Sneaker Dolly Deluxe Kit User manual

OWNER’S MANUAL

Sneaker Dolly Components ............................................................. 1

Mitchell Kit Components .................................................................. 2

Pneumatic Kit Components ............................................................ 3

Maintenance ......................................................................................... 4

Build 1 - Standard Modes ................................................................. 5

Build 2 - High Modes ......................................................................... 6

Build 3A - Low Mode 1 ...................................................................... 7

Build 3B - Low Mode 2 ....................................................................... 8

Build 3C - Low Mode 3 ....................................................................... 9

Build 4 - Mitchell High Modes ...................................................... 10

Build 5 and 6 - Mitchell Low Modes ........................................... 11

Build 7 - Mitchell Base Seat ........................................................... 12

Build 8 - Pneumatic Mode ............................................................. 13

Contents

(A) Sneaker Base w/ 5 wheels

(B) Base Flange w/ 2 Kipp Handles

(C) 4 - Fastening Knobs, 5/16”-18 thread

(D) Seat

(E) Seat Flange w/ 1 Kipp Handle

(F) 4 - Fastening Knobs, 5/16”-18 thread

(G) Pipe Coupler w/2 Kipp Handles

(H) 18” Center Pipe

(I) 12” Center Pipe

(J) 6” Center Pipe

(K) 2 - spare Fastening Knobs

G

H

I

J

D

E

FF

!

!

!

!

!

!

A

!

B

!

c

!

!

!

!

c

K

Sneaker Dolly Components

1

Mitchell Kit Components

A

B

E

F

D

CC

C

C

H

(A) Mitchell Block Top Plate

(B) Mitchell Block Bottom Plate

(C) 3 inch Riser Post (4 total)

(D) 5/16” screws (6 total)

G

(E) Mitchell Thread

(F) Mitchell Castle Nut

(G) 2 - 3/8” Screws for Mitchell Thread

(H) Keyway Screw

(close up)

D

D

D

D

2

Pneumatic Kit Components

(A) Pipe Housing w/ Gas Cylinder

(B) Pneumatic Seat Plate w/

Adjustment Lever

(C) 3 inch Riser Post (4 total)

A

B

C

3

Congratulations on your purchase of the Sneaker Handheld Mobility System. We at Teknicam

are condent that the Sneaker will give you many years of reliable use. Please contact us if you

have any questions or problems with your Sneaker system and we’ll do our very best to

provide a solution. We also appreciate any feedback you may have as we aim to constantly

improve and rene our system to be the best it can be.

Introduction and Maintenance

The Sneaker system is pretty much maintenance free, although for optimum benets, we

recommend the following light maintenance once or twice a year depending how heavily it’s used:

- When the pipes become heavily worn, a light sanding with some ne grit sandpaper will restore

a nice smooth nish. Although a worn pipe does not aect the functionality of the Sneaker.

- We recommend some light lubrication on the threads of the Knobs, Kipp handles and Sneaker

Base mounting holes. A simple, spray protectant/lubricant like WD-40 or Tri-Flo would prevent corro-

sion and keep moving parts smooth and operational. The wheels will eventually gather dust and

dirt depending on the conditions. A yearly cleaning and lubrication of bearings will keep the

wheels rolling and swiveling at peak performance.

All builds pictured in this manual use 4 Knobs

to attach the Base Flange to the Sneaker Base.

However, through eld-testing, we nd that

using only 2 Knobs is perfectly adequate for

this purpose. Also, working with 2 Knobs

instead of 4 greatly quickens conversion times.

So feel free to use 2 Knobs whenever attaching

the Base Flange to the Sneaker Base. However,

4 knobs should always be used when attaching

the Seat Flange to the Sneaker Seat.

Two Knobs vs. Four

4

BUILD 1 - Standard Mode

Build 1A

6” Centerpipe

Build 1C

18” Centerpipe

Build 1B

12” Centerpipe

High

Low

5

BUILD 2 - High Mode

The Pipe Coupler combines

two pipes for specic

heights or when 18” Center

Pipe is not high enough.

Build 2A

12” Centerpipe

and 6” pipe

joined with Coupler

Build 2B

18” Centerpipe

and 6” pipe

joined with Coupler

6

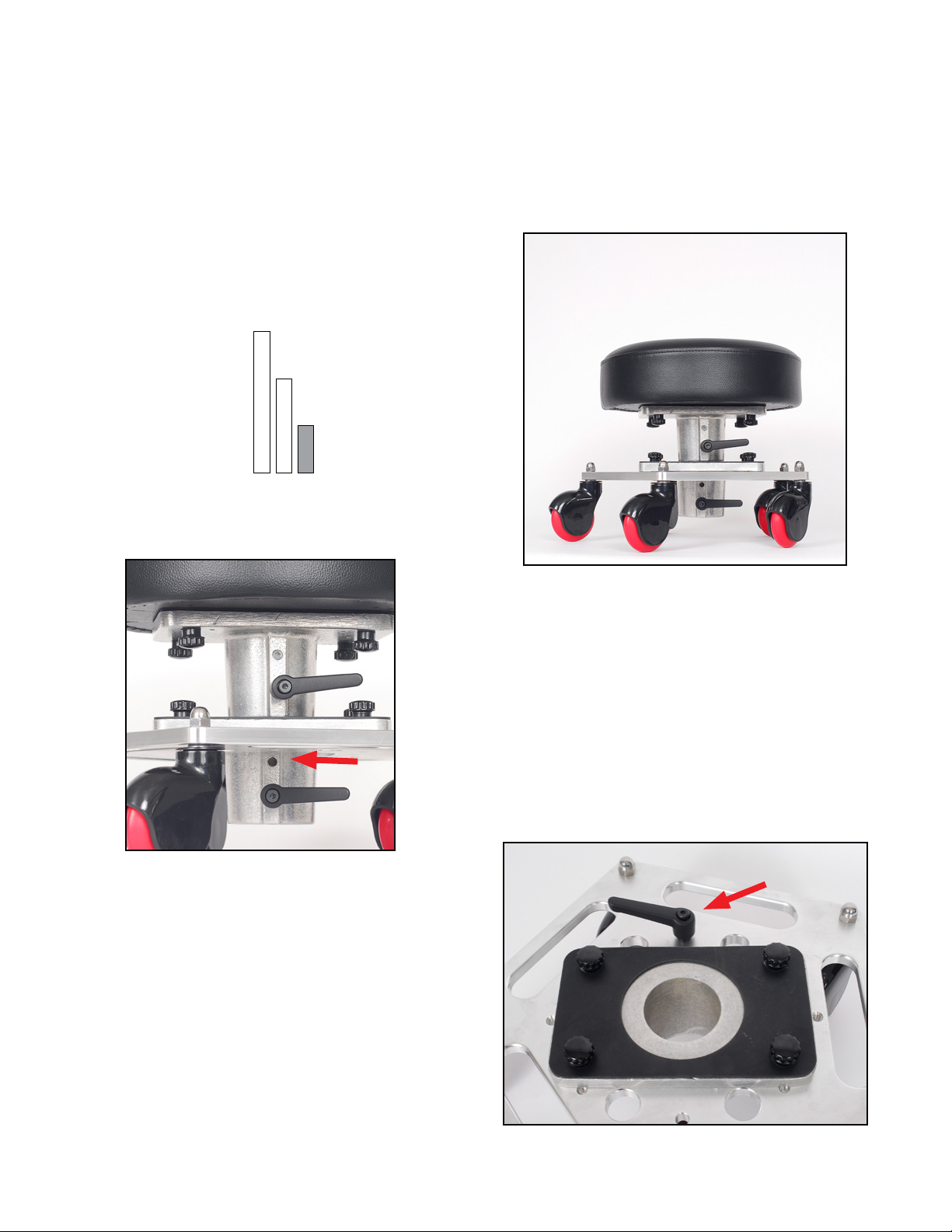

BUILD 3A - Low Mode 1

Build 3A

A 6” Center Pipe is used and the

Base Flange is mounted inverted.

This build places the seat 3 inches lower

than the lowest Standard-mode build.

* Note: It is necessary to temporarily

remove the lower Kipp handle from

the Base Flange in order for it to t

through the bottom of the Sneaker Base.

(see red arrow) Only 1 Kipp handle is used in

the Base Flange when installed inverted.

The un-used Kipp handle can be stored

in the 3/8” hole on the base as shown.

7

In this build, the seat and seat ange rest

rmly atop the Sneaker Base, but they are not

directly attached. This is to achieve a super quick

changeover. The seat can be lifted straight o the

Base. To FASTEN the seat directly to the Sneaker

Base, please refer to Build 3C on the next page.

Build 3B

Step 1: Remove the Base Flange

from the Sneaker Base (Figure 1).

Then screw two Knobs completely down into the

two threaded holes indicated in (Figure 1). The function

of this knob placement is to keep the seat from

rocking side to side.

Step 2: Remove any pipe from Seat Flange. Then thread

the Kipp Handle ( Figure 2) all the way in until it no

longer swivels. This is done to prevent the Kipp Handle

from dangling freely under the Sneaker base.

Step 3: Align the four Knobs of the Seat Flange (Figure 2)

with the four large holes in the Sneaker Base (Figure 3).

Then simply drop the seat into position on the base

BUILD 3B - Low Mode 2

(Fig. 1)

(Fig. 2) (Fig. 3)

8

BUILD 3C - Low Mode 3

Build 3C

This build allows the seat to be FASTENED

directly to the Sneaker Base. It’s also the

lowest conguration of the Sneaker Dolly.

1/2 inch lower than Low Mode Build 4A.

No pipes or anges are used in this setup.

Step 1: Remove the Seat Flange and lay the

seat upside down on a at surface (Fig. 1).

Step 2: Remove the Base Flange from the

Sneaker Base and locate the two 3/8”

non-threaded through-holes (Fig. 2).

They are the only two small non-threaded

holes on the Base.

Step 3: Lay the Sneaker Base on top of the seat,

wheels facing up. Center the Base then rotate to

line up the two through-holes with two thread-

ed inserts in the seat. Then use two Knobs to

attach Seat to the Base (Fig. 3). Only 2 knobs are

used in this build.

(Fig. 1)

(Fig. 2)

(Fig. 3)

9

BUILD 4 - Mitchell High Mode

Build 4

By replacing the Sneaker Seat with the Mitchell

Block, you now have a rolling Mitchell Base.

There are 4 threaded 5/16”holes in the Mitchell

Block Bottom Plate. Use these holes and 4 Knobs

to attach the the Mitchell Block to the Seat Flange.

From here, use the various Center Pipes to adjust

your heights the same as you would in Seat Mode.

To go lower than 14 inches, refer to Build 5 and 6

Mitchell Low Modes on the next page.

Important Note: It is not recommonded to setup higher

than shoulder level in this conguration. Clearly, in this

build, the center of gravity and mass of the camera sit

high on a narrow base and can tip over if not careful.

For this reason it’s highly advisable that whenever built

in high Mitchell Mode, someone remain close to the

camera at all times and common sense is exercised.

10

BUILD 5 and 6 - Mitchell Low Modes

11

Build 5

This setup puts the height of the Mitchell base at

8” from the ground.

Step 1: Remove both Pipe anges from the

Sneaker Base and the Mitchell Block.

Step 2: Locate the 4 non-threaded holes in

the Mitchell Block Bottom Plate. And line them

up with 4 threaded 5/16”holes in Sneaker Base.

Step 3: Use 2 or 4 Knobs to fasten the Mitchell

Block directly to the Sneaker Base.

Build 6

This setup puts the height of the Mitchell

base at 5”. It’s basically a rolling hi-hat.

Step 1: Remove both Pipe anges from the

Sneaker Base and the Mitchell Block.

Step 2: Detach the Mitchell Top Plate from the

Mitchell Block by removing the four 5/16”

screws from the Mitchell Plate.

Step 3: Use the screws to attach the Mitchell Top

Plate to threaded 5/16”holes on Sneaker Base

Step 3 Alternate: Instead of using the athead

screws. The Mitchell Top Plate can be attached from

underneath the Sneaker Base using two knobs.

This setup adds a Mitchell Base to the Sneaker Seat. Mount it to a dolly boom arm,

a dolly oset, a vehicle rig or any special conguration you can dream up.

BUILD 7 - Mitchell Mount Seat

Build 7

Step 1: Remove the Seat Flange and Knobs from

the Sneaker Seat.

Step 2: Dis-assemble the Mitchell Block and

remove the Mitchell Bottom Plate.

Step 3: The Mitchell Kit includes a Mitchell

Thread and Castle Nut. Use the two at-head

3/8“ screws to attach the Mitchell Thread to

the Mitchell Bottom Plate.

Step 4: Attach the Mitchell Bottom Plate with

Thread to the Sneaker Seat using four 5/16”

at-head screws included in the Mitchell Kit.

The Mitchell Block can also be

used as a 4” riser. Simply

thread the Keyway Screw into

the 1/4”-28 hole as pictured.

The Keyway Screw can also be

used in Mitchell Seat mode,

although not very necessary

for most applications.

5/16”

screws

5/16”

screws

Mitchell Thread Castle Nut

Mitchell Bottom Plate

12

BUILD 8 - Pneumatic Mode

Build 8

The Pneumatic Kit provides 6 inches of height range using the

adjustment lever and gas lift. Remove the Seat Flange from the

seat and replace with the Pneumatic assembly.

There are four 3-inch riser posts included with the Pneumatic

Kit. These risers are optional for use in hydraulic mode. They

raise the Base Flange to add 3 inches of height on the top end

while keeping the same low end height. This build gives the

user 15 inches of range up and down without switching pipes.

13

30”

15”

Table of contents