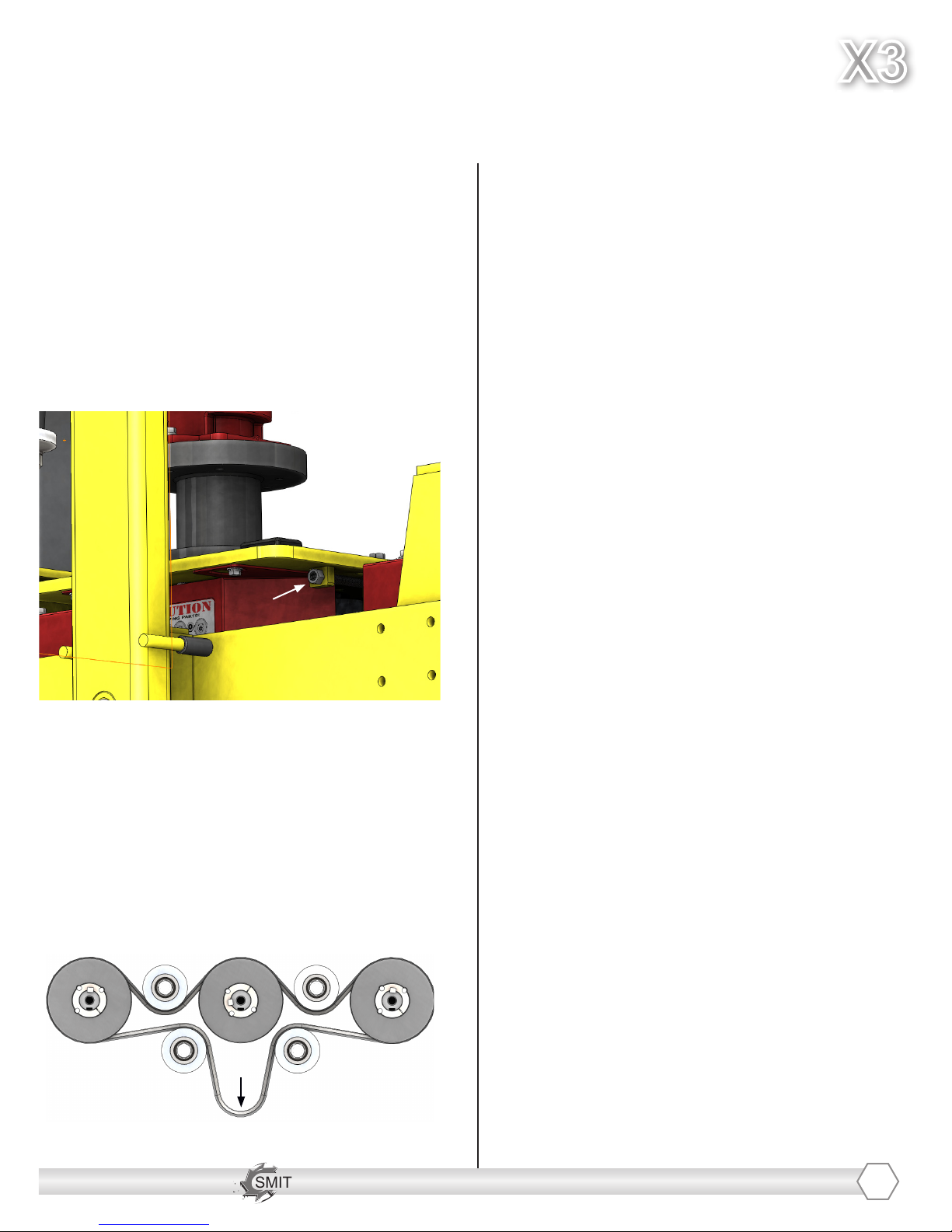

BELT REMOVAL

The X3 is equipped with a PolyChain GT2

drive belt or a multi groove (banded) “V”

belt in a serpentine arrangement. This

allows all three heads to turn in the same

direction to minimize parts inventory of

heads and drive components.

Tools required:

1. 1.5” wrench

2. 7/16” socket or wrench

3. 9/16” socket or wrench

4. 3/16” hex key

14

Before beginning servicing on any

X3 unit, DISCONNECT FROM

HYDRAULIC SUPPLY SOURCE

1. Raise the cutter heads off the ground by

turning the 3 level adjusters all the way up.

Loosen the jam nuts using the 1.5” wrench

and raise the three elevating screws all the

way up. This allows access to the button

head screws holding the upper and lower

covers on.

1)

2. Remove the auxiliary belt cover over

the engine pulley using a 7/16” socket or

wrench.

2)

3. Remove the main belt guards using a

9/16” socket or wrench.

4. Once the beltguards are out of the way,

remove the 4 motor plate screws using a

9/16” socket or wrench.

4) 5)

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

BELT REMOVAL

CONTINUED

5. To loosen the tensnion on the belt,

locate and loosen the two jam nuts on

the adjusting screws for under the motor

mount plate using a 9/16” socket or wrench

and then using a 3/16” hex key back out

the tensioning screws until the drive belt is

completely loose.

7)

8. Lower the motor and belt cover and as

you lower it use the string to pull the belt

over the motor pulley.

9. Using the tension screws begin to

tighten the belt by moving the motor away

from the center of the unit.

10. After the belt has been propely

tightened, reconnect the X3 to the skid

streer and allow it to run for 15 to 20

seconds to allow the belt to set into the

grooves of the pulleys correctly.

It is better to tension the belt tightly

rather than loosely. Loosely tightened belts

will cause the belt to ride out of the pulley

grooves and snap.

11. Reattach all the covers and the unit will

be ready for operation. Periodic tensioning

of the belt will ensure long belt life.Recheck

belt tension again after 30 minutes of use.

15

5)

6. Lift the entire motor mount plate

assembly off and set it aside to allow

access to the drive belt.

7. To install the new belt, remove the old

belt and slide the new one around the three

pulleys and four idlers. Tie a piece of string

around the belt to pull it out towards the

motor pulley at reassembly time.

sing the tension screws begin to

tighten the belt by moving the motor away

from the center of the unit.

10. After the belt has been propely

tightened, reconnect the X3 to the skid

streer and allow it to run for 15 to 20

seconds to allow the belt to set into the

grooves of the pulleys correctly.

It is better to tension the belt tightly

rather than loosely. Loosely tightened belts

will cause the belt to ride out of the pulley

grooves and snap.

11. Reattach all the covers and the unit will

be ready for operation. Periodic tensioning

of the belt will ensure long belt life.Recheck

belt tension again after 30 minutes of use.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

BEARING REPLACEMENT

To remove the drive bearing assemblies

follow the rst procedure to remove the

drive belt. It may needed to completely

remove the motor to have enough working

room. This gives you access to the

bearing assemblies. Note that the

assemblies are matched in sets. The

machine SN and the established length are

stamped on the housing. This insures all

three heads hit the working surface

at the same time.

ORDERING INSTRUCTIONS

MATCH SERIAL NUMBERS

TO ASSURE CORRECT PART!

If ordering a new bearing assemblies,

please be sure you when ordering. identify

the machine serial number. We will send

the correct part and dimension to insure

you machine is tted with a matching

housing.

Tools required:

1. Two 3/4” socket or wrench

2. Flat head screw driver

3. 3/16” hex key

If it has not been done so, follow the

instructions to remove the cutter heads on

pg. 11 before proceding.

1. Follow the instructions on pg. 15 to

remove belt guards, drive belt, and to

remove the hydraulic motor and set it aside

until the machine looks as shown.

16

4. After the collar is removed, use the 3/16”

hex key to remove the two set screws that

are locking down the pulley.

2. At this point there is full access to the

machine drive components to service them

as needed.

3. To service the main bearing housings,

the drive pulleys must be removed. To do

this use a 3/16” hex key to remove the

collar

3)

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

BEARING REPLACEMENT

CONTINUED

4)

5. Use one of the set screws and thread it

into the middle hole to back out the

bushing as shown below.

5)

6. Once the pulley is removed, use a 13/16”

socket and wrench to remove the bearing

housings from the machine.

Bearing housing assembly components

shown below:

6)

17

ASSEMBLY

PN: PM03010000

Bearing housing assembly components

shown below:

On the HYDRAULIC MODEL, the X3 has a

motor mount bearing assembly as shown

below.

ASSEMBLY

PN: X3.00.310A

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MAINTENANCE LOG

18

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 6/2013

X3

Hydraulic

MAINTENANCE LOG

WARRANTY CLAIMS

The manufacturer reserves the right to change or improve the machine design without assuming any

obligation to update any products previously manufactured before this manual. It is the customer’s

responsibility to complete the warranty card and mail it to the seller within 10 days from the date

of purchase. If a failure occurs during the warranty period, the customer must contact the seller

to determine the appropriate action. Any and all transportation charges are to be borne by the

purchaser.

19

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

X3

VERSION 6/2013

Hydraulic

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

Limited Equipment Warranty

All statements, technical information and recommendations contained in SMITH’s literature are based on tests believed to be reliable, but the accuracy

or completeness thereof is not guaranteed and the following is made in lieu of all warranties, expressed or implied. SMITH warrants all equipment or part

referenced in this document which is manufactured by SMITH and bearing its name to be free from defects in material and workmanship on the date of

sale to the original purchaser under normal use and maintenance as herein provided. This warranty does not apply to components manufactured by others

such as, but not limited to, bearings and engines; such components that may or may not have their own warranties.

With the exception of any special, extended, or limited warranty published by SMITH, SMITH will, for a period of three months (90 days) from the

date of sale or up to ve hundred (500) hours of use by buyer, whichever shall occur rst; repair or replace any part of the equipment determined by

SMITH to be defective. This warranty applies only when the equipment or part is installed, operated and maintained in accordance with SMITH’s written

recommendations.

SMITH’s sole obligation for any breach of warranty or breach of contract for defects, deliberate or accidental omissions, shall be limited to repairing,

replacing or allowing credit for, at SMITH’s option, any part which, under normal and proper use and maintenance, proves defective in material or

workmanship within warranty period, provided, however, that notice of any such defect or omission and satisfactory proof thereof is promptly given by

buyer to SMITH, and thereafter, such defective part is returned to SMITH with transportation charges prepaid, and SMITH’s examination proves such part

to have been defective. This warranty does not obligate SMITH to bear any transportation charges or personnel time in connection with the replacement

or repair of defective parts. This warranty does not obligate SMITH to bear any expense for travel time or of personnel in connection with any service calls.

SMITH will not, in any event, be liable to the user for any consequential damages arising out of this sale for the loss of use, lost prots or revenue, interest,

lost goodwill or work stoppage. SMITH shall not be liable for any injury, loss or damage, direct or consequential, arising out of the use or the inability to use

the product or for environmental claims. It being understood that SMITH has no means of controlling the products nal use; therefore, it shall be buyer’s

responsibility to determine suitability of product for intended use and buyer assumes all risks and liabilities whatsoever, in connection therewith. In no event

shall SMITH be liable for consequential or special damages. Used products are sold on an “as is” basis, and there is no implied warranty of merchantability

or of tness for a particular purpose, unless made in writing by an ofcer at SMITH’s ofce.

This warranty does not cover, and SMITH shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation,

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-SMITH component parts.

Nor shall SMITH be liable for malfunction, damage or wear caused by the incompatibility of SMITH equipment with structures, accessories, equipment

or materials not supplied by SMITH, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment

or materials not supplied by SMITH. This warranty does not apply in respect to damages to any product or accessory or attachment thereof caused by

overloading or other misuse, neglect or accident, nor does this warranty apply to any product or accessory or attachment thereof, which has been repaired

or altered in any way which, in the sole judgment of SMITH, affects the performance, stability or general purpose for which it was manufactured. In the

manufacture of buyer’s equipment, parts may be omitted or equivalent functioning equipment and components may be substituted for the original specied

equipment upon the sole judgment and discretion of SMITH.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized SMITH Reseller for verication of the

claimed defect. If the claimed defect is veried, SMITH will repair or replace free of charge any defective parts and return of merchandise back to the

customer freight collect. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable

charge, which charges may include the costs of parts, labor and transportation.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

SMITH’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy (including,

but not limited to, incidental or consequential damages for lost prots, lost sales, injury to person or property, or any other incidental or consequential loss)

shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

SMITH MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY SMITH.

These items sold, but not manufactured by SMITH (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer.

SMITH will provide purchaser with reasonable assistance in making any claim for breach of these warranties. In no event will SMITH be liable for indirect,

incidental, special or consequential damages resulting from SMITH supplying equipment hereunder, or the furnishing, performance, or use of any products

or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of SMITH, or otherwise.

ADDITIONAL WARRANTY COVERAGE - SMITH does provide extended warranty and wear warranty for products.

Corrections - typographical or clerical errors contained herein are subject to correction by SMITH.

Assignment - buyer shall not assign or transfer this warranty without SMITH’s written consent.

Entire agreement and applicable law - the rights and obligations of SMITH and buyer shall be governed by the laws of the state of Florida, U.S.A. In force

on date hereof. The provisions hereof are intended by buyer and SMITH as a nal expression of their agreement, and are intended also, as a complete

and exclusive statement of all terms apply cable to buyer’s order. No waiver, modication, or addition to any of the terms hereof shall be binding on SMITH,

unless made in writing by an ofcer at SMITH’s ofce as stated herein. In the event of conict between buyer’s purchase order and the terms hereof, the

latter shall control. If any provisions herein are to any extent invalid or unenforceable, the remainder of the warranty shall not be effected thereby and shall

be valid and enforceable to the fullest extent permitted by law.

Legal action - buyer shall be responsible for all costs of collection of outstanding indebtedness, including but not limited to attorney’s fees and court costs

to seller. Buyer shall reimburse seller for any and all litigation expenses seller incurs as a result of an unsuccessful buyer claim. The jurisdiction and venue

of the court for any litigation, state or federal, brought by the buyer and/or seller shall be located in venue determined by seller.

Fair labor standards - seller’s products are produced in the United States and in conformity with all applicable provisions of the fair labor standards act of

1938 as amended and any regulations and orders of the United States Department of Labor issued thereunder.

All written and visual data contained in this document reects the most current product information available at the time of this publication. SMITH reserves

the right to make changes at any time without notice.

TO ORDER, contact your SMITH distributor or call 1-800-653-9311 to identify the nearest distributor.

SMITH Manufacturing Co, Inc.

1610 South Dixie Highway

Pompano Beach, FL 33060

www.smithmfg.com

20

Table of contents

Popular Industrial Electrical manuals by other brands

NKT Photonics

NKT Photonics Koheras ADJUSTIK Product guide

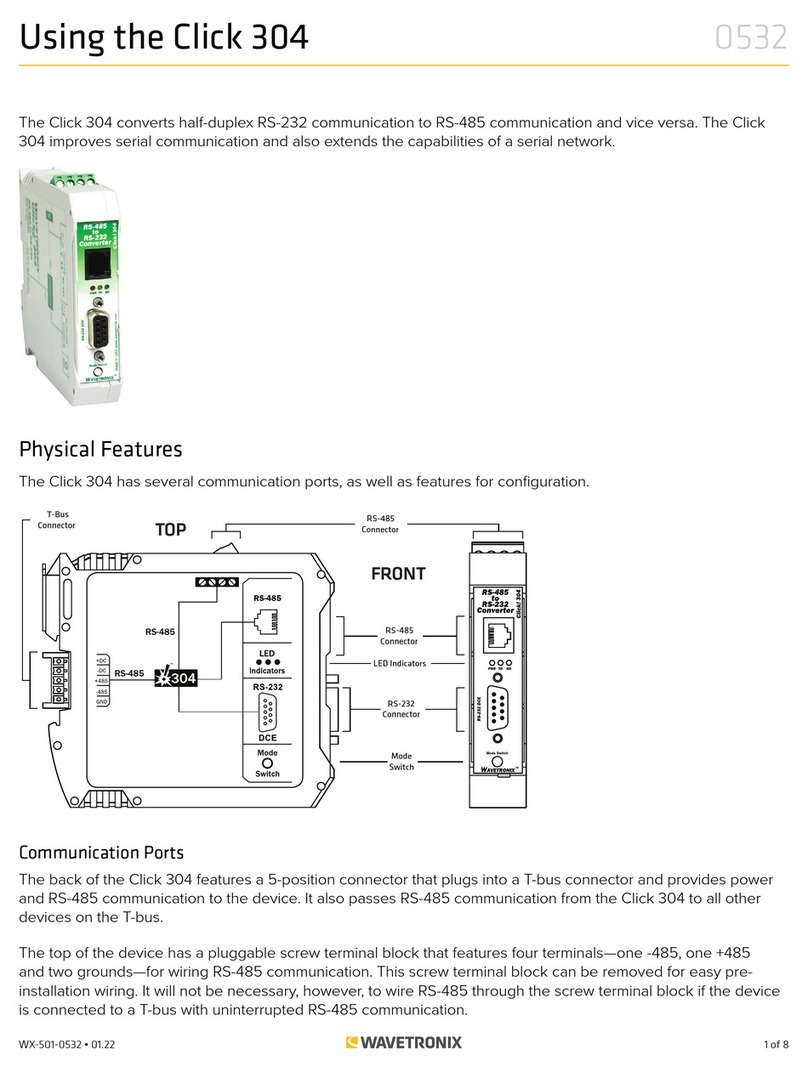

Wavetronix

Wavetronix Click 304 quick start guide

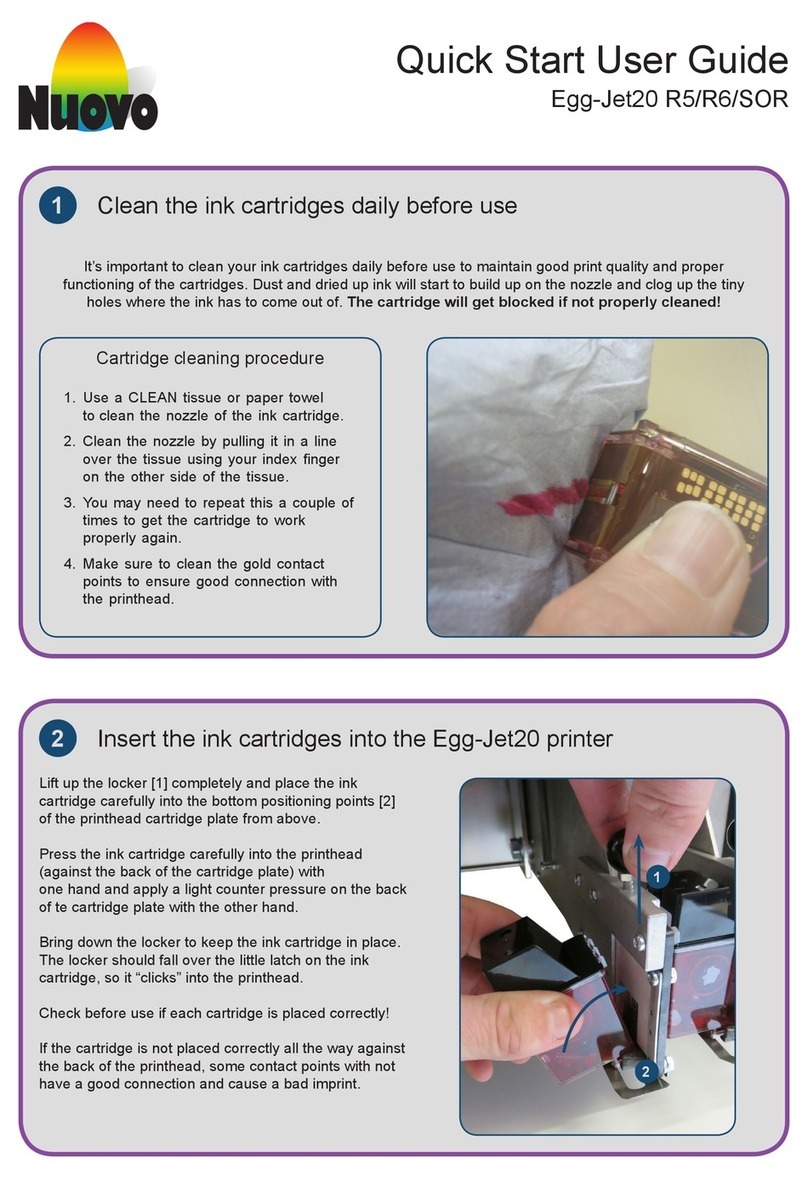

Nuovo

Nuovo Egg-Jet20 R5 Quick start user guide

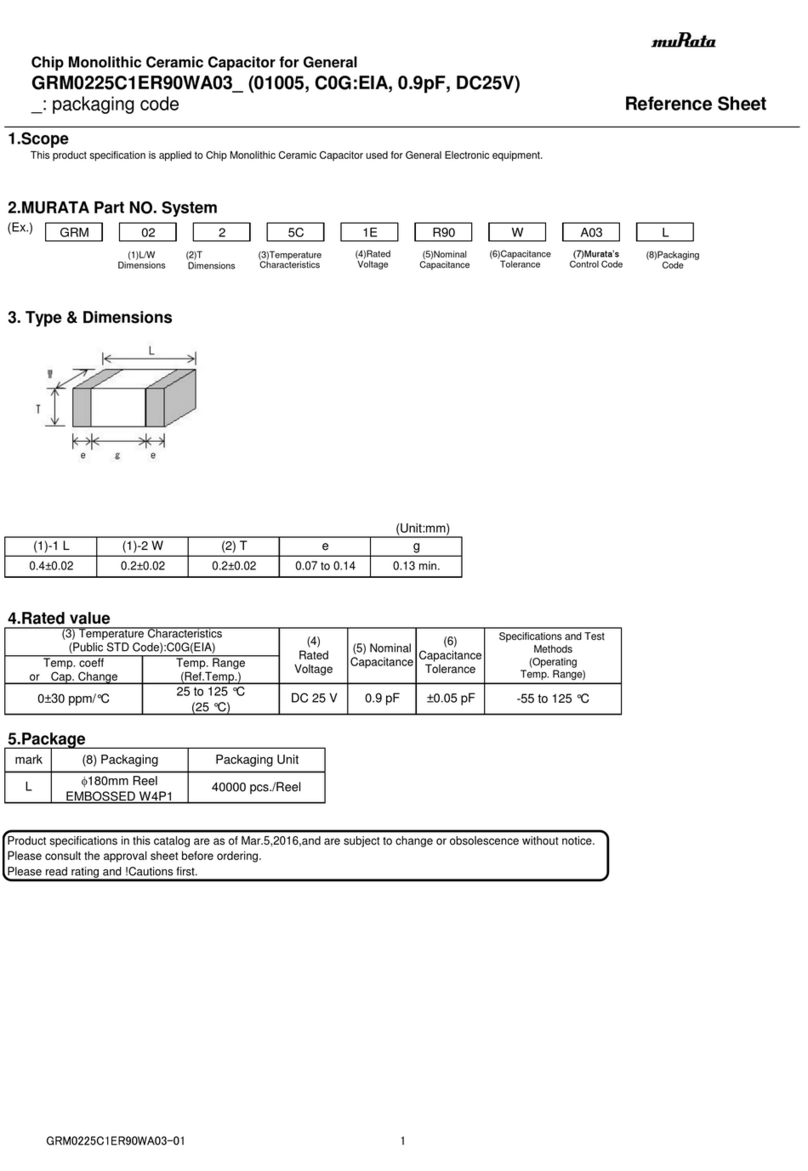

Murata

Murata GRM188R71E332KA01 Series Reference sheet

Murata

Murata GRM0225C1ER90WA03 Series Reference sheet

Murata

Murata GRM033R60J225ME15 Series Reference sheet

Murata

Murata GRM153R60G475ME15 Series Reference sheet

Innovative Advantage

Innovative Advantage AVDS quick guide

Murata

Murata GQM1885C1H680GB01 Series Reference sheet

Minebea Intec

Minebea Intec MP 90/04 installation manual

Geokon

Geokon GK-401 instruction manual

Keysight Technologies

Keysight Technologies N5244AU- 940 Installation note