Sno-Way 99101220 Operating instructions

97101982A

INSTALLATION &

OWNER’S MANUAL

29VSKD SERIES

SKID STEER SNOW PLOW

99101237 & 99101220

WITH SERIAL NUMBERS AFTER:

29VSKD200000

Sno-Way® Is a registered trademark of Sno-Way International, Inc.

V-Wing™and MaxAdjust™are trademarks of Sno-Way International, Inc.

©2015 Sno-Way®International

1

TABLE OF CONTENTS

Page

INTRODUCTION ......................................................................................................... 2

SAFETY ...................................................................................................................... 3

THEORY OF OPERATION.......................................................................................... 4

General .............................................................................................................. 4

Plow Operational Limits ................................................................................... 4

Skid Steer Power Unit....................................................................................... 4

Skid Steer V-Plow Hydraulic System .............................................................. 4

PLOWING OPERATION.............................................................................................. 5

Before The Season Begins .............................................................................. 5

Transporting Vehicle With Plow Attached ...................................................... 5

Plowing Like A Pro ........................................................................................... 5

Plow Storage ..................................................................................................... 5

TROUBLESHOOTING GUIDE.................................................................................... 6

Introduction ....................................................................................................... 6

Trouble Shooting General Quick Reference................................................... 6

Troubleshooting Chart ...................................................................................... 6

MAINTENANCE .......................................................................................................... 7

General .............................................................................................................. 7

Periodic Inspection........................................................................................... 7

Electrical Quick Disconnect Plugs.................................................................. 7

Hydraulic Cylinders .......................................................................................... 7

Fluid Compatibility ........................................................................................... 7

Special Fasteners Torques and Requirements .............................................. 7

INSTALLATION ........................................................................................................... 8

Control Wiring Installation ............................................................................... 8

Mounting Snow Plow To Vehicle ................................................................... 10

Removing Snow Plow From Vehicle ............................................................. 11

Plow Adjustment............................................................................................. 11

Trip Spring Adjustment .................................................................................. 12

WIRING SCHEMATIC ............................................................................................... 13

HYDRAULIC SCHEMATIC........................................................................................ 14

TORQUE SPECIFICATIONS..................................................................................... 15

DEALER CHECKLISTS............................................................................. Rear Cover

2

This manual was written for the assembly, installation and

maintenance of your new Sno-Way Skid Steer V-Snow

Plow. Most importantly, this manual provides an operating

plan for safe use. Refer to the Table of Contents for an

outline of this manual.

Please keep this manual with your machine at all times as

reference material and so it can be passed on to the next

owner if the machine is sold.

We require that you read and understand the contents of

this manual COMPLETELY, especially the chapter on

SAFETY, before attempting any procedure contained in

this manual.

The Society of Automotive Engineers has adopted

this SAFETY ALERT SYMBOL to pinpoint character-

istics that, if NOT carefully followed, can create a

safety hazard. When you see this symbol in this man-

ual or on the machine itself, BE ALERT!, your per-

sonal safety and the safety of others, is involved.

• Defined in the next column, are the SAFETY

ALERT messages and how they will appear in this

manual.

NOTE: Additional information concerning the equipment

or the procedure that may or may not be contained else-

where in this manual.

WARNING

FAILURE TO HEED CAN RESULT IN INJURY OR

DEATH.

CAUTION

Information, that if not carefully followed, can

cause minor injury or damage to equipment!

BE AWARE! It is illegal to remove, deface or other-

wise alter the safety decals mounted on this equip-

ment.

Record the Skid Steer V-Plow Serial Number, Blade

Model Number and Blade Serial Numbers in the space

provided below as a handy record for quick reference.

The Skid Steer V-Plow Serial Number is located on the

main frame. The Blade Serial Numbers are located on

one of the middle ribs of each wing. The Blade Model

Number should be recorded from your sales invoice.

These plates contain information that your Dealer needs

to answer questions or to order replacement parts, if

needed, for your unit.

We reserve the right to make changes or improve the

design or construction of any part(s) without incurring the

obligation to install such parts or make any changes on

any unit previously delivered.

INTRODUCTION

DEALER

NAME

PHONE ( ) –

ADDRESS

CITY STATE ZIP

(FILL IN)

NAME PLATE DATA

LEFT WING SERIAL NUMBER

(FILL IN)

BLADE MODEL NUMBER

(Located on Blade Frame)

ORIGINAL PURCHASER

NAME

PHONE ( ) –

ADDRESS

CITY STATE ZIP

(FILL IN)

RIGHT WING SERIAL NUMBER

(Located on Blade Frame)

SKID STEER V-PLOW SERIAL NUMBER

(Back of A-Frame)

3

BEFORE ATTEMPTING ANY PROCEDURE IN THIS

BOOK, READ AND UNDERSTAND ALL THE SAFETY

INFORMATION CONTAINED IN THIS SECTION. IN

ADDITION, ENSURE ALL INDIVIDUALS WORKING

WITH YOU ARE ALSO FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

For your safety Warning and Information Decals have

been placed on this product to remind the operator

to take safety precautions. It is important that these

decals are in place and are legible before operation

begins. New decals can be obtained from Sno-Way or

your local dealer.

REMEMBER The careful operator is the best

operator. Most accidents are caused by human error.

Certain precautions must be observed to prevent the

possibility of injury to operator or bystanders and/or

damage to equipment.

NEVER operate Plow when under the influence of

alcohol, drugs or other medications that could hamper

your judgement and reactions. An accident may result in

serious injury or death to other persons or yourself.

ALWAYS operate vehicle in a well-ventilated area. The

carbon monoxide in exhaust gas is highly toxic and can

cause serious injury or death.

NEVER allow hands, hair or clothing to get near any

moving parts such as fan blades, belts and pulleys. Never

wear neckties or loose clothing when working on the

vehicle.

NEVER wear wrist watches, rings or other jewelry when

working on the vehicle or individual equipment. These

things can catch on moving parts or cause an electrical

short circuit that could result in serious personal injury.

ALWAYS wear safety goggles when working on the

vehicle to protect your eyes from battery acid, gasoline,

and dust or dirt from flying off of moving engine parts.

ALWAYS be aware of and avoid contact with hot

surfaces such as engine, radiator, and hoses.

ALWAYS wear safety glasses with side shields when

striking metal against metal! In addition, it is

recommended that a softer (non-chipable) metal material

be used to cushion the blow. Failure to heed could result

in serious injury to the eye(s) or other parts of the body.

NEVER allow children or unauthorized person to

operate this unit.

NEVER exceed 45 m.p.h. when snow plow is attached

to vehicle. Braking distances may be increased and

handling characteristics may be impaired at speeds

above 45 m.p.h.

ALWAYS lock the vehicle when unattended to prevent

unauthorized operation of the plow.

ALWAYS check the job site for terrain hazards,

obstructions and people.

NEVER exceed 10 m.p.h. when plowing. Excessive

speed may cause serious injury and damage of

equipment and property if an unseen obstacle is

encountered while plowing.

ALWAYS position blade so it does not block path of

headlamps beam. Do not change blade positions while

traveling. An incorrect plow position blocking headlamp

beam may result in an accident.

ALWAYS check surrounding area for hazardous

obstacles before operating this unit.

ALWAYS inspect the unit periodically for defects. Parts

that are broken, missing or plainly worn must be replaced

immediately. The unit, or any part of it should not be

altered without prior written approval of the manufacturer.

ALWAYS shut off the vehicle engine, place the

transmission in Neutral or Park, turn the ignition switch to

the “OFF” position and firmly apply the parking brake of

the vehicle before attaching or detaching the blade from

the vehicle or when making adjustments to the blade.

ALWAYS inspect lift system bolts and pins whenever

attaching or detaching the plow, and before traveling.

Worn or damaged components could result in the plow

dropping to the pavement while driving, causing an

accident.

ALWAYS keep hands and feet clear of blade and A-

Frame when attaching or detaching plow.

NEVER stand between the vehicle and blade or directly

in front of blade when it is being raised, lowered or

angled. Clearance between vehicle and blade decreases

as blade is operated and serious injury or death can

result from blade striking a body or dropping on hands or

feet.

NEVER work on the vehicle without having a fully

serviced fire extinguisher available. A 5 lb or larger CO2

or dry chemical unit specified for gasoline, chemical or

electrical fires, is recommended.

NEVER smoke while working on the vehicle. Gasoline

and battery acid vapors are extremely flammable and

explosive.

NEVER use your hands to search for hydraulic fluid

leaks; escaping fluid under pressure can be invisible and

can penetrate the skin and cause a serious injury! If any

fluid is injected into the skin, see a doctor at once!

Injected fluid MUST BE surgically removed by a doctor

familiar with this type of injury or gangrene may result.

REMEMBER it is the owner’s responsibility for

communicating information on the safe use and

proper maintenance of this machine.

SAFETY

4

General

The Sno-Way Skid Loader V-Plow is mounted using a

universal mounting plate. The V-Plow pressure and return

lines are connected to the auxiliary hydraulic quick

couplers. Blade extend and retract functions are operated

by using the skid loader auxiliary hydraulics. Reversing

the flow changes the wing directions. The rocker switch

controls which blade is functioned.

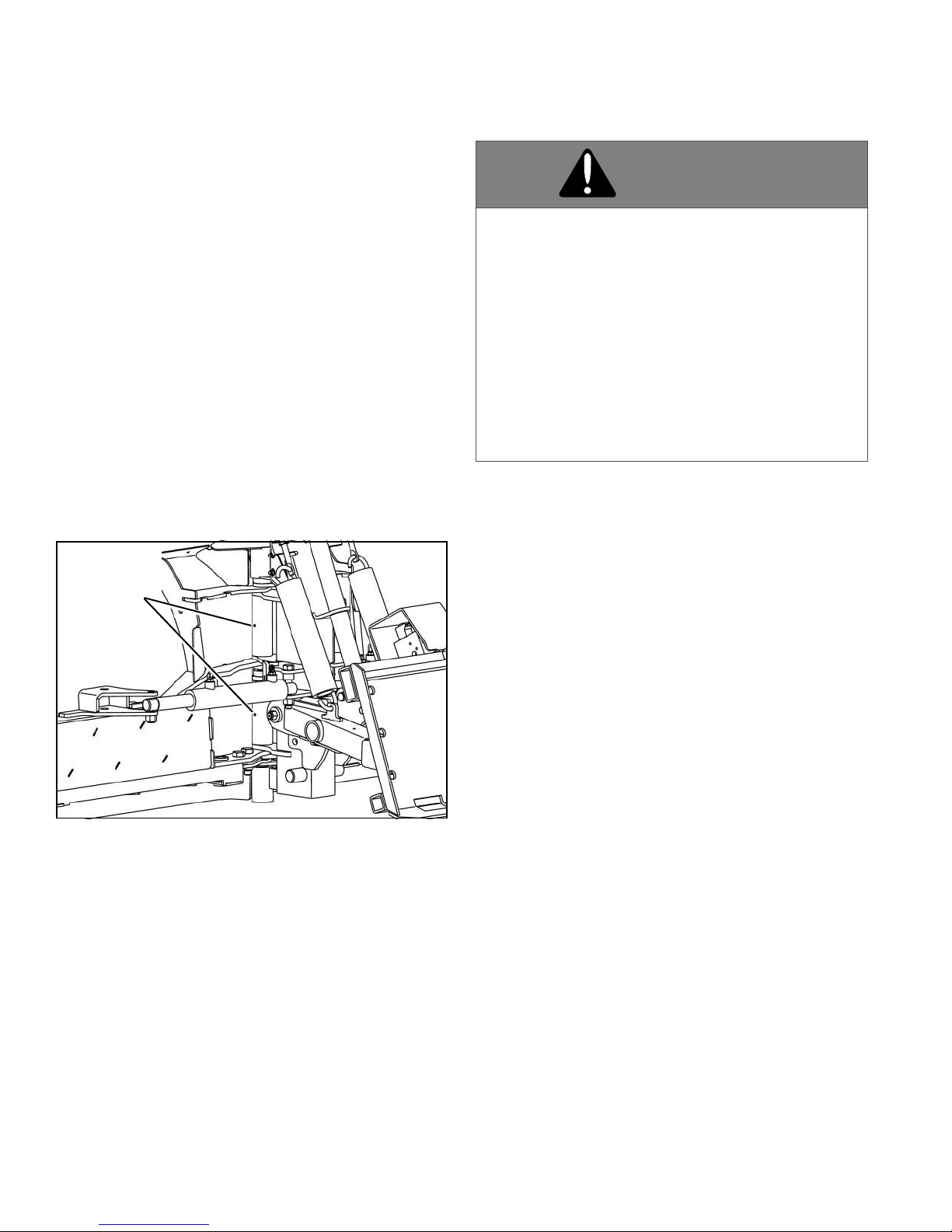

Plow Operational Limits

Figure 1-1

The Sno-Way Skid Steer Plows are designed to plow

snow within certain operational limits. A floating link

enables the plow to "float" over the contours of an uneven

grade during operation. Plowing with all four skid steer

wheels "on the ground" is recommended for optimum

plowing performance and reduced loading on plow

components.

Skid Steer Power Unit

Features

18-30 gpm (gallons per minute)

3000 psi max. operating pressure

3000 psi relief

Auxiliary hydraulic lines

The skid steer is the primary hydraulic source to the V-

Plow. A typical system operates at a maximum pressure

of 3000 psi and maximum flow rate of 30 gpm. The

hydraulic system has a 3000 psi relief that dumps all

excess hydraulic fluid to the tank when the system is

loaded beyond 3000 psi. The auxiliary hydraulic circuit

consists of two lines that come directly from the skid steer

hydraulic pump and are actuated by an auxiliary control in

the cab. The lines are connected to the V-Plow valve

block assembly so that one line feeds pressure and the

other dumps to the tank.

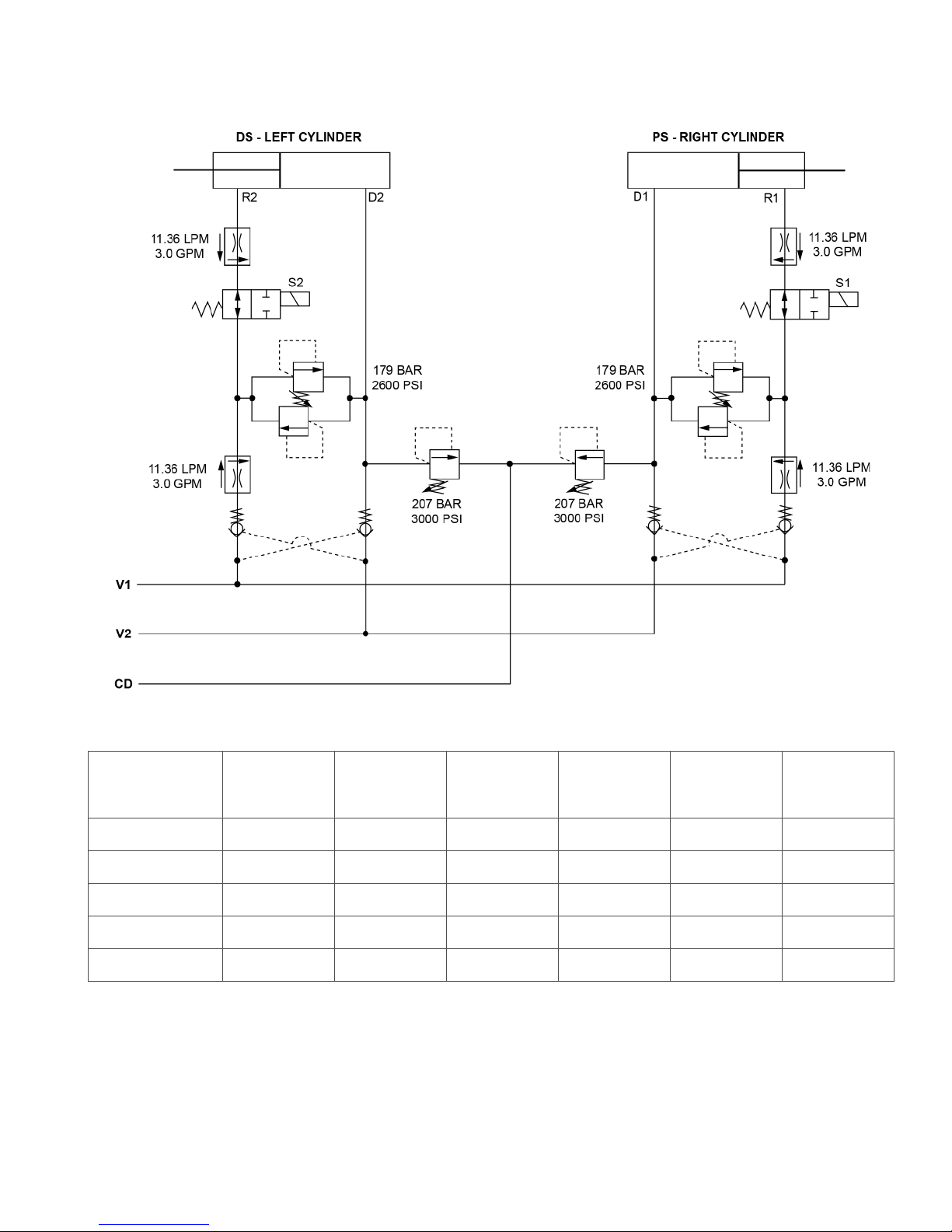

Skid Steer V-Plow Hydraulic System

The auxiliary hydraulics are routed to the valve block

where the hydraulic fluid is diverted for wing functions. To

activate the wing function, diverter valves are actuated for

right wing functions and deactivated for left wing

functions. To change the direction of the wing motion, the

direction of the auxiliary hydraulics is reversed.

Hydraulic Valve Block Assembly

The Hydraulic Valve Block Assembly consists of a valve

body containing two (2) flow control valves and two (2)

check valves.

The valve body directs hydraulic fluid to operate two (2)

hydraulic circuits; angle left side and angle right side. The

angle circuits receive fluid under pressure.

IMPORTANT: The electric coils, which operate the

solenoid valves, require a minimum of 9-1/2 volts DC

for proper operation. Lower voltage will cause erratic

operation, or failure to operate.

Wing Angling Mode Of Operation

Each wing can be angled forward or rearward

independently by operating the wing angle switch for

either the right or the left wing. Operating the wing angle

switch energizes the solenoid valve. Depending on the

auxiliary hydraulics flow direction, this directs hydraulic

fluid, under pressure, to either the base end (extend) or

rod end (retract) of the wing cylinder, which then moves

the wing forward or rearward.

Controls

Left Wing Angle Switch:

Used to angle the left wing forward and rearward.

Right Wing Angle Switch:

Used to angle the right wing forward and rearward.

FLOATING LINK

THEORY OF OPERATION

5

Before The Season Begins

1. Inspect vehicle safety equipment for proper

operation; brakes, headlights, plowing lights, windshield

wipers, flashers, etc.

2. Inspect the plow, plow frame and all attaching

hardware for wear and corrosion. Replace worn or

damaged parts and clean and repaint exposed metal

parts with a high quality, corrosion resistant enamel.

3. Inspect all fasteners to insure that they are properly

tightened. If any fasteners are loose, re-tighten to the

proper torque (refer to the Torque Specification Chart in

this manual) and carefully inspect the adjacent area for

damage or wear as well as carefully inspecting all

adjacent fasteners for proper torque.

4. Apply a small amount of light oil to the hitch pins and

pivots, to pivot pins between the A-frame and center

tower assembly, between wing cylinder pivot pins and the

lift linkage.

5. Apply oil or grease to the wing pivot pin through two

lubrication holes provided in the pin housing. (See Figure

1-2)

Figure 1-2

6. Check the reservoir oil level (see maintenance

instructions) and repair any oil leaks and worn hoses.

7. Install auxiliary and flashing lights (if not equipped).

Transporting Vehicle With Plow Attached

1. Position the blade out of the beam path of the vehicle

work lights before operating.

2. Inspect plow and plow attaching hardware for wear or

damage before transporting and beginning plow

operations.

Plowing Like A Pro

1. Become familiar with the area to be plowed and mark

potential hazards before the snow falls. Many immovable

objects cannot be seen when covered with snow.

Developing a plan early can save valuable time and

equipment damage. Allow sufficient room to pile snow,

out of the traffic area, with enough space for snow when

the next storm comes.

2. Plow with the storm. The “Pros” are out early

removing only several inches of snow at a time. Allowing

snow to accumulate to unmanageable levels can cause

difficult removal problems and can be costly in terms of

“wear and tear” on equipment. The plow is not a “Ram or

Bulldozer”. If used properly, it will give you many years of

safe and reliable service.

3. Research municipal ordinances for restrictions on the

disposal of snow. Many municipalities do not allow snow

to be placed in roads or throughways.

Plow Storage

1. To avoid corrosion during storage, coat the exposed

(chrome) portion of the wing cylinders with a light grease.

2. Lubricate all pivot points.

3. Make sure that protective caps are on all electrical

connections. A small amount of dielectric grease may be

used to insure a moisture proof seal on the caps.

4. Check and replace any worn and/or damaged

component, such as wearstrips, shoes or deflectors.

Performing preventative maintenance tasks in the spring

when the plow is stored will ensure that you will be ready

to plow in the fall.

WING PIVOT

LUBRICATION

POINTS

WARNING

• Never exceed 10 mph when plowing! Serious

personal injury can result, as well as damage to

equipment and property, if an unseen

obstruction is encountered while plowing.

• Wear your seat belt! Contact with a hidden

obstruction can cause serious personal injury

from bodily contact within the vehicle cab or

whiplash from sudden stops.

FAILURE TO HEED CAN RESULT IN INJURY OR

DEATH.

PLOWING OPERATION

6

TROUBLESHOOTING GUIDE

Introduction

Whenever service is necessary, your local Sno-Way

Dealer knows your plow best and is interested in your

complete satisfaction. Return your V-Plow to your local

Dealer for maintenance service or any other assistance

you may require. If you are unable to do so, this

Troubleshooting Guide should help you determine the

problem. Before attempting the servicing of your plow,

you should possess good mechanical abilities and a total

understanding of the mechanism.

PLEASE: Before calling parts and service personnel be

certain that:

1. You have read this manual carefully and are certain

that all of the suggestions pertaining to your problem

have been attempted.

2. You should have the following information available.

A. Date Snow Plow was originally installed.

B. Main Frame Serial Number.

C. Blade Model Number.

D. Blade Serial Number.

This information should be recorded on page 2 of this

Manual.

General Quick Reference

1. Check oil level in hydraulic system reservoir.

2. Check for external leakage at cylinders, hoses and

power unit.

CAUTION

First read all warning instruction, the safety

messages, and directions before attempting any

adjustments or repairs to your unit!

TROUBLESHOOTING CHART

NOTE: Make sure all electrical connections are correct, that wires are not frayed or corroded before consulting the

following chart:

PROBLEM PROBABLE CAUSE

Left wing extends and retracts, Right

wing does not move as intended.

The valve S1 is stuck open

Check switch for electrical shorts. Switch may be stuck “On” for the S1 valve

Right wing extends and retracts, Left

wing does not move as intended

The valve S2 is stuck shut

Check switch for electrical shorts. Switch may be stuck “On” for the S2 valve

Wings do not move Both coils are "ON" (or both valves are internally stuck shut)

Both wings extend together, but

individual left and right functions

are not possible

No power going to the valves.

• The electrical connection to the remote switch is not connected

• The valves coils have become disconnected

Both wings retract together, but

individual left and right functions

are not possibleonly

No power going to the valves

•The electrical connection to the remote switch is not connected

•The valves coils have become disconnected

Retract rate is slower than extend

rate

Flow to block is not very high: Increase the engine speed

Wings will not retract - Extend only,

but not retract

One of the auxilliarly power lines is disconnected

Wings will not collaspe when hitting

an object

Case drain line disconnected

When wings hits an object the other

wing extends

Case drain line disconnected

FOR ANY OTHER ISSUE, CHECK WITH YOUR SNO-WAY DEALER

7

MAINTENANCE

General

• Before operating, perform a thorough visual

inspection of the equipment. Look for fluid leaks,

cracked, bent or broken components, loose nuts,

bolts or attachments and proper fluid levels.

• A clean hydraulic system is essential to long

pump life and proper performance.

• When adding oil to the reservoir, wipe the area

around the filler port clean before removing the

breather cap. Use clean oil and a clean funnel,

(DO NOT use a cloth or rag to strain the oil).

• The operational environment for snow plows is an

extremely harsh and corrosive one.

• Ensure all electrical connections are clean and

tight.

• To prevent rust from forming, clean and repaint

exposed metal surfaces.

• NEVER operate the equipment with the

protective covers or guards removed.

Periodic Inspection

After approximately every 20 hours of operation perform

the following inspections procedures:

1. Inspect the plow assembly for any damage or

excessive wear. Also inspect all fasteners to insure that

they are properly tightened. If any fasteners are loose re-

tighten to the proper torque (Refer to the Torque

Specification Chart in this manual). Also carefully inspect

adjacent area for damage or wear as well as carefully

inspecting all adjacent fasteners for proper torque.

2. Apply a small amount of light oil to the hitch pins and

pivots, between wing cylinder pivot pins and the lift

linkage.

Electrical Quick Disconnect Plugs

Install protective caps on quick disconnect ends to

prevent corrosion from forming on terminal ends during

storage or when Plow is disconnected from vehicle.

Hydraulic Cylinders

To avoid corrosion during storage, coat the exposed

(chrome) portion of the Angle Cylinders with a light

grease.

Fluid Compatibility

Hydraulic fluid used in skid steers is compatible with the

plow system.

Special Fasteners Torques and

Requirements

IMPORTANT: Incorrectly securing fasteners may

result in incorrect operation, excessive wear, and

early failure of Plow components. It may also void

your warranty.

• ALWAYS check to make sure you are using the

correct torque specification for the fastener you

are using.

• DO NOT use any lubricants on the threads of any

fastener unless specifically called for in the

assembly or maintenance story for that

component.

• NEVER use liquid locking materials, such as

Locktite™ or Threadmaker™, on any fasteners

unless specifically called for in an assembly or

maintenance story for that component.

Standard Fasteners:

The Torque Specifications Chart on page 15 of this

manual should be used as the guide for fastener torque

requirements for most standard fasteners used on the

plow.

Standard fasteners with special torque requirements will

be noted in assembly or service stories pertaining to the

specific piece of equipment.

Hydraulic Fittings:

Hydraulic fittings with lock nuts should be assembled with

at least three full turns of the fitting in the port and then the

lock nut should be tightened to 27 lb.-ft.

8

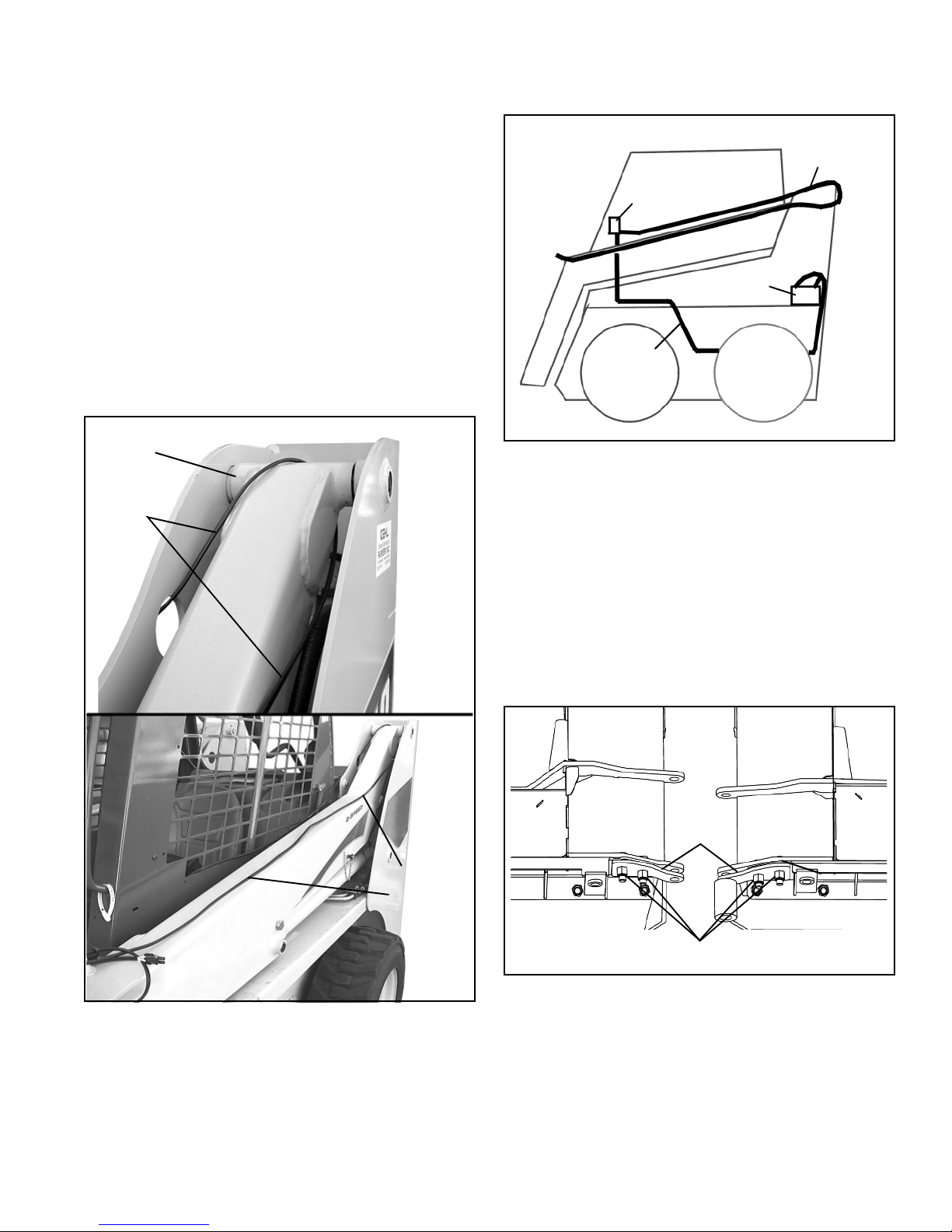

Control Wiring Installation

1. Position the control box in cab. Secure the control box

using hook and loop fastener provided.

2. Route the power harness lead to the battery (See

Figure 1-4). Connect the YELLOW wire to the negative (-

) battery terminal and the WHITE wire to the positive (+)

battery terminal.

3. Route the control harness lead around the pivot point

on the loader arms on the back of the Skid Steer and

down the top of the loader arms to the front. Allow

enough slack when routing wire so that wiring is not put

in tension when the loader arms are moved. Position the

wiring to prevent pinching when loader arms pivot, and

secure with cable ties. (See Figure 1-3) and (See Figure

1-4).

Figure 1-3

Figure 1-4

Mechanical Installation

Final Installation

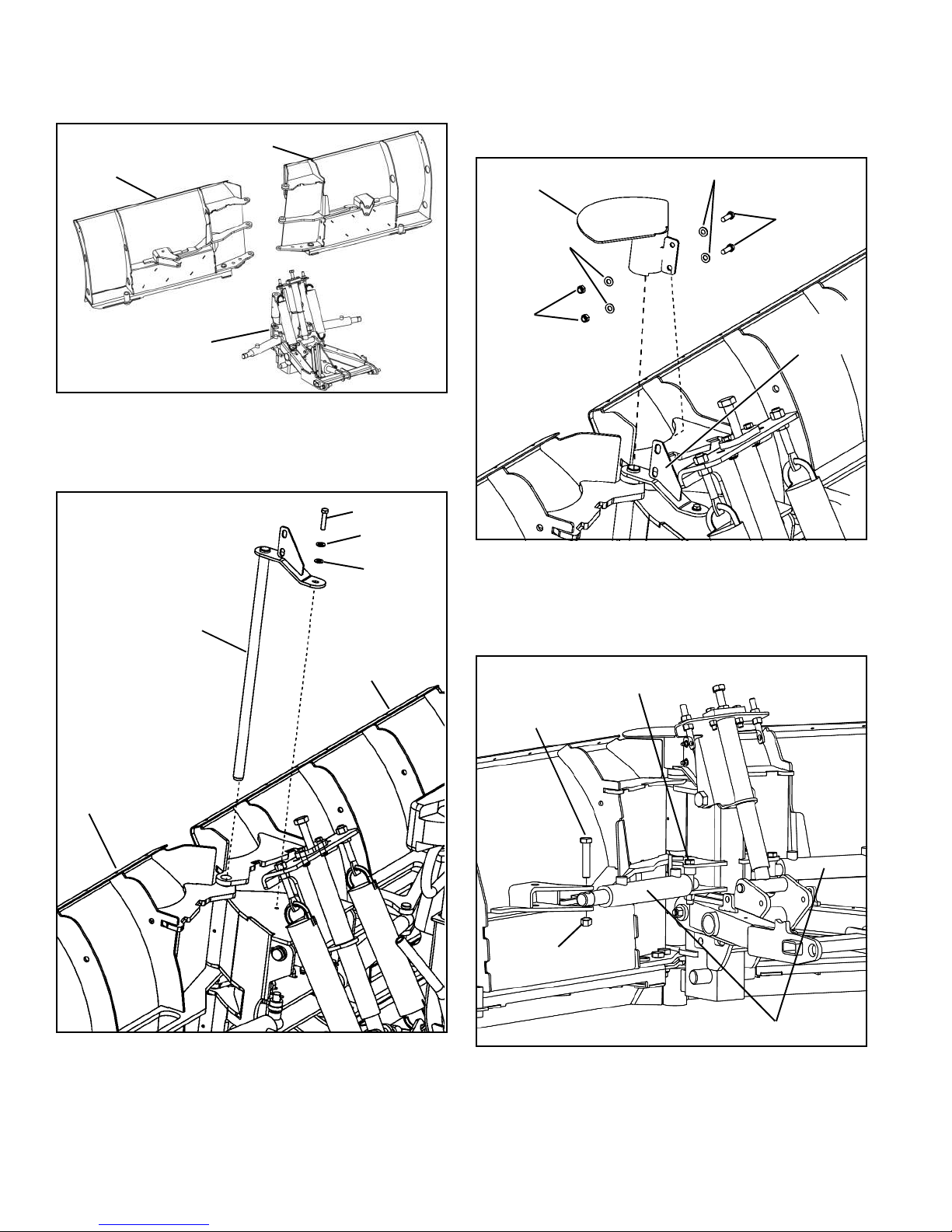

1. Remove the A-frame/tower assembly from the box.

2. Remove power unit.

3. To aid in the pin installation as the blades are

installed, loosen two nuts securing each lower support

plate to the DS and PS wings. (See Figure 1-5)

Figure 1-5

LOADER ARM

PIVOT

CONTROL

HARNESS

LEAD

CONTROL

HARNESS

LEAD

CONTROL

HARNESS

CONTROL

BOX

BATTERY

POWER

HARNESS

LOWER

PLATES

SUPPORT

PLATE NUTS

SUPPORT

INSTALLATION

9

4. Position the drivers side (DS) and passenger side

(PS) wings in front of the A-frame/tower assembly. (See

Figure 1-6)

Figure 1-6

5. Coat main wing pivot pin with grease and insert

completely through the tower, blade section pin holes,

and support plate holes. (See Figure 1-7)

Figure 1-7

6. Secure the main wing pivot pin to the tower assembly

with one 5/16-18 x 1’’ hex head cap screw (p/n

98009149), 5/16" split lock washer (p/n 98009025) and 5/

16 " flat washer (p/n 98009024).

7. After installation of the pin, tighten nuts on the lower

hinge support plates securely if loosened earlier.

8. Install the center shield on the clevis pin retainer

bracket, and secure with two 5/16-18 x 1’’ hex head cap

screws (p/n 98009149), four 5/16" flat washers (p/n

98009024) and two 5/16" lock nuts (p/n 98009150). (See

Figure 1-8)

Figure 1-8

9. Attach angle cylinder base to tower with a 3/4" x 4-1/

2" capscrew and 3/4" locknut. Attach angle cylinder rod to

blade with a 3/4" x 4" capscrew and 3/4" locknut. (See

Figure 1-9) Repeat for opposite angle cylinder.

Figure 1-9

DS WING

A-FRAME/

TOWER

ASSEMBLY

PS WING

CAP SCREW

MAIN WING

LEFT BLADE

RIGHT BLADE

FLAT

SPLIT

PIVOT PIN

WASHER

WASHER

CENTER

SHIELD

NUTS

CAPSCREWS

WASHERS

WASHERS

CLEVIS PIN

RETAINER

BRACKET

CAPSCREW

ANGLE CYLINDERS

3/4" LOCKNUT

3/4"-10 X 4-1/2"

CAPSCREW

3/4"-10 X 4"

10

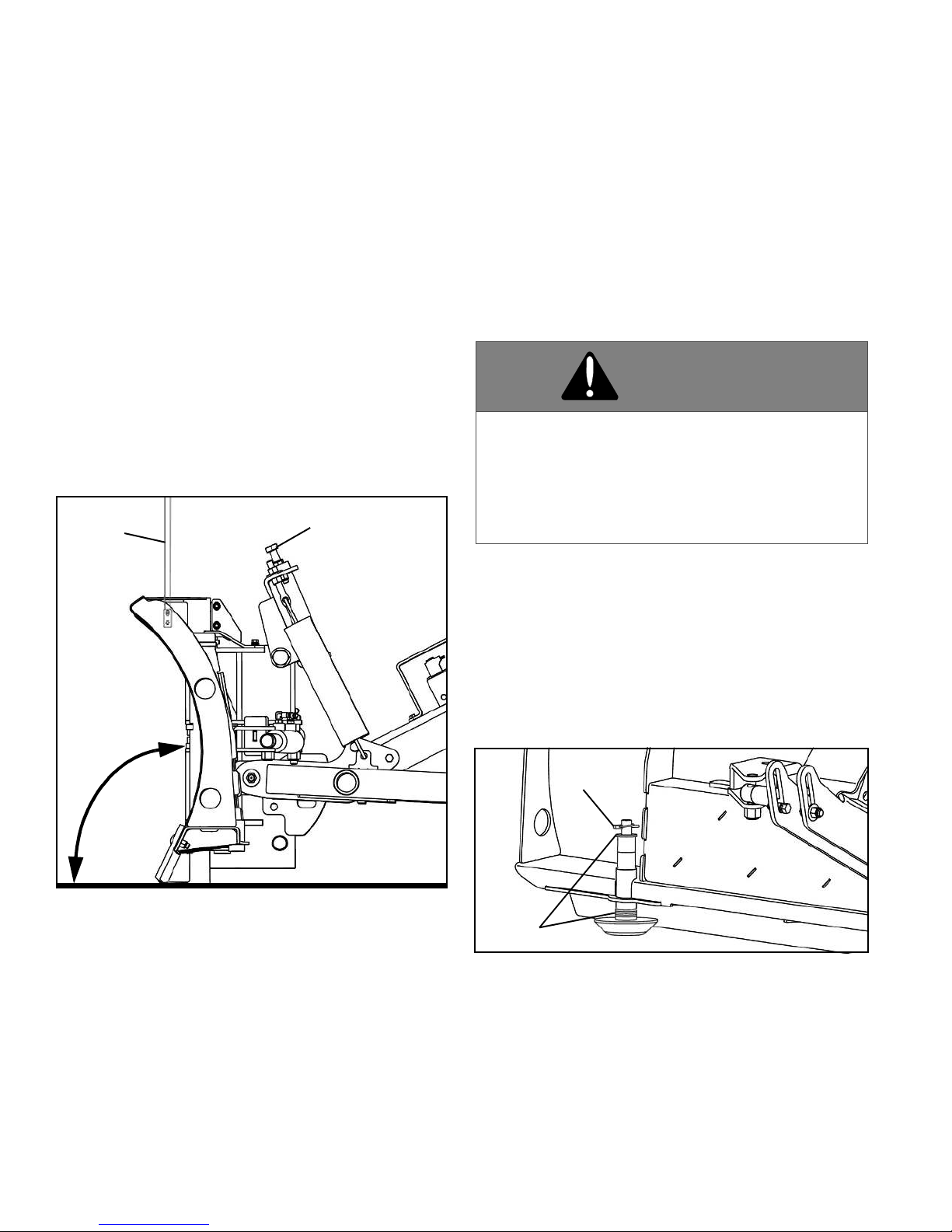

10. Attach a plow marker to each wing as shown and

secure using 5/16" x 1" cap screws and locknuts. (See

Figure 1-10)

Figure 1-10

11. Loosely connect hydraulic hoses to the wing

cylinders. (See Figure 1-11).

Figure 1-11

12. Loosely position hydraulic hoses in hose clamps (A -

5/16" X 2" self-tapping screw, B - plate, C - clamp blocks)

on each side of the A-frame.

13. Adjust each hose length from clamps to hose end

fittings to 33 in. and tighten both clamp screws. (See

Figure 1-12)

NOTE: If installing screw with an impact wrench, ensure

that the wrench in adjusted to its lowest torque setting to

avoid fastener damage.

Figure 1-12

14. Tighten all hydraulic hose fittings securely.

Mounting Snow Plow To Vehicle

1. Drive up to the snow plow and tilt the universal mount

slightly forward.

2. Hook the top of the universal mount under the lip on

the skid steer adapter plate of the snow plow.

3. Position the snow plow so that it rests flush against

the universal mount and lock the snow plow in place.

4. Connect the hydraulic hoses (V1, V2 and CD) to the

auxiliary hydraulic connectors on the vehicle. Refer to

figure below and the hydraulic schematic on page 14.

Figure 1-13

5. Connect the electrical connector to the vehicle.

5/16" x 1"

CAP SCREWS

PLOW

MARKER

A

B

C

D1

R1

R2

D2

33"

11

Removing Snow Plow From Vehicle

1. Lower the snow plow to the ground.

2. Disconnect the hydraulic hoses and electric

connector from the vehicle.

3. Unlock the universal mount from the snow plow and

slowly back the vehicle away, while tilting the universal

mount slightly forward.

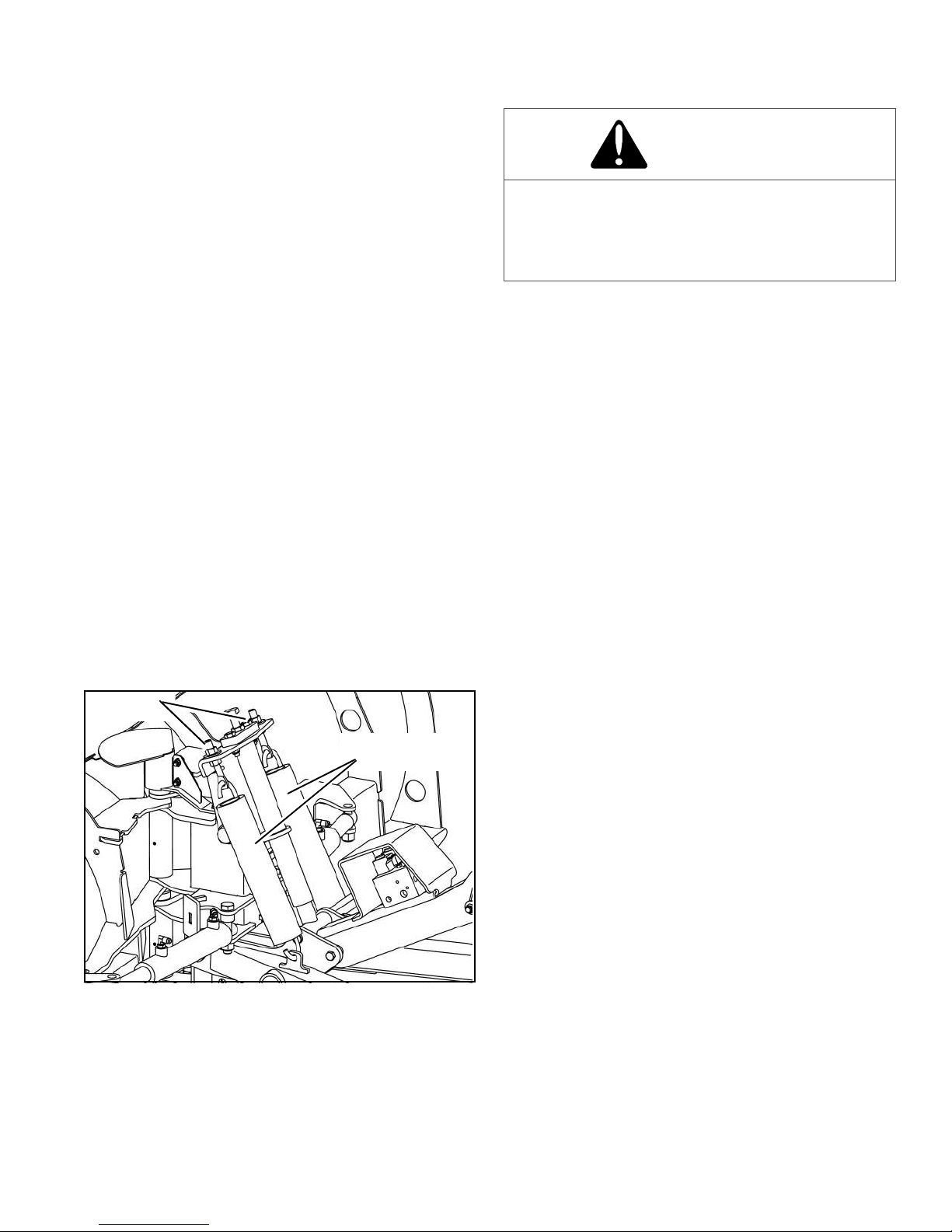

Plow Adjustment

1. The plow frame height should be adjusted relative to

the optimum resting position of the loader arms. To

adjust, remove the locknuts and hex head cap screws

that secure the rear of the A-frame to the mounting lugs

of the universal adapter. Move the A-frame to a higher or

lower position as required and re-install the capscrews

and locknuts. Tighten securely.

2. This plow is equipped with the MaxAdjustTM System

(Patent pending). Adjust capscrew as required to position

center of moldboard at a 90° angle to the ground. (See

Figure 1-14).

Figure 1-14

3. This plow as an option has 4 shoes that may be

installed to help with gravel plowing and aid in over all

cutting edge wear. Two plow shoes are located at the

outboard end of each wing. The two inner plow shoes are

located inboard on the wing underneath the cylinder

mounting area.

IMPORTANT: To ensure the best function of this

Snow Plow, it is a requirement that all four plow

shoes be adjusted equally.

Adjust the plow shoes as follows:

a. Park the vehicle on a smooth level surface. Adjust

the wings straight out on each side and lower the

plow to the ground.

b. When properly adjusted, the plow shoes and

wearstrips contact the ground at the same time.

Determine whether the plow shoes or wearstrips

are off the ground.

• If the plow shoe(s) were off the ground - washers

must be moved from the top to the bottom of the

shoe stem.

• If the wearstrips are off the ground - washers

must be moved from the bottom to the top of the

shoe stem.

c. Raise the plow and place suitable blocking under

the plow to allow at least six inches (6") of

clearance from the bottom of the plow shoes to the

ground.

d. Lower plow onto blocking. Turn ignition switch OFF

and apply the emergency brake.

e. Adjust shoe assemblies by removing shoe mounting

lynch pin and adding or subtracting washers on the

top or bottom of the shoe mounting location. (See

Figure 1-15).

Figure 1-15

PLOW TILT ADJUSTMENT

CAP SCREW

90°

MARKER

WARNING

Keep hands and feet clear of wings and center

section when setting blocking and lowering

plow. Moving or falling assemblies could result

in serious injury.

FAILURE TO HEED CAN RESULT IN INJURY

OR DEATH.

WASHERS

PIN

12

f. After the disk shoe position is properly adjusted

place washers on the shoe stem - above the plow

frame and below the retaining lynch pin - to remove

all up and down movement of the disk shoe in the

frame. Failure to do so will result in excessive wear

of the holes in the frame or bending of the shoe

stem.

IMPORTANT: Snap lynch pin ring over so that it

contacts the pin. If ring does not contact lynch pin,

rotate the pin and reverse the direction of the ring. If

the ring does not contact the pin it is not locked and

could fall out.

g. Lower the plow to the ground and check adjustment.

Repeat adjustment if required.

Trip Spring Adjustment

NOTE: The trip springs are factory installed and

adjusted, but adjustment should be checked during plow

set-up and installation.

Springs are properly adjusted when two or more coils

allow a 0.010" feeler gauge to just pass between the

separated coils. (A 3 x 5" post card is approximately the

same thickness.)

If re-adjustment is required:

1. Raise the plow to the full UP position and support the

blade with suitable blocking.

2. Turn the vehicle OFF, apply the parking brake and

remove the ignition key.

3. Check to make sure that the springs are installed as

illustrated. (See Figure 1-16).

Figure 1-16

4. Loosen the lower jam nut on each eyebolt. (See

Figure 1-16).

5. Tighten the upper retaining nut until a 0.010" feeler

gauge can pass between two or more coils on each

spring.

6. Hold the upper nut and tighten the lower nut securely

on each spring.

NUTS

0.015 (1/64") GA

P

MAXIMUM

CAUTION

• Do not overtighten springs. If more than 0.015"

(1/64") gap appears between coil with Plow at

rest, damage could occur to equipment during

plowing.

13

WIRING SCHEMATIC

14

HYDRAULIC SCHEMATIC

PLOW

FUNCTION

SWITCH

POSITION

CYLINDER

PRESSURIZED

PORT

S1

SOLENOID

STATUS

S2

SOLENOID

STATUS

FLOW

INLET

FLOW

TO TANK

NEUTRAL MIDDLE - OFF N/A OFF OFF V1 V2

LEFT EXTEND LEFT D2 ON OFF V2 V1

LEFT RETRACT LEFT R2 ON OFF V1 V2

RIGHT EXTEND RIGHT D1 OFF ON V2 V1

RIGHT RETRACT RIGHT R1 OFF ON V1 V2

15

TORQUE SPECIFICATIONS

DO NOT use these values if a different torque value or tightening procedure is given for a specific application.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be

tightened to the strength of the original.

a“Lubricated” means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings.

b“Dry” means plain or zinc plated without any lubrication

* Values with asterisk are in lb-in.

Grade 1 Grade 2 Grade 5, 5.1 or 5.2 Grade 8 or 8.2

LubricatedaDrybLubricatedaDrybLubricatedaDrybLubricatedaDryb

SIZE lb-ft lb-ft lb-ft lb-ft lb-ft lb-ft lb-ft lb-ft

8-32 14* 19* 22* 30* 31* 42*

10-24 21* 27* 32* 43* 45* 60*

1/4 2.8 3.5 4.5 5.5 7910 12.5

5/16 5.5 7 91115 18 21 26

3/8 10 13 16 20 26 33 36 46

7/16 16 20 26 32 41 52 58 75

1/2 25 31 39 50 63 80 90 115

9/16 36 45 56 70 90 115 130 160

5/8 50 62 78 100 125 160 160 225

3/4 87 110 140 175 225 280 310 400

7/8 140 175 140 175 360 450 500 650

1210 270 210 270 540 675 750 975

METRIC COARSE THREAD

Grade 8.8

Grade 8.8 Grade 10.9 Grade 12.9

Dry Lubed Dry Lubed Dry Lubed

M6-1 8 6 11 813.5 10

M8-1.25 19 14 27 20 32.5 24

M10-1.5 37.5 28 53 39 64 47

M12-1.75 65 48 91.5 67.5 111.5 82

M14-2 103.5 76.5 145.5 108 176.5 131

M16-2 158.5 117.5 223.5 165.5 271 200

1 or 2

2

55.1 5.2

5

88.2

8

No Marks

No Marks

SAE

Grade

and Nut

Markings

SAE

Grade

and Head

Markings

16

NOTES

Hartford, WI 53027 USA

Website: www.snoway.com

©2015 Sno-Way®International

SNO-WAY®INTERNATIONAL, INC.

18

Hartford, WI 53027 USA

Website: www.snoway.com

©2015 Sno-Way®International

SNO-WAY®INTERNATIONAL, INC.

DEALER PRE DELIVERY CHECKLIST

The following inspections MUST be accomplished prior to delivering the snowplow to the customer.

Place an X in the box after accomplishing each item on the checklist.

CHECK THAT

Parts have not been damaged in shipment. Repair or replace items that are loose, dented or missing.

All decals are in place.

All pivot pins and cotters are installed and secure.

Trip springs are adjusted.

Plow Shoe assemblies are installed and adjusted.

Start the vehicle engine and place an X in the box after accomplishing each item on the checklist.

CHECK THAT

Blades swing.

Cylinders, hoses and fittings DO NOT leak.

No abnormal noises or vibrations are present; Repair or replace as necessary.

DELIVERY CHECKLIST

The following checklist is to be accomplished with the customer present, Place an X in the box after accomplishing

each item on the checklist.

After giving the Customer their Owner’s Manual, instruct them to read it PRIOR to operating the Snow Plow. If

they have any questions or do not understand any part(s) of the Manual, ask them to contact the Dealer for

answers or explanations BEFORE operating the unit.

Record the Serial Numbers, Date of Purchase, Purchaser’s Name and Address, and the Dealers Name,

Address and Phone Number in the space provided on Page 1 of the Owner’s Manual.

Explain connect and disconnect procedures.

Explain the necessity of plow shoe usage at all times to ensure optimum plow performance.

Fill out Warranty Registration Card and mail COPY 1 to the factory to validate Warranty. NO Warranty

claims can be honored if the Warranty Card is not on file at the factory.

x

x

x

This manual suits for next models

2

Table of contents

Other Sno-Way Snow Blower manuals