2 of 8WX-501-0532 • 01.22

The front of the Click 304 features a DB-9 connector and an RJ-11 connector for RS-232 and RS-485

communication. A straight-through cable can be used to connect from the RS-232 DB-9 connector to a computer

so that the device can be configured using Click Supervisor. An RJ-11 cable can be connected from the front of the

Click 304 to the front of the Click 172/174 contact closure cards.

Any data on one port will be transmitted simultaneously on all other ports.

Configuration Features

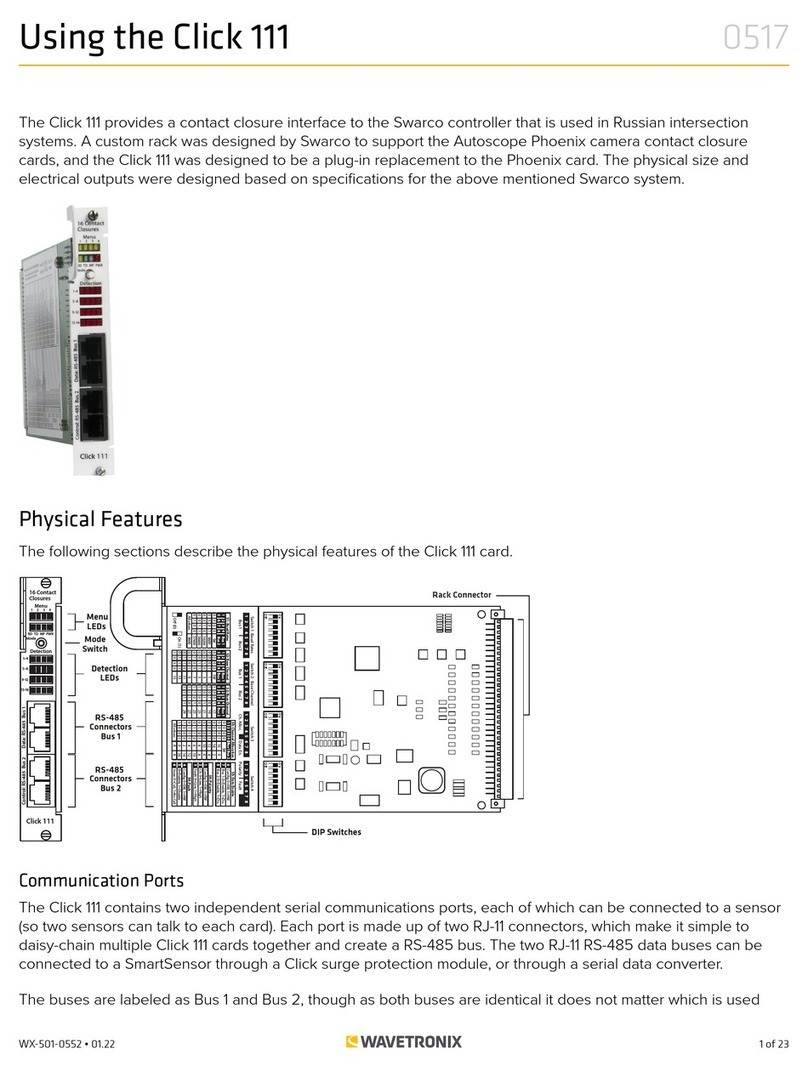

The faceplate of the Click 304 has the following three LEDs:

■ PWR (red) lights up when the device has power.

■ TD (yellow) lights up when the device is transmitting data.

■ RD (green) lights up when the device is receiving data.

The LEDs are also used to indicate operation modes, which will be discussed in the On-device Configuration

section of this document.

The front also has a push-button labeled Mode Switch, which is used to cycle the Click 304 through operation

modes. This will be discussed in the On-device Configuration section of this document.

RS-232 to RS-485 Conversion

To use the Click 304 for

On-device Configuration

The Click 304 can be configured using the push-button on the lower part of the faceplate. Press and hold the

push-button to cycle through the dierent operation modes; release the button when the desired mode is

reached. A quick press and release of the push-button will exit out of any mode and return the unit back to normal

operation. The table below and the following sections describe the dierent operating modes.

Mode LED Definition

Autobaud Green (solid) To autobaud the Click 304, press the push-button, then release when the green LED turns on.

Reset Red (flashing) To reset the Click 304 to factory defaults, press the push-button, then release when the red

LED is blinking.

Autobaud (green solid)

The Autobaud mode is used to match baud rates with an external device. By default, the device will attempt to

match baud rates with a SmartSensor on the bus; however, the device can be configured to autobaud with any

device that supports a serial interface.

While the device is autobauding, the green LED will be on while the red LED blinks. The autobaud was successful

if the red LED stays on and the green LED turns o. If the autobaud is not successful after a few minutes of trying,

the red and green LEDs will stay on indefinitely. In the case of a failed autobaud, push the push-button once to

return the device to its normal state.

Note. On certain devices, the yellow LED may replace the green LED in the autobaud process—that is, the yellow

LED will come on to select the autobaud process, the yellow LED is on during the autobaud process, etc.