SMSC EMC2106 User manual

SMSC EMC2106 Revision 1.1 (08-22-07)

Copyright © 2007 SMSC or its subsidiaries. All rights reserved.

The information contained herein is proprietary to SMSC, shall be used solely in accordance with the agreement pursuant to which it is provided,

and shall not be reproduced or disclosed to others without the prior written consent of SMSC. Although the information is believed to be accurate,

no responsibility is assumed for inaccuracies. SMSC reserves the right to make changes to this document and to specifications and product

descriptions at any time without notice. Neither the provision of this information nor the sale of the described semiconductor devices conveys any

licenses under any patent rights or other intellectual property rights of SMSC or others. The product may contain design defects or errors known as

anomalies, including but not necessarily limited to any which may be identified in this document, which may cause the product to deviate from pub-

lished specifications. SMSC products are not designed, intended, authorized or warranted for use in any life support or other application where

product failure could cause or contribute to personal injury or severe property damage. Any and all such uses without prior written approval of an

officer of SMSC will be fully at the risk of the customer. SMSC is a registered trademark of Standard Microsystems Corporation (“SMSC”).

SMSC DISCLAIMS AND EXCLUDES ANY AND ALL WARRANTIES, INCLUDING WITHOUT LIMITATION ANY AND ALL IMPLIED WARRAN-

TIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE, AND AGAINST INFRINGEMENT AND THE LIKE, AND ANY

AND ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR USAGE OF TRADE. IN NO EVENT SHALL SMSC BE LIABLE FOR

ANY DIRECT, INCIDENTAL, INDIRECT, SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES; OR FOR LOST DATA, PROFITS, SAVINGS

OR REVENUES OF ANY KIND; REGARDLESS OF THE FORM OF ACTION, WHETHER BASED ON CONTRACT; TORT; NEGLIGENCE OF

SMSC OR OTHERS; STRICT LIABILITY; BREACH OF WARRANTY; OR OTHERWISE; WHETHER OR NOT ANY REMEDY OF BUYER IS

HELD TO HAVE FAILED OF ITS ESSENTIAL PURPOSE, AND WHETHER OR NOT SMSC HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES.

EMC2106 EVB User Manual

EMC2106 EVB User Manual

Revision 1.1 (08-22-07) SMSC EMC2106

2

1 Overview

The EMC2106 is an SMBus compliant fan controller with up to five (up to 4 external and 1 internal)

temperature channels including hardware set thermal / critical shutdown circuitry. The fan drivers can

be operated using two methods each with two modes. The methods include an RPM based Fan Speed

Control Algorithm and a direct fan drive setting. The modes include manually programming the desired

settings or using the internal programmable temperature look-up table to select the desired setting

based on measured temperature.

The temperature monitors offer 1°C accuracy (for external diodes) with sophisticated features to

reduce errors introduced by series resistance and beta variation of substrate thermal diode transistors

commonly found in processors.

The EMC2106 also includes a hardware programmable temperature limit and dedicated system

shutdown output for thermal protection of critical circuitry.

A block diagram of this EVB is shown in Figure 1.1 below.

Figure 1.1 EMC2106 EVB Block Diagram

EMC2106

28 QFN

C8051F320

USB to SMBus Bridge

Temperature

Monitoring

Circuits

USB

Connector

SMBus

Connector

SMBus

FAN

32.768kHz

Oscillator

ALERT#

HW Thermal

Shutdown

Config

EMC2106 EVB User Manual

SMSC EMC2106 Revision 1.1 (08-22-07)

3

1.1 Related Documents

The CD included with the evaluation board contains the following documents:

nEvaluation Board Checklist

nBill Of Materials

nSchematic

nDatasheet

nChip Manager Application

nRegister Definition File (EMC2106.xml)

EMC2106 EVB User Manual

Revision 1.1 (08-22-07) SMSC EMC2106

4

2 Getting Started

2.1 System Requirements

To use the EVB you will need:

nA PC running Windows 2000 or XP

nDisplay resolution 800x600 (or larger to view several windows simultaneously)

nAn available USB port

2.2 Feature Summary

nThe SMSC Chip Manager application allows viewing and changing register values

nGraphing of any register

nHeaders for connecting a remote diode or CPU/GPU

nResistance Error Correction verification

nSaving of settings of all registers allowing for quick loading at a later time

nAutonomous register loading via included EEPROM

nUSB communication to evaluation board

nAn external SMBus master may also be used via jumper settings

2.3 Installing the EVB

1. Install the Chip Manager (ChipMan) application and device driver on a PC by running Setup.exe

from the ChipMan distribution CD. A revision history and install/uninstall notes may be found in the

readme.txt file on the disk.

2. Connect the supplied USB cable to an available USB port on the PC. Plug the “mini-B” end of the

USB cable into EVB connector P2. The +3.3V and Bridge ACT LEDs should illuminate. After the

EVB is connected to the PC the “Find New Hardware” wizard will pop up for USB driver installation.

Follow the instructions in the readme.txt file to complete the installation process.

3. Start the EVB Software by selecting the Chip Manager application from the SMSC folder from the

Programs Windows Start menu. The EVB will initialize and the Chip Manager Quick Help screen

will appear as in Figure 2.1. The USBAct LED should be blinking when the Chip Manager is

running. For more help with ChipMan, select Help -> Contents for an html based help document

as shown in Figure 2.2.

Note: The SMSC ChipMan application allows viewing and changing register values for a variety of

EVBs including the EMC2101, EMC2102, EMC2103, EMC2104, EMC2105 and EMC2106. The

ChipMan software only needs to be installed once to support all of these EVBs. The list of

supported EVBs may be found in the pulldown menu under Options -> Select Device.

EMC2106 EVB User Manual

SMSC EMC2106 Revision 1.1 (08-22-07)

5

..

Figure 2.1 Chip Manager Quick Help Startup Screen

EMC2106 EVB User Manual

Revision 1.1 (08-22-07) SMSC EMC2106

6

..

Figure 2.2 Chip Manager Help Screen

EMC2106 EVB User Manual

SMSC EMC2106 Revision 1.1 (08-22-07)

7

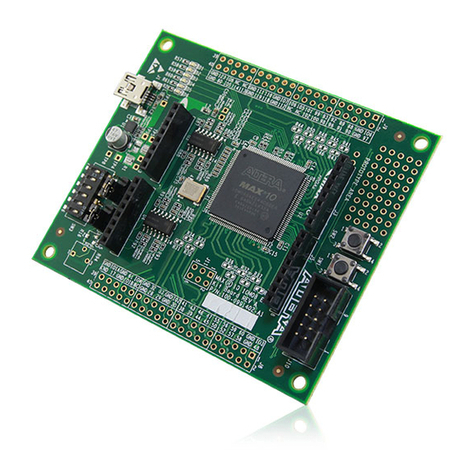

2.4 Board Layout

The EVB was designed for ease of use and user experimentation with easily accesible jumpers and

access to the SMBus data lines. Figure 2.3 below shows the silkscreen for the EMC2106 EVB.

Figure 2.3 EMC2106 Board Outline and Silkscreen

EMC2106 EVB User Manual

Revision 1.1 (08-22-07) SMSC EMC2106

8

3 Hardware Description

3.1 Introduction

The EMC2106 EVB provides the means to demonstrate EMC2106 features and to view and modify

registers. LEDs indicate status information and test points are included to monitor system voltages with

a user provided voltmeter or oscilliscope.

3.2 EMC2106

The EMC2106 is an SMBus temperature sensor with 1 internal and 4 external sensor in an 28 pin

QFN package. Communications with the EMC2106 sensor is via the SMBus.

3.3 USB to SMBus Bridge

The USB to SMBus bridge is based on an 8051 microcontroller with integrated USB and SMBus

interfaces as well as internal flash and RAM. During EVB manufacture, firmware is loaded into the

bridge that provides the interface between the USB and the SMBus. Power is sourced to the

microcontroller from the USB interface for device power and communication.

3.3.1 Direct SMBus Connect Option

It is also possible to connect an external SMBus master to the EMC2106 EVB. A few jumper settings

are all that is required to drive the EMC2106:

nSimply remove the jumpers on JP13 and connect the SMBus master to the SDA, SCL, and ALERT

pins (pins 3, 5, and 7 respectively), as well as an external supply for +3.3V (pin 1).

nThe +3.3V can be supplied by the SMBus bridge by leaving the +3.3V jumper in place and retaining

the USB connection.

3.4 Connecting to Remote Diodes

This EVB is populated with jumpers (JP5, JP6, and JP8) to connect to an external diode or CPU/GPU.

If connecting to a CPU’s thermal diode, it is necessary to provide a common ground. Also, it is usually

necessary to bias the appropriate CPU Vcc plane above this common ground to avoid forward-biasing

the ESD diodes with the temperature sensor signals. Test point TP1, TP2, TP3, or TP4 can provide a

ground connection. Consult the CPU manufacturer’s datasheet for guidance on interfacing and biasing

the thermal diode. Refer to the schematic SCH-7106.pdf for details on the EVB header connections.

3.5 Resistance Error Correction (REC)

External diode 3 DN signal path has a 100 ohm series resistor to demonstrate the EMC2106’s REC

feature. The resistor may be effectively removed from the circuit by installing a jumper on JP9. See

Table 3.3 for details on the REC jumper settings.

3.6 Power Source

This EVB simply requires a single USB cable to operate. The USB-SMBus bridge regulates the +5V

USB power to +3.3V used by the EMC2106 and other EVB circuitry. If a user-provided high current

fan (>0.5A) is connected to the EVB, the user may connect a +5V power supply to terminal P3 and

move jumper JP15 to position 2-3.

3.7 Test Points

Test points are provided for the following signals and voltages:

nPower: +3.3, +5V, and Ground

EMC2106 EVB User Manual

SMSC EMC2106 Revision 1.1 (08-22-07)

9

nOutputs: FAN_OUT, DAC2, ALERT#, OVERT1#/PWM1, OVERT2#/GPIO4, OVERT3#/GPIO5, and

SYS_SHDN#

nInputs: CLK_IN and TACH1

3.8 LED Indicators

LEDs indicate the status of the following signals (Table 3.1).

3.9 Jumper Settings

This EVB has many jumper configurations to evaluate all of the features of the EMC2106.

Fan control can conveniently be evaluated with the onboard 5V fan. Connecting this fan to J3 will allow

full control from the EMC2106 via Chipman.

If a 5V 4-wire fan is available, connectors J1 and J2 can be used to evaluate the EMC2106’s ability

to drive and control these types of fans. If PWM1 is to control the 4-wire fan, the appropriate register

in Chipman should be set. If PWM2 is desired to drive a 4-wire 5V fan, J2 should be used. In addition,

JP18 must be in postion 2-3 and JP7 in Position 2-3.

Table 3.1 LED Status Indicators

LED SIGNAL OFF GREEN RED

D3 SYS_SHDN# +3.3V power OFF NA SYS_SHDN#

asserted

LED1 ALERT# +3.3V power OFF ALERT# not asserted ALERT# asserted

LED2 OVERT1# +3.3V power OFF OVERT1# not

asserted

OVERT1# asserted

LED3 OVERT2# +3.3V power OFF OVERT2# not

asserted

OVERT2# asserted

GPIO4 +3.3V power OFF GPIO4 logic high GPIO4 logic low

LED4 +3.3V +3.3V power OFF +3.3V power ON NA

LED5 Bridge Activity NO Activity on

USB/SMBus Bridge

Activity on

USB/SMBus Bridge

NA

LED6 USB Activity NO Activity on USB port Activity on USB port NA

LED7 OVERT3# +3.3V power OFF OVERT3# not

asserted

OVERT3# asserted

GPIO5 +3.3V power OFF GPIO5 logic high GPIO5 logic low

LED8 GPIO1 +3.3V power OFF GPIO1 logic high GPIO1 logic low

LED9 GPIO2 +3.3V power OFF GPIO2 logic high GPIO2 logic low

LED10 GPIO3 +3.3V power OFF GPIO3 logic high GPIO3 logic low

LED11 GPIO6 +3.3V power OFF GPIO6 logic high GPIO6 logic low

EMC2106 EVB User Manual

Revision 1.1 (08-22-07) SMSC EMC2106

10

Table 3.2 summarizes the options available to drive various 5V fans..

The remote diode on board the EMC2106 EVB has a heater and an optional inline series resistance

adjustment. Checking the REC feature of the EMC2106 is accomplished by removing the jumper on

JP9. This adds 100 ohms of series resistance to the DN line of the diode connection. To return to 0

ohm series resistance, replace the jumper on JP9.

To heat the diode, place a jumper on JP10 in position 1-2. To return to ambient conditions, place

shorting bar in position 2-3 on JP2. These remote diode options are summarized in Table 3.3 below.

Table 3.2 Fan Driver Configuration

FAN DRIVER

CONFIGURATION FAN TYPE

FAN

CONNECTOR

REQUIRED

JUMPERS

FAN_OUT 3-wire J3 None -

PWM1 4-wire J1 None, SW programmed

PWM2 4-wire J2 JP7 -Position 2-3

JP18 - Position 2-3

DAC2 2 or 3-wire TP17 user provided offboard

circuitry needed

Table 3.3 Remote Diode and Thermistor Connections and Heater Settings

NAME JUMPER CONDITION 1 CONDITION 2

Ext Diode 1 JP5 onboard diode

JP5 - positions 1-2 and 3-4

JP14 - open

external offboard diode

JP5 - connect DP to pin 1 and DN to pin 3

JP14 - open

Ext Diode 2 JP6 onboard diode

JP6 - positions 1-2 and 3-4

JP16 - open

external offboard diode

JP6 - connect DP to pin 1 and DN to pin 3

JP16 - open

Ext Diode 3/4 JP8 onboard diodes

JP8 - positions 1-2 and 3-4

JP17 - open

external offboard diodes

JP8 - connect DP to pin 1 and DN to pin 3

JP17 - open

REC JP9 100 ohms in

DN line (diode remote -)

JP9 - Open

0 ohms in

DN line (diode remote -)

JP9- Short

HEATER JP10 1W resistive heater on remote

diode Q1

JP10 - Position 1-2

Ambient temp on remote diode Q1

JP10 - Position 2-3

Thermistor 1 JP14 onboard thermistor 1

JP14 - positions 1-2 and 3-4

JP5 - open

Thermistor 2 JP16 onboard thermistor 2

JP16 - positions 1-2 and 3-4

JP6 - open

Thermistor 3 JP17 onboard thermistor 3

JP17 - positions 1-2 and 3-4

JP8 - open

EMC2106 EVB User Manual

SMSC EMC2106 Revision 1.1 (08-22-07)

11

This EVB also allows for GPIO control and monitoring (see Table 3.4). Switches SW1 and SW2 allow

GPIO drive capabilites and LEDs provide visual confirmation of state change. .

The EMC2106 EVB also allows testing of all the muxed pins as well as voltage input adjustments for

the TRIP_SET and VIN4 functions. Ta b l e 3 . 5 summarizes all of the jumpers that appear on page 2 of

the schematic SCH-7106.

Table 3.4 GPIO Configurations

CHANNEL SW1 SW2 LED

GPIO1 switch 1 NA 8

GPIO2 switch 2 NA 9

GPIO3 switch 3 NA 10

GPIO4 NA switch 1 3

GPIO5 NA switch 2 7

GPIO6 NA switch 3 11

Table 3.5 Jumper Selection

JUMPER NAME POSITION 1-2 POSITION 2-3 OPEN

JP1 CLK_IN GPIO1 CLK-IN TO CHIP, SW

configuration required

NA

JP2 SHDN_SEL SHDN disabled INTEL mode 92C to 154C AMD mode 60 to 122 C

JP3 EXT_CLK power OFF ON NA

JP4 ADDR_SEL SMBus Client,

Address = 1001_101x

SMBus Client,

Address = 1001_100x

EEPROM Load,

Address = 1001_100x

JP11 TRIP_SET/VIN4 TRIP_SET function

adjust R65 resistor

pot for trip temp

VIN4 function

adjust R65 resistor pot for

voltage input adjustment

TRIP_SET function

adjust R65 resistor pot

for trip temp

JP7 GPIO3/PWM2 GPIO3 PWM2 NA

JP18 GPIO2/TACH2 GPIO2 TACH2 NA

EMC2106 EVB User Manual

Revision 1.1 (08-22-07) SMSC EMC2106

12

4 Software Description

4.1 Chip Manager Overview

The Chip Manager application (ChipMan) initially displays the main Help screen, where detailed

description of the application’s features may be found. The Help screens can be displayed at any time

by selecting Help from the menubar. ChipMan enables the user to display temperature readings, set

temperature limits and read/write configuration register values.

4.2 Temperature/Register History Graph

To open a Temperature or Register History Graph window, select the register or registers to plot in the

ChipMan application. then select Options -> Plot Register Data from the menubar. Once the graph

appears, select Control -> Start to begin plotting data. The history plot continuously updates the

register data reported by the EMC2106. Figure 4.1below is a typical Temperature History with the

external diode starting at room temp and then being heated using the HEATER jumper (JP10).

:

Figure 4.1 EMC2106 Temperature History Graph

Table of contents

Other SMSC Microcontroller manuals

Popular Microcontroller manuals by other brands

Lamina

Lamina Atlas NT-4000 White Developer Kit Series manual

Freescale Semiconductor

Freescale Semiconductor *KE02 Series Technical data

Elkron

Elkron MEDEA Programming manual

Infineon

Infineon EVAL-M3-302FTOBO1 user guide

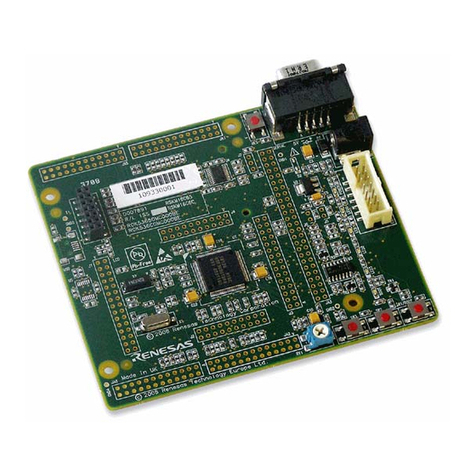

Renesas

Renesas M16C-Flasher quick start guide

Plankton Electronics

Plankton Electronics BUMBLEBEE Tutorial Guide