BOGBALLE M2 User manual

M-line

GB

M2(W) / M3(W) / M6W

Operator’s Manual

0404-02-01-14 V15

M2(W) / M3(W) / M6W

1

CONTENTS

SUBJECT

Page

OVERVIEW ……………………………………..

2

TECHNICAL SPECIFICATIONS …………………………………….. 3

STANDARD EQUIPMENT …………………………………….. 4

OPTIONAL EQUIPMENT …………………………………….. 4

MAINTENANCE AND CARE

Normal maintenance………………….. 5

Special maintenance……………………. 6

Lubrication………………………………. 7

Generally…………………………………. 7

Spreading vanes…………………………. 7

…………………………………….. 5

GUARANTEE / RESPONSIBILITY …………………………………….. 8

GENERALLY ……………………………………..

8

SAFETY and PROTECTION AGAINST ACCIDENT …………………………………….. 8

SPREADING SYSTEM …………………………………….. 9

SETTING SYSTEM …………………………………….. 10

FUNCTION – How to do …………………………………….. 11

MACHINE SETTINGS / Normal and late application

PTO- speed…………………………… 13

TILT ANGLE…………………………….. 14

HEIGHT,

incl. late application….... 14

SETTING OF QUANTITY……………….. 16

VANE / SPREAD WIDHT…………….. 17

FUNCTION SPREADING VANE…….. 18

Trend SYSTEM…………………………… 19

…………………………………….. 13

NORMAL spreading

Practical test………………………………. 21

Test with test trays……………………… 22

Examples of NORMAL spread patterns...24

…………………………………..… 21

HEADLAND spreading TO BORDER

Practical test………………………………. 28

Test with test trays……………………… 28

Ex. of HEADLAND spread patterns….. 29

…………………………………….. 26

HEADLAND spreading FROM BORDER

Ex. of HEADLAND spread patterns.. 31

…………………………………….. 30

REDUCED SPREAD WIDTH …………………………………..… 32

TURNING AT THE HEADLANDS …………………………………..… 33

SPREADING ON NON-RECTANGULAR FIELDS …………………………………….. 34

CHECK THE TRACTOR – before use …………………………………….. 35

CHECK THE SPREADER – before use …………………………………….. 35

PRACTICAL HINTS …………………………………….. 36

M2W/M3W – special …………………………………….. 37

USE OF CALIBRATION RATE CHECK KIT

REST EMPTYING……………………….. 38

…………………………………….. 38

EC-Declaration of Conformity …………………………………….. 43

PICTOGRAM ……………………………………..

44

NOTES ……………………………………..

45

NB ! Fitting instruction for different options – are supplied with the options.

M2(W) / M3(W) / M6W

2

OVERVIEW – M3 illustration

F) Setting pointer

Degree meter

To

p

link fixture

J) Link pins

I) Angle transmission

G) Connection rod

D

)

Shutter

A) Cardan joint

B) Telescope

Serial No. plate

E) Setting axle

H)

Friction clutch

M2(W) / M3(W) / M6W

3

TECHNICAL SPECIFICATIONS, general

•

M2(W) Hopper volume : base 1.250 – 2.350 Litres

•

M2(W) Hopper volume : plus 1.800 – 3.000 Litres

•

M3(W) Hopper capacity : plus 1.800 – 4.050 Litres

•

M6W Hopper capacity : plus 4.050 – 5.550 Litres

•

M2(W) Hopper capacity : base Max. 2.500 Kg.

•

M2(W) Hopper capacity : plus Max. 3.000 Kg.

•

M3(W) Hopper capacity : plus Max. 4.000 Kg.

•

M6W Hopper capacity : Plus Max. 6.000 Kg.

•

Spread width : 12 – 42 Metres

•

Spreading capacity : Ca. 0,35 – 400 Kg/min.

•

3-point linkage : M2/M3

M6W

Cat. II / ISO 730/I

Cat. III / ISO730/I

TECHNICAL SPECIFICATIONS, specific

The volume of the M2/M2W base machine can be increased in steps of 550 litres by

mounting modules (max. 2 modules).

The volume of the M2/M2W plus machine can be increased in steps of respectively 450

litres and/or 750 litres by mounting modules.

The volume of the M3/M3W and M6W plus machine can be increased in steps of 750 litres

by mounting modules (M3/M3W max. 3 modules – M6W max. 5 modules).

SPECIFICATION M2base

1.250

M2base

1.800

M2base

2.350

M2plus

1.800

M2plus

2.550

M2plus

3.000

M3plus

1.800

M3plus

2.550

M3plus

3.300

M3plus

4.050

M6Wplus

5.550

Load height cm. 102 120 140 110 130 141 110 130 148 167 204

Hopper volume Litres 1250 1800 2350 1800 2550 3000 1800 2550 3300 4050 5.550

Hopper capacity Kg. 1375 1980 2500 1980 2500 3000 1980 2.800 3630 4000 6.000

Hopper width cm. 240 240 240 290 290 290 290 290 290 290 290

Hopper depth cm. 125 125 125 140 140 140 140 140 140 140 140

Fill opening cm. 234 x 116 234 x 116 234 x 116 284 x 131 284 x 131 284 x 131 284 x 131 284 x 131 284 x 131 284 x 131 284 x 131

Outside b x l cm. 240 x 137 240 x 137 240 x 137 290 x 144 290 x 144 290 x 144 290 x 164 290 x 164 290 x 164 290 x 164 290 x 164

Outside “W” cm. 240 x 137 240 x 137 240 x 137 290 x 144 290 x 144 290 x 144290 x 172 290 x 172 290 x 172 290 x 172 290 x 172

Net weight Kg. 406 435 464 450 492 518 510 552 594 636

Net weight “W” Kg. 490 519 548 534 576 602 660 702 744 786 1.044

Total weight Kg. 1496 2125 2754 2430 2992 3518 2490 3352 4224 4636

Total weight “W” Kg. 1580 2209 2838 2514 3076 3602 2640 3502 4374 4786 7.044

The hopper capacity is made from hopper volume in litres multiplied with a specific weight of 1,1 Kg/litres.

NB! Max. hopper capacity: M2(W)base : 2.500 Kg

M2(W)plus : 3.000 Kg

M3(W)plus : 4.000 Kg

M6W plus : 6.000 Kg

M2(W) / M3(W) / M6W

4

STANDARD EQUIPMENT

The M() / M()W machine is from factory supplied with all necessary standard equipment.

•PTO shaft with free wheeling

•Headland spreading TO BORDER, Trend with manually reversible transmission.

•Agitators, Excentric free- and slow rotating.

•Screens to open, 2 units with cones.

•Closing of only one outlet, choose right or left.

•Reduction outlet for micro granules, without use of tools.

•System for late application, link pins can be mounted in 2 heights.

•Degree meter, for setting the tilt angle of the machine.

•Transmission, with reversible gear and friction clutch / overload coupling.

•Mud guards

•TREND shift (only M2W, M3W and M6W)

•Traffic Lights

OPTIONAL EQUIPMENT

The following options can be supplied for the machine:

COMPONENT DESCRIPTION DIMENSION ART. NO.

Module, base M2(W) 550 litres 240 x 125 cm 6920-01

Module, plus M2(W) 450 litres 290 x 140 cm 6930-17

Module, plus M() / M()W 750 litres 290 x 140 cm 6930-10

Hydraulic control M(), Incl. tube with valve 6381-01

Cable control M(), Only between 0 and 250 Kg/min. 6380-01

CALIBRATOR ZURF M(), Electric operating system 6386-01

TREND kit, FROM BORDER M() / M()W, fixtures FROM BORDER

6395-10

BORDER-kit,

Manual, DOUBLE SHIFT M() / M()W, Fittings TO and FROM BORDER 6395-20

TREND, SHIFT M2 / M3, Electric shift 6390-30

TREND, DOUBLE SHIFT M() / M()W, Electric shift 6395-40+30

Cable kit, HEADLAND spreading M(), Operation from drivers seat 280

cm 4690-28

do. M(), Operation from drivers seat 380

cm 4690-38

do. M(), Operation from drivers seat 480

cm 4690-48

Hydraulic motor M() / M()W, Incl. tubes and valves 6932-50

Hopper cover, base M2(W), Foldable w/full opening 240 x 125 cm 6921-45

Hopper cover, plus M() / M()W,Foldable w/full opening 290 x 140 cm 6931-45

Transport wheels M() / M()W, 4 Ø110 mm plastic wheels 6930-50

Connection system M(), +40% / -40% 6381-23

do. M()W, +40% / -40% 6381-29

Ladder M2 / M2W 6932-70

Ladder Extension M() / M()W, only with M-Trail 6932-85

Set of screens f/wide tyres M2/ M2W 6930-90

M2-Trail M2(W), Chassis Kit 1800-55

M3-Trail M3(W), Chassis Kit 1830-03

Trend Vanes, complete M() / M()W, System E1-T (L/R) 12 – 18 metres 4650-12

do. M() / M()W, System E2-T (L/R) 20 – 24 metres 4650-20

do. M() / M()W, System E6-T (L/R) 28 – 36 metres 4650-28

do. M() / M()W, System E8-T (L/R) – 42 metres 4650-36

do. M() / M()W, System U1-T (L/R) 12 – 18 metres 4650-50

All BOGBALLE products are subject to a continuous development. Therefore the list might not always be up-to-date.

M2(W) / M3(W) / M6W

5

MAINTENANCE AND CARE

NORMAL MAINTENANCE

The BOGBALLE machine is manufactured in such a way that it requires a minimum

of maintenance.

In the construction it is considered that cleaning and lubrication can be completed

quickly and thoroughly – without taking apart the machine.

The surface treatment consists of a robust powder paint – in addition all essential

wear parts and bolt assemblings are made of stainless steel.

Many of the components of the machine are greased once and need no extra

maintenance, for instance the central and angle gears of the transmission.

The maintenance mentioned below is absolutely necessary!

”If the machine is maintained – it will still be new - in 5 years!”

”If the machine is not maintained – it will be old – next year!”

The machine must always be thoroughly cleaned after use. The cleaning

should be done with water perhaps with soap in it. When using a high-

pressure cleaner only use low pressure and do not clean direct on the axle

seals of the transmission.

Do not use grease-removing cleaning liquid – without giving the

machine – just after drying – an application of anti corrosion oil.

It is strongly recommended to grease the machine - BEFORE using it

first time. Remember always to grease all of the machine in a

corrosion protecting liquid (for instance oil). It is not sufficient just to wash

the machine.

•Without protection, rust might arise within a few hours in

areas, where the paint has been damaged – because fertiliser

salts hold acid and is therefore most corrosive.

Any paint damage should be cleaned and painted. A possibility could also be to treat

the damage by Tectyl or a similar product.

Please consider that cleaning products and corrosion protecting

liquids might include dissolvents that might dissolve the glue fixing the

transfers.

M2(W) / M3(W) / M6W

6

SPECIAL MAINTENANCE, Friction clutch

The transmission of the machine is equipped with friction/overload

clutch.

The friction clutch is a most important component protecting against

overload – and a damaged transmission / PTO- shaft.

The friction clutch protects especially the reversible gear system

of the Trend transmission. The Trend-system is based on an

inpact clutch.

The friction clutch must be maintained, and it must be checked,

that it is not corroded.

The friction clutch must ”slip” at START of the tractor PTO.

If the clutch does not slip – the transmission will be damaged.

The friction clutch ”slips” approx. 1-2 turns at START of the tractor PTO. This reduces

the load on the components of the transmission to approx. 1/10 of the load to which the

transmission is exposed, if the coupling is not able to ”slip”.

As principal rule the coupling must be separated and cleaned if

the machine has not been used for more than 6 months.

Alternatively minimum once a year.

It is always necessary to START the tractor PTO

”slowly / smoothly”!

GUIDANCE ON HOW TO CLEAN THE FRICTION CLUTCH.

Demount the 6 bolts of the clutch – and the clutch is

separated.

Clean all the ”slip sur-

faces” for rust (perhaps

with a wire brush) – and

reassemble the bolts.

If needed replace the

clutch plates.

The clutch surfaces should not

be greased with oil/grease!

The friction clutch’s bolts are tightened by a torque wrench:

The splined axle has to slip at:

60 N/m

180 – 220 N/m

2 coupling plates

BOLTS

Splined axle

M2(W) / M3(W) / M6W

7

LUBRICATION

The components below must be greased according to below instruction.

See the explaining sketch in the paragraph ”OVERVIEW”.

LUBRICATION ONCE A DAY:

POS. COMPONENT INSTRUCTION

A

B

C

D

E

F

G

Cardan joint and lock of the PTO

Telescope axles of the PTO

Agitator R and L (Under cone)

Setting and closing shutter (Bottom of hopper)

Adjustment axle (Cross axle w/ 4 bearings)

Setting handle (Axle w/ 2 bearings)

Connection rods (Rods between axle and shutters)

Use grease

Use grease

Use grease

Use oil

Use oil

Use oil

Use oil

Note

C)

If the agitators are overgreased, a high pressure might restrict the rotation of the

agitator bearing. If this is the case the lubricator nipple must be demounted, which

will release the pressure. Grease sparingly – e.g. one pump/season.

PARTS GREASED ONCE:

The central and angle gears are filled with special grease and needs

no lubrication.

GENERAL

A new machine will always ”move” a little bit in all nuts +bolts.

Therefore all nuts and bolts of the machine must be retightened

- first time it is put into operation - after 5 to 8 hours’ operation.

Exception is the bolts in the central and angle gears – these are

locked with lock-tite.

Be aware that stainless nuts + bolts might ”weld together” When

mounting such bolts – the thread must be greased with cutting

lubricant or copper grease !

SPREADING VANES

The spreading vanes are manufactured of high quality manganese

steel, MN12. (MN 12 has a hardness corresponding to 3 times the hardness of

stainless steel).

But still the vanes will be worn due to modern and abrasive fertilisers.

Therefore the vanes must be considered a wear part – that must be

exchanged dependent on the quantity / type of fertiliser.

Always clean contact surfaces of the vanes and the spreading

disc for dust etc – before mounting and tightening the vane !

IF HOLES ARE WORN IN THE VANES THEY MUST BE

EXCHANGED AT ONCE!

M2(W) / M3(W) / M6W

8

GUARANTEE / RESPONSIBILITY

•Claim conditions are according to Danish legislation. Service and repair are

made free of cost within 12 months from date of purchase on the following

conditions:

•That the failure is due to construction or material faults

(Normal wear, missing maintenance and misuse not included).

•That the failure is not due to not original components / equipments.

•That persons with no technical knowledge to the machine have not tried to repair.

•Compensation for person or crop injury do not fall on the supplier.

GENERALLY

This machine is intended for spreading all common types of fertiliser.

Spreading of other flowing materials might also be possible. If so we draw the

attention to data list of the material concerned in order to determine possible safety

or health measures to be taken.

If the machine is used for spreading material which is not defined in the spread

charts for the spreader, the manufacturer of the machine can never be held

responsible.

SAFETY and PROTECTION

The transmission system of the machine:

PTO shaft, friction clutch and spreading discs w/vanes – must be considered”as

dangerous”, and absolute care must be taken with these machine parts, especially

in connection with rotation of the tractor PTO system.

DO NOT LEAVE THE TRACTOR CABIN – WITHOUT STOPPING THE PTO

SYSTEM OF THE TRACTOR!

Except when you have to calibrate the machine.

•Never go behind the machine – with rotating spreading discs.

•Never go under the machine – with rotating spreading discs.

•Never clean the machine - with rotating spreading discs.

•Never put hand/object into the hopper – with rotating spreading discs.

•Always check that the spreading vanes are correctly fixed.

•Check that the protection tubes of the PTO are intact.

•Check that the security chain of the PTO is fixed.

•Check that top link and top link pins are intact and secured by lynch pin.

•Check that lift arms and link pins are secured by lynch pin.

M2(W) / M3(W) / M6W

9

SPREADING SYSTEM

The BOGBALLE spreading system is base on an Integrated Center System – ICS,

where the spreading discs of the machine during NORMAL spreading – rotate

against each other – and spread in an angle on 180°, with full overlap.

The spreading system can with optimum fertilisers manage full overlap, on spread

width up to 28 metres.

This means in practice that right and left spreading disc form two opposite spread

patterns – overlapping each other.

Each spreading disc spreads the full spreading width. That means that the fertiliser

from the two spreading discs A and B – overlap each other. The spread width is

with good fertilisers - twice as wide as the distance between the tramlines - up to

28 metres.

This way you achieve a 4-double overlap – which ensures a most even distribution

of the fertiliser.

As shown in the diagram the spreading is made from the

present tramline – to the middle of the next two tramlines.

The spreading system is developed in such a way that

you are able to spread the fertiliser with a minimum of

machine setting.

This means in practice that you get a uniform distribution – no matter

which type of fertiliser and without special settings.

The BOGBALLE machine is therefore only equipped with one setting

handle – for setting the quantity.

+=

M2(W) / M3(W) / M6W

10

SETTING SYSTEM

The setting system consists of a scale pointer, different connection rods and

outlet shutters.

SETTING POINTER, Hydraulic / CALIBRATOR.

➊& ➋

The connection rod of the setting pointer must

be mounted / adjusted in such a way, that the

shutters of the spreader are closed - when the

setting pointer is placed on the scale ciffer ”0”.

(approx. 0,5 mm. opening)

The adjustment is made on the connection rod.

➌

As standard the connection rod is mounted in position (Ø10 mm.)

In case very large quantities being used on 28 - 42 metres' spread width, a +40% /

-40% connection rod (Ø12 mm.) can be used as option.

Same connection rod is used for very small quantities (Ø8 mm.).

ADJUSTMENT SHUTTERS

The shutters in the adjustment system are factory set so

that the machine distributes the fertiliser symmetrically.

That means that the fertiliser is shared in equal quantities

to each side of the machine.

The adjustment shutters must be adjusted so that the

shutters close exactly in the middle of the V-mark of

the bottom plate.

Normally you should not adjust the 4 connection rods

connecting the adjustment axle of the machine and the

shutters of the machine. These connection rods should

only be adjusted in case the system has been

dismantled and therefore misadjusted.

The setting is of great importance for the symmetry of the spread pattern.

Be aware that the adjustment shutters do not open equally in comparison to the V-

mark. This assymmetric function ensures automatic adjustment of the feed point

for precise spreading.

➊

➌

➋

M2(W) / M3(W) / M6W

11

OUTLET SHUTTERS

The machine’s hopper bottom is equipped with a turnable outlet shutter for right

and left side respectively.

The outlet shutter can be locked in three different positions.

0 Closed outlet (Calibration / rest emptying)

1 Normal outlet (For fertiliser)

2 Reduced outlet (For micro granules)

”2” .is only used if stated in the contents page of the spread chart.

The outlet shutters are set by pressing the handle

(A) against the hopper – and at the same time turn

the outlet shutter to the required position. The

handle locks the shutter in the U- cut.

FUNCTION

•The Trend sytem gives distribution of fertiliser a totally new dimension, where

PRECISION, USER FRIENDLINESS and RELIABILITY, are the three main

areas in which BOGBALLE M() / M()W – differs most essentially from the other

products in the market.

•The Trend system is the only transmission in the market with

reversible rotation direction.

The reversible rotation direction gives the optimum result for use of the

rotation direction, … towards the centre is most suitable for spreading on

the main area on the field, NORMAL spreading – and the reverse rotation

direction is most suitable for HEADLAND spreading at field borders.

…..high PRECISION is achieved, no matter which type of

spreading !

2

0

1

A

U- cut

M2(W) / M3(W) / M6W

12

•The Trend system ensures an optimum result, with a minimum of setting.

•The transmission of the machine with reversible rotation direction

together with the double function of the spreading vane ensure that the

spreader can be transformed from NORMAL spreading to HEADLAND

speading – by making only one change.

•The full 180°overlap is the key reason for achieving an optimum

NORMAL spread pattern – without other setting of the machine.

Therefore neither the length or the angle of the vane must be adjusted.

Also no side adjustmnet is necessary.

•The feed point of the machine is automatically shifted in comparison to

the quantity of fertiliser spread. This means that the feed point need

not be set.

…..high USER FRIENDLINESS is achieved, no matter which spreading!

•The design of the machine ensures maximum flexibility – without

making compromises.

•The slow rotating agitators of the machine prevents ”crushing” of the

fertiliser. The agitators are mounted directly on the axles of the

spreading discs, which means that the rotation is directly transferred –

and not through chains, belts etc. The agitators are not ”driven forcibly”

and the excentric movement means that the ”efficiency / function” of

the agitator is automatically adapted to the character of the fertiliser, so

that you will always have an even quantity – no matter how fastrunning

the fertilsier is, no matter how much fertiliser is in the hopper an no

matter in which angle the spreader is tilted (the angle of the spreader in

comparison to horizontal).

•The spreading discs of the machine have a diameter of 600 mm, which

ensures together with the shape of the vanes that one and same

machine is able to spread from 12 to 42 metres, with quantities from

0,35 to 400 kg/min.

•All the ”key parts” of the machine are made of stainless steel. This

includes also the parts that are painted (for instance the bottom of the hopper).

An exception is the spreading vanes which are for wear resistance

made of manganese steel (MN12).

•All the components of the machine are powder painted – before

assembly – and only stainless steel bolts are used.

…..high RELIABILITY, in all circumstances!

M2(W) / M3(W) / M6W

13

MACHINE SETTINGS

GENERAL GUIDANCE FOR MACHINE SETTINGS

PTO- speed, NORMAL spreading 540 rpm.

TILT- angle See chart (°)

WORKING HEIGHT, Standard 75 cm

WORKING HEIGHT, Late application Max. cm

WORKING HEIGHT, Chassis kit 100 cm

QUANTITY SETTING See chart Kg/Ha

VANE / SPREAD WIDTH, Position POS. 1-2

In the following you will find a more thorough explanation for the different

settings.

PTO- SPEED

When spreading fertilisers with low grain strength (< 2,0

kg), the PTO speed is lowered to 450 rpm.

In such cases the PTO speed will be indicated in the

spread chart for the fertiliser in question.

The machine has however at spread widths lower than 24 metres and when

spreading granular fertilisers, so much ”power surplus”, that deviations of ±5 %

(between 515 and 565 rpm.) will have no serious influence on the spreading result.

REMEMBER !

Consider a ”slow / smooth” START of the tractor PTO - with the tractor

idling!

ALWAYS STOP THE TRACTOR PTO – WHEN CHANGING THE

ROTATION DIRECTION !

Check that the PTO has a correct length in order not to damage the

transmissionCheck that the PTO has a correct length!

– in order not to damage the transmission!

540 r

p

m.

NORMAL spreading

Excl. HEADLAND spreading:

540 rpm.

HEADLAND spreading:

See instruction conc.

”HEADLAND SPREADING”

M2(W) / M3(W) / M6W

14

24 – 305

E-2 1-2

Kg/ Ha

Km/ h

Kg/min

±cm

8101214

1,0 24 19 16 14 7,7 3 4

1,5 53 42 35 30 16,9 3 4

2,0 94 75 63 54 30,1 3 4

2,5 147 118 98 84 47,1 3 4

3,0 206 165 137 118 66,0 2 3

TILT ANGLE

The machine must be ”tilted” as indicated in the spread chart. The tilt angle

is important for the spread width and is – besides the quantity setting – in

reality the only setting to be done on the machine.

Setting the tilt angle optimizes of the spread pattern – which means in

practice that a minimum variation coefficient (Vk) is achieved.

(See ”Examples of NORMALspread patterns”)

If you doubt, it is better to tilt the machine TOO MUCH – than too little!

In case the fertiliser quantity is changed (±Kg/Ha, for instance with CALIBRATOR or cable

control) – it will not influence the spread pattern seriously.

WORKING HEIGHT–STANDARD

Mount the spreader horizontally – or tilted

according to the statement in the spread

chart in question.

The tilt angle is adjusted on the top link of

the tractor and the present angle is seen

on the degree meter of the spreader.

+°

-°

Alternatively:

Distance from the upper

side of the spreading

disc – in horizontal

position – to the top of

the crop: 75 cm.

Distance from the centre of

the upper link pins – to the

top of the crop: 73 cm.

Spread chart

The pointer of the degree meter is set

to the tilt angle stated in the spread

chart.

Afterwards the machine is tilted by

adjusting the top link of the tractor –

until the level of the degree meter is in

the centre.

The setting is done with the tractor

parked on level ground.

It is recommended to check the setting of the degree meter by placing a level on the spinding discs of the machine.

75 cm

73 cm

Top of crop

M2(W) / M3(W) / M6W

15

WORKING HEIGHT – LATE APPLICATION

The spreader must be tilted when used for late application – dependant on

the distance between the crop top and the spreading discs: A

The chart below indicates the correction to be made – in relation to the tilt

angle of the spreader for NORMALspreading, and according to the chart.

Spread width

A = 15 – 35 cm.

Tilt addition (°)

A = 35 – 55 cm.

Tilt addition (°)

15

-

-

12

42

metres

metres

+ 4°

+ 3°

+ 3°

+ 2°

Example:

Tilt angle during NORMALspreading (15-42 metres) according to spread chart = +2°

Hight above crop (A) = 45 cm

Tilt angle during LATE APPLICATION = ( +2°+2°)= + 4°

WORKING HEIGHT – CHASSIS KIT

See the manual of the chassis kit.

Options are not necessary for

late application in high crops.

•The link pins of the spreader

are moved to the lowest

position in order to lift the

machine as much as possible.

This will minimize the risk of

damage to the crop.

A

Crop top Link pins

M2(W) / M3(W) / M6W

16

24 – 305

E-2 1-2

Kg/Ha

Km/ h

Kg/min

±cm

8101214

1,0 24 19 16 14 7,7 3 4

1,5 53 42 35 30 16,9 3 4

2,0 94 75 63 54 30,1 3 4

2,5 147 118 98 84 47,1 3 4

3

,

0206 165 137 118 66,0 2 3

Såtabel

QUANTITY SETTING, Spread chart / Internet: www.bogballe.com

The spread chart for M() is identical to the EX chart.

Spread chart for M()(+40%) is identical with EX(2)-chart. (Quantity + 40%).

If case the machine is not equipped with CALIBRATOR, the quantity setting is made

on the basis of the instructions in the spread chart.

It must be noted that the spread chart is only a guide, because the quantity spread

depends on the exactness of the driving speed and the tramline distance, but also

of the quality of the fertiliser in question.

The fertiliser will change character according to temperature, air humidity and often

varies with each delivery.

If an exact quantity is required (Kg/Ha), it is recommended to CALIBRATE the

machine by use of the BOGBALLE rate check kit. (See the paragraph ”USE OF RATE

CHECK KIT”)

Refer to the appropriate chart for the material to be spread for the settings required.

Spread chart

Vane type

Scale

setting

Vane

position

Tilt

angle (°)

Kg/Ha

Km/h

NB !

Vane type:

E-1 corresponds to E1 T (L/R)

E-2 corresponds to E2 T (L/R)

E-6 corresponds to E6 T (L/R)

E-8 corresponds to E8 T (L/R)

U-1 corresponds to U1 T (L/R)

The quantity (Kg/Ha) is set by the scale pointer of the

machine.

The setting system is equipped with a scale and a scale

stop with stepless movement – and fixed in the inverval

from 0 to 9 and with ”marks” for each 0,25 scale step.

The example shows the scale stop set to ”0”, corresponding

to a closed outlet of the machine.

Example: 12 Km/h

Scale = 2,5

98 Kg/Ha

Tilt

=

3

°

Kg/min

Chart

number

Spread

width

24-305

±cm

M2(W) / M3(W) / M6W

17

VANE / SPREAD WIDTH Setting U- cut

The spreading vanes are made in such a way that they are mounted in POS. 1-2, no

matter which type of fertiliser is used – and no matter which quantity is spread. This

means in practice that the spreading vane should only be ”moved / demounted” in case

a calibration or emptying of the hopper is made.

Take care that the vanes are mounted and fixed correctly !

The vanes are TYPE- MARKED respectively:

”R” (Right) For right spreading disc – seen from behind

”L” (Left) For left speading disc – seen from behind

E( )T-R

E( )T-L

The vane TYPE is chosen in relation to the required spread width and/or fertiliser type.

Below is shown spread width / vane type for the main fertiliser types in the market.

If there are deviations from this it will appear on the spread chart in question.

VANE TYPE SPREAD WIDTH MARK

Trend (Normal / headland vane) E1T 12 – 18 metres E1T R or L respectively

Trend (Normal / headland vane) E2T 20 – 24 metres E2T R or L respectively

Trend (Normal / headland vane) E6T 28 – 36 metres E6T R or L respectively

Trend (Normal / headland vane) E8T – 42 metres E8T R or L respectively

Trend (Normal / headland vane) U1T 12 – 18 metres U1T R or L respectively

The vanes are mounted as standard in POS. 1-2

When mounting the fixing bolt must be pulled fully out

into the U-shaped cut before tightening the nut.

If in special cases it is

necessary to mount

the vanes in an

alternative position –

this will appear from

the spread chart in

question.

POS.- guidance is

shown on a label

fixed to the machine.

POS. 1 - 2

H (R)

V (L)

Vane ”TYPE”

One vane in POS. 1

One vane in POS. 2 On each spreading disc

M2(W) / M3(W) / M6W

18

FUNCTION OF SPREADING VANE

The spreading vane is a key part of the machine – for which reason it is ver

y

important to mount the vanes correctly – and that they are intact.

The Trend system is using both sides of the spreading vanes with: FRONT

SIDE for NORMAL- spreading – and in connection with reversing the rotation

direction the BACK SIDE is used for HEADLAND- spreading.

NORMALspreading

•The very special shape of the vane ensures that at NORMAL spreading –

the fertiliser is following the total vane length – and 180°overlap is

achieved.

HEADLAND spreading

At HEADLAND spreading the fertiliser stream passes through the vane –

which reduces the fertiliser speed – therefore the spread width towards

headland is reduced – and adapted to the distance between tramlines and

border with 110°overlap.

It is very important that the spreading vanes are intact. This means that the

vanes should not be deformed and that no ”holes” are worn.

If there is rust/paint on the surface of the vanes – it will influence the spread

pattern. The fertiliser will grind away the rust – after spreading 100 – 200 Kg.

NORMALspreading is made with

the FRONT SIDE – of the

spreading vane – and with the

spreading discs rotating towards

eachother.

(

See next

p

a

g

e

)

HEADLAND spreading is made with the

BACK SIDE of the spreading vane-

and with the rotation of the spreading

discs away from each other.

(See next page)

M2(W) / M3(W) / M6W

19

The Trend SYSTEM….. will basically:

”Use the rotation direction which is most suitable for NORMAL spreading

……and HEADLAND spreading respectively.”

This means in practice that the system ensures with NORMAL rotation direction,

full overlap at NORMAL spreading on the main area of the field ……and a limited

spread pattern with single overlap towards the border at headland spreading – with

reversed rotation direction.

ALWAYS STOP PTO – WHEN CHANGING THE ROTATION DIRECTION !

ALWAYS START PTO SLOWLY / SMOOTHLY !

NORMAL spreading

HEADLAND spreading

The spreading discs rotating towards

eachother

4 –double overlap

180

°

overlap

The spreading discs rotating away from

eachother

Single overlap

110

°

overlap

This manual suits for next models

4

Table of contents

Other BOGBALLE Spreader manuals

Popular Spreader manuals by other brands

H&S

H&S 3123 Operator's manual

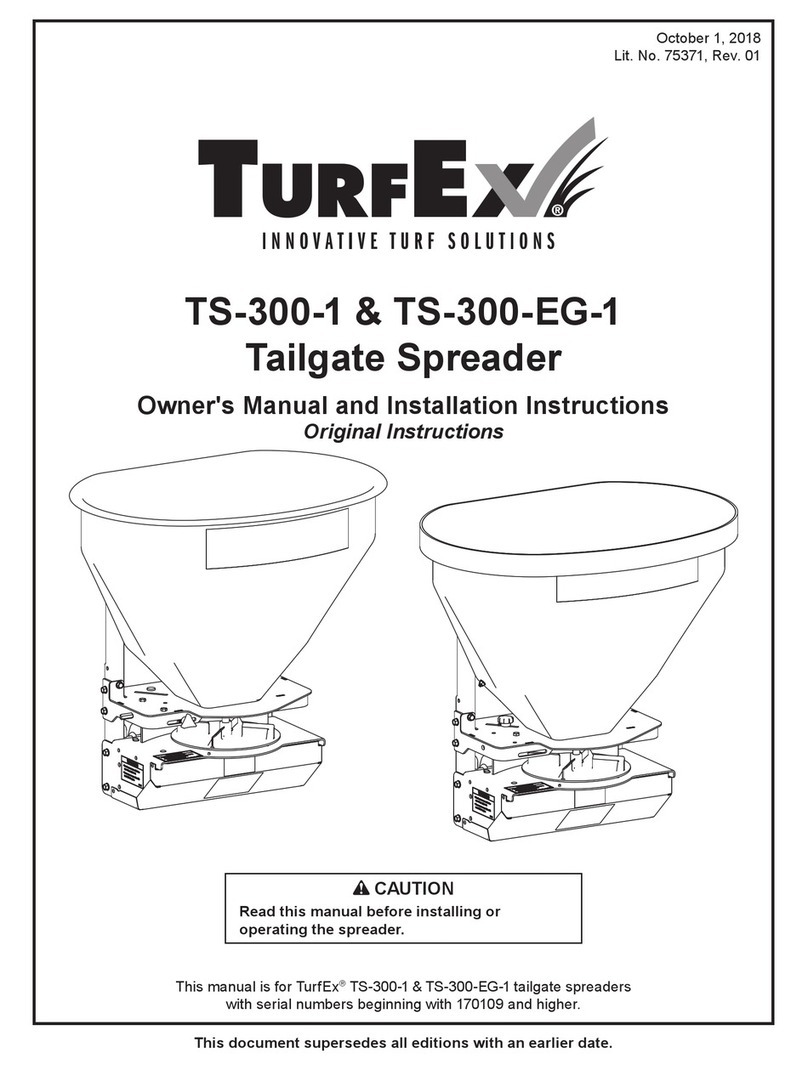

TurfEx

TurfEx TS-300-1 Owner's manual and installation instructions

Ecolawn

Ecolawn Eco 50 Operator's manual

Meyer

Meyer BL 240 PARTS LIST & INSTALLATION GUIDE

Kugelmann Maschinenbau

Kugelmann Maschinenbau DUPLEX operating instructions

P.Lindberg

P.Lindberg 9029312 Original manual

Finn

Finn BARK BLOWER BB-1208 Operator Instructions And Parts Manual

Cresco

Cresco 10SW manual

Western

Western Striker 98825 installation instructions

Art's Way

Art's Way Roda V140 Operator manual & illustrated parts list

Meyer

Meyer Blaster 750 Installation instructions and owner's manual

Jula

Jula 707-017 Assembly instructions