11 S/N 4055 WO#38113Copyright 4/07

Smoracy, LLC

MODEL 4680 TRACK SAFETY PROCEDURES

SAFETY PROCEDURES

Never work under or around the Feedwheel without

first disengaging clutch, turning off engine, waiting for

the Cutterhead to come to a complete stop, turning

Battery Disconnect Switch off, and you must have the

ignition key in YOUR possession. Some maintenance

requires that you work under the Feedwheel while it is

in the raised position. The Feedwheel Yoke assembly

is equipped with two safety devices that must be put in

place before work commences.

1. Yoke Lock Bars:

With the engine running, clutch disengaged, and the

Cutterhead completely stopped, raise the Feedwheel

Yoke to its maximum height using the Feedwheel Yoke

manual control valve. Then locate the Hydraulic Yoke

Lock valve and pull the lever. The Yoke Lock Bars

located on top of the Cutterhead housing will extend or

engage.

2. Safety Chain:

Now use the Safety Chain attached to the Discharge

Belt Conveyor rest and secure it to the lug located on

the right side of the Feedwheel Yoke. With the safety

devices in place lower the Feedwheel Yoke until it

contacts the Yoke Lock Bars and the Safety Chain pulls

tight. Disengage clutch, turn off engine, wait for the

Cutterhead to come to a complete stop, turn Battery

Disconnect Switch off, and you must have the ignition

key in YOUR possession. For added safety it is a good

practice to use an additional log chain to help support

the Feedwheel Yoke to the conveyor rest. When all

safety devices are in place you may start performing

maintenance to the machine.

Do Not feed this machine with the top feedwheel

pinned, blocked or secured in the open position.

Before you change the Screen in your Recycler

you must remember to never do any maintenance

work inside or around your Recycler without first

disengaging clutch, turning off engine, waiting for the

Cutterhead to come to a complete stop, turning Battery

Disconnect Switch off, and you must have the ignition

key in YOUR possession.

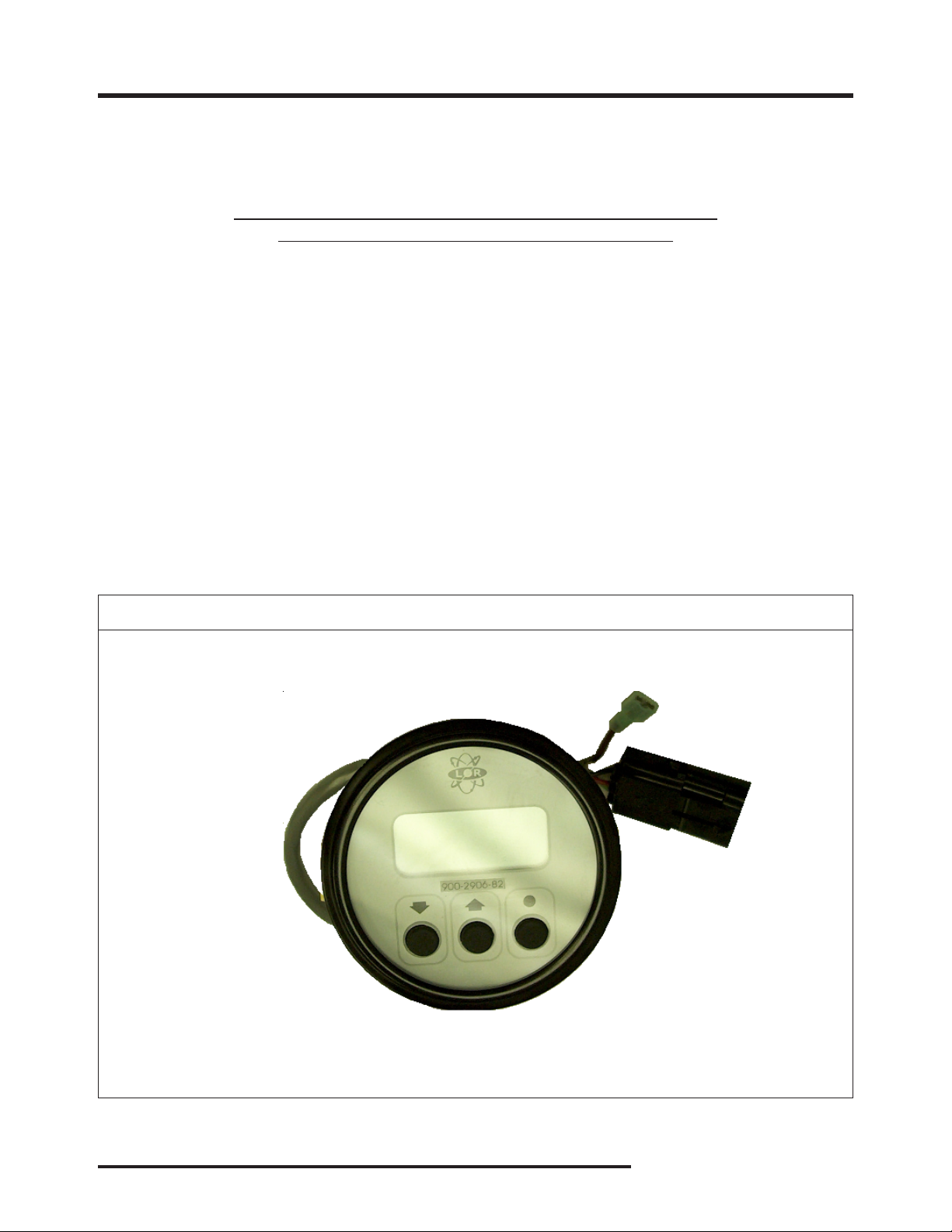

The Recycler is equipped with a remote controlled

electric lift to assist service person while changing the

screen. It is only to be used to assist in changing the

screen!!! Always follow the instructions in the lift

owners manual! Never attempt any maintenance or

service unless the equipment is completely shut down!

Never overload lift or its cable, it is only to be used to

handle the recycler screens (max. 300 lbs. or 136 kg)!

Always keep components 100% operational and

maintained: cable, hooks, wiring, connections, bolts and

nuts, controls, etc.! Always replace wire rope if it shows

kinks, frayed wires, broken or worn strands! Always

wear quality leather gloves when handling wire rope!

Always stay clear of wire rope, hooks, lift and screen

while operating! Always insure that the brake device in

lift is operational and maintained, before using it!

First lower winch cable to Screen area, remove winch

hook stop block from winch hook. Hook winch up to

the back of Screen and snug up the cable. Remove the

eight mounting bolts that hold the screen in place.

Remove Screen using winch. Clean ALL debris from

Screen mounting area, then install new Screen.

Reinsert clamp locks and bolts into Screen mounting

area. Lightly snug up bolts then adjust Screen. Screen

must ALWAYS be at least 1/8” (3.2 mm) minimum from

teeth. When final adjustment is completed torque bolts

to 376 ft.-lbs (510 Nm). Reinstall winch stop block before

reeling in winch cable. Stop block must pull tightly to

engine base when winch operation is complete.

Do not hand feed this machine! This machine is

designed to only be fed by a mechanical log loader.

Feeding material into this machine by hand is not

permitted or authorized. Severe injury or death can

result!

Do not run or operate this machine with any door/

compartment open. Door enclosures are guards, you

can be injured if open during operation.

Do not open the belt shield door unless engine and all

machine parts have completely stopped moving. Open

this door only to check for proper drive belt tension. Do

not start or operate this machine unless door is

securely in place.

DANGER

DANGER

DANGER

WARNING

WARNING