Table of contents

1 Introduction......................................................................................................................................... 3

1.1 Read the manual.........................................................................................................................................................3

1.2 This is what instructions look like.............................................................................................................................3

1.3 This is what lists look like...........................................................................................................................................3

1.4 This is what menus and soft keys look like.............................................................................................................3

1.5 This is what safety instructions look like.................................................................................................................3

1.6 Hotline..........................................................................................................................................................................4

2 Safety instructions...............................................................................................................................5

2.1 General notes..............................................................................................................................................................5

2.2 Intended use................................................................................................................................................................5

2.3 Incoming goods inspection.......................................................................................................................................6

2.4 Before operational startup........................................................................................................................................6

2.5 Repairs and maintenance..........................................................................................................................................6

2.5.1 General information ........................................................................................................................................6

3 Specications ...................................................................................................................................... 7

3.1 Equipment supplied................................................................................................................................................... 7

3.2 Technical Data.............................................................................................................................................................8

3.3 Electromagnetic Compatibility (EMC) .....................................................................................................................8

3.4 Dimensions..................................................................................................................................................................9

4 Installation and connection information ............................................................................................ 10

4.1 General information................................................................................................................................................. 10

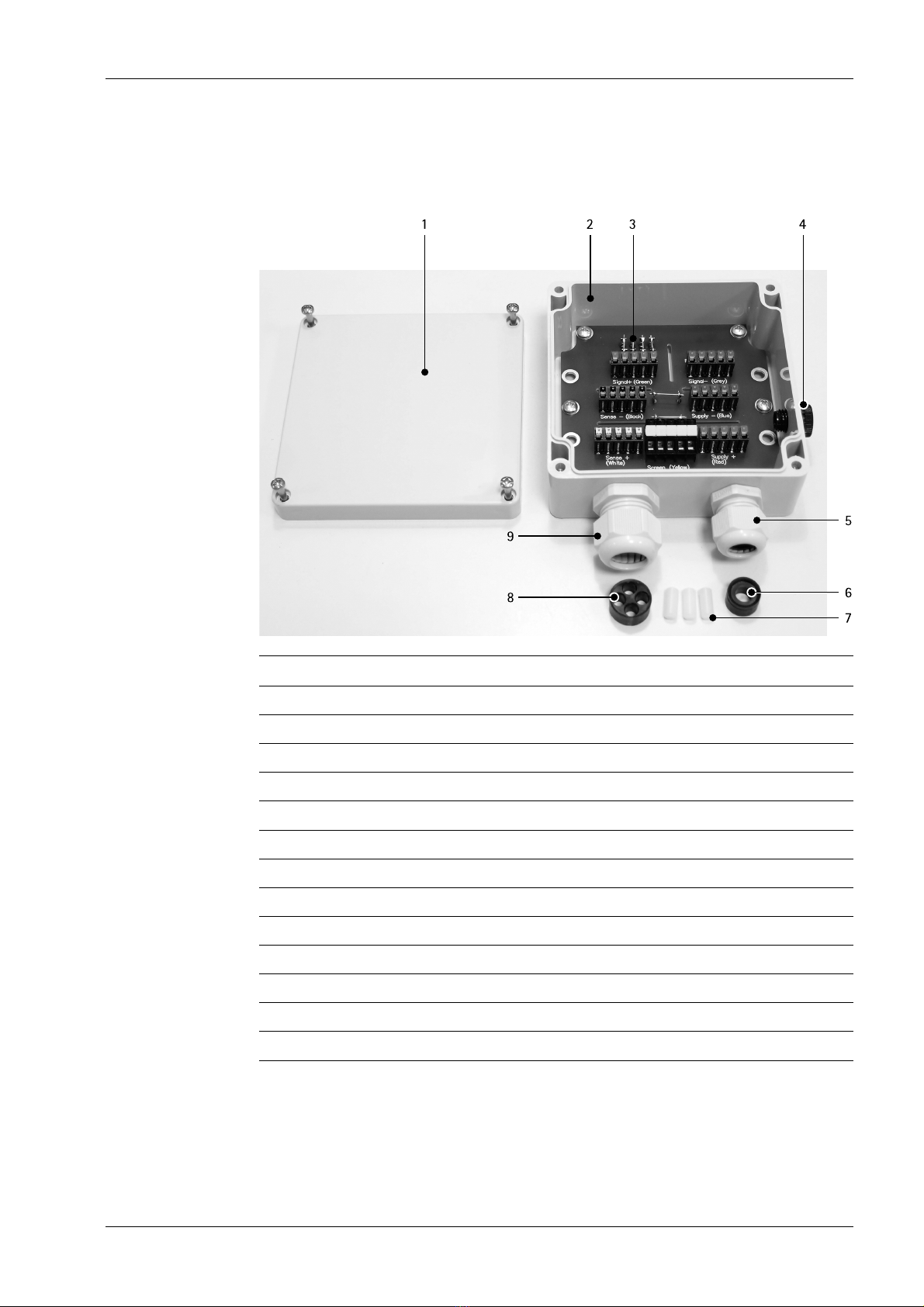

4.2 Terminals and jumpers............................................................................................................................................ 10

4.3 Cable gland................................................................................................................................................................. 11

4.4 Attaching the cable gland ........................................................................................................................................12

4.5 Fitting the reduction sealing ring/4-seal insert....................................................................................................13

5 Cable connections.............................................................................................................................. 14

5.1 General information................................................................................................................................................. 14

5.2 Connecting cables .................................................................................................................................................... 14

5.3 Cable connections .................................................................................................................................................... 14

5.4 Equipotential bonding conductor...........................................................................................................................15

5.5 Electronic corner correction.................................................................................................................................... 16

5.5.1 General information ...................................................................................................................................... 16

5.5.2 Procedure.........................................................................................................................................................17

6 Maintenance/repairs/soldering work/cleaning ................................................................................. 18

6.1 Maintenance.............................................................................................................................................................. 18

6.2 Repairs........................................................................................................................................................................ 18

6.3 Soldering work.......................................................................................................................................................... 18

Cable Junction Box MP 90/04 Table of contents

EN-1 Minebea Intec