OPERATORS MANUAL –PSV-8L (ELECTRIC) AIR FLO MANUFACTURING., CO INC.

3 | P a g e

Spreader and Material Weights

Safety

1. Persons who install, mount, operate,

or service this equipment must be

properly instructed and warned.

2. Read operator manuals completely

before operating the equipment.

3. Read all instructional, cautionary,

and warning decals.

4. Check the spreader to ensure that

all shields and gates are in place.

5. Use care when mounting and

dismounting the spreader.

6. Make sure to turn off all power to

the spreader before performing any

repairs, maintenance, or

inspections.

7. Keep all personnel and property

away from the chute/spinner

assembly while the spreader is in

operation.

8. Keep the spreader unit and

components in proper working

condition. Replace any missing or

damaged safety signs.

9. Any unauthorized modifications to

the spreader and related

components may impair its

functions and/or safety.

10. Check to make sure all safety guards

are securely mounted into place

before operating the spreader.

11. Keep all loose clothing, hair, jewelry

and limbs clear of the spreader

before starting or operating the

spreader.

12. Do not adjust, clean, oil or unclog

material jams without first turning

off the spreader, removing the

engine spark plug and control panel

fuse.

13. Do not climb on or in the spreader

during operation.

14. Do not ride the spreader while in

operation.

15. Do not attempt to operate the

spreader when it is in need of

maintenance or repair.

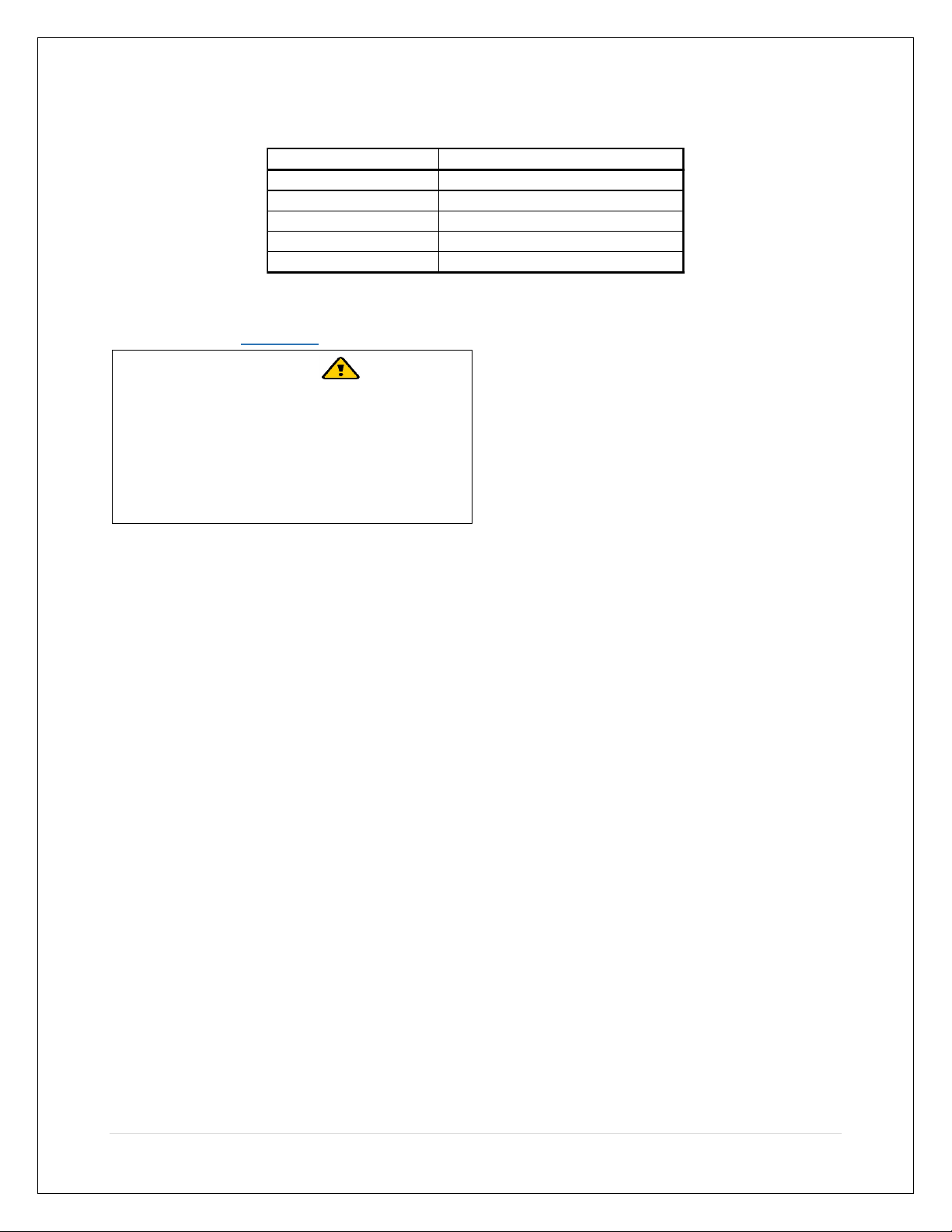

MATERIAL WEIGHT (POUNDS PER CUBIC YARD)

PSV-8E 650 lbs.

#1 Rock Salt 950 lbs.

#2 Rock Salt 1,215 lbs.

Coarse Sand-Dry 2,565 lbs.

Coarse Sand- Wet 3,240 lbs.

WARNING

Observe the following Safety Precautions

before, during and after operating the

spreader. By following these precautions

and common sense, possible injury to

persons and potential damage to this may

be avoided.