Smokaroma Bar-B-Q Boss Guide

Broaster Company

2855 Cranston Road, Beloit, WI 53511-3991

608/365-0193 broaster.com

© 2017 Broaster Company

Printed In U.S.A.

Smokaroma® is a registered trademark.

Be sure ALL installers read, understand, and have access to this manual at all times.

Design Certified By:

UL, CUL & NSF

SERVICE & PARTS MANUAL

Bar-B-Q Boss®Pressure Smoker

Models BC71 and BC73

Manual #17897 7/17

W-1

FOR YOUR SAFETY

Do not use or store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Improper installation, adjustments, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and mainte-

nance instructions thoroughly before installing or servicing this equipment.

For the sake of safety and clarity, the following words used in this manual are defined as follows:

Indicates an imminently hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in minor injury, property damage or both.

All adjustments and repairs shall be made

by an authorized Smokaroma representa-

tive.

If there is a power failure, turn the timer

knob to "0" .

Failure to read and

understand this manual

completely could result in serious injury

or death. Be sure ALL operators read,

understand and have access to this

manual at all times.

Rags or paper containing

cooking oil can catch fire

if exposed to heat. Laundering will not

remove the oil. Dispose of all oil-soiled

papers and rags in a trash container that

is in a ventilated area away from all

cooking equipment or other heat

sources such as direct sunlight.

broaster.com Manual #17897 7/17

i

TABLE OF CONTENTS

1. Warning Labels ....................................................................................... 1 - 1

2. ELECTRICAL POWER SUPPLY ................................................................................... 2 - 1

WIRING DIAGRAM 1 PHASE .................................................................................. 2 - 2

WIRING DIAGRAM 3 PHASE .................................................................................. 2 - 3

3. CONTROL PANEL ......................................................................................................... 3 - 1

4. ELECTRICAL COMPONENTS ....................................................................................... 4 - 1

5. PARTS ............................................................................................................................. 5 - 1

CABINET & PANELS ................................................................................................ 5 - 1

BASE ......................................................................................................................... 5 - 2

PRESSURE AND EXHAUST SYSTEM .................................................................... 5 - 3

CONTROL PANEL .................................................................................................... 5 - 4

HEATING ELEMENTS AND INSULATION .............................................................. 5 - 5

COOKING WELL ...................................................................................................... 5 - 6

LOWER CONTROL BOX .......................................................................................... 5 - 7

COVER ASSEMBLY ................................................................................................. 5 - 8

MEAT RACK ............................................................................................................. 5 - 9

TIERED FOOD BASKET ........................................................................................ 5 - 10

broaster.com Manual #17897 7/17

1 - WARNING LABELS

1-1

broaster.com Manual #17897 7/17

2 - ELECTRIC POWER SUPPLY

2-1

broaster.com Manual #17897 7/17

ELECTRICAL SAFETY

Many parts of this section

pertain to checking and re-

pairing electrical components. High Voltage

will be encountered in several instances.

Only persons trained and equipped for

checking high voltage shall undertake such

repairs.

If no component operates, check main pow-

er supply. Be sure main circuit breaker is ON

and main fuses are good.

Correct voltage is specified on the specifi-

cation plate located on the rear panel. It will

be either 208V or 240V for domestic units

and 220V for export units.

If the unit will not turn on, perform the follow-

ing:

1. Disconnect main power supply.

2. Be sure all connections are tight. If

power supply is proper, see TROU-

BLESHOOTING section.

ACCESS FOR SERVICE

For access to the electrical compartment,

remove rear cover.

2-2

208V, 220V & 240V 1ph:

broaster.com Manual #17897 7/17

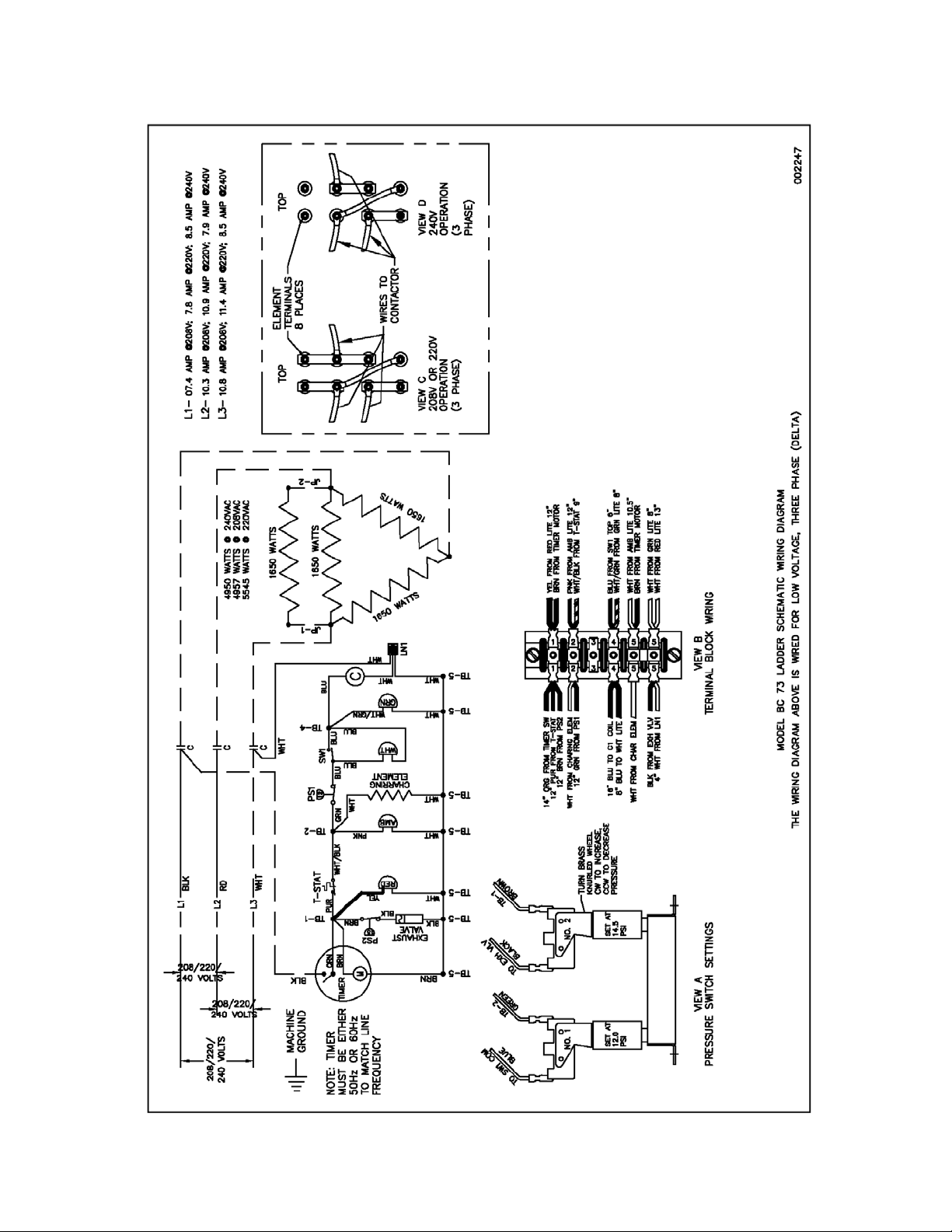

2-3

broaster.com Manual #17897 7/17

208V, 220V & 240V 3ph:

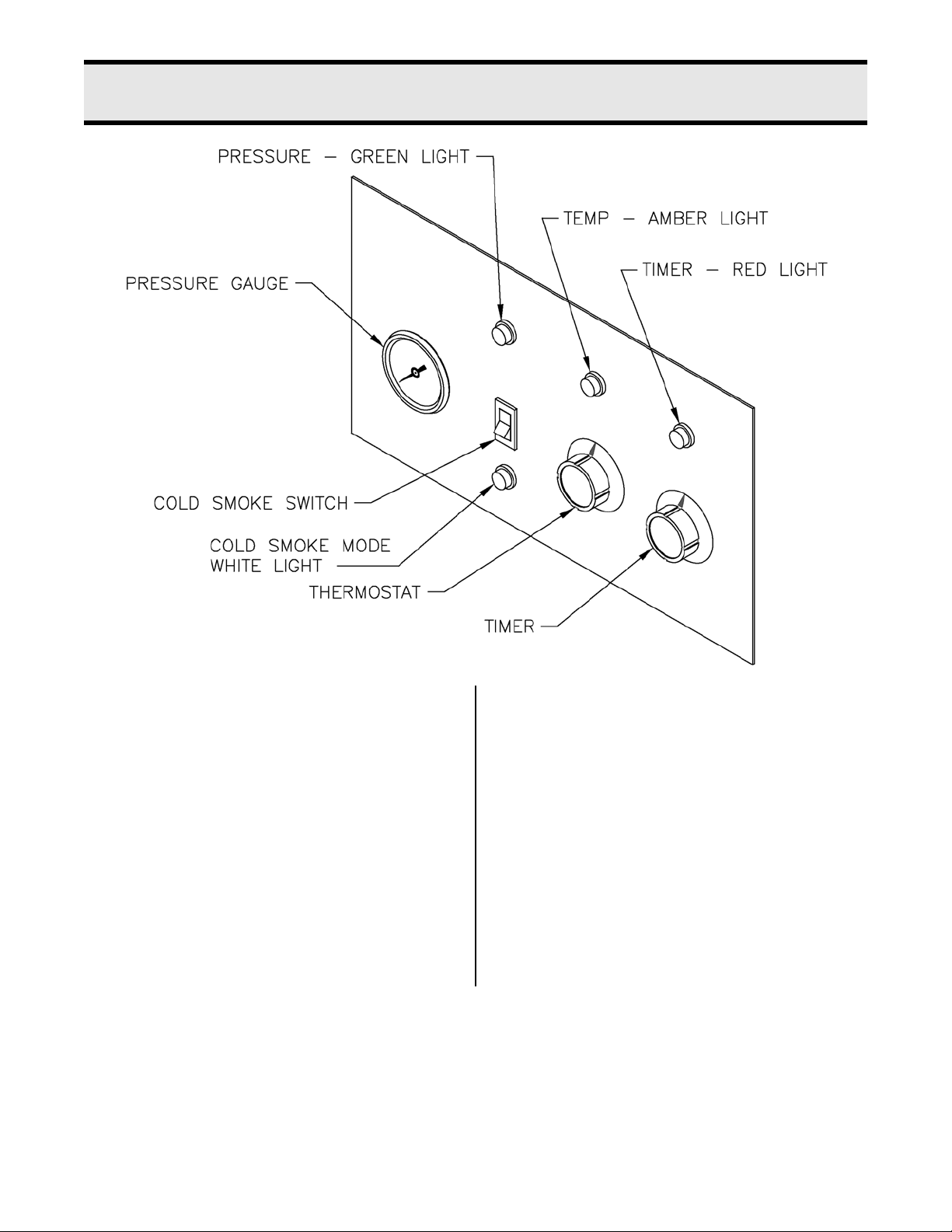

3 - CONTROL PANEL

3-1

broaster.com Manual #17897 7/17

THERMOSTAT: Puts the smoker in either

BAR-B-Q or HOLD mode. When set, pro-

vides power to the power relay/contactor to

the heating elements.

COLD SMOKE SWITCH: Puts the smoker

into Cold Smoke Mode.

COLD SMOKE - WHITE LIGHT: Illumi-

nates when the TIMER and THERMOSTAT

are set and the COLD SMOKE SWITCH is

on.

PRESSURE GAUGE: Indicates the pres-

sure present in the Cooking Well.

PRESSURE - GREEN LIGHT: Illuminates

when the THERMOSTAT and TIMER are set

and the COLD SMOKE SWITCH is off. And

also when Pressure Switch #1 is closed

sending power to the elements.

TEMPERATURE - AMBER LIGHT: Illumi-

nates when the THERMOSTAT and TIMER

are set and when the thermostat is calling

for heat.

TIMER - RED LIGHT: Illuminates when the

TIMER is set.

TIMER: Sets the product cook time. When

the timer is set, it provides power to the

control circuit.

3-2

ACCESS FOR SERVICE

1. Unplug power cord.

2. Remove rear cover of unit.

broaster.com Manual #17897 7/17

3-3

PRESSURE GAUGE

1. See ACCESS FOR SERVICE.

2. Disconnect the hose from the fitting on

the back of the pressure gauge.

3. Remove the (2) mounting nuts and the

mounting clamp from the gauge.

4. Pull gauge out of control panel from

the front.

5. Remove fitting from back of gauge.

6. Install new pressure gauge in reverse

order.

COLD SMOKE SWITCH

1. See ACCESS FOR SERVICE.

2. Remove blue wires from switch.

3. The switch is removed from the front

of the control panel. To remove the

switch, depress the keepers on the top

and bottom of the switch and push

switch out toward the front of the

panel.

4. To install the new switch make sure

the center pole is toward the right as

you look at the back of the unit. (see

diagram below)

broaster.com Manual #17897 7/17

3-4

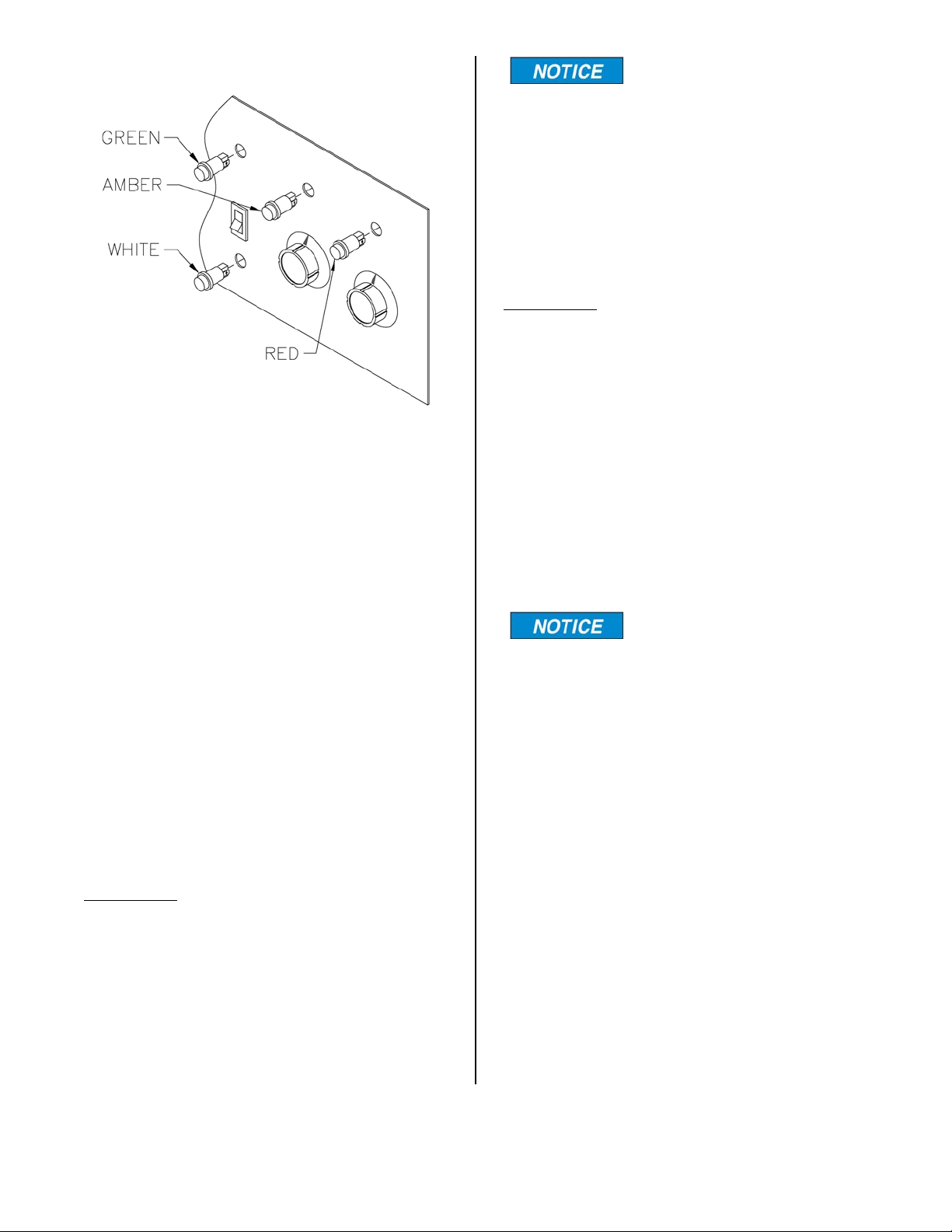

LIGHTS

1. See ACCESS FOR SERVICE.

2. Remove the wires from the light being

replaced.

3. Depress the keepers and push the

light out of the control panel.

4. Install the new light in reverse order.

Push light in until the chrome ring is

flush with the front of the control

panel.

TERMINAL BLOCK

Replacing the terminal block can be

done in one of two ways.

Method 1 (recommended)

1. Remove the (2) nuts holding the

block in place then remove the

terminal block leaving the wires

connected to the old block.

2. Mount the new terminal block

and secure with the original

mounting nuts.

Terminals 5 & 6 are jum-

pered together and

should be toward the right end when

facing the back of the control panel.

3. Transfer the wires from one ter-

minal to the same terminal on the

new terminal block.

Method 2

1. Remove the wires from the termi-

nal block.

2. Remove the (2) mounting nuts

and pull out the old terminal

block.

3. Mount the new terminal block

and secure with the original

mounting nuts.

Terminals 5 & 6 are jum-

pered together and

should be toward the right end when

facing the back of the control panel.

4. Reinstall the wires on the new

terminal block. See wiring dia-

grams in section 2 of this manual

for correct wire connections to

the terminal block)

broaster.com Manual #17897 7/17

4 - ELECTRICAL COMPONENTS

4-1

broaster.com Manual #17897 7/17

Many of the components

in this section will have

wires that will need to be connected to

the terminal (TB) the diagram below

shows how the terminals are numbered.

Terminal 5 has a jumper between them to

provide more terminals.

TIMER

Removal:

1. Unplug power cord.

2. Remove rear panel of unit..

3. Remove timer knob from front of panel

by pulling away from panel.

4. Remove timer mounting screws from

front holding the timer in place.

5. Remove timer from panel and discon-

nect the black and orange wires from

the terminal on the timer.

6. Disconnect the (2) brown wires from

the terminal block.

New Timer Installation:

7. Install new timer using mounting

screws removed earlier and connect

wires as shown above.

8. Push knob on to shaft on front of unit.

9. Reinstall rear panel.

10. Plug in power cord to put unit back in

service.

4-2

THERMOSTAT:

Removal & Installation:

1. Unplug power cord.

2. Remove rear panel of unit.

3. Lay unit on its back and loosen the

clamp holding the thermostat bulb in

place.

4. Set unit upright on its casters.

5. Remove thermostat knob from front of

panel by pulling away from panel.

6. Remove thermostat mounting screws

from front holding the timer in place.

7. Disconnect wires from the thermostat.

8. Pull capillary tube and bulb up through

hole in bottom of control box.

9. Thread capillary and bulb of new ther-

mostat down through hole in bottom of

control box.

10. Mount new thermostat to back of panel

using the screws removed earlier.

11. Reconnect wires to thermostat.

12. Install thermostat knob.

13. Lay unit on its back.

14. Insert bulb under clamp on bottom of

cooking well and tighten screw enough

to hold bulb in place.

Tightening screw too much

may damage the bulb.

15. Set unit upright on its casters.

16. Reinstall rear panel.

17. Plug in power cord to put unit back in

service.

broaster.com Manual #17897 7/17

4-3

PRESSURE SWITCHES:

REPLACEMENT:

PRESSURE SWITCH PS1:

When pressure is below its set point, PS1 is

closed, providing power to the power relay/

contactor, which powers the heating ele-

ments.

To remove PS1 it is neces-

sary to remove PS2.

1. Unplug power cord.

2. Remove rear panel of unit.

2. Remove wires from both pressure

switches.

3. Remove pressure switch PS2.

4. Remove pressure switch PS1.

5. Install the new pressure switch.

6. Reinstall pressure switch PS2.

7. Reconnect wires as indicated in the di-

agram at left.

8. Adjust pressure switch PS1 as de-

scribed in the PRESSURE SWITCH

ADJUSTMENT section.

9. Reinstall rear panel.

10. Plug in power cord to put unit back in

service.

PRESSURE SWITCH PS2

When pressure is below its set point, PS2 is

closed providing power to the exhaust

valve, keeping it closed to build pressure.

1. Unplug power cord.

2. Remove rear panel of unit.

3. Remove wires from pressure switch

PS2.

4. Remove pressure switch PS2.

5. Install new pressure switch.

6. Reconnect wires as indicated in the di-

agram at left.

7. Adjust pressure switch PS1 as de-

scribed in the PRESSURE SWITCH

ADJUSTMENT section.

8. Reinstall rear panel.

9. Plug in power cord to put unit back in

service.

broaster.com Manual #17897 7/17

4-4

PRESSURE SWITCH ADJUST-

MENT

1. Put one quart of water in cooker.

2. Place cover on cooking well and tight-

en.

3. Turn power on by setting timer to “1”

hour.

4. If the exhaust valve releases pressure

lower than 14.5 PSI, adjust knurled nut

on the pressure switch clockwise to in-

crease pressure. As the pressure pass-

es 14.5 PSI turn the knurled nut

counterclockwise to activate the ex-

haust valve. Test to insure that the ex-

haust vlave continues to be activated

at 14.5 PSI.

5. Continue to adjust until solenoid valve

maintains a pressure between 14 to15

PSI on the pressure gauge. Try to set it

at 14.5 PSI.

6. Open ejector valve to reduce pressure

in the cooking well to approximately 10

PSI.

7. If the power relay/contactor de-ener-

gizes before the pressure reaches 12

PSI, adjust the knurled nut on PS2

clockwise to re-energize the power re-

lay/contactor. As the pressure passed

12 PSI adjust the knurled nut counter-

clockwise to de-energize the power re-

lay/contactor. Test to ensure that the

power relay/contactor continues to de-

energize at 12 PSI.

broaster.com Manual #17897 7/17

This manual suits for next models

2

Table of contents

Other Smokaroma Smoker manuals