Smith Manufacturing FS200 User manual

CUTTERS / REMOVERS / PARTS / SUPPORT

SMITH MANUFACTURING

1-800-653-9311

www.SmithMfg.com

Phone: 954-941-9744 • Fax: 954-545-0348

FS200™/FS209™

Compact Remover

User Guide & Parts List Manual

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

21/2008

FS200/FS209

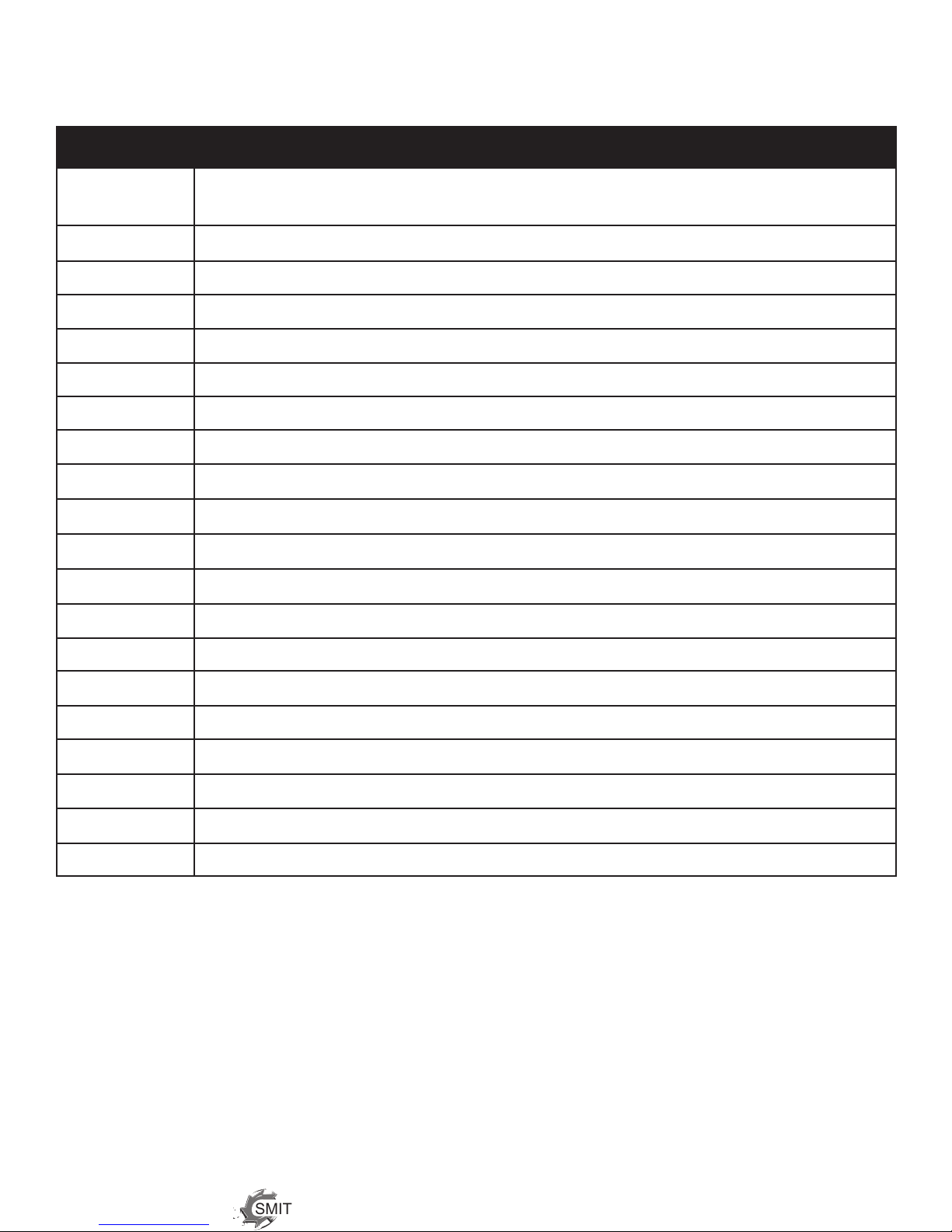

INDEX

Page Contents

2 Index

3 Introduction

4 Safety Guidelines

5 Your FS200 Surface Preparator

6 Cutter Drum Assembly

7 Machine Start-Up

8 Transporting & Substrate Removal

9 Storage & Ordering

10 Troubleshooting

11-12 Parts List

13-14 Optional Electric Motor

15 Drum Assembly

16 Carbide Prep-It™ Strip Drum Assembly

17-18 Cutter Set-Up

19 Recommended Spares List

20-21 Edger Assembly

22 Maintenance Log

23 Limited Equipment Warranty Info

24 Warranty Activation

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 3

FS200/FS209

INTRODUCTION

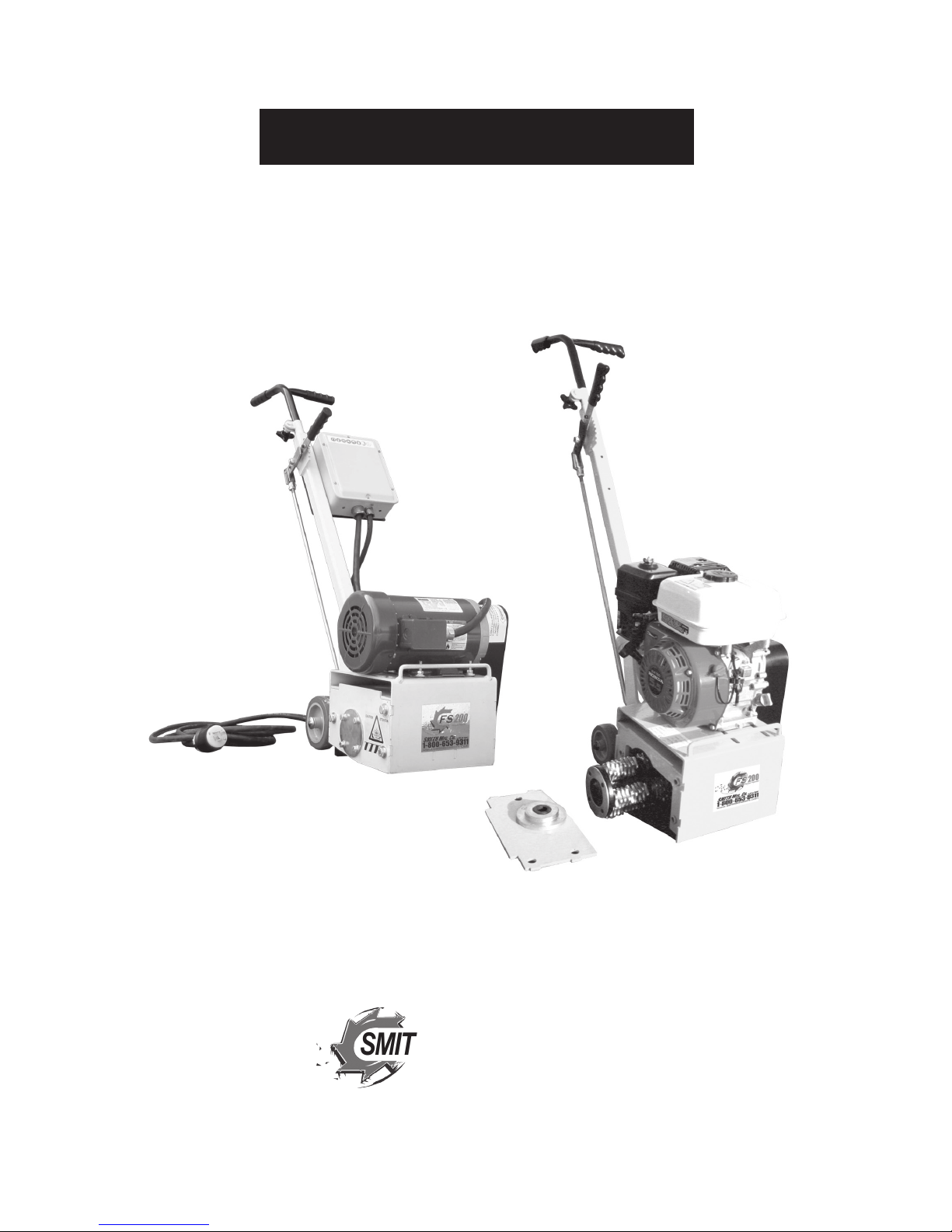

Congratulations on purchasing the FS200™/FS209™ Compact Remover from SMITH Mfg. Company.

The FS200™ uses a 5.5 Honda Engine, while the FS209™ uses a 9 HP Honda Engine.

Your machine will:

•Cleansurfacesimpactedbygrease,oil,plastics,tars,resins,tileadhesives,iceandmore

•Planeormillasphaltandconcretesurfaces

•Removehighspotsincurbsandgutters

•Eliminatetrip-hazardsonconcretesidewalks

•Millareasforrumblestrips

•Cleanoutcracksandjoints

•Createanti-slippatternsinwalkwaysandbarns

•Preparesurfacesfornewcoatingapplications

•Permanentlyremoveallroadandsurfacecoatingstoinclude:

epoxy,urethane,thermoplastic,paint,glue-backedtapesandmore...

•Groove-inlayasphaltforstriping

•Preparesurfacepriorto“HotTape”applications

BEFORE START-UP, READ THIS...

Please read all operating instructions, including the provided engine manual and be completely fa-

miliar with your equipment before operating. When in doubt, please contact SMITH Manufacturing or

your local dealer for operation details.

ThisOwner’sManualwillguideyouthroughtheremovalprocess,fromstarttonish,andshowyou

how to care for your machine.

Remember to activate your warranty - refer to

“Pre-Operation Inspection and Warranty Activation” page

at the end of this manual.

UNCRATING YOUR EQUIPMENT

Whenyouuncrateyourequipment,makecertainthatthemachinehasnotbeendamagedand

that all fasteners and guards are properly tightened.

Your machine may not have been shipped assembled with cutters and other accessories.

Assembly may be required.

Remember:Onlyauthorized,experiencedandproperly

trained personnel should operate this equipment.

Operating personnel should practice safety at all times

and wear protective gear (breathing apparatus, gloves,

goggles, safety vests, ear plugs, steel-toe shoes, etc.)

Model #: Serial #:

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

41/2008

FS200/FS209

SAFETY GUIDELINES

Incorrect use of the surface planer can result in

property damage, personal injury, or death.

Be sure to read and follow all directions and

precautions as outlined in this manual.

Operation •Getacquaintedwiththecontrols(pg.3)

•Alwayswearprotectiveequipment,includingearprotection,breathing

apparatus, steel-toed shoes, and goggles.

•Neverwearbaggyorloosettingclothingthatcanbecaughtoncontrolsor

moving parts.

•Thesurfacepreparatorcanemityingparticlesanddebrisduringoperation.

Neveroperatethemachinenearbystanders,animalsorchildren.

•Donotoperatethemachineinanexplosiveatmosphere,nearcombustible

materials, or when gas fumes may not be properly dispersed.

•Neverleavethemachineunattendedwhenrunning.

Operator must hold onto the handle with two hands when the cutter drum is

engaged.

•Avoidcontactwiththemuferwhentheengineishot,asitmaycaisesevere

burns.

•Whenusingavacuumsystem,avoidhosecontactwiththemufer.

•Stopenginebeforerefuelingtank.Donotallowfueltocomeincontactwiththe

hot parts of the engine or spill on the ground.

•Donotsmokeorhandleopenrenearthismachine.

•Gastanklidmustclosetightly.Shutofffuelcockwhenshuttingoffengine.

Whentransportingthemachine,thefueltankmustbecompletelydrained.

Service •Makesurethattheengineisshutdownandthesparkplugisdisconnected

before servicing.

•Repairanyfuelleaksimmediatelyandremoveaccumulateddustfrequently

fromtheairltersystem.

•Cleanthemachineregularly.

•Removesideplatescrewsandcheckforwear.

Daily Checklist •Checkuidlevels

•Ensurethatallguardsareinplacebeforethemachineisoperated,since

rotatingandmovingpartswillcauseinjuryuponcontact.

•CheckandReplace(asneeded):

•Cutters •Bearings

•Shafts •DriveShaft

•DustFlap •Wheels

•Checkthatallfastenersaresecure

•CheckthatallControlsandSafetyDevicesarefuntioningproperly

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 5

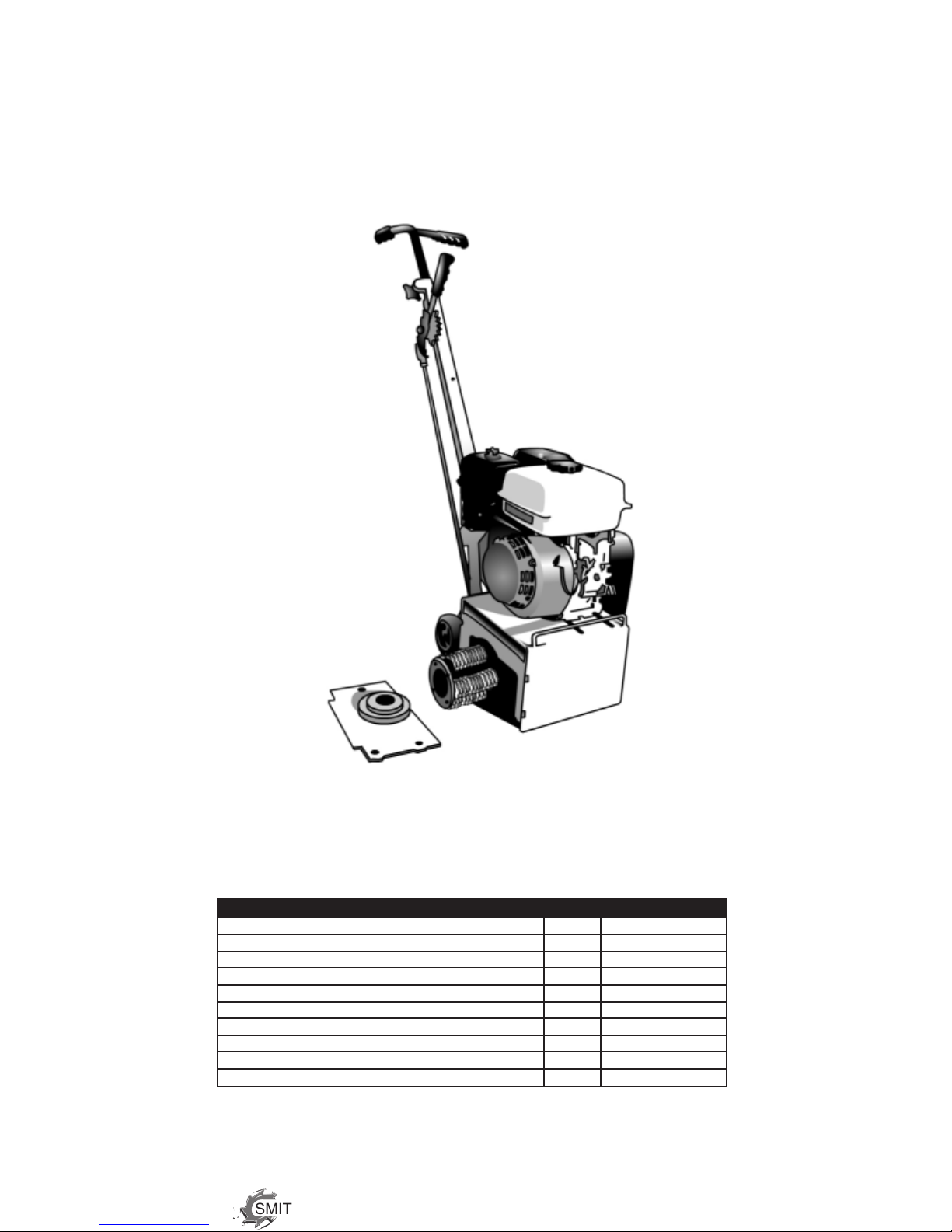

FS200/FS209

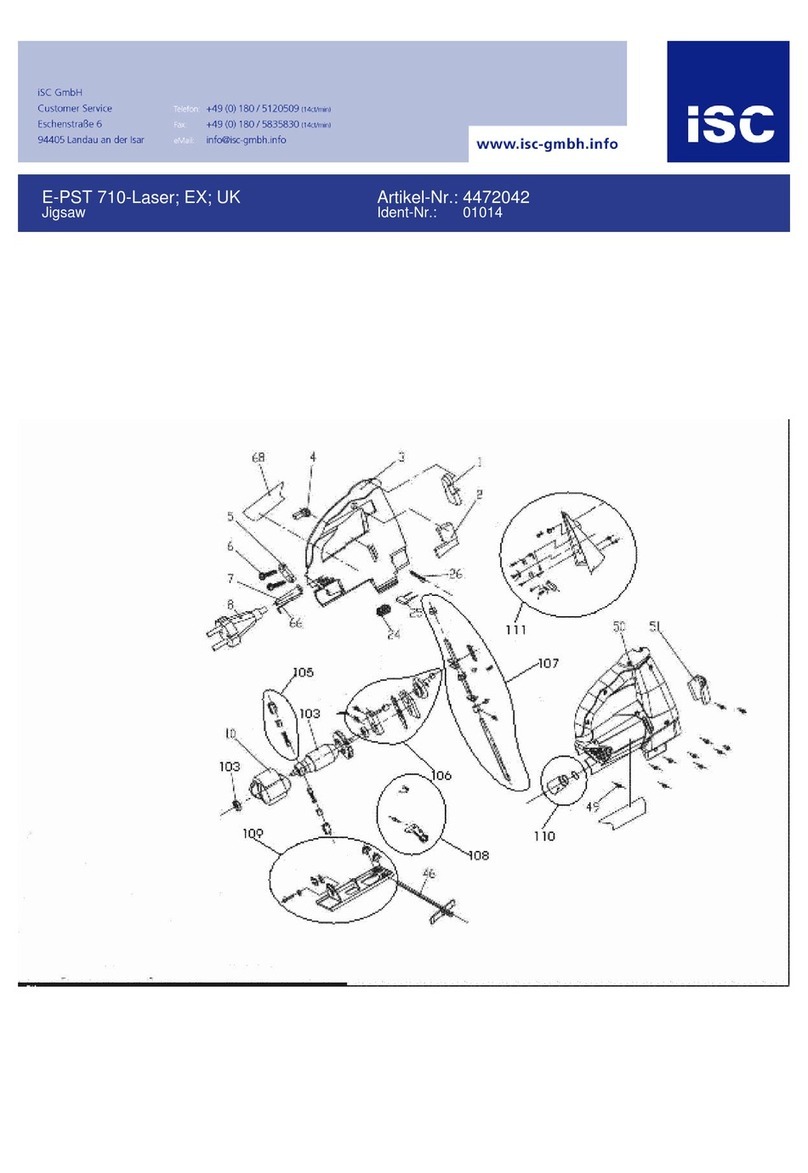

YOUR FS200™ SURFACE PREPARATOR

PleasetakeamomenttofamiliarizeyourselfwiththeFS200™’s

controls, as well as some of the features of your new machine.

For Assembly diagrams and parts numbers, please refer to pages 9-16.

Read the engine manual before preparing the engine for starting.

(c/w CF2515™ Ultra-Premium Carbide cutters - depicted)

AdjustableHandlebar

Throttle

GasTank

OilDipstick

Removalble Side Plate

Drum Assembly

Depth Control Lever

Engine Cleaner

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

61/2008

FS200/FS209

CUTTER DRUM ASSEMBLY

CARBIDE or STEEL?

Whenconguringyourcutterdrumforremoval,oneofthemost

importantquestionstoaskis:“WhichcuttertypedoIuse,carbideorsteel?”

Tungstencarbidewillproduceasmoothersurfacenishifsetupproperly:

without spacers, in an offset pattern. Professionals use

SMITH’s Ultra-Premium tungsten carbide cutters to save time and money.

NOTE: OnlySMITHBrandUltra-PremiumTungstencarbideisthemost

cost-effective cutting tool and lasts up to 25x longer than conventional cutters

while removing 5x faster on asphalt or concrete.

There are many types of cutters that you can use on this machine

(RefertoourCutterDatasheetforspecicsizesandorderinginformation):

1 Beamsteelcuttersfor

HS1013™ gentle scarifying.

2Star steel cutters for light

to medium scarifying.

HS1003™

Tungstencarbidespikedcutterstoremove

3coatings, as well as clean, plane, mill, scarify,

CF2515™ CF2516™ roughen, smooth, groove, grind, eradicate or

remove on concrete or asphalt.

4Special carbide scrapers designed for asphalt-removing Hot Tapes,

CF2519™ CF2535™ preformtapes,thermoplasticsorthicklmcoatings.

5 Angleddirectionalsteelcutterforremovingtoughnon-skidcoatings.

HS1011™

CUTTER SET-UP

Remove one retaining plate(ILL #3, pg. 11) and load the cutters and spacers on each shaft using the

cutter charts (pg. 12-13) as a guide.

Makecertainthatthedrumisbalanced.Anunbalaneddrumisunsafeandmaycauseexessive

vibration,damagedbearings,brokenshaftsandreducedcutterlife.

TIP:Loadcutterswithoutspacersforthebestnish.

Offsetoraligncarbide-spikedcutters(#3-5,above)forgrooving,

surface leveling, or removing. And ALWAYS load the special

milling cutters in the same direction, with the carbide adge cutting

rst,andspacedwithatleastonespacer(seepage13fordetails).

Thereshouldbe1/8”-1/4”playoneachsectionofcuttershaft.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 7

FS200/FS209

MACHINE START-UP

Do not start machine while drum is in contact with

the ground. Doing so can cause the operator to lose control of

themachine,resultinginpropertydamageand/orpersonalinjury.

1)Openthefuelcockonthegastankandthenplacethethrottleleveratthe

“FastIdle”position.

2)Starttheengine,openchokeslightlytopreventooding.

3) Move throttle control to open or run position when engine is warmed up.

4)Increasethrottletomaximumoperatingposition(approx.1800RPM)andclosechoke.

Beforesubstrateremoval,testrunthedrumwithcuttersnottouchingthesurface.Ifthereis

exessivevibration,youneedtore-balancethecutterset-up,checkbearingcondition,and/or

makesurethattheengineside-plateissecured.

IF THE ENGINE DOES NOT START...

1)CheckEngineforpropergasandoillevels(refertoEnginemanual)

2)Checksparkplug.Makesurethesocketareasarecleanandclearofdebris,andthatthe

proper gap is set. (Replace if needed).

3)TurntheOn/Offswitch,onthefrontoftheEngine,to“On”.

4)Enginemayhavetiltedbackwards.Ifso,allowoiltodrainafterremovingsparkplug.

*Engine repair and engine warranty issues are handled directly by

your local Honda engine service center.

Warning: Should you desire to tilt the machine, always tilt forward.

Tiltingthemachinebackwardsatanytimewilloodthesparkplug

with oil and may cause damage to your engine!

RIGHT WRONG

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

81/2008

FS200/FS209

Transporting

Duringtransport,loadingandunloadingofthescarierbymeansofliftingdevices,useappropriate

slings,orhooksontheliftingpoints,providedforthispurpose.

Theload-carryingcapacityhastobesufcientandsecuresuchthattheycannotturnover.Make

sure that no one is endangered by the machine turning over. When being transported on vehicles,

precautionshavetobetakenthatthescariersaresecuredanddonotmove.

SUBSTRATE REMOVAL

AdjusttheheightofthecutterdrumwiththeDepthControlLever.Setthedepthofcuttoallow

the cutters to go through only the materials to be removed.

Makecertainthethedrumispositionedtowhereonlythecuttersstrikethesurface,andthatthedrum

assembly never comes into contact with the substrate.

The cutter tips alone should strike the surface(1/8”to1/4”maximumdepthperremovalpasson

new cutters).

The drum will not withstand substrate contact. Contacting the removal surface too deeply will

cause premature wear to cutters, shafts, drum and other components! TIP: The correct depth

setting is indicated by relatively little machine vibration.

Too much downward pressure only has negative results. Try to remove materials in several

passes rather than one, deep pass. Several tests will show the best, most appropriate cutter impact.

Useaforward,backwardand/orcircularpatterntoachieveyourdesirednish.

NOTE: Only use a forward motion when using the CM2519™ or CM2535™ carbide scraping cutters.

TIP: Position the machine over the surface in many direrctions

to help create desirable surface patterns. After several hours of

practice, the operator will become comfortable and should be able

to remove materials faster with enhanced results.

Whenthejobiscompleted,ortheoperatorwantstoceasework,stoptheenginebyrstlifting

the drum above the substrate using the Depth Control lever. Stop the machine only at the engine.

Thenclosethefuelcocktoshutoffthefuelsupply.

The drum assembly must be removed daily and inspected for drum wear, hole elongation and

possible weld seperation. Replace the cutter shafts prior to any drum wear. If the drum’s center

holes are elongated, order another SMITH cutter drum.

Refer to pg. 8 for troubleshooting problems.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 9

FS200/FS209

STORAGE

•Shutofffuelvalveandsiphonallexcessfuel.

•Startengineandrununtilitstalls.

•Removesparkplugandpourtwoouncesofmotoroilinto

cylinderandslowlycranktheenginetodistributeoilto

prevent rust during storage.

•Replacesparkplugandstoremachineuprightinacool,

dry, and well-ventilated area.

Maintenance Checks

Accordingtotheconditionsandfrequencyofuse,scariers

havetobecheckedforsafeoperationatleastonceayearby

skilledtechnicians,suchasthosefoundatthemanufacturer’s

service depots, and have to be repaired if necessary.

ORDERING

When ordering please specify the model and serial number

of the machine. In addition, give a part number, description,

and quantity as listed on your parts list.

If you have any questions about the operation of your machine

orwouldliketoorderreplacementparts,contactyourdealeror

SMITH Manufacturing.

Contact SMITH at 1-800-653-9311 (954-941-9744) for information,

or visit our website at www.smithmfg.com.

To ensure product safety and reliability, and to maintain

your warranty, always use genuine replacement cutters

and parts from SMITH MFG when making repairs to

equipment.

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

10 1/2008

FS200/FS209

TROUBLESHOOTING

If engine does not start, read pg. 5

Problem Possible Reason(s)/Solution(s)

Cutters wearing unevenly/prematurely 1Drum is too low, 2Incorrect set-up,

3Material build-up,

4Cutters too tightly loaded, and/or

5Wrongcuttersforthejob.

Cuttershaftbreakageprematurely 1Drum too low, 2End plates worn,

3Shafts worn, and/or

4Wrong cutter set-up.

Drumwearingprematurelyorcracking 1Drum hitting ground, and/or

2Shafts not replaced in time.

Excess vibration 1Bearingfailure,2Hex bushing worn,

3Drive shaft worn,

4Improper cutter set-up,

5Drum contacting ground, and/or

6Wheels worn out.

Machinejumpserratically 1Drum hitting ground, 2RPM is too low,

and/or 3Surface is severely uneven.

“V”beltwearprematurely 1Pulley is misaligned, 2Wrong belt,

and/or 3Drum is contacting surface.

DepthControlLeversettoolow AdjustHeightofLever:

1)OpenSpringx(#9B,pg.9),usingascrewdriver

to gently pry it open, if needed.

2) Disengage Clevis from Handle Assembly by pulling

straight out, away from handle.

3)ToAdjustHeight:

TurnLocknut(#9C,pg.9),andmovetodesired

position.

4) Reattach Clevis and Snap outer piece into place.

*NOTE:Forevengreateradjustments,repeat

procedure for Clevis at bottom of Handle Assembly

Uneven Cutting 1Cutting too deeply, and/or

2Rearwheelforkisbent.

For any other problems or questions, please contact your local representative

or SMITH Mfg today at 800-653-9311 or (954) 941-9744.

*Engine repair and engine warranty issues are handled

directly by your local engine service center.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 11

FS200/FS209

ILL # Description Part Number Qty.

1 Housing 511.1063.2 1

2 DustFlapRetentionBar 511.1021.240 1

3 Dust Flap 511.1022.240 1

4 Hex Screw M10 x 20 998.1009.25 10

5 Spring Washer 991.1020.10 10

6 Plain Washer M10 991.1002.10 3

7 Penny Washer 991.1091.10 3

8 Sideplate Assembly (w/bearings) 511.1055A 1

9 AdjustmentRodAssembly 516.1000A 1

A ClevisM10Springx 516.1004 1

B ClevisSpringM10Springx 516.1006 1

C LockNut 990.1020.10 1

D AdjustmentRod 513.1000 1

E LockNut 990.1020.12 1

F ClevisSpringM12Springx 516.1007 1

G ClevisM12Springx 516.1005 1

10 AdjustableHandleAssembly 500.2000.9 1

A Grip 510.1016.2 1

11 HanldeBar 510.1020.1 1

12 Rubber Handle Grip 510.1016.1 2

13 Plastic Knob 907.1001.1 1

14 Handle 510.1000 1

15 VacuumPortCap 904.1000.3 1

16 BackWheelAssembly 515.1007A 1

A Cotter Pin 989.3002.20 2

B PlainWasherM14 991.1001.14 4

C Wheel 905.1000.1 2

D Wheel Carrier 515.1007 1

ILL # Description Part Number Qty.

16E HexHeadBolt 506.1008 2

F Plain Washer M12 991.1001.12 4

G NylonInsertNut 506.1009 2

17 Honda Engine w/oil alert

5.5 HP 15026 1

9 HP 15027 1

18 BeltGuardBracketAssembly 511.1060A 1

A BeltGuardBracket 511.1060 1

B HexScrewM8x30 998.1008.30 2

C Plain Washer M8 991.1002.8 4

D NylonInsertNutM8 990.1001.9 2

E Hex Screw M10 x 20 998.1009.25 2

F Spring Washer 991.1020.10 2

G Plain Washer M10 991.1002.10 2

19 BeltGuard

FS200 505.1001 1

FS209 505.1001.9 1

20 Engine Mounting Hardware 501.1011.4A 2

A “U”Bolts 501.1011.4 1

B PlainWasherM8 991.1002.8 2

C NylonInsertNutM8 990.1001.8 2

21 Front Wheel Assembly 530.1006A 1

A Front Wheel 530.1006 1

B HexHeadBolt 990.1009.75 1

C Plain Washer M10 991.1001.10 1

D FrontWheelBushing 530.1005.10 2

E NylonInsertNutM10 990.1001.10 1

22 Serial Plate 80001 1

23 Drive Screw 10129 2

Parts List

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

12 1/2008

FS200/FS209

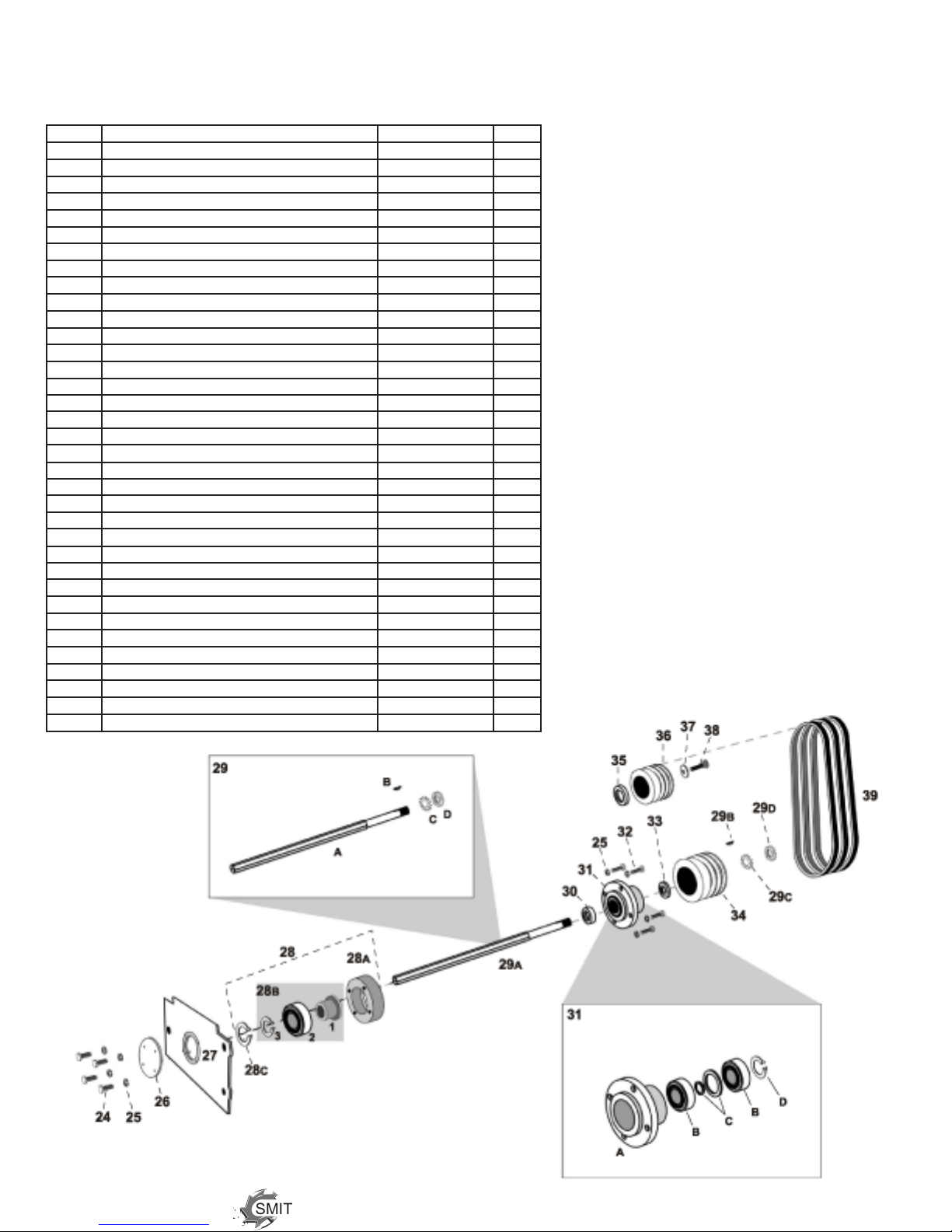

ILL # Description Part Number Qty.

24 Screw M8 x 20 998.1020.20 4

25 Spring Washer M8 991.1020.8 8

26 BearingCover 511.1020 1

27 Side Plate 511.1055.2 1

28 DriveBearingAssembly,Outer 979.1000A 1

A BearingFlange 512.1002 1

B HexBearingAssembly 514.1000A 1

1HexBushing 514.1000 1

2BallBearing(6006-2RS) 979.1000.18 1

3 External Circlip, 30 mm 977.1010.30 1

C Internal Circlip, 55 mm 977.1000.55 1

29 Shaft Assembly 513.1000A 1

A Hex Shaft 513.1000.1 1

B WoodruffKey 979.9021 1

C Tabbed Washer 979.1021.1 1

D LockNut 979.9020.1 1

30 Shaft Spacer 109.1033.7 1

31 DriveBearingAssembly,Inner 512.1000A 1

A BearingHousing 512.1000 1

B Bearing(6303-2RS) 979.1000.12 2

C Setof2BearingSpacers,Large&Small 109.1033.11 1

D Internal Circlip, 47 mm 977.1010.47 1

32 Cap Screw M8 x 12 997.1008.12 4

33 Pulley Spacer 506.1007 1

34 Drive Pulley w/set Screw, Lower 518.1006 1

35 Engine Spacer 302.1005.9 1

36 Engine Pulley w/set Screw, Upper 1

for 5.5 HP (FS200) 518.1005 1

for 9 HP (FS209) 518.1009 1

37 Pulley Retaining Washer 302.1008 1

38 Bolt5/16-24x1” 998.1035.16 1

39 Belts,Vfor5.5HP 3

SPZ 710 (for early gas models) 967.1010.710 3

SPZ 722 (for later models) 967.1010.722 3

for 9 HP (SPZ 750) 961.1010.750 3

Parts List

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 13

FS200/FS209

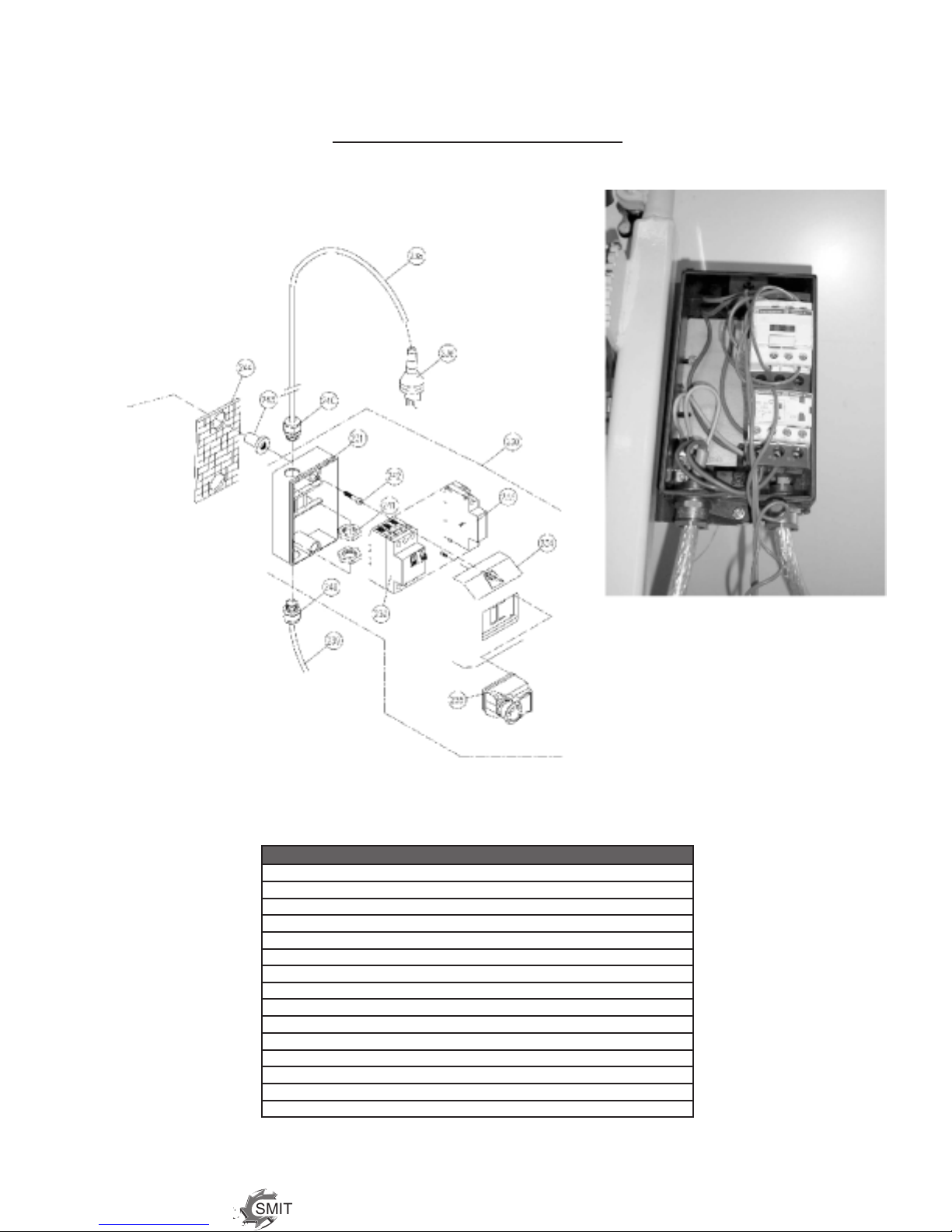

Optional ELECTRIC MOTOR

ID # PART # QTY. DESCRIPTION

150 ES-200-698 1 ElectricMotor,230V

151 ES-200-1209 1 Starting Condender

152 ES-200.1210 1 Operating Condenser

153 ES-200-12101 2 Holder for Condenser

154 ES-200-12102 1 TerminalBoxCover

155 ES-20-12111 1 Fan Cover

156 ES-200-12113 1 Fan

157 ES-200-1211 1 Relay

158 ES-200-7616 4 Hexagon Screw

159 ES-200-7633 4 Conical Spring Washer

160 ES-200-762 4 Spacer

161 NotUsed

162 ES-200-12103 1 TerminalBox

163 ES-200-902 1 Key for Electric Motor

164 ES-2009051 1 Spacer for Electric Motor USA

165 ES-200905 1 Driving Disc Electric Motor USA

166 NotUsed

167 NotUsed

168 ES-200-907 1 LockingRing

169 ES-200-913 1 Spring Washer

170 ES-200-914 1 Hexagon Screw

171 ES-200-740 2 Plate for Electric Motor

172 ES-200-850 2 Counterplate Electric Motor

173 ES-200-9021 1 Key for Gaoline Motor

174 ES-200-903 1 DrivingDiscB.-MotorHONDA

175 ES-200-9031 1 SpacerB.-MotorHONDA

176 ES-200-904 1 DrivingDiscB.-MotorB&S

177 ES-200-9041 1 SpacerB.-MotorB&S

178 ES-200-7615 4 Hexagon Screw

179 ES-200-7001 1 Air Filter

180 ES-200-700 1 Gasoline Motor Honda

181 ES-200-760 2 CounterplateB.-Motor

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

14 1/2008

FS200/FS209

Optional ELECTRIC MOTOR

ID # PART # QTY. DESCRIPTION

230 ES-200-1066 1 Switch Complete

231 ES-200-1047 1 Lower Switch Housing

232 ES-200-1060 1 CircuitBreaker

233 ES-200-1052 1 Undervoltage Release

234 ES-200-10471 1 Upper Switch Housing

235 ES-200-1048 1 Emergency Stop Switch

236 ES-200-1151 1 Plug

237 NotUsed

238 ES-200-1101 1 Lead Wire

239 ES-200-1102 1 Connection Cable

240 ES-200-108 2 Conduit Gland

241 ES-200-1081 2 LockingNut

242 ES-200-10421 2 Allen Screw

243 ES-200-1055 2 Shock-Reducer

244 ES-200-1056 1 Rubber Plate

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 15

FS200/FS209

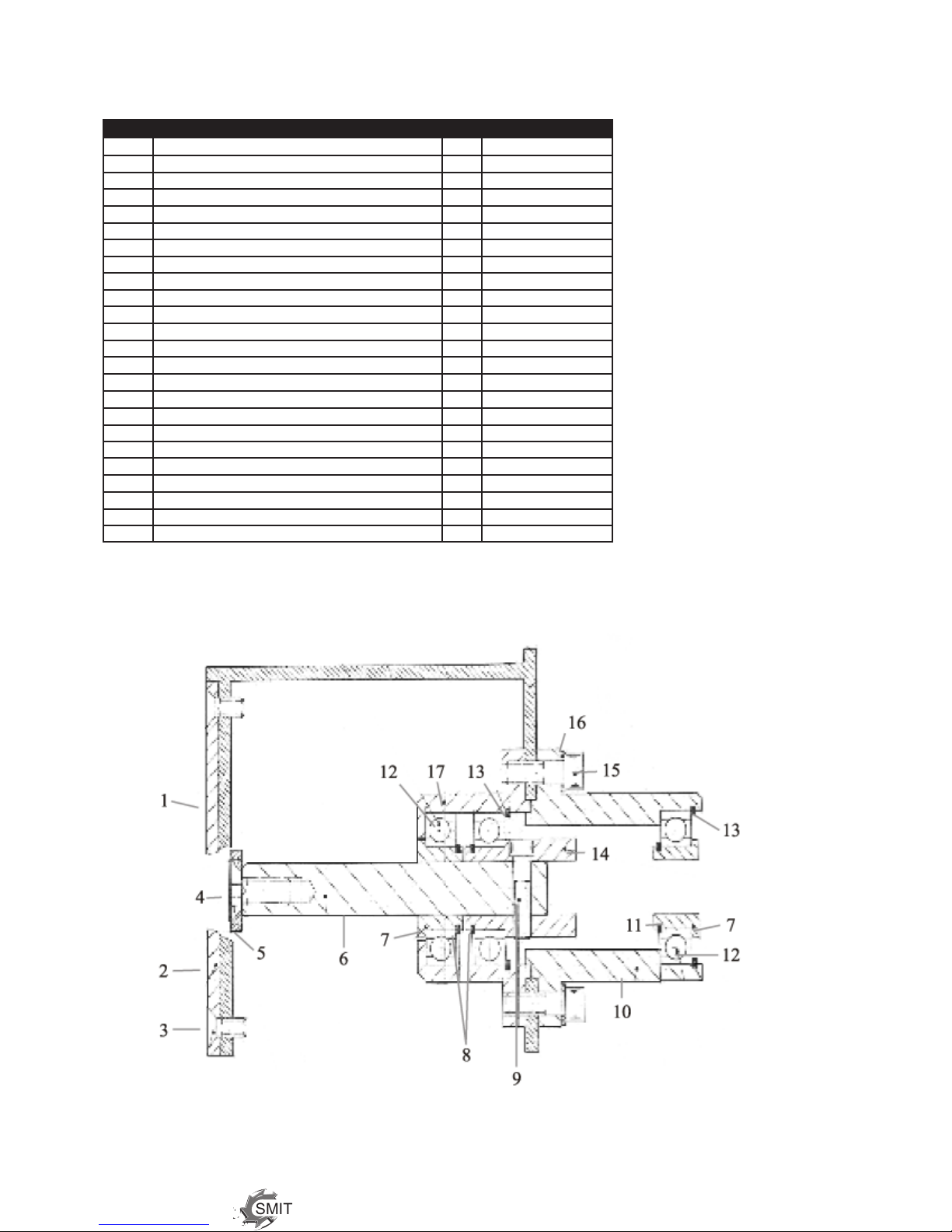

Drum Assembly

ILL# P/N Oty. Description

1 504.4021.12 1 Drum Assembly (includes #2 - #5)

2 S-507.1001 4 Cutter Shaft (12 mm)

3 504.2035 2 Retaining Plate

4 998.1005 8 LockNut

5 990.1001 8 Cap, Screw

6 CF2515™ $ 5SpikeTungstenCarbideCutter

CF2516™ $ 6SpikeTungstenCarbideCutter

CF2535™ $ 5 Edge Carbide Scraping Cutter

CF2519™ $ 7 Edge Carbide, Angled Scraping Cutter

HS1003™ $ Steel Star Cutter

HS1011™ $ Steel Cutter, Angled

HS1013™ $ SteelBeamCutter

122230™ $ Spacer,1/2”

$ Refer to cutter set up on pages 12-13

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

16 1/2008

FS200/FS209

Carbide Prep-It™ Strip Drum Assembly

P/N: 8200.02

Therubber“PrepStrip™”drumcomespresetwithstripsinstalledina

staggered pattern to ensure contact with the surface being stripped.

The following guidelines will show you how to get the longest life out of

your drum:

•Afterinstallation,lowerthedrumslowlytobegincontactingthe

surface.

•Loweronlyenoughtocontactthesurfaceanddothejob.

•Excesspressureonlyincreaseswear,notcuttingspeed.

•Runengineatmoderatespeeds.

•Slowspeedswillnotprovideagoodnish.

•Fastspeedsacceleratewearonallmachinepartsaswell

as the stripping bits.

•Afterextendedusage,examinethecuttingtips.Ifworn

excessively, remove the drum and replace all 7 strips.

Replacing Rubber Prep-It™ Strips

The rubber strips are set up at the factory in precut lengths. When worn, all 7 strips must be replaced

to ensure that equal contact is made with the surface.

Tools needed: Wrenches, Screw Driver, Pliers, Silicone Spray

1. Remove the side plate and slide drum off.

2.Setthedrumonyourworksurfaceandremoveallthemetric socket head screws

from one end plate.

3. Use a screw driver and a pair of pliers to pry the rubber strips from the drum slots.

4. Clean the drum slots with a tool brush to remove dirt.

5. Spray each replacement strip(P/N:8200.00)withsiliconesprayandslidethemintothe

drumslotsuntiltheyrestrmlyagainstthestop screws at the end of the slots.

6.Locatethestampednumber“1”or“2”ontheendofonerubber strip to align with the

corresponding number on the end plate.

7. Install the end plate retaining screws with the original lock washers and tighten

(*DO NOT OVER TIGHTEN. Over-tightening the screws may strip the threads).

8. After reinstalling the drum, you can begin using the equipment again.

For additional assistance and/or troubleshooting, please call us

at (954) 941-9744, or visit our website at www.smithmfg.com.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 17

FS200/FS209

CARBIDE FLAIL CUTTER SET-UP

Note:Thefollowingdiagramsareintendedtoguideyoutroughgeneralcutterset-ups.

QuantitiesofCuttersandSpacersmayvary,dependingonthenishyoudesire.

Placingmorecuttersoneachshaftwillprovideasmoothernish.Addingspacerswill

giveamorecoarsenish.Aligningthecutterswillcreateagroovepattern.

GROOVEFINISH GENERALFINISH FINEFINISH SUPER-FINEFINISH

Align Cutters and Spacers 40 CUTTERS (approx.), 76 CUTTERS (approx.) 112 CUTTERS (approx.)

2 Spacers per Cutter 1 Spacer per Cutter 0 Spacers

STEEL CUTTER SET-UP (Finishing Drum)

SUPER-FINEFINISH 180STEELCUTTERS(approx.)

(Note:QuantityofCuttersmayvary)

Super-Fine Finish

HS1003

HS1013

HS1011

Flip charts upside-down for set-up of other side of drum.

Cutter Set-Up

CF2515 CF2516

Offset with spacers

to prevent grooving

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

18 1/2008

FS200/FS209

SPECIAL TUNGSTEN CARBIDE MILLING SCRAPER

MILLING SCRAPER USE INSTRUCTIONS:

Milling Scrapers (CM2535™) are not made for cutting into portland cement surfaces. They are made

forremovingmaterialsinoronsoftasphaltorremovingthicklmcoatingsontopofsmoothconcrete

surfacesonly.Ifyouneedtocutconcrete,pleaseuseSMITH’sUltra-Premiumtungstencarbidespike

cutters(CF2515™andCF2516™).Makecertainthespecialmillingscrapersareloadedonthedrum

intheproperdirection,wherebytheleadingcarbideedgewillcutrst.Loadingthescrarpersback-

wards will damage the cutters and the drum.

CM2535™ Setup

(Note:QuantityofCuttersandSpacersmayvary).

USE A FORWARD MOTION ONLY.

Front of Drum

BackofDrum

*Note:AmountsofSpacersmayvary.Pleaseallowfrom1/8”-1/4”playineachsectionofdrum.

Cutter Set-Up

CM2535™

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2008 19

FS200/FS209

Recommended Spares List

Description Oty. Part Number

Spares Kit (Wear Parts) 1 500.2090.1

Cutter Shaft (P/N:500.1007)

BallBearing60062RS(P/N:979.1000.18)

BallBearing63032RS(P/N:979.1000.12)

VBelts*

LockNut 1 979.1020.1

Tabbed Washer 1 979.1021.1

Hexagon Drive Shaft 1 513.1000.1

Dust Flap 1 511.1022.240

*Specify5.5HP(P/N:967.1010.710)or9.0(P/N:961.1010.750)HPEngine

SMITH Manufacturing 1-800-653-9311 www.SmithMfg.com

20 1/2008

FS200/FS209

Edger Assembly

Item Description Oty. Part Number

Edger Assembly c/wBareDrum 500.2020.1

Edger Assembly c/w Carbide Cutter Drum 500.2020.2

1 ChassisMk1FS200 1 511.1030

ChassisMk2FS200 1 511.1064

ChassistosuitVonArxFR200 1 511.1050

Chassis to suit Airtec RT200 1 511.1065

2 Cover Plate 1 511.1031.1

Cover Plate tosuitVonArxFR200/AirtecRT200 1 511.1054

3 SocketCountersunkScrewM6x16 4 982.1007.16

4 Securing Washer Screw 1 982.1008.25

5 Securing Washer 1 506.1006.1

6 Shaft 1 513.1001.2

7 Hexagon Driving Support 2 514.1000

8 Internal Circlip 30 mm 2 977.1010.30

9 SocketHeadCapScrewM6x30 1 984.1007.30

10 BearingHousing 1 512.1004

11 External Circlip 30 mm 1 977.1010.30

12 Bearing6006-2RS 1 979.1000.18

13 Internal Circlip 55 mm 1 977.1000.55

14 Long Hexagon Support 1 514.1001

15 SocketHeadCapScrewM8x25 4 984.1008.25

16 Spring Washer M8 4 991.1020.8

17 BearingHousing 1 512.1003

This manual suits for next models

1

Table of contents

Popular Power Tools manuals by other brands

HIKOKI

HIKOKI M1808DA Handling instructions

norbar

norbar TTi20 instructions

Metabo

Metabo W 2200-230 Original instructions

Harbor Freight Tools

Harbor Freight Tools Chicago Electric 91082 Assembly and operating instructions

Clarke

Clarke Strong-Arm CSA20F Operation & maintenance instructions

Princess auto

Princess auto 8408197 user manual