Sno-Pro Fast-Cast 550 series User manual

®

™

Fast-Cast 1CS6E - Aluminum Hopper with Stainless Steel Body & Electric Motor

Fast-Cast 1CS6H - Aluminum Hopper with Stainless Steel Body & Gas Motor

Fast-Cast 1CS6CPH - Poly Hopper with Carbon Steel Body & Gas Motor

1 of 18

FAST-CAST 550 SERIES SPREADERS

Curtis Industries Inc. LLC, 111 Higgins St., Worcester, MA 01606 TEL: (800) 343-7676 FAX: (508) 854-3377 For Parts and information visit us at www.Curtisindustries.net

Curtis Industries Inc. LLC, reserves the right to change product design or specifications without notice or liability.

Assembly and Owner's Manual - January 2011

1CS6E

Electric Spreader

Revised 7 February 2011

2 of 18

►DonotattempttooperatethisSpreaderuntilyouhavereadandunderstandallwarningsandinstructions

intheOwner’smanualandonSpreaderunit.Failure to read and follow all warnings and instructions

may lead to serious injuries or death.

►Foryoursafety,warningandinformationdecalshavebeenafxedtothisproducttoremindall

operatorsofsafetyprecautions.Ifdecalsaremarked,damagedordestroyed,replacewithnewdecals

orderedfromCurtisIndustries,LLC.

IMPORTANT: Before you Start...

1. Most accidents are preventable and caused by human error.

Exercise care and precautions to prevent the possibility of injury to operator or to others.

2. Before working with the Spreader, secure all loose tting clothing and unrestrained hair.

3. Always wear safety glasses with side shields when working metal against metal. Failure to do

so could result in serious injury to the eyes.

4. Never allow children to operate or climb on equipment.

5. Never attempt to adjust or service Spreader while engine is running.

6. Never attempt to un-jam Conveyor Chain while engine is running.

7. Do not stand behind Material Chute while Spreader is discharging.

8. Do not refuel a hot engine. Allow time to cool before refueling.

9. Never weld or grind on equipment without having a re extinguisher available.

10. Always inspect unit for defects: Broken, worn or bent parts, weakened areas on Spreader or

Mount.

11. Always shut off vehicle and power source before attempting to attach or detach or service

Spreader unit. Be sure vehicle/power source is properly braked or chocked.

12. Always make sure personnel are clear of areas of danger when using equipment.

13. Always keep hands, feet, and clothing away from power-driven parts.

14. Remember, it is the owner’s responsibility to communicate information on safe usage and

proper maintenance of all equipment.

■ NEVER enter Hopper Box while Conveyor Chain is moving.

■ DO NOT RIDE on any part of the Spreader while vehicle is in motion.

■ Disconnect & lock out Power source before adjusting or servicing.

DANGER

WARNING

MOVING PART HAZARD

TO AVOID INJURY

3 of 18

IMPORTANT

■ Always check areas to be spread to be sure no hazardous conditions or substances are in the

area.

■ Never operate equipment when under the inuence of alcohol, drugs or medication that might

alter your judgement and / or reaction time.

■ Do not overll Spreader. (See decal on Spreader for ll capacities)

■ Failure to keep Conveyor Chain Links lubricated and free running can damage the Conveyor Chain,

Drive Shafts and body structure.

■ Failure to maintain Conveyor Chain or other components can void warranty.

Complete this Check List Prior to Initial Start-Up & Operation

Read and understand Curtis Owner’s & Operator’s Manual.

Read and understand Engine Manual.

Read and understand ALL Warning Decals.

Check Fuel Level.

Check Engine Oil Level.

Grease all Lubrication Points.

Oil Conveyor Chain.

Wire In-Cab Control Panel.

Coat Harness Connector Ends with Dielectric Grease.

Verify Spreader is secure in Vehicle using provided Ratchet Straps.

For Utility Vehicle applications (i.e. JD Gator, Kawasaki Mule, etc.)

Dump Body Safety Chain must be attached to secure Dump

Body & Prevent accidental release of Dump Body.

For Pickup Truck Applications make sure locking Bolts are in place

before moving vehicle.

General Maintenance Requirements

1. Wash Unit thoroughly after each use.

2. Lubricate Bearings

3. Periodically Lubricate Conveyor Chain with new or used Engine Oil.

4. Check Engine Oil every 5 hours or daily before use.

5. Change Engine Oil every 50 hours of Operation or every season.

6. Service Engine Air Filter every 100 Hours of Operation or every season.

When choosing a location

for the Control Panel, do not

position the Panel in line with

the Driver’s or Passenger’s seat

to ensure the Control Panel is

not hit accidentally.

1D. Body Safety Chain Installation

For UTV applications: A Dump

Body Safety Chain must be

attached to secure the Dump

Body and prevent the accidental

release of the Dump Body.

InstallEyeboltstoVehicleFrameandDumpBodyof

theUtilityVehicle.Usinga32"ChainandaOneLink

Connector,attachChaintotheEyeboltsmountedto

theFrameandDumpBody.SafetyChainsaretobe

usedinconjunctionwiththeHoldDownAssemblies.

AttachingaChainwillpreventanaccidentalrelease

oftheDumpBody.TheChain/Eyeboltsetupisnot

requiredforPickuptruckapplications.

Section 1. Installation Instructions

1A.TheFast-Cast550Spreaderisdesignedformounting

inthebedofmostUtilityVehicles.FourHold-Down

AssembliesareprovidedforsecuringtheSpreaderto

theVehicle.

For Pickup Truck Installation

See page 15.

1B.RemovetheTailgatecompletelyfromtheVehicleif

possible.CentertheSpreaderinthebedoftheUTV

andshifttheSpreaderasfarforwardaspossible,

butleavingenoughclearancefortheMaterialChute

installationattherear.UsingfourHoldDown

Assemblies,securetheSpreadertotheVehicle.

1C.In-Cab Control Panel Installation

ConnecttheWireTerminalEndoftheHarnessCable

totheControlPanel.Whenconnectingwires,besure

theignitionswitchisinthe'OFF'position.Mountthe

ControlPaneltotheundersideofthedashboard,

makingsuretheControlPanelisgroundedtothe

Vehicle.

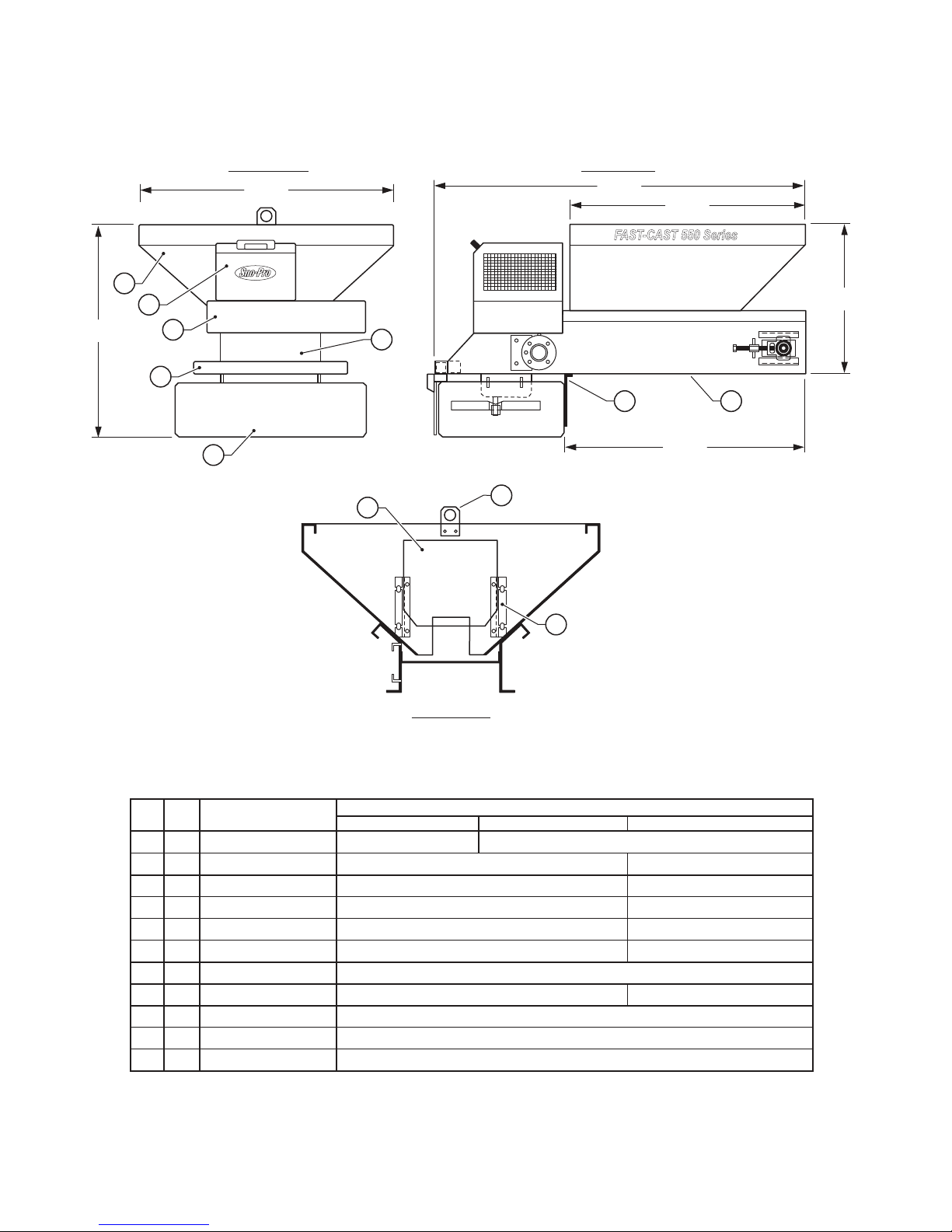

Figure 1. Fast-Cast 550 Spreader Overview (UTV mounted)

Hopper Assembly

Conveyor Assembly

Engine Assembly

Discharge

Assembly

Hold-Down Assemblies

(2 per Side)

Hopper

Gate

IMPORTANT

4 of 18

Sno-Pro Fast-Cast 550 Spreader

CAUTION

NOTE

5 of 18

Sno-Pro Fast-Cast 550 Spreader

1D. (continued)

Failure to attach this Chain

may result in an accidental

Body Dump, damaging the

Spreader, the Utility Vehicle,

persons seated in the Vehicle,

or standing nearby.

Section 2. Operating Instructions

2A. Engine Starting and Cab Controls (Gas Motors)

Step 1.Verifythatthe'ON/OFF'Switchisinthe

'ON/RUN'positionontheCabControlPanel.

Step 2.GotoEngineattherearofSpreader.

MovetheThrottleControltothe'FAST'

Position.

PushPrimerBulbrmly3-5times.

GraspRopeHandleandpullcordrapidly

tostartEngine.

(SeeEnginemanualfordetails.)

Step 3.FromtheCabControlPanel,ipthe

ConveyorSwitchtothe'ON'position.

ThiswillengagetheConveyorChainand

SpinnerDisc.

Figure 3. 1CS6E-C Electric Spreader Cab Control

2B. Electric Spreader and Cab Controls

Step 1.Verifythatthe'ON/OFF'Switchisinthe

'ON'positionontheCabControlPanel.

ThiswillengagetheConveyorChainand

SpinnerDisc.TheGreenIndicatorLightwill

comeon.

Step 2.SpinSpeedControllertodesiredspeedsetting.

Step 3.Anadditionalamountofmaterialcanbe

spreadinspotsbytogglingthe'BLAST'Switch.

TheSwitchcanalsobeheldonforincreased

dispersalwhenneeded.

TheYellowindicatorlightilluminateswhenever

the'ON'switchistoggledtoindicatea3-Spin

Burstspinisoccuringtoclearthe

Spinner/ConveyorSystemontheSpreader.

TheSpreaderwillthenoperateatthespeed

settingonthedial.

TheRedIndicatorLightilluminateswhenthe

isoverloaded.StoptheSpreaderfunctionsand

checktheSpreaderformaterialproblemsinthe

Spinner/ConveyorandtheGateareawhereit

feedsfromtheHopperbeforeresuming.

2C. Gate Height Adjustment Steps

Step 1. LoosentwoGateScrews.

Step 2.AdjustGatetodesiredheight.

Step 3.TightenGateScrews.

WARNING

2D. Material Chute Deectors

AdjusttheMaterialDeectorstonetunethe

spreadpattern.KeepallMaterialDeectorsatthe

sameangle.

Foralargerspreadpattern:RaiseDeectors.

Forasmallerspreadpattern:LowerDeectors.

Never attempt to adjust

Material Deectors while

Spreader is operating.

2E. Conveyor Chain Adjustment

TightenbothTake-UpBoltsequallyuntilslackis

goneintheConveyorChain.

After adjusting the Conveyor

Chain, verify that the Take-Up

Shaft is not at an angle.

Never attempt to adjust

Conveyor Chain while Spreader

Engine is running.

2F. Fast-Cast 550 Spreader Storage

1.)WashUnitThoroughly

2.)OilConveyorChain

3.)LubricateAllBearings

2G. Fast-Cast 550 Spreader Lubrication Requirements

2H. Fast-Cast 550 Service Requirements

Section 3. Fast-Cast 550 Spreader Drawings

Thefollowingpagesshowthedimensions,parts

andspecicationsoftheFast-Cast550Spreader.

Sno-Pro Fast-Cast 550 Spreader

6 of 18

WARNING

IMPORTANT

WARNING

Location

Engine Oil

Take-Up Bearings

4 Bolt Flange Bearings

Spinner Bearings

Conveyor Chain

Lube Type

SAE 30

Bearing Grease

Bearing Grease

Bearing Grease

Engine Oil

Location

Engine Oil

Engine Oil

Engine Filter

Spark Plugs (.030 Gap)

Harness Connectors

All Bearings

Conveyor Chain

Interval

5 Hours or Daily

50 Hours or 1 Season

100 Hours or 1 Season

100 Hours or 1 Season

50 Hours or Monthly

50 Hours or Monthly

100 Hours or 1 Season

Recommend

Check

Change

Check or Change

Check or Change

Check Condition

Lubricate

Lubricate

• 5.5 Hp Honda

Vertical Shaft Engine

• 500 lbs. Capacity

• 4 to 24 ft. Spreading

Width

• Stainless Steel Body

• In-Cab Contol Panel

1CS6H

• 5.5 Hp Honda

Vertical Shaft Engine

• 500 lbs. Capacity

• 4 to 24 ft. Spreading

Width

• Carbon Steel Body

• In-Cab Contol Panel

1CS6CPH

• Electric Motor draws

less than 20 amps

• 500 lbs. Capacity

• 4 to 24 ft. Spreading

Width

• Stainless Steel Body

• In-Cab Contol Panel

1CS6CE

Options available for all Fast-Cast 550 Spreaders

• 1WC2 - Weather Cover

• 1CS6-SCR - Top Screen

• 1SM6 - Truck Bed Mount

(trucks only)

Fast-Cast 550 Spreader Models

Sno-Pro Fast-Cast 550 Spreader

7 of 18

40.00

33.38

REAR VIEW

SIDE VIEWREAR VIEW

58.50

23.50

37.00

38.00

1

2

3

4

6

8

7

9

5

11

10

1CS6 Fast-Cast 550 Spreader Assembly Overview - Illustrated Parts List

1

2

3

4

5

6

7

8

9

10

11

1CS6-P1-00

1CS6-P3-00

1CS6-P3-01

1CS6-P2-03

1CS6-P2-08

1CS5-P2-09

1CS6-P1-11

1CS6-P2-06

1CS6C-P3-00

1CS6C-P3-01

1CS6C-P2-03

1CS6C-P2-08

1CS5C-P2-09

1CS6C-P1-11

1CS6C-P2-06

1CS6P-P1-00

See Page 7

1CS6-P1-12

1CS6-P1-14

Hopper Assembly

Engine Cover

Motorbed Plate

Bumper

Deflector - Fixed

Deflectors

Conveyor Assembly

Gate

Gate Guide

Spinner Cover

Lifting Eye

Item

No.

1

1

1

1

1

3

1

1

1

1

1

Qty. Description Part Number

ALUM HOPPER/SS BASE POLY HOPPER/SS BASE POLY HOPPER/CARBON STEEL BASE

®

FAST-CAST 550 Series

Sno-Pro Fast-Cast 550 Spreader

8 of 18

REAR

VIEW A - A

1

14

19 17 12

5

18

TOP

A A

13

4

15

7

6

11

Side View

typical of both sides

9

8

16

3

10

2

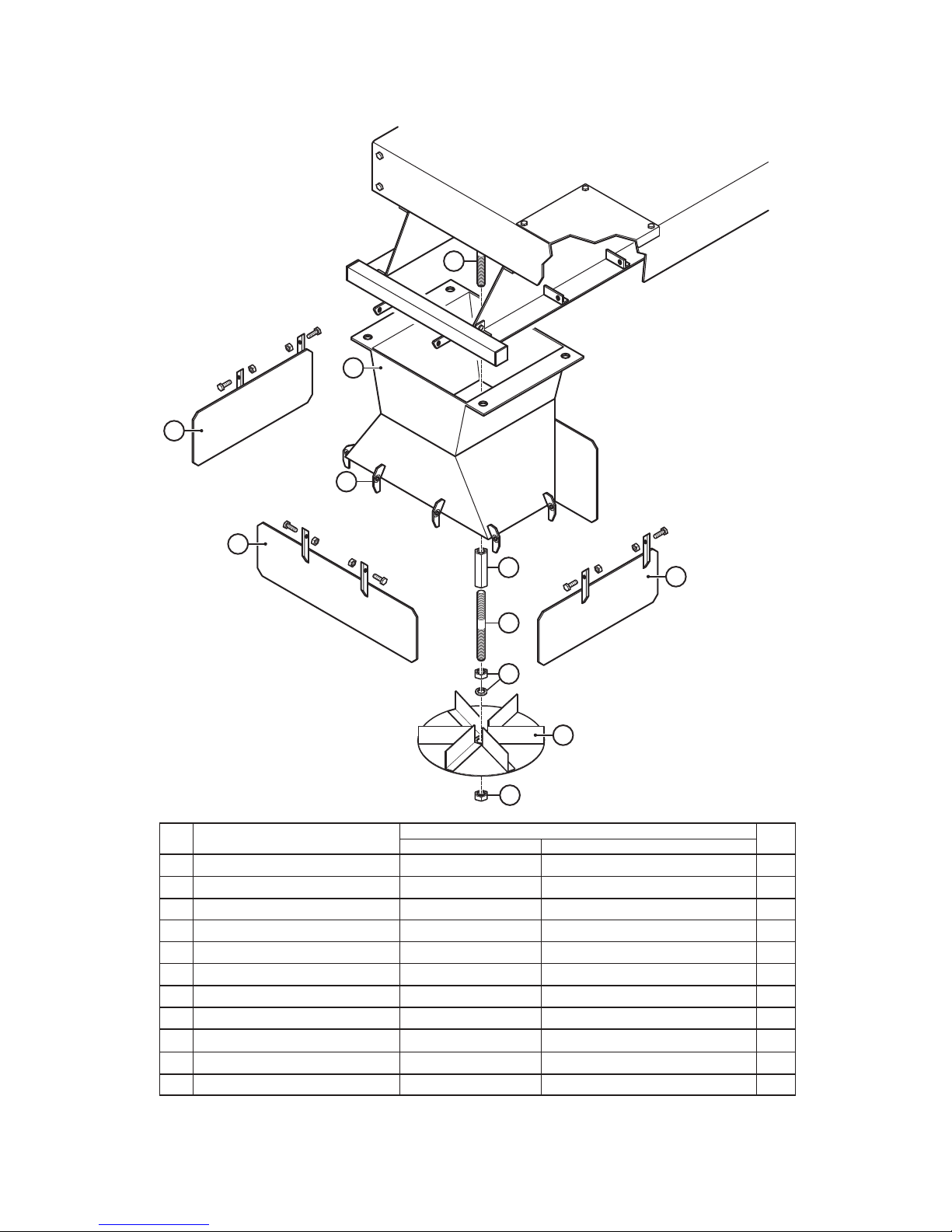

1CS6 Drive Assembly - Illustrated Parts List

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

1CS6-P3-375

1CS6-P4-02

1CS6-P4-03

1CS6-P4-04

1CS6-P4-05

1TS17-E11

1CS6-P4-06

1CS6-P4-07

1CS6-P4-08

1CS6-P4-09

1TS17-E10

1CS6-P4-11

1CS6-P4-12

1TS17-E13

1CS6-P4-14

1TS17-E104

1CS6-P4-16

1CS6-P5-03

1CS6-P2-01

3.75 HP Engine

# 40 Spinner Drive Chain

# 40 Clutch Drive Chain

Conveyor Chain

Gear Box

8 T Sprocket 1" Bore

11 T Sprocket 7/8" Bore

16 T Sprocket 1" Bore

52 T Sprocket 3" Bore

24 T Sprocket 3/4" Bore

1" Take Up Bearing

3/4" Pillow Block Bearing

1" Take Up Shaft

4 Bolt Bearing

Conveyor Belt

5/8" Take Up Bolt

Spinner Shaft Nuts

Clutch

Pillow Block Bracket

Item

No.

1

1

1

1

1

4

1

1

1

1

2

2

1

1

1

2

2

1

1

Qty.

Part

No. Description

Sno-Pro Fast-Cast 550 Spreader

9 of 18

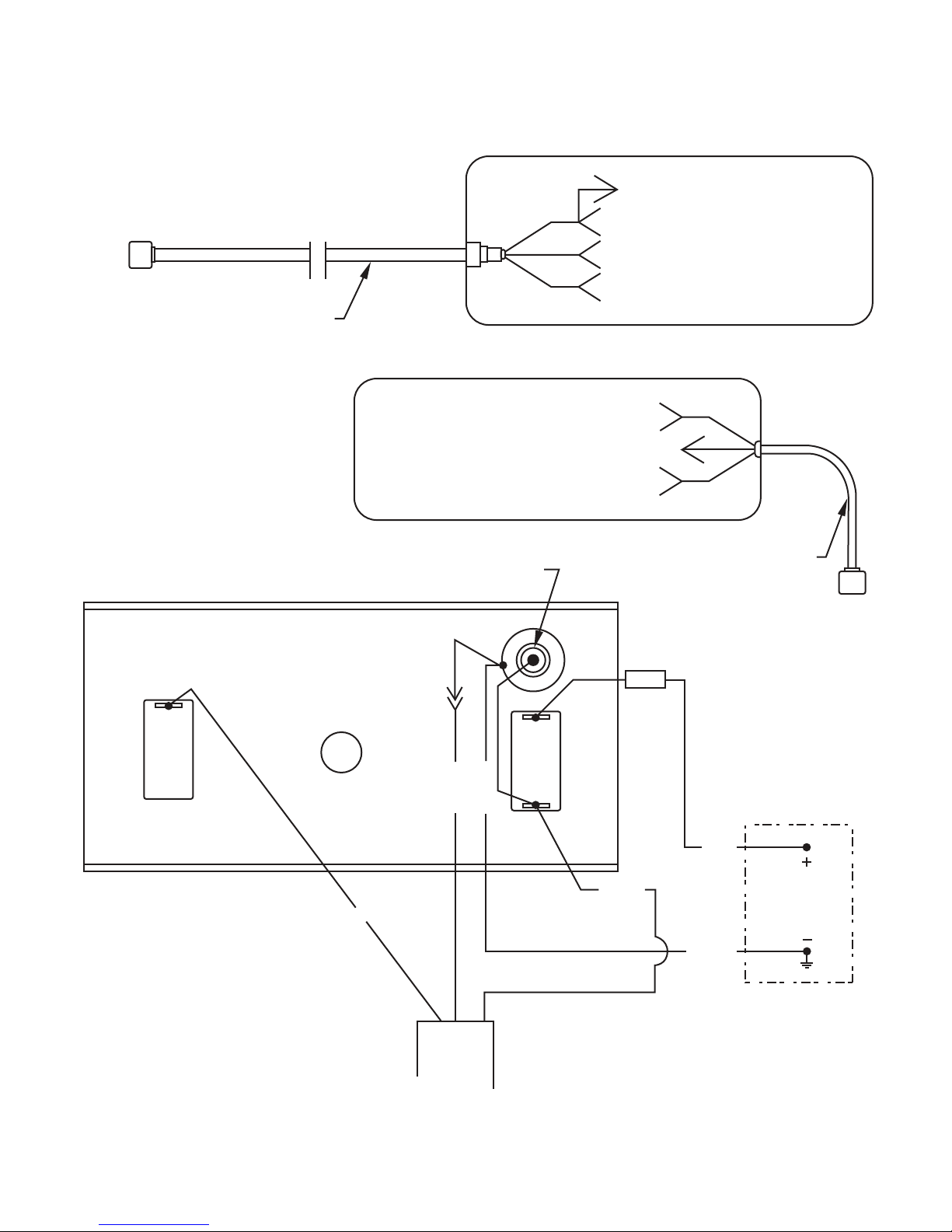

CAB CONNECTIONS

WHITE - CONVEYOR

GREEN - GROUND

BLACK - ENGINE

WHITE - CONVEYOR

1CS6-P5-05-2

26' LONG

1CS6-P5-05-21

4' LONG

INDICATOR LIGHT

REAR VIEW OF

BLACK

GREEN

RED

12VDC BATTERY

OR POWER POINT

BY CUSTOMER

FUSE

WHITE

WHITE

CONV.

SWITCH

ENG.

SWITCH

CLUTCH

3 WIRE

GREEN

GREEN

GREEN - GROUND

BLACK - ENGINE

SANDER CONNECTIONS

CONTROL PANEL

1CS6 Fast-Cast 550 Spreader Control Diagram for Gas Motor Powered Spreaders

Sno-Pro Fast-Cast 550 Spreader

10 of 18

1

2

3

4

6

7

8

9

10

1CS6E-M

1CS6E-MP

1CS6E-HWK

1CS6E-HWK

1CS6E-HWK

1CS6E-HWK

1CS6E-SB

1CS6E-SA

1CS6E-H

Electric Motor

Electric Motor Mounting Plate

3/8"-16 x 3/4" Hex Bolt SS

3/8" Flat Washer SS

3/8" Split Lock Washer SS

3/8"-16 Hex Nut SS

11T Drive Sprocket

54T Sprocket

Electrical Harness

Item No.

1

1

8

8

8

1

1

1

1

Qty.Part NumberDescription

1CS6E Electric Drive Assembly - Illustrated Parts List

Spreader

Chassis

1

2

9

3

6

8

6

7

4

3

4

10

Sno-Pro Fast-Cast 550 Spreader

11 of 18

1CS6E-H Electrical Harness for Electric Motor Spreaders

1CS6E-H Electrical Harness Connections for Electric Motor Spreaders

SB 50 Red

Multipole Connectors

Powerpole

Connectors

SB 50 Red

Multipole

Connectors

1CS6E-C Controller

Electric

Spreader

Motor

1 9

0

2 8

4 6

3 7

10

OVERLOAD

SPEED CONTROLLER

ON

OFF

BLAST

5

VEHICLE

BATTERY

Fuse Holder

TO

VEHICLE

GROUND

TO POSITIVE

TERMINAL

-

--

+

++

AB

C

SB 50 Red

Multipole

Connector

SB 50 Red

Multipole

Connector

SB 50 Red

Multipole

Connector

A

B

C

Powerpole

Connectors

1/4" Ring

Terminals

10 Ga Red

8 ft. Long

10 Ga Black

8 ft. Long

10 Ga Yellow

20 ft. Long

10 Ga Green

20 ft. Long

10 Ga Yellow

3 ft. Long

10 Ga Green

3 ft. Long

Sno-Pro Fast-Cast 550 Spreader

12 of 18

1CS6 Optional Pick Up Chute Assembly (includes 1SM6 Mount) - Illustrated Parts List

1

2

3

4

5

6

7

8

9

10

11

1CS6-P10-00

1TS17A-E6

1CS1P25

1CS6-P4-24

Not Orderable

Not Orderable

1CS6-P10-06

1CS6-P10-05

1CS6-P4-16

1CS6-P4-18

1CS6-P4-16

Material Chute Assembly

Material Deflector - Hinged

Material Deflector - Adjustable

Hinge

Material Deflector - Adjustable

Existing 17" Shaft

Coupling Nut - 3/4"-10 x 2-3/4"

6" Extension Stud - 3/4"-10 x 6"

3/4" Nuts & Lock Washer

Existing 14" Spinner Disc

Existing 3/4" Nut

1CS6-P10-A00

1CS6-P4-22

Material Deflector - Adjustable

1CS6-P4-24

Material Deflector - Adjustable

1CS6-P4-22

1CS6-P10-06

1CS6-P10-05

1CS6-P4-16

1CS6-P4-18

1CS6-P4-16

Item

No.

1

3

1

6

1

1

1

1

2

1

1

Qty.

Part Number

Description STAINLESS STEEL CHUTE CARBON STEEL CHUTE

NOTE: Specify which Chute type during order

6

4

9

8

7

11

Spreader Chassis

2

1

3

5

10

Sno-Pro Fast-Cast 550 Spreader

13 of 18

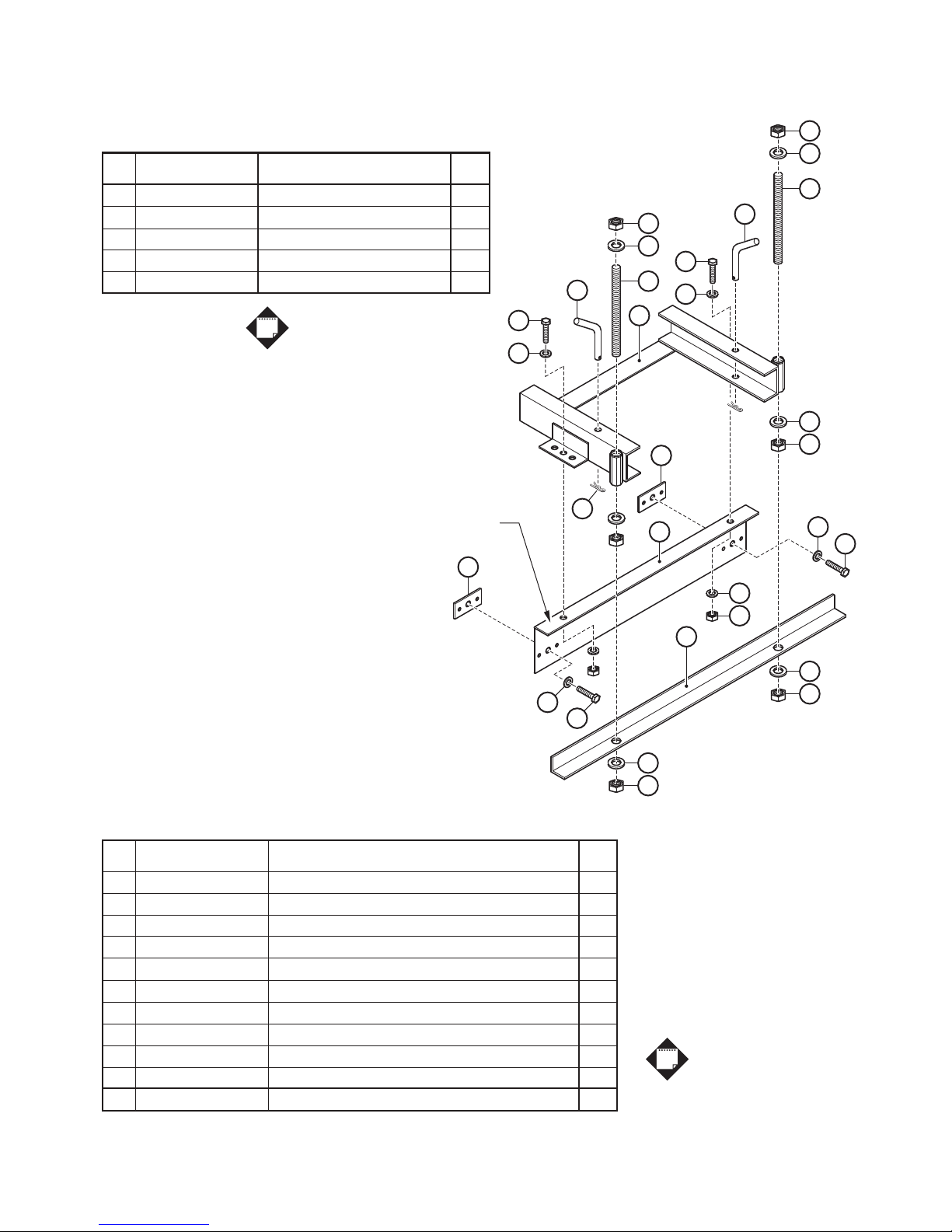

1SM6 Optional Pickup Truck Mount - Illustrated Parts List

1SM6 Pickup Truck Mount - Illustrated Parts List

Item

No.

5

6

7

8

9

10

11

12

13

14

15

1CS6-P10-22

1CS6-P10-09

1CS6-P10-10

1CS6-P10-11

1CS6-P10-12

1CS6-P10-13

1CS6-P10-14

1CS6-P10-15

1CS6-P10-16

1CS6-P10-17

1CS6-P10-18

1/2-13 x 10" Threaded Rod

1/2-13 UNC Hex Nut

1/2" Flat Washer

1/2" Hitch Pin x 3"

Hair Pin

3/8-16 x 1-1/4" Hex Bolt

3/8-16 UNC Hex Nut

3/8" Flat Washer

#10-24 x 3/4" Bolt

#10-24 Lock Nut

#10 Flat Washer

2

8

8

2

2

4

2

6

4

4

4

Qty.

Part

No. Description

The following is a HW Kit listing and are not sold separatley. Buy replacements locally.

6

9

See Page 14

for mounting

7

10

12

12

11

10

12

10

12

10

12

5

6

7

6

7

6

7

6

7

5

8

4

4

8

2

3

1

The 1SM6 Optional Pickup Truck Mount is 2 Assemblies.

The Mount plus the Pickup Chute Assembly.

1

2

3

4

NS

1CS6-P10-20

1CS6-P10-04

1CS6-P10-01

1CS6-P10-07

1CS6-P10-A10-HW

Receiver Mount

Sill Mounting Angle

Bumper Angle

Sill Mounting Bracket

Hardware Kit

Item

No.

1

2

1

1

1

Qty.

Part

No. Description

NOTE

Item numbers 13,14 and 15

are shown on page 14.

NOTE

Sno-Pro Fast-Cast 550 Spreader

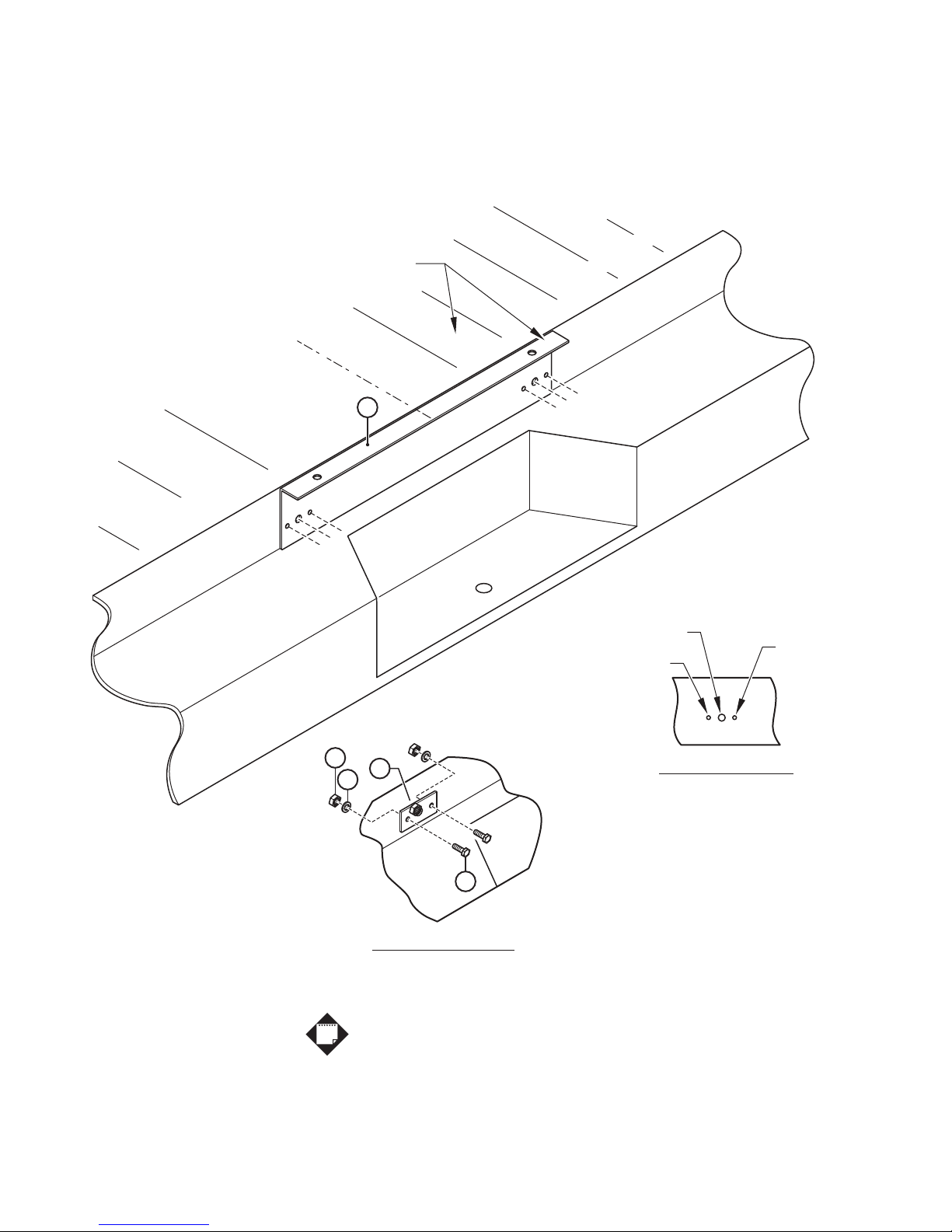

14 of 18

14

15

13

CURTIS

CU

B

B BA

B

A

B

B

A

SILL

SILL

VEHICLE BUMPER

THESE TWO SURFACES

MUST BE FLUSH

MOUNTING DETAIL

DRILLING DETAIL

1/4" DIA.

1/4" DIA.

1/2" DIA.

TRUCK BED

TRUCK BED

3

4

1SM6 - Sill Angle Mounting Diagram

See Parts listing on Page 13.

NOTE

Sno-Pro Fast-Cast 550 Spreader

15 of 18

1CS6 Fast-Cast 550 Spreader - Recommended Installation For Pickup Truck Applications

Eyebolts may be mounted to Truck bed, or existing Bed Hooks may be used.

FAST-CAST 550 Series

Turnbuckle

with Hook

Straps

Tiedown

Safety Cable

Eyebolts

TOP VIEW

SIDE VIEW

Hook

1. Insert Cable through the two Eyebolts at the front of Hopper.

2. Attach Hook to Tiedown and insert Cable through the loop in the Hook.

3. Tighten the Cable Clamp and cut excess Cable off.

4. Adjust the tension of the Cable by turning the Turnbuckle - Do Not Overtighten.

NOTE

Sno-Pro Fast-Cast 550 Spreader

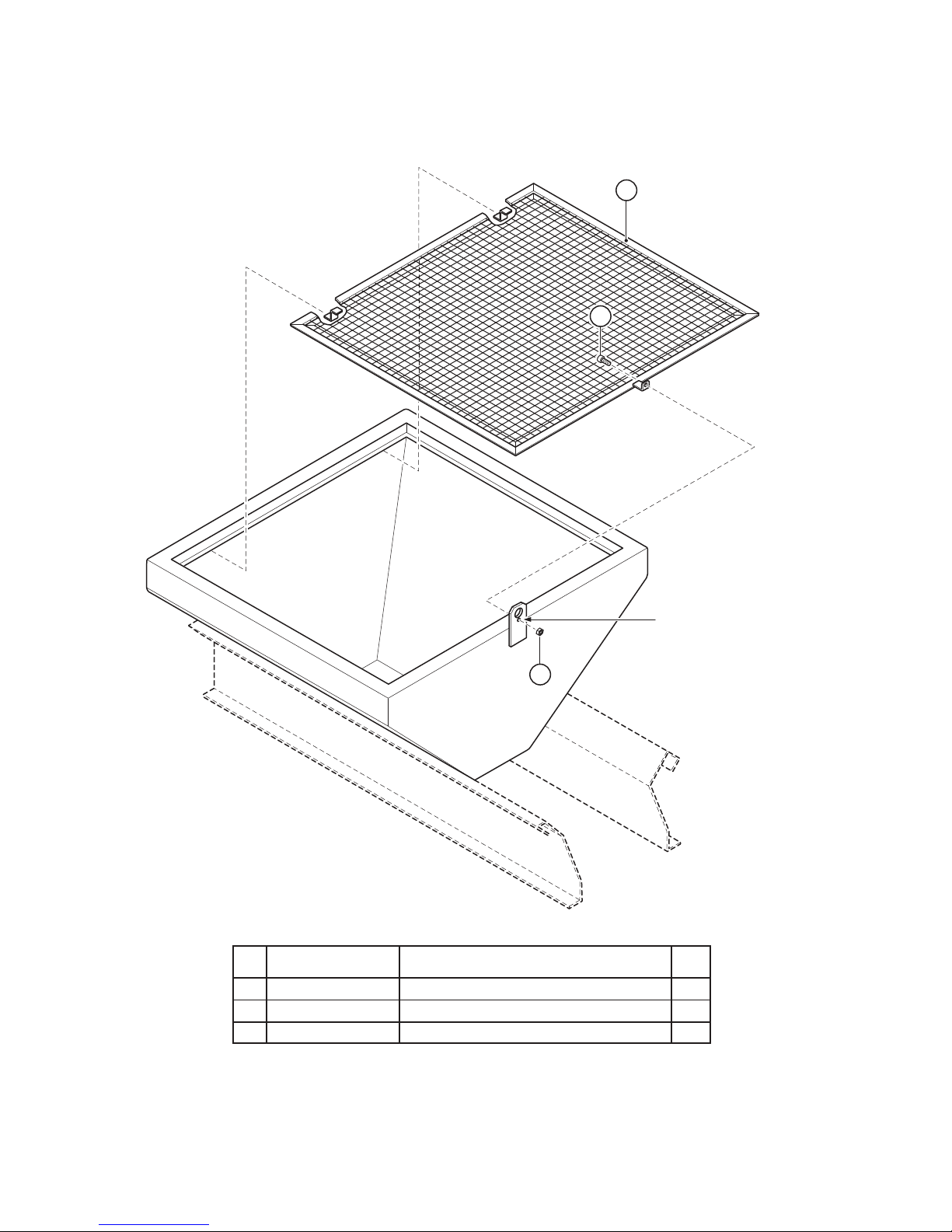

16 of 18

1

3

2

Mark and drill hole

in Lifting Eye

for 1/4" Fastener

1

2

3

1CS6-P10-32

1CS6-P10-33

1CS6-P10-34

Screen - 550 Mini

1/4-20 x 3/4" HHCS

1/4-20 Hex Nut

Item

No.

1

1

1

Qty.

Part

No. Description

1CS6-SCR Fast-Cast 550 Spreader Screen Option - Illustrated Parts List

Sno-Pro Fast-Cast 550 Spreader

17 of 18

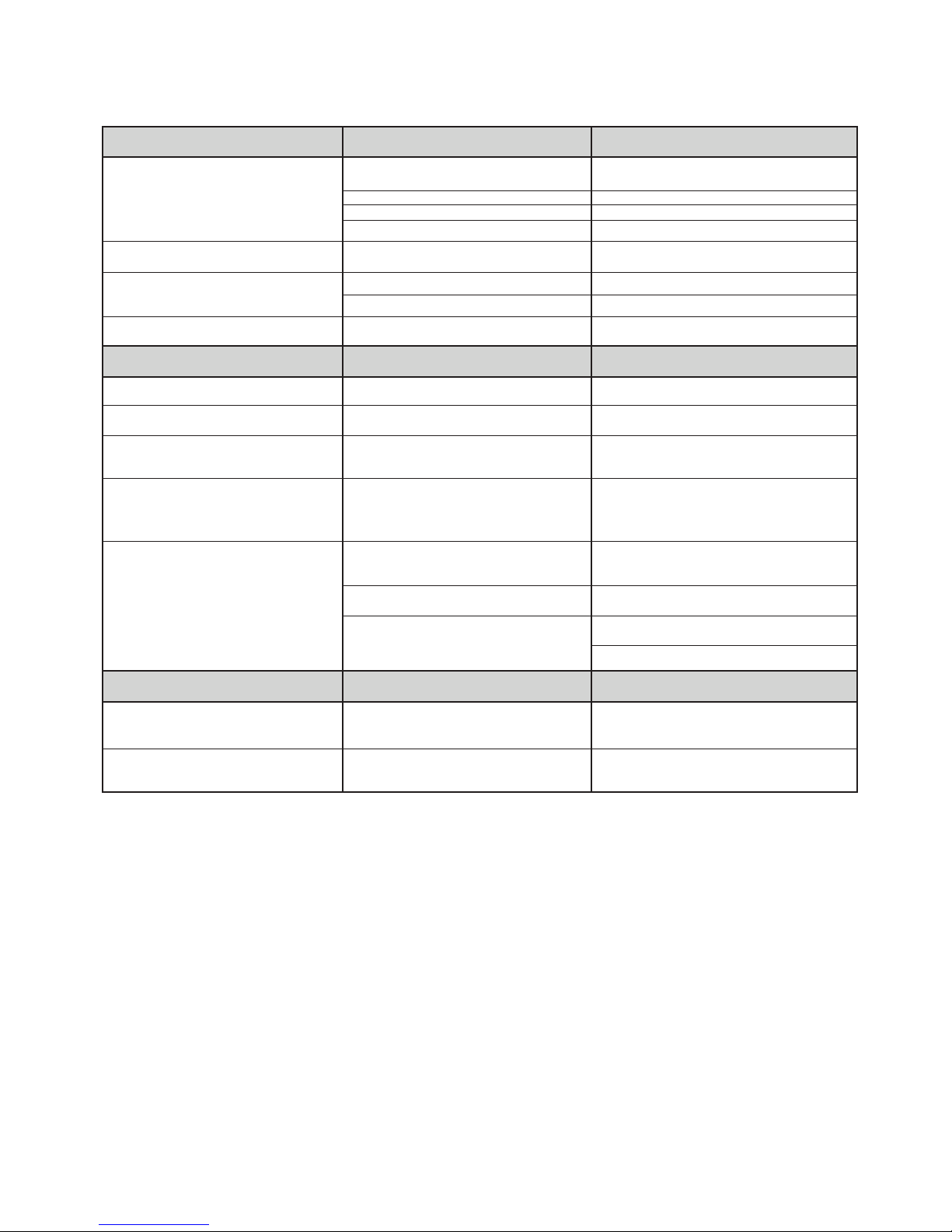

Engine will not start

Engine will not shut off

Engine smokes while running

General Engine questions

Not enough material being spread

Too much material being spread

Conveyor chain has too much slack

Take-up bolts have no adjustment left

Conveyor Chain does not move

Spinner Disc does not turn

Spinner Disc vanes wear early

On/Off Switch on Control Panel

in off position

Fuel Tank empty

Water in fuel

Loose wiring connection

Bad or missing ground at Control Panel

Clogged Air Filter

Overfilled oil level in engine

Gate not adjusted properly

Gate not adjusted properly

Take-up Bearings out of adjustment

Conveyor Chain has stretched

Debris or frozen material stuck in

Conveyor Chain

No power to Electrical Clutch

Loose connection between Shaft

& Disc

Suspect material

Put On/Off Switch in ON position

Add fuel

Drain fuel tank, add fresh fuel

Visually inspect Harness connections

Ground Control Panel to vehicle

Clean & replace Air Filter

Check Engine oil level

Refer to Engine Owners Manual

Open Gate for desired amount of material

Close Gate for desired amount of material

Adjust Take-up Bolts at front of Spreader.

Tighten Bolts to reduce slack.

Loosen Take-up Bolts completely.

Remove Links from Conveyor Chain.

Re-adjust Take-up Bolts.

Dislodge material from Conveyor Chain

Verify Electric Switch is getting power

Check and inspect Harness connections

Verify connections at Electric Clutch.

Tighten mounting Nuts on Shaft

Check material being spread

for rocks

Engine/Electrical Symptom Possible Problem Solution

Conveyor Symptom Possible Problem Solution

Spinner Symptom Possible Problem Solution

Fast-Cast 550 Spreader Troubleshooting Chart

Sno-Pro Fast-Cast 550 Spreader

18 of 18

LIMITED WARRANTY

Curtis warrants that Products sold to Customer shall be free from defects in material and

workmanship under normal use and service for one (1) year from the date of shipment.

IN NO EVENT SHALL CURTIS BE LIABLE FOR LOSS OF PROFITS OR INCIDENTAL,

INDIRECT, SPECIAL, CONSEQUENTIAL OR OTHER SIMILAR DAMAGES ARISING OUT OF

ANY SALE OF PRODUCT OR FROM DEFECTIVE PRODUCT.

This limited warranty shall automatically terminate if any product has been improperly installed,

maintained or operated or used for a purpose for which it was not designed. The limited warranty

does not cover Product which has been altered or parts which are expendable by their nature

(e.g. springs, nuts, bolts, pins, hoses, etc.).

In the event that a Product is defective, Curtis, at its option, will correct such defect at its expense

upon delivery of the Product to Curtis FOB, its Worcester, Massachusetts facility, or refund that

portion of the purchase price allocatable to the defective Product. The remedy contained in the

preceding sentence will be the sole and exclusive remedy against Curtis.

EXCEPT AS SPECIFICALLY PROVIDED IN THIS DOCUMENT, THERE ARE NO OTHER

WARRANTIES EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE.

From all of us at Curtis, Thank You for choosing our products!

Notes:

This manual suits for next models

3

Table of contents

Other Sno-Pro Spreader manuals

Popular Spreader manuals by other brands

Earth Way

Earth Way EV-N-SPRED C24HD Assembly and operating instructions

Earth Way

Earth Way 2600A-Plus Estate Assembly and operating instructions

Scotts

Scotts AccuGreen 3000 manual

Meyer

Meyer Blaster 350 Installation instructions and owner's manual

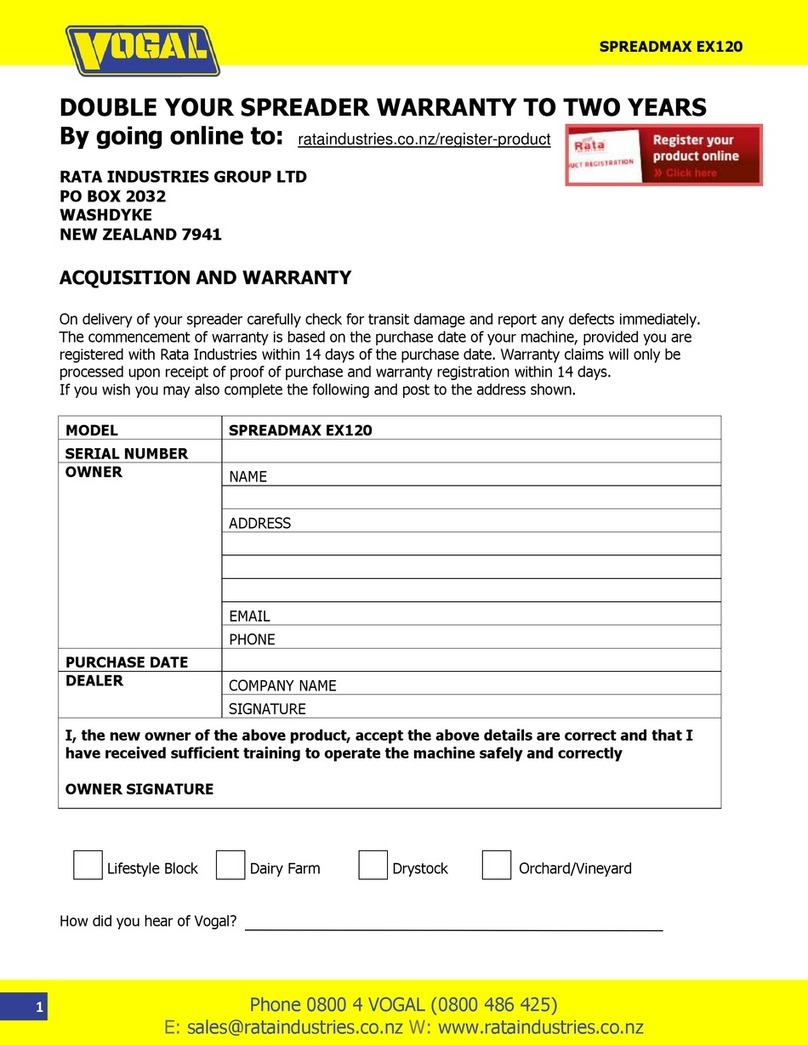

Vogal

Vogal SPREADMAX EX120 Operation Maintenance & Parts Manual

Meyer

Meyer V-FORCE 7400 Series Operator and parts manual