SMORACY Bandit Beast Recycler User manual

RECYCLER

MODEL 1680

OPERATING & PARTS MANUAL

ATTENTION:

Depending on what replacement

parts you are ordering, we will

need the following information:

RECYCLER COMPONENTS

Serial Number

Model Number of Recycler

ENGINE COMPONENTS

Brand

Engine Serial Number

Engine Spec. Number

CLUTCH COMPONENTS

Brand

Serial Number

Assembly of Clutch

Model No: _________________

Serial No: _________________

DEALER:

Name: ____________________

Address: __________________

City/State: _________________

Phone No: _________________

Delivery Date: ______________

Engine Make: ______________

Serial No: _________________

Clutch Make: _______________

Model: _________ S/N _______

Copyright 6/08

1680

BUILT WITH QUALITY

AND DESIGN FIRST

MANUFACTURED BY

SMORACY, LLC

6750 Millbrook Road

REMUS, MICHIGAN, USA 49340

PHONE: (800) 952-0178 IN USA

PHONE: (989) 561-2270 OR 561-2272

FAX: (989) 561-2273 ~ SALES DEPT.

FAX: (989) 561-5343 ~ PARTS/SERVICE

E-MAIL: www.banditchippers.com

I have inspected this equipment and nd it in correct working condition. To the best of my knowledge, the customer and

his/her personnel are aware of, and agree to the above procedures.

Signed: ________________________________________________________________________ Date: ______________

(Dealer Representative)

The equipment has been thoroughly checked by the above named dealer representative, and I am satised with his/her

instructions. I have also read, understand, and agree to reverse side of page.

Signed: ________________________________________________________________________ Date: ______________

(Customer)

IT IS VERY IMPORTANT THAT THIS FORM IS FILLED OUT COMPLETELY & ACCURATELY. IF WE CANNOT READ THE

PURCHASER’S INFORMATION OR IT IS INCORRECT, OUR CUSTOMER LIST WILL NOT BE ACCURATE.

IMPORTANT - THIS FORM MUST BE RETURNED TO THE

CUSTOMER DATA DEPARTMENT WITHIN TEN (10)

DAYS IN ORDER TO VALIDATE WARRANTY

Customer Data Department

6750 Millbrook Road

Remus, MI, USA 49340

Phone: (800) 952-0178 in USA

Phone: (989) 561-2270

Fax: (989) 561-2273

E-mail: www.banditchippers.com

Copyright 3-15 FORM #WV-118

1. _______ Customer has been instructed and understands operation and all safety aspects of operating the equipment.

2. _______ Customer has been instructed and understands that everyone within 100 feet of machine must wear

personal safety equipment (i.e. hard hat, face shield, safety glasses, gloves, ear protection, etc.)

3. _______ Customer has been instructed and understands equipment maintenance schedules, procedures, and that it

is their responsibility to perform maintenance that includes periodic relief valve adjustments, retightening

all fasteners as needed, teeth replacement, especially clutch and belt adjustments, etc.

4. _______ Customer understands hazards of working under, and how to properly lock, the feed wheel in the up position.

5. _______ Customer has been instructed and understands that any machine operators must, always be located within easy

reach of controls and shut down devices, and know how to use, activate, and maintain the re extinguishers.

6. _______ Customer has been instructed, understands, and agrees that all potential operators must use proper shut

down procedures, check for res, and remove all potential re hazards. Always clean off and remove all

ammable debris such as: wood, mulch, oils, fuels, etc. from anywhere materials collect.

7. _______ Customer understands the purpose of and how to operate all the safety devices and guards and to never

attempt to override any safety devices or guards.

8. _______ Customer has been instructed and understands to always remove the ignition key, completely disconnect battery

from cables or by using the battery disconnect switch, and to wait for the cutter head to come to a complete stop.

Allow all the time necessary for the cutter head to come to a complete stop before performing any type of service

or maintenance procedures. Customer has been shown and understands the purpose of the beltshield inspection

hole and to not attempt any maintenance until belts are visually conrmed to have come to a complete stop.

9. _______ Customer has been instructed and understands the operational, electrical, and radio devices on the

machine, and no one is to be within restricted area, around recycler, while it is running.

10. _______ Customer has reviewed and understands limited warranty, and all written and visual instructions.

11. _______ Customer has received, been advised, and understands the manuals, and the Safety/Service video supplied

with the recycler. A video is supplied for equipment models as available.

12. _______ All Danger, Warning and Operational decals are properly displayed on equipment and fully understood by customer.

13. _______ Customer has been instructed, understands, and agrees that all potential operators must: See the supplied video,

be instructed on all the Danger, Warning and Operational decals, read the manual and follow the procedures.

PURCHASER / OWNER INFORMATION:

Company Name __________________________________________________ Contact Name ______________________________

Mailing/Street Address _____________________________________________________ City _______________________________

State ____________________ Zip Code _________ Country ___________________ Telephone Number ( ___ ) _____________

E-mail _______________________________________ Machine Model No. _____________ Date Put Into Service _____________

Machine Serial No. __________________________________ Machine Work Order No. _____________ Machine Hours _________

Engine Make ______________________________ Engine Serial No. ___________________________ Machine Color _________

DEALER / SELLER INFORMATION:

Dealer/Seller Name ________________________________________________ Contact Name _______________________________

Mailing/Street Address _____________________________________________________ City _______________________________

State ____________________ Zip Code _________ Country ___________________ Telephone Number ( ___ ) _____________

WARRANTY VALIDATION FORM

(RECYCLER)

THIS IS GENERAL INFORMATION REVIEW, UNDERSTAND AND FOLLOW DETAILED

INFORMATION IN MANUALS AND DECALS AT ALL TIMES

Before starting the machine, take a minute to

check a few things. The machine should be in an

area restricted from people passing by. This area

around the machine must be free of all objects that

can obstruct your movement when working with the

machine. The machine should be checked for loose

tools or foreign objects, especially in the infeed area.

All tools not in use should be secured in a tool box.

Torn or loose clothing is more likely to get caught in

moving machinery parts or tree branches. Keep such

items as long hair, shirt sleeves, and shirt tails properly

contained. Avoid wearing necklaces, rings, watches,

and especially neckties while operating this machinery.

Make sure the machine is in excellent condition, and all

the guards are in place, tight and secure.

Wear all personal protection equipment and follow

all safety standards per ANSI and OSHA instructions.

Examples of equipment: hard hat, safety glasses, gloves,

ear protection, etc. Do not wear gauntlet or secured t

gloves. Always keep a fully charged re extinguisher with

the machine while operating or servicing the machine.

DANGER

DANGER

This machine is equipped with safety decals, guards

and designs for your protection.

Don’t ever take the machine for granted, always be

cautious and careful when operating your equipment.

Read and follow all the instructions in your

manual thoroughly. Your safety is dependent on

your knowledge of how to operate and maintain this

machine. You may obtain additional copies of this

manual from your Bandit Dealer.

Before operating machine, you must have all potential

operators; read and understand manuals and decals,

watch the video and follow the recommendations.

Regardless of how hard a manufacturer tries to produce

a safe machine, accidents still happen. Normally accidents

are caused by people making mistakes. They do not read

the manual, they ignore warning decals or do not use lock-

outs provided for their safety. This normally happens after

the person has become accustomed to the machinery.

In the initial start up and operation of the machinery, they

are cautious, they are very careful because they do not

understand the machine.

There must be at least two qualied and trained

operators at the work site. They must be positioned in

safe working locations, following safety procedures and

instructions, and aware of each others whereabouts.

There must, also, be at least two people on site during

maintenance and service procedures in case an

accident should occur. Never operate any machine

while under the inuence of drugs or alcohol.

Keep children, bystanders and animals clear of

working area. Never operate equipment that is in

need of repair or adjustment.

DANGER

Signal Word Likelihood of Occurrence Degree of Potential

Injury or Damage

DANGER Will occur if warning is ignored

Can occur if warning is ignored

W i l l o r c a n o c c u r i f w a r n i n g i s i g n o r e d

Important, but not hazard related

Severe

Severe

Minor

Minor to Severe

SAFETY ALERT SYMBOLS AND NOTATIONS

WARNING

CAUTION

NOTICE

Check for res, clean off debris, switch off battery.

Do not leave this machine unattended until all

potential re debris is removed, no re or smoldering

exists and battery is switched off. The diesel engine

creates many hot spots, including exhaust manifold

and turbo. Remove all ammable debris (wood,

mulch, oil, fuels, etc.) from: engine turbo and exhaust,

beside and around engine, under engine and

tanks, inside beltshield, inside control cabinets and

anywhere materials collect. Do not leave this machine

unattended until all potential re hazards are removed,

hot spots are cold and battery is disconnected. Always

keep several type A:B:C re extinguishers on the job

at all times. Smoracy, LLC is not responsible for res

caused by re hazards left to smolder and burn, or

improper shutdown procedures.

WARNING

SAFETY PROCEDURES

SMORACY, LLC BEAST RECYCLERS

CUTTERHEAD SECTION

The Beast Recycler will give you many hours of

production time with inexpensive repairs if you follow

the proper maintenance instruction in the operation

and part manual.

The following is one of the most important parts

to keep a preventative maintenance schedule

on. NEVER RUN THE MACHINE WITH THE

FOLLOWING FAILURES. THIS WILL CAUSE

SERIOUS DAMAGE TO YOUR MACHINE AND

POSSIBLE SERIOUS INJURY TO OPERATORS.

The single most important thing to understand

is that bolts will come loose due to the pounding

and vibration of the machine. ALWAYS keep the

Cutterbody bolts tight (700 ft.-lbs.). Failure to do

so will cause premature wear to the Cutterbody.

Loose bolts could also cause the holder arm to

crack. Replace holder arms if the mounting holes

measure mare than 1.042”. ALWAYS use Smoracy,

LLC replacement parts. Using parts not made for

the machine could cause premature damage to the

machine. Unauthorized use of parts will void warranty.

ALWAYS keep Cutterteeth tight (675 ft.-lbs.). NEVER

allow the Cutterttooth to fall below 1/8” of carbide or

wear material. Replace immediately. ALWAYS keep

the optional Raker Inserts tight (376 ft.-lbs.). The

Cutterbody holder bolts should be 1/8” from the edge

of the arm. When clamping the Cutterbody be sure

the nut does not bottom out.

NOTE: It is a good practice to stop after 20 to 30

minutes of running new teeth and/or Cutterbodies

in order to retighten any loose nuts and bolts to their

specied torque.

Adjust the Infeed Conveyor Chain tension

daily. Incorrect adjustments will cause expensive

Cutterhead and Infeed Conveyor Chain damage.

Adjust per operation and parts manual. The Infeed

Conveyor Chain location must be 3/4” from the tip of

a new tooth. Measure from the end of the sprockets

of the chain head shaft.

START-UP PROCEDURES

1. Wear all applicable personal protective

equipment per ANSI and OSHA standards: hard

hat, gloves, eye protection, ear protection, etc.

2. Observe all safety procedures on decals, in

video tape and from manual.

3. Check inserts and Cutterbody bolts. Change

if necessary.

4. Inspect/replace axle dust caps, oil axles per

axle MFG. manual. Inspect and adjust brakes as

needed per axle MFG. manual.

5. Check the entire machine for any loose parts

or components. Check for loose nuts or bolts,

torque, tighten or replace.

6. Check hydraulic pump and motor shaft for t

and tightness.

7. Check the infeed area for any foreign objects.

8. Daily grease all related bearings and oil all

roller chains.

9. Check radiator, debris screen. Clean as

necessary.

10. Check the fuel level, check the fuel lines, fuel

tank, and ttings for fuel leaks.

11. Check and/or adjust belt tension on recycler

belt drives.

12. Check the engine oil and coolant levels, make

sure they are at the proper level for operation per

Engine MFG.

13. Check hydraulic oil level, this should always

be 7/8 full. Remember to check DAILY to avoid

excessive heat build up.

14. Check the air cleaner and precleaner. Clean

as necessary.

15. Make sure all guards and shields are tight and

securely in place.

16. Check around the machine for tools, cans,

saws, etc.

17. Make sure Discharge Belt Conveyor is located

in a safe direction.

18. Check clutch for proper engagement tension

and lubrication, frequently adjust and grease , per

PTO manufacturers manual recommendations.

19. Block tires and tongue for stability before operation.

20. Check Infeed Conveyor Chain tension, keep

tight and lubricated.

21. Fasten debris screen in front of radiator.

22. Confirm that all manual hydraulic control

valves are in the off position.

23. Fold clutch handle out from its transport

position and pin into place.

24. Make sure clutch is disengaged.

25. Check to ensure Hydraulic Shut Off Valve is open.

26. Turn the Battery Disconnect switch on

27. Check to ensure remote control switch on

engine gauge panel is on manual.

28. Make sure throttle switch is in the idle position.

29. Remove all potential re hazards.

30. Remember to check everything on the checklist.

Copyright 9-02 FORM #Q-110

DATE PURCHASED: _________________

MODEL: ___________________________

SERIAL NUMBER: ___________________

DEALER NAME: ____________________

___________________________________

TO BE RETURNED AFTER THIRTY (30) DAYS OF OPERATION

Please return to: Customer Data Department

6750 Millbrook Road

Remus, MI 49340

PH: (800) 952-0178 in USA

PH: (989) 561-2270

FAX: (989) 561-2273

E-MAIL: www.banditchippers.com

RECYCLER QUALITY REPORT

All of the employees that build your equipment strive to manufacturer the very best quality product on the market.

We would appreciate your efforts in letting us know how we are doing.

We would like you to operate your machine for thirty (30) days and then ll out this questionnaire and mail it to us.

This will help us to keep producing a good product and improving our products through your recommendations.

1. Did your machine perform to your expectations? ____________________________________________

2. Was the machine delivered on schedule? __________________________________________________

3. Was the paint color and nish to your satisfaction? __________________________________________

4. Was machine equipment as ordered? _____________________________________________________

5. Did all welds appear to be of high quality? _________________________________________________

6. Was the overall machine to your liking? ___________________________________________________

7. What problems have you experienced? ___________________________________________________

8. Have any components regularly loosened that caused problems? _______________________________

9. Does the hydraulic system seem to have adequate power for feeding wood into the recycler? ________

10. Is the machine manufactured to accommodate service in an adequate manner? If not, please explain:

___________________________________________________________________________________

11. General comments and/or suggestions: ___________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

12. Would you like to be contacted concerning more of our equipment? _____________________________

YOUR COMPANY:__________________________________

NAME: __________________________________________

ADDRESS: ______________________________________

CITY: ___________________________________________

STATE & ZIP: ____________________________________

PHONE: ( ______ ) ________________________________

E-MAIL: _________________________________________

Smoracy, LLC

Copyright 6/08 PAGE 1

MODEL 1680

TABLE OF CONTENTS

PAGES

INTRODUCTION & WARRANTY .................................................................... 2

SERIAL NUMBER LOCATIONS ..................................................................... 6

SAFETY PROCEDURES ................................................................................ 7

EQUIPMENT SPECIFICATIONS .................................................................... 14

DECALS .......................................................................................................... 16

AUTOFEED ..................................................................................................... 21

CONTROLS ..................................................................................................... 24

TRANSPORTATION PROCEDURES ............................................................. 32

MAINTENANCE .............................................................................................. 35

HYDRAULIC SECTION ......................................................................... 65

CUTTERHEAD SECTION ..................................................................... 70

LUBRICATION & COOLANT ................................................................ 78

ELECTRICAL SECTION ....................................................................... 79

REPLACEMENT PARTS SECTION ............................................................... 81

INFEED CONVEYOR COMPONENTS ................................................. 82

BASE COMPONENTS .......................................................................... 84

CUTTERHEAD COMPONENTS ........................................................... 86

SCREEN COMPONENTS ..................................................................... 88

FEEDWHEEL/YOKE COMPONENTS .................................................. 89

DISCHARGE CONVEYOR COMPONENTS ......................................... 90

FRAME & ACCESSORY COMPONENTS ............................................ 92

AIR BRAKE COMPONENTS ................................................................ 96

TANK COMPONENTS .......................................................................... 98

ENGINE COMPONENTS ...................................................................... 102

HYDRAULIC COMPONENTS ............................................................... 106

REMOTE CONTROL COMPONENTS .................................................. 112

SERVICE RECORD ........................................................................................ 114

TABLE OF CONTENTS

ANYPART,PORTION,DESIGN,NUMBER,SPECIFICATION,AND/ORDIMENSIONINTHIS

MANUAL IS SUBJECT TO CHANGE WITHOUT NOTICE BY THE MANUFACTURER.

NOTICE

Smoracy, LLC

Copyright 6/08 PAGE 2

INTRODUCTION

The purpose of this manual is to provide the user with specications and procedures for the operation,

maintenance and repair of this SMORACY product. As with any piece of equipment, safety should always

be a constant thought while the machine is being operated, serviced or stored. In order to highlight this

consideration, the material which addresses safety is proceeded by the following signal words:

Theequipment isdesignedandmanufacturedinaccordancewiththelatest productindustry standards.

This alone does not prevent injury. It is the operator’s responsibility to use good judgement and follow

the warnings and instructions as indicated in this manual, on the machine and follow all safety standards

per ANSI and OSHA instructions.

Improper use of the product can result in severe personal injury. Personnel using the equipment

must be qualied, trained and familiar with the operating procedures as dened in this manual, prior

to operating the product.

It is the responsibility of the owner or employer to insure that the operator is trained and practices

safe operation while using and servicing the machine. It is also the owner’s responsibility to provide

and follow a regularly scheduled preventative maintenance and repair program on the product,

using only factory approved replacement parts. Any unapproved repairs or modications may not

only damage the machine and its performance, but could result in severe personal injury. Unapproved

repairs or modications will void warranty and eliminate manufacturer of any liability claims. Consult

the equipment manufacturer!!!

Each machine is shipped with a manual, a customer’s check sheet on the product, and any

available parts & service manuals on component parts not produced by this manufacturer. Additional

copies of these manuals and check sheets can be purchased from the manufacturer, or through the

dealer. Engine parts, service and maintenance manuals MUST be purchased through the engine

manufacturer or their dealer.

The producer of this Smoracy product reserves the right to make any modications or revisions to the

design or specications of its machine without advance notice. The producer also reserves the right

to change machine and part prices as needed without advance notice.

INTRODUCTION & WARRANTY

WARNING

WARNING

NOTICE

Signal Word Likelihood of Occurrence Degree of Potential

Injury or Damage

DANGER

WARNING

CAUTION

NOTICE

Will occur if warning is ignored

Can occur if warning is ignored

Will or can occur if warning is ignored

Important, but not hazard related

Severe

Severe

Minor

Minor to Severe

Smoracy, LLC

Copyright 6/08 PAGE 3

SMORACY, LLC

EXPLANATION OF LIMITED WARRANTY

There are several forms that must be

completely filled out and returned to us

in reference to our portion of warranty.

Read and understand the Smoracy Limited

Warrantyresponsibilities. Somecomponents

on your machine are covered by their

respective manufacturers and cannot be

handled through Bandit Industries as stated

in Warranty Section of this manual.

Use this manual to help you resolve what and

where your problem is, in most cases you

can x it easily. If you still have problems,

work through the dealer you purchased the

machine through, or contact Smoracy, LLC

direct if needed.

Make sure the following forms are used, for

us as well as you, to keep track of service

and pending warranty request. It is our

company policy that all parts shipped out will

be invoiced until the possible warranty parts

are returned with a Warranty Claim Form

completed for consideration.

Make sure the Warranty Validation Form is

completed and sent in to us as soon as you

receive the machine. This will activate our

warranty responsibilities.

If Warranty Validation Form is not on le,

all Warranty consideration is null and

void.

The manufacturer will not reimburse the customer or dealer labor costs incurred for installing

“bolt-on” or “slip-on” items, such as hydraulic pumps and motors, control valves, ow dividers,

belts, sheaves, etc. The manufacturer will provide replacement parts to the customer for

defective parts during the warranty period. Defective parts must be returned to Smoracy,

LLC. It will be the customer’s responsibility to install the replacement parts unless arrangements

are made with the selling dealer.

The manufacturer will not reimburse travel costs to servicing dealer unless prior approval has

been obtained from the manufacturer. It is the customer’s responsibility to deliver the machine

to dealer’s service facility, unless other arrangements have been agreed to between selling

dealer and customer.

The manufacturer may elect, at its discretion, to reimburse reasonable labor costs to customer

or dealer for major defect repairs. Diagnostic labor and overtime labor will not be covered

under warranty. Prior approval must be obtained from Smoracy, LLC.

Prior to delivery to nal owner and during storage, this machine must be serviced and

lubricatedtoavoiddamagethatwillnot be covered under warranty, see “Lubrication & Coolant”

page.

Also, damage or premature failure of equipment components because of incorrect or

incomplete service and maintenance by the equipment owner will not be covered under

warranty.

All controls, safety devices, guards, and shields must be correctly operational and securely

in place at all times during equipment operation.

NOTICE

Smoracy, LLC

Copyright 6/08 PAGE 4

SMORACY, LLC LIMITED WARRANTY

(989) 561-2270

INTRODUCTION & WARRANTY

Smoracy, LLC also referred to as “Manufacturer” warrants this new product to be free of defects in

workmanship and material for a period of 6 months or 1000 operating hours, which ever comes rst.

This warranty takes effect upon delivery to the original retail purchaser. The manufacturer at it’s

option will replace or repair at a point designated by the manufacturer, any parts which appear to have

been defective in material or workmanship. The manufacturer is not responsible for labor, consequential

damages, traveling or down time expenses.

This warranty and any possible liability of Smoracy, LLC is expressly in lieu of any other warranties,

expressed or implied, including but not limited to, any implied warranty or merchantability of tness

for a particular purpose and of any noncontractual liabilities including product liabilities based upon

negligence or strict liability. Smoracy, LLC will not be liable for consequential damages resulting from

breach of warranty.

All parties involved agree that the Owner’s Sole and Exclusive Remedy against the Manufacturer,

whether in contract or arising out of this warranty, instructions, representations, or defects shall only

be for the replacement or repair of defective parts as provided herein. In no event or circumstances

shall the Manufacturer’s liability exceed the purchase price of the machine. The buyer also agrees

that no other remedy (including but not limited to consequential or incidental loss) shall be available

to him or her.

It is absolutely necessary to return the Warranty Validation Form, completely and accurately lled

out, and notify Smoracy, LLC in writing within ten (10) days from the date of purchase to validate this

warranty. If Warranty Validation Form is not on le, all Warranty Consideration is NULL AND VOID.

This warranty will not apply if the Smoracy product is not operated with replacement parts or

equipment not manufactured or recommended by Smoracy, LLC.

This warranty will not apply if the Smoracy product is not operated in a manner recommended by the

manufacturer. The following examples would void the warranty:

1. The completed Warranty Validation Form is not on le.

2. The Smoracy product has been abused, or not serviced properly.

3. Repairs or attempted repairs made without prior written authorization.

4. Repairs made due to normal wear are not warrantable.

5. The Smoracy product was involved in, or damaged by an accident.

6. The Smoracy product was damaged from any type of foreign material.

The owner is responsible for all scheduled maintenance as explained in the Operators Manuals.

Negligence of proper maintenance or any other negligence, accident or re; nor with failure to adjust,

tighten, or replace wear items included but not limited to items such as cutter teeth, cutterbodies,

belts, lubrication uids, bearings, lters, hydraulic components, loose nuts or bolts, etc. may void

warranty.

All components and parts being returned to Smoracy, LLC for warranty consideration must

be complete and assembled when delivered. Hydraulic components and parts must be returned

assembled with all uid ports capped or plugged and free of foreign contamination, or warranty will

not be considered.

Smoracy, LLC

Copyright 6/08 PAGE 5

SMORACY, LLC LIMITED WARRANTY

(989) 561-2270

INTRODUCTION & WARRANTY

Smoracy, LLC, reserves the right to alter, improve, revise or modify any parts or products with the altered,

improved, revised or modied parts or products. They also may change design, specications, or part prices

without advance notice.

Smoracy, LLC, is NOT responsible for updating or upgrading completed machines with design changes that

are made after it’s production.

Smoracy, LLC, expects the Customer/Owner to bring their machine to the Dealer/Manufacturer for Warranty

Repairs. The Manufacturer DOES NOT pay Dealers or Customers for bringing their machine in for repair. Nor

does the Manufacturer furnish loaner machines while the unit is being repaired.

In order to process any warranty claims, it is the owner’s responsibility to report the claims promptly to the

Manufacturer, or our authorized dealer from whom the equipment was purchased.

It is necessary to include the following information on any and all requests for warranty:

1) Warranty Claim Form, obtained from Smoracy, LLC or it’s dealers, completely and accurately lled out.

2) Dealer from whom purchased.

3) Date of delivery.

4) Serial number of unit.

5) Model number of unit.

6) Engine make and serial number.

7) Length of time in use (hours on machine).

8) Date of Failure.

9) Nature of Failure.

Caterpillar Engines (Thru 275Hp) 1-800-551-2938 E.S.I. 1-815-985-0383

Caterpillar Engines (300Hp & Up) 1-866-228-2111 L.O.R. MFG. 1-866-644-8622

Cummins Engines 1-248-573-1592 Omnex Radios 1-419-294-4985

Perkins Engines 1-800-551-2938 Dexter Axles 1-574-295-7888

Honda Engines 1-734-453-6258 Tires 1-989-463-4088

John Deere Engines 1-888-803-9175 Caterpillar Tracks 1-309-636-1100

PT Tech Clutch 1-330-414-3172 Interstate Batteries 1-800-331-2000

NACD, Rockford Clutch 1-800-383-9204 Petro-Canada Hydrex XV 1-888-284-4572

Twin Disc Clutch 1-262-638-4000

(Phone numbers for outside the continental U.S. can be supplied from your phone directory or local Smoracy dealer.)

CONTINENTAL U.S. INFORMATION PHONE NUMBERS FOR ACCESSORIES

(NOT COVERED UNDER PRODUCT WARRANTY PROGRAM)

NOTICE This warranty applies only to new and unused equipment or parts thereof manufactured by

Smoracy, LLC and is void if the machine is operated with replacement parts or equipment not manufactured or

recommended by Smoracy, LLC.

All other components are warranted by their respective manufacturers (i.e. engines, axles, hydraulic pumps

and motors, clutches, tires, batteries, etc.) Any machines used for lease or rental purposes warranty is limited

to 90 days from the rst day of initial service.

NOTICE Clutch maintenance and adjustments and engine maintenance (air lter maintenance, oil

changes, oil lter maintenance, etc.) are important to your machine. Refer to the clutch or engine manual

for the maintenance schedule. Failure to perform the clutch or engine maintenance will void the warranty

with the respective manufacturer, Smoracy, LLC does not warranty these components!

Smoracy, LLC

Copyright 6/08 PAGE 6

MODEL 1680

TYPICAL GRINDER SERIAL NUMBER AND/OR

WORK ORDER NUMBER LOCATIONS

1. Serial Number stamped into

bearing pad.

2. Serial Number on equipment tag.

3. Work Order Number stamped

into top of rear bumper.

NOTE: Theengine informationis located on the

engine block. The clutch information

is located on the clutch plate (if

equipped).

SERIAL NUMBER LOCATIONS

23

1

Smoracy, LLC

Copyright 6/08 PAGE 7

MODEL 1680

WARNING

SAFETY PROCEDURES

Before starting the machine, take a minute to check a

fewthings. Therecyclershouldbeinanarearestricted

frompeople passing by. Thisareaaround therecycler

mustbe free of all objectsthat canobstruct movement

when working with the recycler. The machine should

be checked for loose tools or foreign objects, especially

inthe infeedconveyor area. All tools not in use should

be secured in a tool box.

Operators must at all times be located within easy

reach of all feed control and shut-off devices when the

unit is running. They must be attentive and prepared

to activate the devices.

Torn or loose clothing is more likely to get caught in

moving machinery parts. Keep such items as long hair,

shirt sleeves, and shirt tails properly contained. Avoid

wearing necklaces, rings, watches, and especially

neckties while operating this machinery. Make sure

the machine is in excellent condition, and all the guards

are in place, tight and secure.

Wear all personal protection equipment and follow

all safety standards per ANSI and OSHA instructions.

Examples of equipment: hard hat, face shield, safety

glasses, gloves, ear protection, etc. Always keep a

fully charged re extinguisher with the machine while

operating and servicing the machine.

SAFETY PROCEDURES

DANGER

DANGER

DANGER

The words Danger, Warning, Caution, and

Notice are used on the safety decals and throughout

this manual, to make you aware of the safety

procedures. These procedures are very important,

read and obey them.

YOUR SAFETY IS VERY IMPORTANT TO US!

This machine is equipped with safety decals, guards

and designs for your protection.

Don’t ever take the machine for granted, always

be cautious and careful when operating your

equipment.

Read and follow all the instructions in your

manual thoroughly. Your safety is dependent on

your knowledge of how to operate and maintain this

machine. You may obtain additional copies of this

manual from your Smoracy, LLC Dealer.

Before operating machine, you must have all potential

operators; read and understand manuals and decals,

watch the video and follow the recommendations.

Regardless of how hard a manufacturer tries to

produce a safe machine, accidents still happen.

Normally accidents are caused by people making

mistakes. They do not read the manual, they ignore

warning decals or do not use lockouts provided for

their safety. This normally happens after the person

has become accustomed to the machinery. In the

initial start up and operation of the machinery, they

are cautious, they are very careful because they do

not understand the machine.

This equipment is intended for use by personnel

who are experienced with similar equipment. Always

operate safely. It is also recommended that someone

else is present while operating or servicing in case an

accident should occur. Never operate any machine

while under the inuence of drugs or alcohol.

Keep children, bystanders and animals clear of

working area. Never operate equipment that is in need

of repair or adjustment.

Smoracy, LLC

Copyright 6/08 PAGE 8

MODEL 1680

SAFETY PROCEDURES

SAFETY PROCEDURES

Entanglement in the discharge belt conveyor can

cause serious injury. Stay away from the conveyor

during operation. If the conveyor drive is not shut

off, a stalled conveyor may restart unexpectedly as

the obstruction is removed. Avoid the discharge belt

conveyor area. Ejected material can cause serious

injury. Stay away! Stay clear of thrown and falling

objects. Take the following precautions to avoid injuries

from thrown and falling objects: Wear all applicable

safety equipment. Only properly protected workers are

allowedin“thrownobjectarea”. Allmachinesin“thrown

objectarea”musthaveoverheadprotection. Machines

used to load the recycler must have an enclosed cab.

Do not leave controls unattended while machine is

operating. Locate the recycler a safe distance from

buildings, public roads and populated areas.

DANGER

Never stand at the entrance to the infeed conveyor

or look over the infeed conveyor side panels. Never

attempt to manually dislodge material located on

the infeed conveyor while the machine is running.

Never raise feedwheel yoke and look inside, or look

down infeed conveyor while machine is working.

Entanglement in infeed conveyor can cause serious

injury. Stay away from the infeed conveyor during

operation. If the conveyor drive is not shut off, a stalled

conveyor may restart unexpectedly as the obstruction

isremoved. Donothandfeedrawmaterialontoinfeed

conveyor.

DANGER

Avoid power lines. Electrocution is possible if the

recycler touches a power line. Take the following

precautions. Position the recycler and any loading

equipmentatleast10feet(3meters)fromelectriclines.

If the machine contacts an electric line stay away from

the machine.

DANGER

DO NOT operate this machine indoors! Exhaust

fumes can be fatal. Never refuel while the machine is

running. Never refuel in the shop or building. Always

refuel in a well ventilated area, away from sparks or

open ames, DO NOT SMOKE. Extinguish all smoking

materials. Wipeup allspilledfuel beforerestartingthe

engine. Do not ll above 1/2” (12.7 mm) from top of

tank.

To obtain the most from your machine, for the least

amount of cost, it is a good practice to set up and follow

a scheduled preventative maintenance program. It will

eliminate many possible problems and down time.

DANGER

Smoracy, LLC

Copyright 6/08 PAGE 9

MODEL 1680

SAFETY PROCEDURES

SAFETY PROCEDURES

DANGER

Do not work on the machine if the engine is running

with the clutch disengaged. A clutch can self engage

if either the pilot or throw-out bearing happens to seize

to the main output shaft.

There are various types of clutches (PTO’s)

available for this type of equipment. Make sure to

study the original clutch manufacturer’s manual that

isprovided with themachine and followits instructions

for operation, service, and adjustments. Some styles

require clutch engagement to be maintained so that it

takes a lot of force, others will require very little force,

and some are push button, electric, manual lever, or

hydraulic activation. Each different style clutch (PTO)

is a very expensive item that will fail if not correctly

maintained and adjusted. It will be quite costly if a

few minutes are not taken daily, weekly, and monthly

to keep the clutch serviced as required.

The operator must take care in the engagement

and disengagement of the clutch, engine RPM should

always be below 1000 RPM. When the engine has

sufciently warmed up, bump the clutch handle against

engagement to start the cutterhead turning. This will

have to be repeated until the cutterhead is turning at

proper ratio with engine RPM. Then push the handle

all the way in gear until it locks into position securely.

After engagement raise engine RPM to full throttle.

Engaging and disengaging the clutch at high engine

RPM will quickly and excessively wear out clutch plates

as well as bearings. Refer to clutch manufacturer’s

manual for proper service and operation.

DANGER

Never work under or around the feedwheel without

rst disengaging clutch, turning off engine, waiting for

the cutter head to come to a complete stop, turning

battery disconnect switch off, and make sure the

ignition key is in your possession. Some maintenance

requires that you work under the feedwheel while it is

in the raised position. The feedwheel yoke assembly

is equipped with two safety devices that must be put

in place before work commences.

1. Yoke Lock Pins:

With the engine running, clutch disengaged, and the

cutterhead completely stopped, raise the feedwheel

yoke to its maximum height using the feedwheel yoke

manual control valve. Install the yoke lock pins in

the yoke lock holes or locate the hydraulic yoke lock

valve and pull the lever. The hydraulic yoke lock pins

located on top of the cutterhead housing will extend

or engage.

2. Safety Chain:

Now use the safety chain attached to the discharge

belt conveyor rest / feedwheel lift cylinder mount and

secure it to the lugs located on the feedwheel yoke.

With the safety devices in place lower the feedwheel

yoke until it contacts the yoke lock pins and the safety

chain pulls tight. Disengage clutch, turn off engine,

wait for the cutterhead to come to a complete stop,

turn battery disconnect switch off, and make sure the

ignition key is in your possession. For added safety

it is a good practice to use an additional chain to help

support the feedwheel yoke to the discharge belt

conveyorrest / feedwheellift cylindermount. Whenall

safety devices are in place you may start performing

maintenance to the machine.

Do Not feed this machine with the top feedwheel

pinned, blocked or secured in the open position.

Avoid moving parts. Keep hands, feet, and clothing

away from power driven parts. Keep all guards and

shields in place and properly secured.

DANGER

Stay away from the feedwheel and cutterhead

areas. Never stand close to the feedwheel assembly

while the machine is running. Never attempt to do

work on or near a raised feedwheel without making

sure all safety devices are secured. Always install or

engage the yoke lock pins, and use the safety chain to

secure the feedwheel assembly to the discharge belt

conveyor rest / feedwheel lift cylinder mount. Follow

proper shut down procedures before beginning any

type of maintenance to the recycler.

DANGER

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth defects,

and other reproductive harm.

NEVER sit, stand, lay, climb or ride anywhere

on this machine while it is running, operating, or in

transit. You will be injured.

DANGER

Smoracy, LLC

Copyright 6/08 PAGE 10

MODEL 1680

SAFETY PROCEDURES

SAFETY PROCEDURES

DO NOT run or operate this machine with any

door/compartment open. Door enclosures are guards,

you can be injured if open during operation.

DONOTopenthebeltshield doorunlessengineand

all machine parts have completely stopped moving.

Open this door only to check for proper drive belt

tension. DONOTstart oroperate thismachine unless

door is securely in place.

DANGER

WARNING

DO NOT operate this machine unless all hydraulic

control devices operate properly. They must function,

shift and position smoothly and accurately at all times.

Faulty controls can cause personal injury!

WARNING

Inspect raw materials pile for prohibited materials.

The following are examples of prohibited materials to

be avoided. Material and products containing toxic

substances, explosive or ammable materials including

chemicals, liquids, gases, pressurized containers etc.,

tires, glass, heavy rigid plastic, sheet metal, masonry,

stone materials, and solid metals.

DANGER

The machine was built with a cutterhead hood

engine disable plug which disables the engine if it is

not installed properly with the cutterhead hood in the

closed position. Correctly installed and maintained, the

engine will not start or it will shut off if the cutterhead

hood engine disable plug is disconnected. The

cutterhead hood must NEVER be open or opened

during operation.

WARNING

It is very important after you have operated a new

machine for approximately an hour to shut down the

machine and recheck all nuts and bolts. It is normal

for nuts and bolts to loosen once on a new piece of

machinery. If you tighten them now, there is a good

possibility they won’t loosen again. Certain nuts and

bolts must be checked periodically such as cutterbody

and cutter teeth nuts and bolts, etc. for torque and

t.

Most of the nuts used on the Smoracy Recycler are

self locking. After a nut or bolt has been removed ve

times, it should be replaced to insure proper tightness.

This is especially critical on the cutterbody and cutter

tooth nuts and bolts!

After the engine is started, let the cutterhead turn at

the lowest RPM’s possible. Listen for any type of noise

that is foreign. Any steel on steel noise is foreign. If

you hear a noise, stop the engine, nd the problem

and x it.

WARNING

WARNING

Never use jumper cables during freezing temperatures.

Tow the machine inside and allow the battery time to

warm up. If the machine must be started outside,

inspect the battery acid for ice formation. Explosion

will occur with a frozen battery. If the machine is going

to be operated in excessively cold conditions, a larger

cold cranking amp battery may be needed to insure

proper and prompt starting. Never use jumper cables

in a conned or unventilated area. Battery acid fumes

are explosive. Battery acid can cause severe burns.

Never expose an open ame or spark near the battery.

Keep all burning materials away from the battery.

When servicing the battery, shield eyes and face, and

do not smoke. Service in a well ventilated area.

WARNING

It is very important after you have operated a new

machine for approximately an hour to shut down the

machine and recheck all hydraulic ttings. Retighten

as needed.

DO NOT GO NEAR HYDRAULIC LEAKS! High

pressure oil easily punctures skin causing serious

injury, gangrene, or death. Avoid burns from uid. Hot

uid under pressure can cause severe burns. DO NOT

use ngers or skin to check for leaks. Lower load or

relieve hydraulic pressure before loosening ttings.

Relieveallpressureinthesystembeforedisconnecting

the lines, hoses, or performing other work. Use a piece

of cardboard to nd leaks. Never use your bare hands.

Allow system to cool down to ambient temperature

before opening any coolant or hydraulic oil system.

In cold weather situations let your hydraulic system

idle for approximately 15 minutes to allow the system

to warm up to operating temperature. Beast knives are sharp and can be dangerous. It is

always necessary for your protection to be extra careful

and wear leather gloves when handling knives.

DANGER

The knives must be securely fastened and torqued

in position. If one comes loose or breaks during

operation, someone or something may get injured.

DANGER

Smoracy, LLC

Copyright 6/08 PAGE 11

MODEL 1680

DO NOT hand feed this machine! This machine is

designed to only be fed by a mechanical log loader.

Feeding material into this machine by hand is not

permitted or authorized. Severe injury or death can

result!

DANGER

Do not attempt to start the engine or engage the

engine PTO (power-take-off) system on this machine

if the cutterhead is jammed or frozen in place. If you

do, you will damage or ruin the drive belts and/or the

PTO which will not be covered under warranty and will

cost you down time and money.

NOTICE SAFETY PROCEDURES

SAFETY PROCEDURES

Always block the tires and the machine tongue

whenever the machine is unhooked for operation.

DO NOT rely on the hydraulic stabilizers. With the

bouncing and rocking, the stabilizer cylinders may

have a tendency to leak off allowing the machine to

dropslowlydown. Donot depend onthemforstability.

Install secure blocking as needed.

DANGER

Keep the machine in good condition. Be sure the

machine is in good operating condition and that all

safety devices, including guards and shields are

installed and functioning properly. Visually inspect the

machinedailybeforestartingthemachine. Refertothe

“Daily Start Up & Maintenance”. Make no modications

to your equipment unless specically recommended

or requested by Smoracy, LLC.

DANGER

Check laws and regulations. Know and obey all

federal, state, and local laws and regulations that

apply to your work situation and the transportation of

a machine this size.

WARNING

WARNING

Before transporting the machine: 1) Clean out

any existing material on the machine by allowing

the machine to operate for several minutes without

further loading. 2) Idle engine and disengage clutch.

3) Make sure that the feedwheel is in the lowered

position. 4) Make sure all manual hydraulic control

valves are in the off position. 5) Switch engine off

and remove ignition key. 6) Lock radiator debris

screen in transport position, if equipped. 7) Stow

remote cable controls inside hydraulic compartment.

8) Lock compartment doors. 9) Clean off all debris

and potential re hazards from the machine. Along

with these procedures make sure to follow all of the

transportation procedures on pages 32 - 34. Make sure

that the tongue has been raised to the proper height

andattach the machinesecurelyto thetowing vehicle.

Once secured to vehicle, locate stabilizer leg and

secure it in the transport position. Always hook safety

chains to vehicle by crossing them under the tongue

allowing enough slack to avoid binding or dragging

the ground when making turns. Check brakes and

highway lights make sure that they are all operating

properly. Check that the plug terminal functions

match the towing vehicle for proper operation. Make

sure that the discharge conveyor is in the transport

position. Be sure to check tire pressure before you

begintotransportthemachine. If machine is equipped

with a vise, make sure to secure in place and clamp

jaws closed. Close and secure any of the following,

if equipped: tool box, battery box, engine cowl doors

and side panels, radiator debris screens, inspection

doors, cabinet doors, housing covers, tank caps and

covers, etc.

Tongue jacks or optional rear stabilizers, whether

hydraulic or manually operated are designed to stabilize

the machine. The tongue jack or rear stabilizers are

not designed to hold the machine off the ground at

any time. Install secure blocking and / or chocking as

needed. Before transporting the machine, insure the

tongue jack and rear stabilizers are fully retracted and

secured to the transport position.

NOTICE

Smoracy, LLC

Copyright 6/08 PAGE 12

MODEL 1680

Check for res, clean off debris, switch off battery.

Donotleavethismachineunattended until allpotential

re debris is removed, no re or smoldering exists

and battery is switched off. The diesel engine creates

many hot spots, including exhaust manifold and turbo.

Remove all ammable debris (wood, mulch, oils, fuels,

etc.) from: engine turbo and exhaust, beside and

around engine, under engine and tanks, inside belt

shield, inside control cabinets, anywhere materials

collect. Do not leave this machine unattended until

all re hazards are removed, hot spots are cold and

battery is disconnected. Always keep several re

extinguishers on the job at all times. Smoracy, LLC

is not responsible for res caused by re hazards

left to smolder and burn, or improper shutdown

procedures.

WARNING

SAFETY PROCEDURES

SAFETY PROCEDURES

If standard or available the self activating fire

extinguishers located in various places will not stop

your machine from burning. They are there to help

put out a re that may start. If a re gets going after

you have left the machine, they will be ineffective.

You must clean the debris away from the engine

and other hot areas before leaving the machine! It

is your responsibility to properly maintain and test

the extinguishers as instructed by the directions that

come with the re extinguisher. If you do not have that

information contact Smoracy, LLC.

WARNING FIRE HAZARD

Smoracy, LLC

Copyright 6/08 PAGE 13

MODEL 1680 SAFETY PROCEDURES

SAFETY PROCEDURES

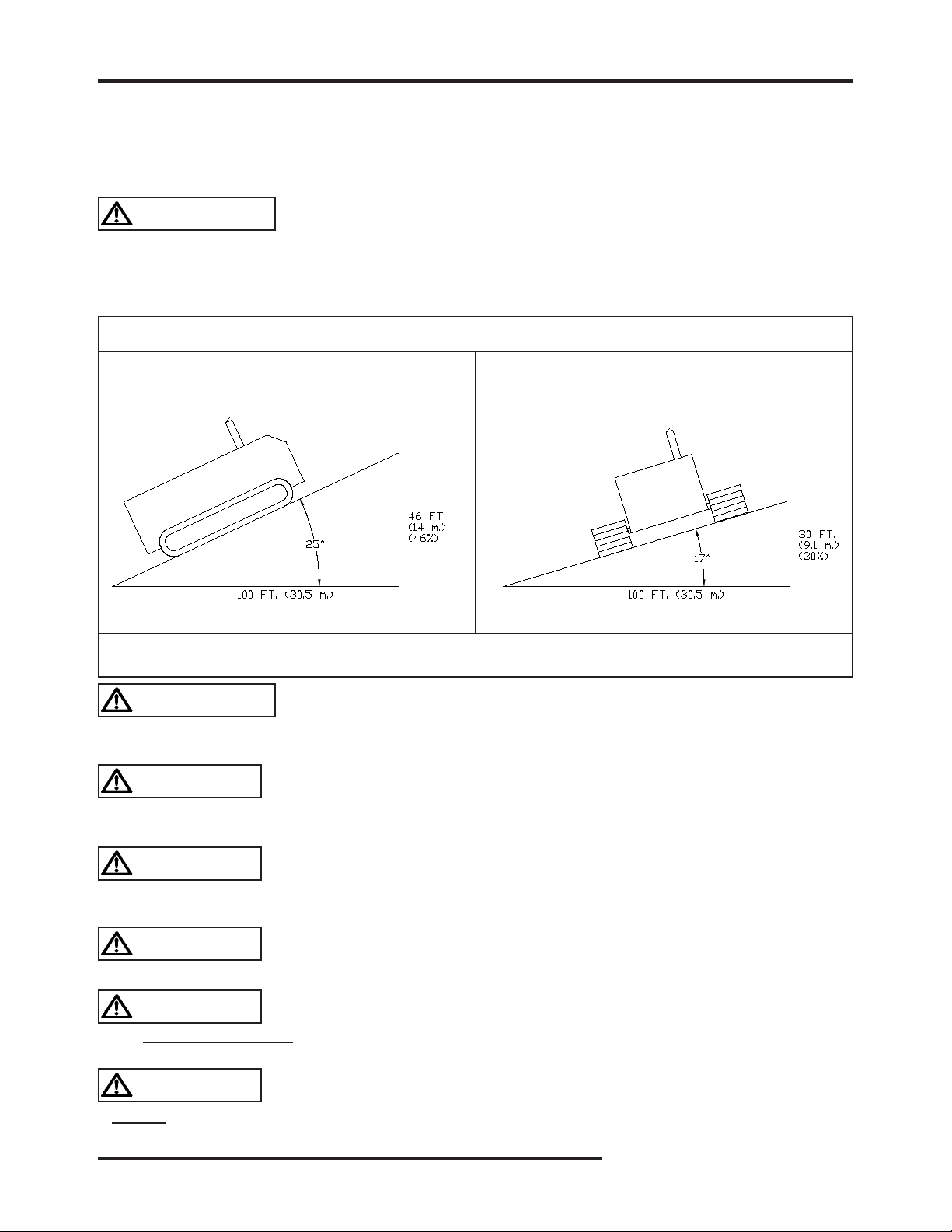

Do not attempt to operate the machine on an ascending or descending slope of more than 25° or 46% or a

side slope of more than 17° or 30%, it is Dangerous and could be Fatal. This is the maximum slope grade the

machine can be operated on if the hydraulics, self propelled undercarriage, and engine are running at maximum

performance and good traction is sustained.

The machine should never be parked on a slope at any time. The machine can coast or creep causing

equipment and/or personal injury.

DANGER

Make sure everyone is clear of machine before moving the machine. Stay clear of undercarriagetravel system

when the machine is moving.

DANGER

DO NOT entangle feet or hands in undercarriage travel system.

DANGER

NEVER sit, stand, lay, climb or ride anywhere on this machine while it is running, operating, or in transit. You

will be injured.

DANGER

Use EXTREME CAUTION when traveling over non-level surface! This machine can tip over or tip backwards

on non-level surface. You will cause engine damage, machine damage and possible personal injury!

DANGER

WARNING

Any increase from the specied maximum operating angles may cause loss of lubrication function and damage

the engine.

WARNING

Maximum Slope Grade

Diagram shows percentage to degree of slope.

Percentage is in vertical feet for every 100 horizontal feet.

Ascending or Descending Slope Side Slope

IF MACHINE IS EQUIPPED WITH A SELF PROPELLED UNDERCARRIAGE

Machines equipped with undercarriage tracks are shipped with a manual from the track manufacturer. Refer

to it for service, operation, and safety information.

Smoracy, LLC

Copyright 6/08 PAGE 14

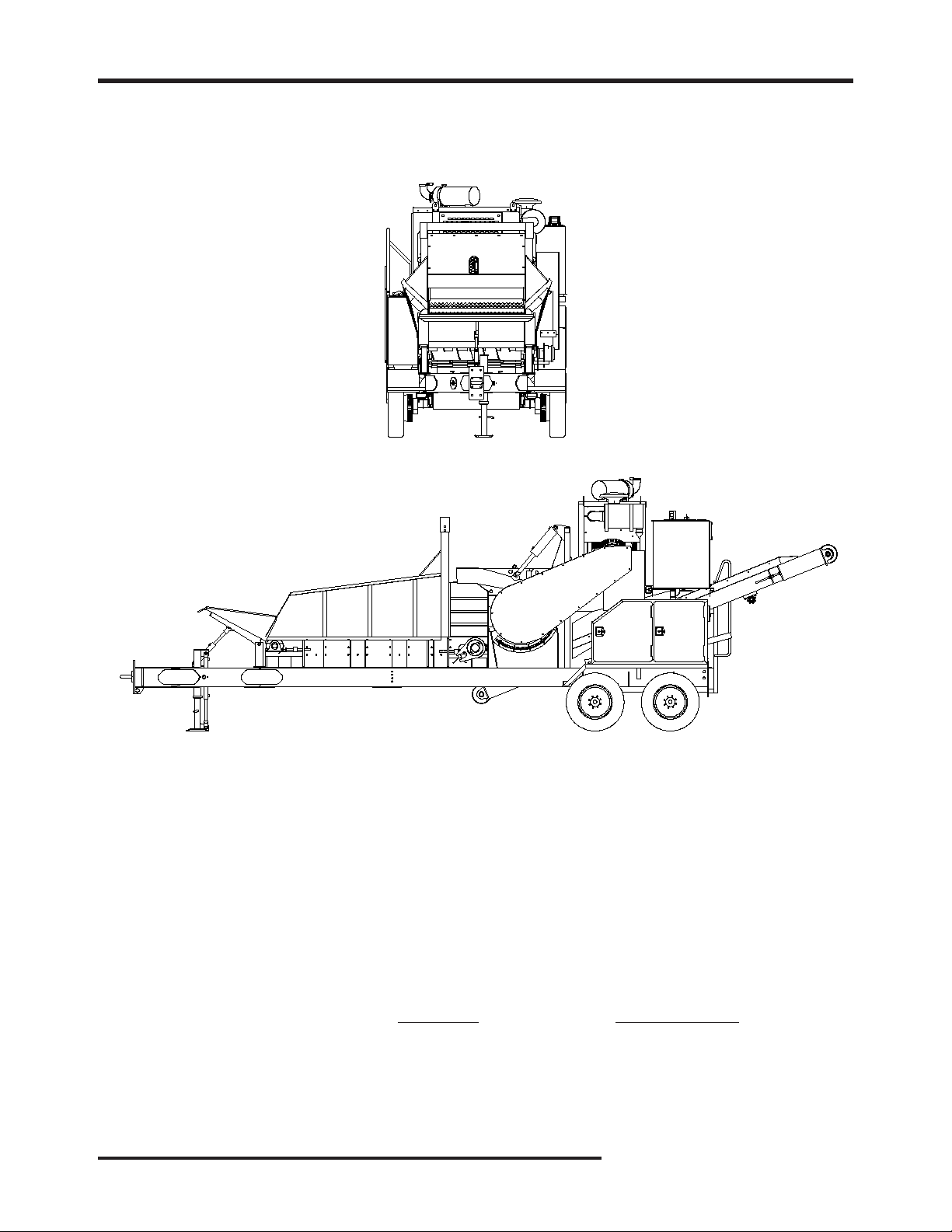

MODEL 1680 EQUIPMENT SPECIFICATIONS

EQUIPMENT SPECIFICATIONS

Approximate Dimensions & Weights

(Dimensions & weights will vary depending on optional equipment)

Approx. Model 1680: 26,000 lbs. (11,790 kg)

Weight: Model 1680 Track: 32,500 lbs. (14,740 kg)

(Approximate weights depending on engine and equipment options.)

Overall Model 1680: Height: 12’ (3.7 m), Length: 32’ (9.8 m), Width: 8’ (2.4 m)

Dimension: Model 1680 Track: Height: 12’ 4” (3.8 m), Length: 27’ (8.2 m), Width: 8’ 2” (2.5 m)

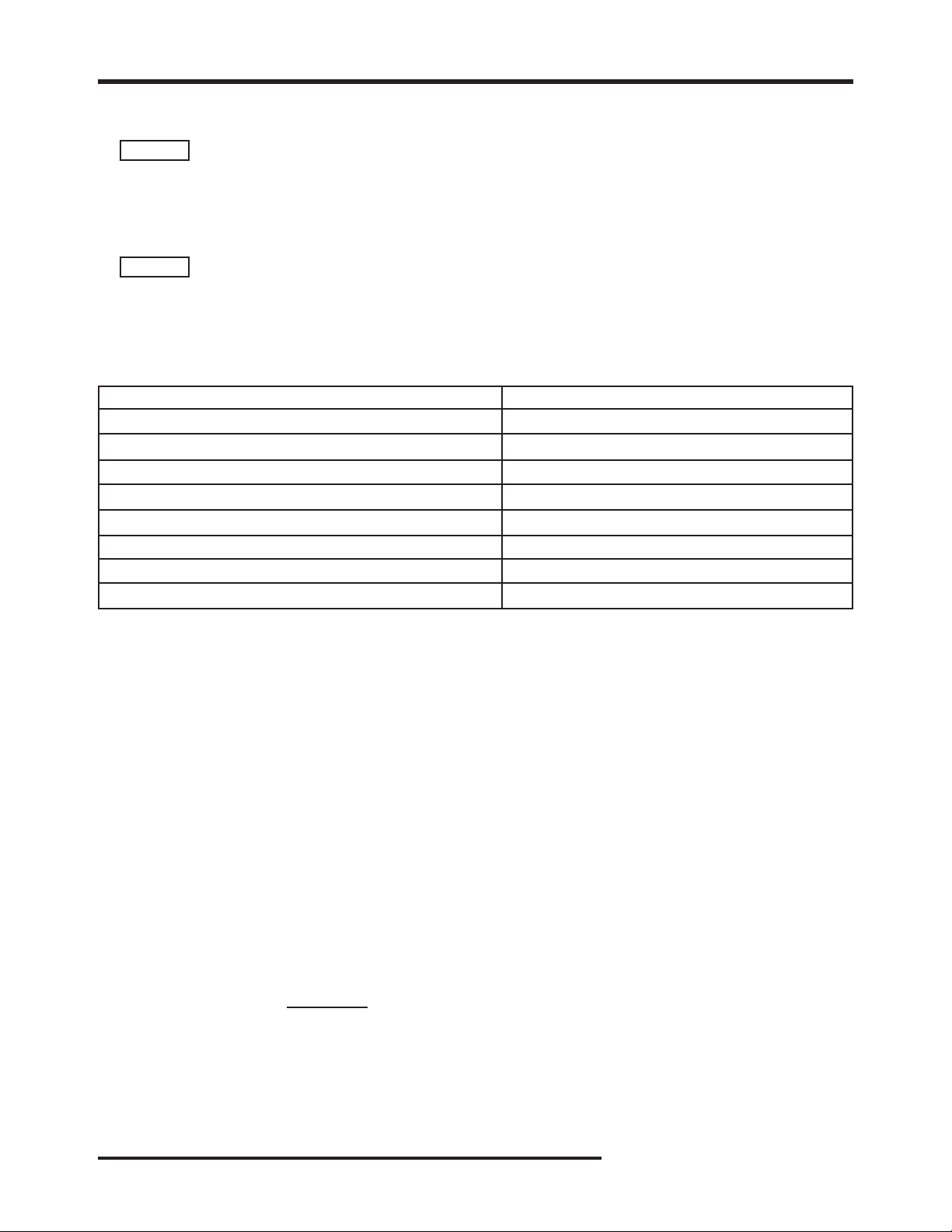

Model 1680 Model 1680 Track

Fuel Tank Capacity: 50 Gallons (189 Liters) 50 Gallons (189 Liters)

Hydraulic Tank Capacity: 60 Gallons (227 Liters) 60 Gallons (227 Liters)

(Approximate dimension depending on equipment options.)

Other manuals for Bandit Beast Recycler

1

This manual suits for next models

1

Table of contents

Other SMORACY Lawn And Garden Equipment manuals