Sno-Pro Fast-Cast 2000 (1CS1) User manual

®

™

Fast-Cast 2000 (1CS1), Fast-Cast 300 (1CS9), Fast-Cast 400 (1CS10)

1 of 17

FAST-CAST SERIES SPREADERS

Curtis Industries Inc. LLC, 111 Higgins St., Worcester, MA 01606 TEL: (800) 343-7676 FAX: (508) 854-3377 For Parts and information visit us at www.Curtisindustries.net

Curtis Industries Inc. LLC, reserves the right to change product design or specifications without notice or liability.

Assembly and Owner's Manual - September 2010

2 of 17

►Beforeattemptinganyprocedureinthismanual,thesesafetyinstructionsmustbereadandunder-

stoodbyallworkerswhohaveanypartinthepreparationoruseofthisequipment.

►Foryoursafety,warningandinformationdecalshavebeenafxedtothisproducttoremindall

operatorsofsafetyprecautions.Ifdecalsaremarked,damagedordestroyed,replacewithnewdecals

orderedfromCurtisIndustries,LLC.

1. Most accidents are preventable and caused by human error.

Exercise care and precautions to prevent the possibility of injury to operator or to others.

2. Never operate equipment when under the inuence of alcohol, drugs or medication that might

alter your judgement and / or reaction time.

3. Before working with the Spreader, secure all loose tting clothing and unrestrained hair.

4. Always wear safety glasses with side shields when working metal against metal. Failure to do

so could result in serious injury to the eyes.

5. Never allow children to operate or climb on equipment.

6. Never weld or grind on equipment without having a re extinguisher available.

7. Always check areas to be spread to be sure no hazardous conditions or substances are in the

area.

8. Always inspect unit for defects: Broken, worn or bent parts, weakened areas on Spreader or

Mount.

9. Always shut off vehicle and power source before attempting to attach or detach or service

Spreader unit. Be sure vehicle/power source is properly braked or chocked.

10. Always make sure personnel are clear of areas of danger when using equipment.

11. Always keep hands, feet, and clothing away from power-driven parts.

12. Remember, it is the owner’s responsibility to communicate information on safe usage and

proper maintenance of all equipment.

WARNING

IMPORTANT: Before you Start...

1CS9 ▪ Fast-Cast 300

• Rock Salt, Deicers

• Light Duty Grade Applications

• 3.0 Cu. ft./180 lb. Capacity

• 4 to 20 ft. Spreading Width

• 7-10 Amperage Draw

• Fine Material Applications

• 3.0 Cu. ft./180 lb. Capacity

• 4 to 20 ft. Spreading Width

• 7-10 Amperage Draw

1CS10 ▪ Fast-Cast 400

3 of 17

■ Never exceed 45 m.p.h. when loaded spreader is attached to vehicle. Braking distances may be

affected and handling characteristics may be impaired at speeds above 45 m.p.h.

■ Never use wet materials, or materials with foreign debris in the Fast-Cast Spreaders.

These units are designed to handle dry, clean, free-owing material.

Curtis Spreaders can not spread water softener salt.

■ Never leave material in Hopper for long periods of time. Be aware that all ice melters are

hygroscopic and will attract atmospheric moisture and harden up.

■ Always inspect pins, and latches whenever attaching or detaching Spreader, and before traveling.

■ Inspect the unit periodically for defects. Parts that are broken, missing, or worn out must be

replaced immediately. The unit, or any part of it should not be altered without prior written

permission from the manufacturer.

CAUTION

1CS1 ▪ Fast-Cast 2000

• Rock Salt, Deicers

• Free-Flowing Materials

• 5.0 Cu. ft./350 lb. Capacity

• 4 to 40 ft. Spreading Width

• 12-15 Amperage Draw

NOTE

1g. Installignitionwiretoanauxiliarycircuitthatishot

whentheignitionkeyisturnedtoONposition.This

wireis60"longandhasafemaleterminalattached

toit.ThiswirewillplugintobackofController.

ThiswiremustbeinstalledinorderforControllerto

operate.

1h.PushtheON/OFFbuttonontheControllertocheckfor

power,whenthathasbeenconrmedturnpowerOFF.

Theelectricalportionoftheinstallationiscomplete.

If adding an inline fuse,

use a 35 amp slow blow fuse

on Fast-Cast 2000 only.

SECTION 2. OPERATING THE SPREADER

2a. PREPARATION

Sweep area clear of foreign

objects or obstacles that could

cause personal injury.

Keep other persons, children,

or animals out of the area to

be spread.

2b. SPREADER LOADING

Do not overload vehicle. Rock

Salt weighs 35-40 pounds per

cubic foot.

Maximum weight of materials

for the Fast-Cast 2000 is

350 lbs. for a pickup truck,

and 250 lbs. for a UTV mounted

Spreader.

Always comply with

manufacturer’s maximum

gross vehicle weight ratings.

Never leave materials in

Hopper for long periods of

time as salt is hygroscopic

and will attract atmospheric

moisture and harden up.

4 of 17

Sno-Pro Fast-Cast Series Spreaders

NOTE

CAUTION

CAUTION

WARNING

SECTION 1. SPREADER WIRING STEPS

(Refer to Page 17)

1a. TheHarnessAssemblywillberoutedfromtherearof

thevehicletothefront.RouteHarnessalongframe

andattachtoframeholesandframesupports.

It is not recommended to

attach to fuel or brake lines

for obvious reasons.

Donotrouteclosetoexhaustsystemorengine,

eventhoughCurtisuseshightemperaturewiring,

thewiringcouldstillmeltunderextremeheatand

shortthespreaderelectricalsystem,aswellasthe

vehicleelectricalsystem.

1b. MountRearPlugonbumperusingsuppliedbolts.

Locatetowardsthecenterofthebumpertoreduce

theamountofdebristhetireswillthrowtotherear.

Apply a small amount of

dielectric grease to the plug.

1c.SecureHarnessfromthereartothefrontusing

heavydutytie-wrapsorframeclipsalongtheframe

andlighterdutytie-wrapsinallotherlocations.

1d. LayoutHarnessportionthatconnectstothebattery

alongtherewallandfenderwell.Donotconnect

powerleadstoBatteryatthistime.Drilla3/4"hole

intherewall,oruseexistingaccesshole,forthe

controlportionoftheHarnessandrouteconnector

andHarnessthroughhole.Besuretocheckthe

areaontheothersideoftherewalltobecertain

thatyouarenotgoingtodrillintothevehicleharness

oraControlModule.Generallyyoucandrilloneither

sideofthesteeringwheelforagoodlocation.

1e.ConnectHarnesstothebackoftheControllerand

mounttoasuitablelocation.

You may want to contact

customer before mounting

controller, some prefer not to

have holes drilled into the

dashboard.

Tie-wraplooseControllerHarnessandmoveto

thevehicleenginecompartment.

1f. Connectpowerleadstothe

Battery: Red (+) Positive, Black (–) Negative.

AlwaysconnecttotheprimaryBatteryifusingaDual

BatterySystem.Securelooseloomtoanyotherlarge

ormediumvehicleharnesswithmediumdutytie-

wraps;thiswillsecurewiringHarness.

WARNING

IMPORTANT

IMPORTANT

NOTE

Sno-Pro Fast-Cast Series Spreaders

5 of 17

2c. SPREADER LOADING TIPS

► Never exceed 10 m.p.h. when spreading.

► For a wider pass, increase Spinner speed.

► For a heavier pass, drive slower.

► Never operate Spreader near pedestrians.

► Spread ice melters with the storm to prevent

unmanageable levels of ice.

► Calculate spread pattern when near vegetation.

2d.FAST-CAST 2000 OPERATION

(1.) TheVariableSpeedControllerhasnger-tip

dialaction.

(2.) ToStart,pressPowerSwitchonControllerand

Spreaderwillacceleratetospeedsetondial.

(3.) ToStop,pressPowerSwitchonControllerto

offposition.

(4.) AdjustspeedofSpinnerbyusingdialonright

sideofController.

SECTION 3. FAST-CAST 400 ASSEMBLY

STEPS (Refer to Page 12)

3a. AttachHopperTubeSupport(17)toTransmission

Weldment(18)usingfour5/16"-18x1-3/4"HexBolts

(11)andfour5/16"LockNuts(3)Usethefourbottom

mountingholesatendsofHopperTubeSupport(17).

3b. LocateSpreaderGateDeck(15)andplaceupside

downonaatworksurface.

3c. AssembleGateIndicator/Stop(12)onStopSlidewith

GateKnob(7).GateIndicator/Stopmustbeonthe

insideofGateDeckwhereitwillstopthetrack.

3d. Insertone5/16"Boltwithhole(10)throughGate

Indicator/Stop(12).Handtightenone5/16"LockNut

(3)onBolt.

3e. LocateBulkheadCableFitting(9).Threadonto

T-HandleCable-20'(8)rubbercoating.

3f. InsertCableassemblythroughTabonGateDeck.

SecurewithsuppliedWasherandNuts.

A Nut must be positioned on

both sides of tab on Gate Deck.

3g. TurnoverGateDeckandlowertheassemblyover

theSpinnerShaft.TheSpinnerShaftmustbeinserted

throughthe5/8"holeonGateDeck.

3h. FastenGateDecktoHopperTubeusingfour5/16"

HexBolts(11)andfour5/16"LockNuts(3).

First tighten bottom bolts,

pull front of Gate Deck up,

then tighten top set of bolts.

3i. PlaceHopper(16)onGateDeckandoverthe

SpinnerShaft.

3j. Handtightenthetwo5/16"x1"Bolts(5)inserted

throughbottomofHopper.

3k. PlaceoneFenderWasher(1)overeachofthefour

HexBolts(11).InsertthefourBoltswithFender

WashersthroughHopperbackandthroughTube

Support.Securewithfour5/16"Locknuts(3).

3l.FullytightenthetwoBoltsinbottomofHopperthat

securetheHoppertotheDeckinstalledinStep3j.

Refer to Page 13 for the

following Steps.

3m. PositionAgitator(11)onSpinnerShaft.Tightento

middleofatwithshortallenkey.

3n. AttachReceiverMount(18)toTransmission

Weldment(17)usingfour1/2"HexBolts(19)and

four1/2"LockNuts(20).

CABLE INSTALLATION STEPS

3o.MountSpreaderonvehicleinitspermanentlocation.

InsertHitchPininhitchtopreventunitfrommoving.

3p. RouteT-Handletodesiredoperatinglocation.There

cannotbeanybendsorsharpcornersintheCable.

3q. TakeT-HandleoutofSleeve.TakeNutsandWasher

offSleeve.

3r. Drilla1/2"diameterholetomountT-Handle.Thread

onesuppliedNutandWasheronCableafterinserting

throughdrilledhole.

3s. CompletelyclosetheGateSlide.

3t. Re-insertCableHandleandwireallthewayuntilthe

HandleportionofT-HandleCable(8)contactsBulk-

headCableFitting(9).AimthroughBoltwithhole(10)

andtightenBolt.

NOTE

NOTE

NOTE

6 of 17

Sno-Pro Fast-Cast Series Spreaders

SECTION 4. FAST-CAST 300 ASSEMBLY STEPS

(Refer to Page 10 & 11)

4a. AttachHopperTubeSupport(6)toCompleteDrive

Assemblyusingfour5/16"-18x1-3/4"HexBolts(3)

andfour5/16"LockNuts(2).Usethefourbottom

mountingholesatendsofHopperTubeSupport.

4b. LocateAuger(11)andsetonaatworksurfaceto

taponeblackplasticCapintotubebetweenAuger

uprightsifnotalreadyinstalled.

4c. PlaceAugeronShaftofTransmissionandtighten

totopofatwithoneSetScrew(8).

4d. PlaceSalterThroatDeck(5)overAugerand

betweenHopperTubingSupport.

4e. Usingfour5/16"-18x1-3/4"Bolts(3)and(4)5/16"

LockNuts(2),handtightenthroughuppersetof

holesonTubeSupport.

4f. With1/2"wrenchandsocket,tightenbottomsetof

boltsonThroatDeck.

4g. LiftuponThroatDeckatthefront(Augerholeside)

tolevelDeck.TightentopsetofBolts.

4h. PlaceHopperThroat(4)throughDeckaroundAuger.

HolesinHoppershouldlineupwithholesinTube

Support.

4i. Placeone3/8"FenderWasher(1)onallfour5/16"

HexBolts(3).InsertthroughHopper,andthrough

tube,thensecurewitha5/16"Nut(2)onbackofunit.

Tighten.

4j. AttachReceiverMount(7)toTransmission

Weldment(17)usingfour1/2"HexBolts(19)and

four1/2"LockNuts(20).

4k. InsertReceiverTubeendintoReceiverHitchand

securewithHitchPin(2).

4l. WireSpreaderaccordingtowiringinstructions

foundonPage17.

SECTION 5. FAST-CAST 300 / 400 WIRING

STEPS (Refer to Page 17)

5a. InstallSwitch/Controlatdesiredlocation.

5b. RunSpreaderVehicleHarnessfromtherearof

vehicletoSwitch/Controlarea.

Attachthefemale spade/red wire to the switch or

the positive (+) output connectionoftheControl.

IfusingControl,attachthemale spade/black wire on

the negative (-) output connectionoftheControl.

IfusingSwitch,leavetheblackwireforStep5e.

5c. RoutethePowerHarnessfromtheBatterytothe

Switch/Control.

5d. Attachthered lead to the positive side (+) of the

Batteryandtheblack lead to the negative side (-)

of the Battery.

5e. IfusingtheControl,attachthefemale spade red lead

from the Power Harness to the Battery positive (+)

terminal.

Attachthemale spade black wire to the Battery

negative terminal (-).IfusingSwitch,attachthe

femalespaderedwireonSwitchTerminal.

Using3"doublefemaleblackwirejumper,attachthe

blackwirefromthePowerHarnesstotheblackwire

ofthevehicleharness.

5f. InstallRubberWeatherproofBootonSwitchbefore

nishinginstallation.

5g. ApplyDielectricGreasetoterminalsofSAEPlugat

rearofvehicle.

SECTION 6. TROUBLESHOOTING

Wheneverserviceisnecessary,yourlocaldealer

knowsyourCurtisSpreaderbest.TakeyourCurtis

Spreadertoyourlocaldealerforanymaintenance

orserviceneedsonyourunit.Ifthisisnotpossible,t

theTroubleshootingGuideonthenextpagemay

assistyouinidentifyingtheproblem.

First read all Warning

instructions and Safety

messages on Pages 2 & 3

before servicing your Spreader.

Preliminary Checks

►Checkthatallelectricalconnectionsaretight

andclean.

►CheckthatnothingisjammedintheHopper.

WARNING

Use Dielectric Grease on all

electrical connections to

prevent corrosion at the

beginning and end of the

season and each time power

plugs are disconnected.

Wash unit after each use to

prevent material build-up and

corrosion.

When pressure washing motor

enclosure area, stay at least 36"

away from motor enclosures.

Paint or oil all bare metal

surfaces at the end of the

season.

Apply small amount of

light oil to latches as needed.

If motor cover is removed for

any reason, use silicone sealant

to ensure weather proong

of enclosure.

After rst use, tighten all

nuts and bolts on Spreader

and mount.

Sno-Pro Fast-Cast Series Spreaders

7 of 17

Always shut off vehicle and

power source before attempting

to attach or detach or service

Spreader unit. Be sure vehicle /

power source is properly braked

or chocked.

Always keep hands, feet,

and clothing away from

power-driven parts.

SECTION 7. SPREADER MAINTENANCE

When servicing is necessary,

perform it in a protected area.

Do not use power tools in rain

or snow because of danger of

electrical shock or injury.

Keep area well lighted.

Use proper tools.

Keep the area of service clean

to help avoid accidents.

Disconnect electricity to

Spreader before servicing.

The Controller is a solid state

electronic unit and is not

serviceable.

Any attempt to service

Controller will void warranty.

CAUTION

DANGER

WARNING

IMPORTANT

WARNING

CAUTION

IMPORTANT

NOTES

MORE

NOTES

PROBLEM POSSIBLE CAUSE SOLUTION

Motor Doesn't Run

Controller Shut Down

Material Not Flowing

Loose Electrical Connections

Blown Fuse

Motor Seized

Jammed Auger

Poor Electrical Connections

Electrical Short

Controller Failure

Empty Hopper

Wet Material

Frozen or Coarse Material

Spinner Not Turning

Auger Loose on Shaft

Check All Connections

Replace Fuse

Replace Motor

Carefully Clear Jammed Material

Clean or Replace Connectors

Use Dielectric Grease

Check Electrical Connections

Check for Bare Wires

Replace Controller

Fill Hopper

Replace With Dry Material

Replace Material

Check Drive Assembly

Tighten Locking Bolt on the Side of Auger.

Align Auger with Flat Side of Driver Shaft

and Tighten Bolt.

8 of 17

Sno-Pro Fast-Cast Series Spreaders

1CS1 Fast-Cast 2000 - Illustrated Parts List

®

™

13

12

12

14

7

15

16

18

17

10

13

13

20

21 19

11

19

20

21

1SM2P1

1SM1P2

1SM1P3

2" Receiver Hitch

5/8" x 5-1/2" Hitch Pin

2-5/16" Hair Pin Clip

Item

No.

1

1

1

Qty.

Part

No. Description

Optional Mount

Required for Fast-Cast 2000 Spreader

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1CS1P1

1CS1P2

1CS1P3

1CS1P4

1CS1P5

1CS1P42

1CS1P48

1CS1P12

1CS1P49

1CS1P10

1CS1P11

1CS1P8

1CS1P9

1CS1P41

1CS1P6

1CS1P47

1CS1P46

1CS1P7

Lid With Latches

Flexible Draw Latch

Hopper

Main Frame

Throat Clamp

Stainless Throat Liner

Latch Keeper

Deflector 20"

Complete Drive Assembly

1/2"-13 x 1-1/2" Hex Bolt

1/2"-13 Lock Nut

3/8"-16 x 1" Hex Bolt

3/8"-16 Lock Nut

3/8" Flat Washer

5/16"-18 x 1-1/4" Phillips Bolt

3/8" S/S Washer

5/16" Lock Washer

5/16"-18 Hex Nut

Item

No.

1

2

1

1

1

1

2

1

1

4

4

8

8

2

2

2

2

4

Qty.

Part

No. Description

3

1

4

6

8

9

5

2

FAST-CAST 2000

12

Sno-Pro Fast-Cast Series Spreaders

9 of 17

6

4

2

7

5

8

9

11

15

14

10

13 16

12

3

1

1CS1 Fast-Cast 2000 Complete Drive Assembly - Illustrated Parts List

1

2

3

4

5

6

7

8

1CS1P16

1CS1P53

1CS1P17

1CS1P13

1CS1P21

1CS1P19

1CS1P22

1CS1P29

Motor 12 Volt DC

Transmission

Motor Cover

Drive Enclosure

Fast-Cast 2000 Power Cable

Auger

Cord Restraint

3/16" Aluminum Rivet

Item

No.

1

1

1

1

1

1

1

6

Qty.

Part

No. Description

9

10

11

12

13

14

15

16

1CS1P25

1CS1P24

1CS1P30

1CS1P27

1CS1P28

1CS1P23

1CS1P18

1CS1P51

1/4"-20 x 3/4" Hex Bolt

5/16"-18 x 1/2" Hex Bolt

1/4" Lock Washer

#10-32 x 5/8" Cap Screw

#10 Lock Washer

5/16"-18 x 3/8" Set Screw

10" Steel Spinner

Motor Drive Coupler

Item

No.

4

1

4

2

2

1

1

1

Qty.

Part

No. Description

Sno-Pro Fast-Cast Series Spreaders

10 of 17

1CS9 Fast-Cast 300 - Illustrated Parts List

1

2

3

4

5

6

7

1CS2P15

1SM5P1

D6462

1CS9P1

1CS9P2

1CS9P3

D6485

3/8" Fender Washer

5/16"-18 Lock Nut

5/16"-18 x 1-3/4" HHCS

Fast-Cast 300 Salt Hopper

Salter Throat Deck

Hopper Tube Support

Light Duty Receiver Mount

Item

No.

4

12

12

1

1

1

1

Qty.

Part

No. Description

3

3

2

2

2

6

3

7

1

3

4

5

Sno-Pro Fast-Cast Series Spreaders

11 of 17

1CS9 Fast-Cast 300 Complete Drive Assembly - Illustrated Parts List

2

6

7

11

8

4

20

3

13

19

1

18

10

16

15

9

12

1

2

3

4

6

7

8

9

10

11

12

13

15

16

17

18

19

20

1SM1P3

1SM1P2

1CS1P25

1CS1P24

1CS1P27

1CS1P28

1CS1P23

1CS1P18

1CS1P51

1CS1P19

1CS2P10

D6487

1CS9P5

1CS9P16

D6480

D6485

D4116

D4120

2-5/16" Hair Pin Clip

5/8" x 5-1/2" Hitch Pin

1/4"-20 x 1/2" Hex Bolt S.S.

5/16"-18 x 1/2" Hex Bolt

#10-32 x 5/8" Cap Screw

#10 Lock Washer

5/16"-18 x 3/8" Set Screw S.S.

10" Steel Spinner

Motor Drive Coupler

Auger

Motor, 12 Volt DC

#8 x 1/2" Sheet Metal Screw

Transmission 14.5 to 1

Plastic Bottom Cover

Transmission Weldment

Light Duty Receiver Mount

1/2"-13 x 1-1/2" Hex Bolt

1/2"-13 Lock Nut

Item

No.

1

1

4

1

2

2

1

1

1

1

1

5

1

1

1

1

4

4

Qty.

Part

No. Description

17

Sno-Pro Fast-Cast Series Spreaders

12 of 17

1CS10 Fast-Cast 400 Spreader - Illustrated Parts List

1

2

3

4

5

6

7

8

9

10

1CS2P15

1CS1P24

1SM5P1

1CS1P46

-

1CS1P7

1CS10P6

1GC1A

1CS2P16

1CS2P17

3/8" Fender Washer

5/16"-18 x 1/2" Hex Bolt

5/16"-18 Lock Nut

5/16" Lock Washer

5/16"-18 x 1" Hex Bolt

5/16"-18 x 1" Hex Nut

Gate Knob

T-Handle Cable - 20'

Bulkhead Cable Fitting

5/16"-18 x 3/4" Bolt w/hole

Item

No.

4

2

14

1

2

1

1

1

1

1

Qty.

Part

No. Description

11

12

13

14

15

16

17

18

19

20

21

D6462

1CS10P5

1CS10P4

1CS10P3

1CS10P2

1CS10P1

1CS9P3

D6480

D6485

D4116

D4120

5/16"-18 x 1-3/4" HHCS

Gate Indicator / Stop

Fast-Cast 400 Gate Track

Fast-Cast 400 Gate Slide

Fast-Cast 400 Gate Deck

Fast-Cast 400 Hopper

Hopper Tube Support

Transmission Weldment

Light Duty Receiver Mount

1/2"-13 x 1-1/2" Hex Bolt

1/2"-13 Lock Nut

Item

No.

12

1

1

1

1

1

1

1

1

4

4

Qty.

Part

No. Description

11

11

11

3

3

3

1

11

16

15

19

17

18

2

55

2

2

6

8

9

7

13

10

14

15 Gate Deck Underside View

Sno-Pro Fast-Cast Series Spreaders

13 of 17

2

6

7

11

8

4

20

3

13

19

1

18

10

16

15

9

12

1

2

3

4

6

7

8

9

10

11

12

13

15

16

17

18

19

20

1SM1P3

1SM1P2

1CS1P25

1CS1P24

1CS1P27

1CS1P28

1CS1P23

1CS1P18

1CS1P51

1CS2P7

1CS2P10

D6487

1CS9P5

1CS9P6

D6480

D6485

D4116

D4120

2-5/16" Hair Pin Clip

5/8" x 5-1/2" Hitch Pin

1/4"-20 x 1/2" Hex Bolt S.S.

5/16"-18 x 1/2" Hex Bolt

#10-32 x 5/8" Cap Screw

#10 Lock Washer

5/16"-18 x 3/8" Set Screw S.S.

10" Steel Spinner

Motor Drive Coupler

Agitator

Motor, 12 Volt DC

#8 x 1/2" Sheet Metal Screw

Transmission 14.5 to 1

Plastic Bottom Cover

Transmission Weldment

Light Duty Receiver Mount

1/2"-13 x 1-1/2" Hex Bolt

1/2"-13 Lock Nut

Item

No.

1

1

4

1

2

2

1

1

1

1

1

5

1

1

1

1

4

4

Qty.

Part

No. Description

17

1CS10 Fast-Cast 400 Complete Drive Assembly - Illustrated Parts List

14 of 17

Sno-Pro Fast-Cast Series Spreaders

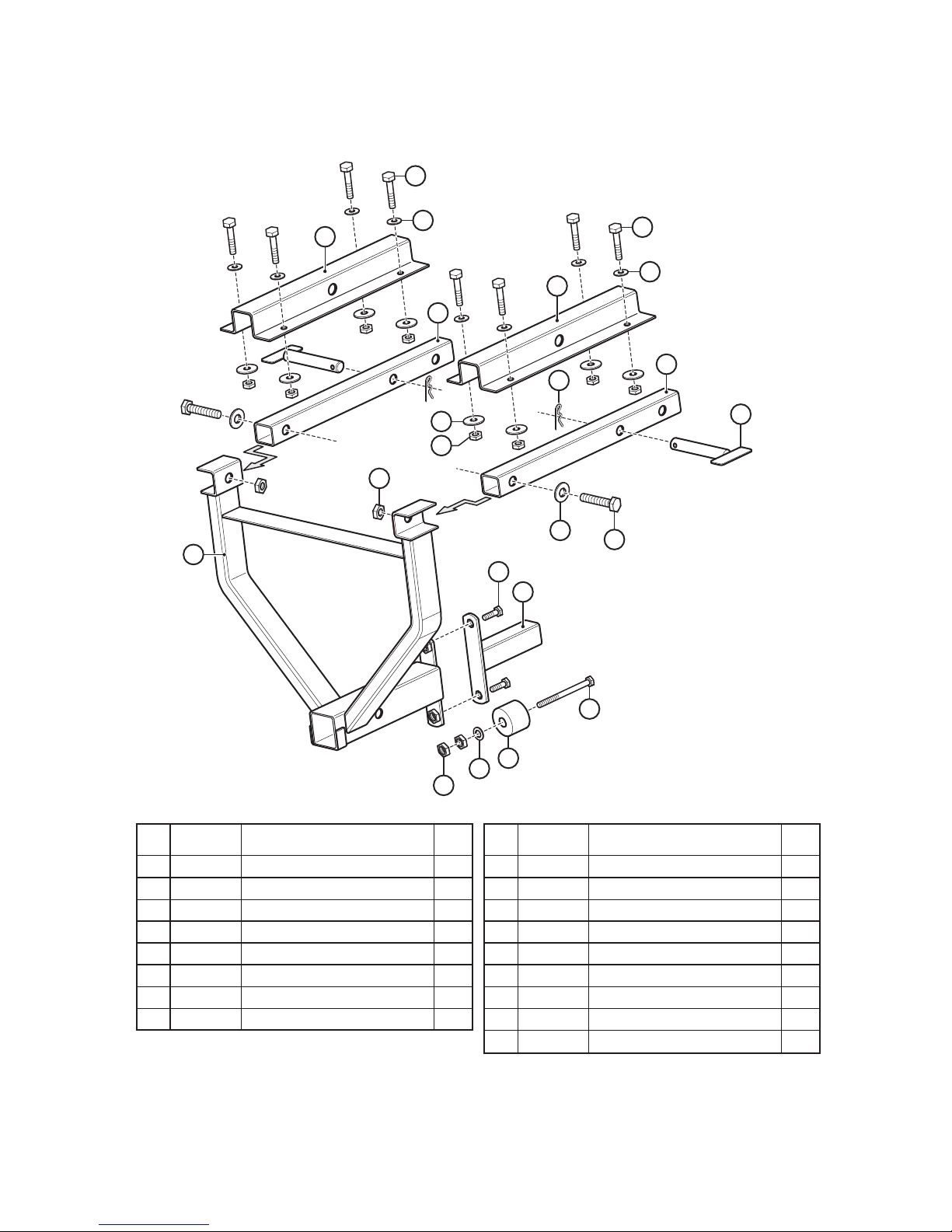

1SM4 Drop Utility Hitch for Fast-Cast 300 and 400 - Illustrated Parts List

15

3

7

6

14

14

10

5

10

5

9

4

2

8

1

11

513

12

17

16

16

Maximum Load Weight

Not to Exceed 240 lbs. Gross

(including the weight of the Spreader)

1

2

3

4

5

6

7

8

1SM3P4

1CS1P11

1CS1P8

1CS1P9

1CS1P41

1SM1P3

1SM1P2

1SM4P10

1/2" Flat Washer

1/2"-13 Lock Nut

3/8"-16 x 1" Hex Bolt

3/8"-16 Lock Nut

3/8" Flat Washer

2-5/16" Hair Pin Clip

5/8" x 5-1/2" Hitch Pin

1/2"-13 x 2" Hex Bolt

Item

No.

2

2

2

8

9

2

2

2

Qty.

Part

No. Description

9

10

11

12

13

14

15

16

17

1CS2P15

1SM4P2

1SM4P3

1SM4P4

1SM4P5

1SM4P9

1SM4P6

1SM4P7

1SM4P8

3/8" Fender Washer

3/8"-16 x 2" Truss Bolt

3/8"-16 Hex Nut

3/8"-16 x 5" Hex Bolt

2" Rubber Stopper

Mounting Rail

Drop Mount Weldment

Mounting Rail Hat Section

Mule Adapter

Item

No.

8

8

2

1

1

2

1

2

1

Qty.

Part

No. Description

15 of 17

Sno-Pro Fast-Cast Series Spreaders

1SM3 3-Point Tractor Mount - Illustrated Parts List

1

2

3

4

5

1SM1P7

1SM1P3

1SM1P2

1SM1P6

1SM1P1

5/16" Linch Pin

2-5/16" Hairpin Clip

5/8" x 5-1/2" Hitch Pin

7/8" x 5-1/2" Lift Arm Pin

3-Point Frame

Item

No.

2

1

1

2

1

Qty.

Part

No. Description

5

3

2

1

4

16 of 17

Sno-Pro Fast-Cast Series Spreaders

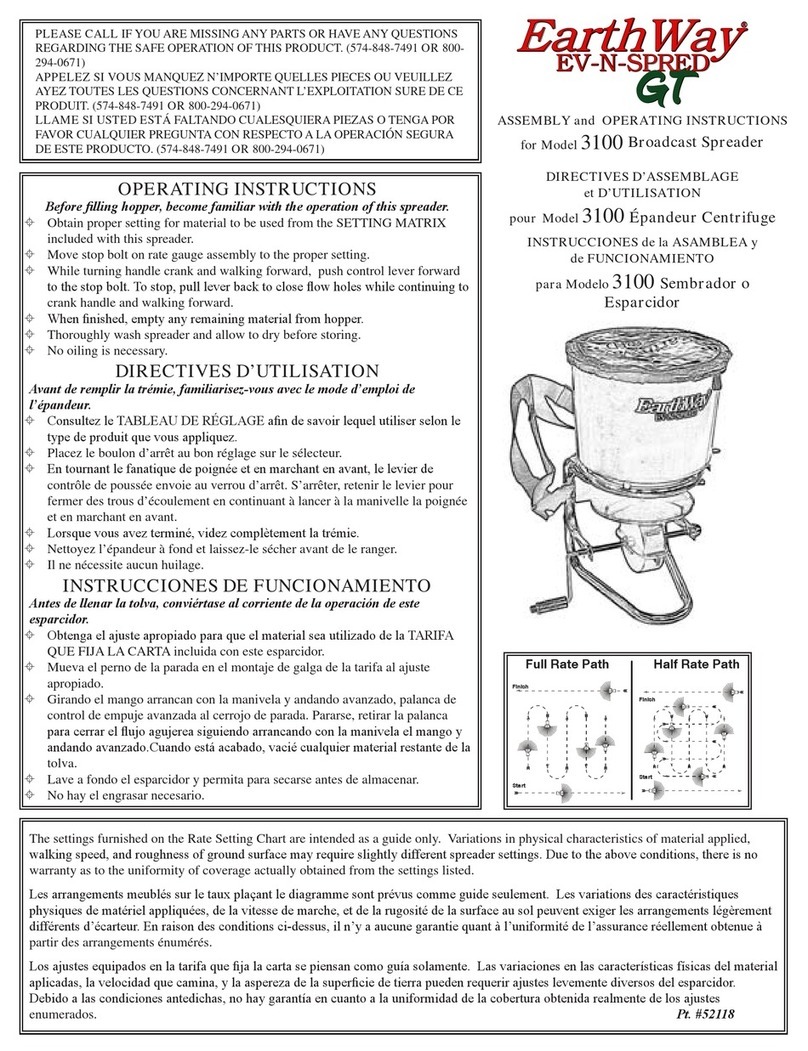

1AD1 - Adjustable Deflector (Controls Spread Pattern) 1GC1 - Gate Flow Control Kit for Fast-Cast 2000

1SC3 - Variable Speed Control for Fast-Cast 300 or 400

1SM2 - 2" Light Duty Receiver Mount

(Required for all Fast-Cast 2000 Installations)

1WC3 - Weather Cover for Fast-Cast 300 or 400

ON

POWER SPEED

VARIABLE SPEED CONTROL

3456

7

8

4

4

2

1

GATE POSITION

1

2

3

4

5

Fast-Cast Spreader Optional Accessories

Sno-Pro Fast-Cast Series Spreaders

17 of 17

20

AMP

INPUT OUTPUT

BATTERY

OPTIONAL

CONTROLLER

Move leads to positions

shown when installing

Optional Controller.

SAE 2

COND PLUG

DOUBLE FEMALE 3" JUMPER

(remove jumper for use with

VC-150 Variable Speed Control)

4

6

5

1 2

7

3

8

1

2

3

4

1CS2P27

1CS2P27

1CS2P25

1CS2P29

Wiring Harness for Fast-Cast 300

Wiring Harness for Fast-Cast 400

On / Off Switch

Rubber Switch Boot

Item

No.

1

1

1

1

Qty.

Part

No. Description

5

6

7

8

1CS2P33

1CS9P7

1CS2P34

1SC3

Fuse Holder

20 Amp Mini-Fuse

3/8" Ring Terminal

Optional Variable Speed Controller

Item

No.

1

1

2

1

Qty.

Part

No. Description

Wiring Harness for Fast-Cast 300 and 400 Spreaders - Illustrated Parts List

From all of us at Curtis, Thank You for choosing our products!

Notes:

This manual suits for next models

8

Table of contents

Other Sno-Pro Spreader manuals

Popular Spreader manuals by other brands

Earth Way

Earth Way EV-N-SPRED C22HD Assembly and operating instructions

Earth Way

Earth Way EV-N-SPRED GT 3100 Assembly and operating instructions

Earth Way

Earth Way Ev-N-SprEd 2030 Series Assembly and operating instructions

TMG

TMG TMG-MSS10 product manual

BE Ag & Industrial

BE Ag & Industrial BE-PFS G Series Operations & parts manual

HURST

HURST KL-32 operating instructions