Sno-Way 22 Series Operating instructions

97102326A

INSTALLATION &

OWNER’S MANUAL

22 SERIES 2 DRIVEWAY SNOW PLOWS

FOR DOWN PRESSURE® HYDRAULICS

WITH SERIAL NUMBER AFTER 22DW100000

!"

#$

%&'

()

*+

1

TABLE OF CONTENTS

Page

INTRODUCTION ........................................................................................................................ 2

SAFETY ..................................................................................................................................... 3

INSTALLATION INSTRUCTIONS ............................................................................................. 4

General............................................................................................................................... 4

Electrical Installation ........................................................................................................ 4

Mechanical Installation...................................................................................................... 5

Mounting Snow Plow To Vehicle ..................................................................................... 7

Installing The Cylinder Lock Clamp ................................................................................ 8

Removing Snow Plow From Vehicle ............................................................................... 9

MAINTENANCE ....................................................................................................................... 10

General............................................................................................................................. 10

Break In Period................................................................................................................ 10

To Remove Excessive Free Play.................................................................................... 10

Periodic Inspection......................................................................................................... 10

Plow Storage ................................................................................................................... 11

Polycarbonate Blade Care ............................................................................................. 11

Polycarbonate Blade Cleaning Instructions................................................................. 11

Special Fasteners Torques and Requirements ............................................................. 11

Fluid Requirements......................................................................................................... 11

Changing Oil and Cleaning Filter Screen ..................................................................... 12

Cutting Edge.................................................................................................................... 13

Plow Shoe Adjustment ................................................................................................... 14

Trip Spring Adjustment .................................................................................................. 14

Blade Stop Replacement ................................................................................................. 14

Emergency Plow Raise.................................................................................................... 14

PLOWING OPERATION .......................................................................................................... 15

Operating Class .............................................................................................................. 15

Before the Season Begins ............................................................................................. 15

Transporting Vehicle With Plow Attached .................................................................... 15

Plowing Like A Pro ......................................................................................................... 15

Using The Down Pressure (DP) Hydraulic Systems.................................................... 16

Clearing Driveways......................................................................................................... 16

TROUBLESHOOTING ............................................................................................................. 17

Introduction ..................................................................................................................... 17

Troubleshooting Quick Reference................................................................................. 17

Troubleshooting Guide................................................................................................... 17

THEORY OF OPERATION ...................................................................................................... 23

Hydraulic Power Unit...................................................................................................... 23

Hydraulic Controls.......................................................................................................... 23

Electro-Hydraulic Operation .......................................................................................... 23

Raise Mode Of Operation ............................................................................................... 23

Lower Mode Of Operation - Gravity Down and Float................................................... 23

Down Pressure (DP) System.......................................................................................... 23

Angle Left or Right Mode of Operation ......................................................................... 24

Fuse.................................................................................................................................. 24

HYDRAULIC SCHEMATIC (Down Pressure System) ........................................................... 25

WIRING SCHEMATIC (Down Pressure System) (22DW) ...................................................... 26

TORQUE SPECIFICATIONS ................................................................................................... 27

2

This manual was written for the assembly, installation and

maintenance of your new Sno-Way plow. Most

importantly, this manual provides an operating plan for

safe use. Refer to the Table of Contents for an outline of

this manual.

Please keep this manual with your machine at all times as

reference material and so it can be passed on to the next

owner if the machine is sold.

We require that you read and understand the contents of

this manual COMPLETELY, especially the chapter on

SAFETY, before attempting any procedure contained in

this manual.

The Society of Automotive Engineers has adopted

this SAFETY ALERT SYMBOL to pinpoint character-

istics that, if NOT carefully followed, can create a

safety hazard. When you see this symbol in this man-

ual or on the machine itself, BE ALERT!, your per-

sonal safety and the safety of others, is involved.

• Defined in the next column, are the SAFETY ALERT

messages and how they will appear in this manual.

NOTE: Additional information concerning the equipment

or the procedure that may or may not be contained else-

where in this manual.

BE AWARE! It is illegal to remove, deface or other-

wise alter the safety decals mounted on this equip-

ment.

Record the Power Pack Model Number, Power Pack

Serial Number, Controller Serial Numbers, Blade Model

Number, Blade Serial Number and the Pump Serial

Number in the space provided below as a handy record

for quick reference. The Power Pack Serial Number is

located on the A-Frame (driver’s side near the front), the

Blade Serial Number is located on one of the middle ribs

of the blade. This plate contains information that your

Dealer needs to answer questions or to order

replacement parts, if needed, for your unit.

We reserve the right to make changes or improve the

design or construction of any part(s) without incurring the

obligation to install such parts or make any changes on

any unit previously delivered.

Graphics and illustrations may be used which may show

equipment and/or options not included in every

installation without incurring the obligation to install such

parts or make changes on units previously delivered.

Sno-Way Service Parts Manuals are available on-line or

at your authorized Sno-Way dealer. Request part number

97102305 & 97101915 for the 22 Series 2 Snow Plow.

Factory contact information is available at

www.snoway.com.

WARNING

INDICATES A HAZARDOUS SITUATION WHICH,

IF NOT AVOIDED, COULD RESULT IN DEATH

OR SERIOUS INJURY.

CAUTION

INDICATES A HAZARDOUS SITUATION WHICH,

IF NOT AVOIDED, COULD RESULT IN MINOR

OR MODERATE INJURY.

NOTICE

IS USED TO ADDRESS PRACTICES NOT

RELATED TO PHYSICAL INJURY. FAILURE TO

FOLLOW COULD LEAD TO PROPERTY

DAMAGE.

DEALER

NAME

PHONE ( ) –

ADDRESS

CITY STATE ZIP

(FILL IN)

ORIGINAL PURCHASER

NAME

PHONE ( ) –

ADDRESS

CITY STATE ZIP

(FILL IN)

NAME PLATE DATA

POWER PACK MODEL NUMBER

BLADE SERIAL NUMBER

PUMP SERIAL NUMBER

(FILL IN)

POWER PACK SERIAL NUMBER

CONTROLLER SERIAL NUMBERS:

BLADE MODEL NUMBER

(Located on Blade Frame)

(Located on A-Frame)

TRANSMITTER S.N.

RECEIVER S.N.

INTRODUCTION

3

BEFORE ATTEMPTING ANY PROCEDURE IN THIS

BOOK, READ AND UNDERSTAND ALL THE SAFETY

INFORMATION CONTAINED IN THIS SECTION. IN

ADDITION, ENSURE ALL INDIVIDUALS WORKING

WITH YOU ARE ALSO FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

For your safety Warning and Information Decals have

been placed on this product to remind the operator

to take safety precautions. It is important that these

decals are in place and are legible before operation

begins. New decals can be obtained from Sno-Way or

your local dealer.

REMEMBER The careful operator is the best

operator. Most accidents are caused by human error.

Certain precautions must be observed to prevent the

possibility of injury to operator or bystanders and/or

damage to equipment.

NEVER operate plow when under the influence of

alcohol, drugs or other medications that could hamper

your judgement and reactions. An accident may result in

serious injury or death to other persons or yourself.

ALWAYS operate vehicle in a well-ventilated area. The

carbon monoxide in exhaust gas is highly toxic and can

cause serious injury or death.

NEVER allow hands, hair or clothing to get near any

moving parts such as fan blades, belts and pulleys.

Never wear neckties or loose clothing when working on

the vehicle.

NEVER wear wrist watches, rings or other jewelry when

working on the vehicle or individual equipment. These

things can catch on moving parts or cause an electrical

short circuit that could result in personal injury.

ALWAYS wear safety goggles when working on the

vehicle to protect your eyes from battery acid, gasoline,

and dust or dirt from flying off of moving engine parts.

ALWAYS be aware of and avoid contact with hot

surfaces such as engine, radiator, and hoses.

ALWAYS wear safety glasses with side shields when

striking metal against metal! In addition, it is

recommended that a softer (non-chipable) metal material

be used to cushion the blow. Failure to heed could result

in injury to the eye(s) or other parts of the body.

NEVER allow children or unauthorized person to

operate this unit.

NEVER exceed 45 m.p.h. when snow plow is attached

to vehicle. Braking distances may be increased and

handling characteristics may be impaired at speeds

above 45 m.p.h.

ALWAYS lock the vehicle when unattended to prevent

unauthorized operation of the plow.

ALWAYS check the job site for terrain hazards,

obstructions and people.

NEVER exceed 10 m.p.h. when plowing. Excessive

speed may cause serious injury and damage of

equipment and property if an unseen obstacle is

encountered while plowing.

ALWAYS check your local laws with regards to

transporting plow mounted on vehicle on public roads.

NEVER change blade position while traveling.

ALWAYS check surrounding area for hazardous

obstacles before operating this unit.

ALWAYS inspect the unit periodically for defects. Parts

that are broken, missing or plainly worn must be replaced

immediately. The unit, or any part of it should not be

altered without prior written approval of the manufacturer.

ALWAYS insert the cylinder lock when plow is not in

use. If the cylinder lock is not installed, the plow blade

could inadvertently drop and cause injury.

ALWAYS shut off the vehicle engine, place the

transmission in Neutral or Park, turn the ignition switch to

the “OFF” position, firmly apply the parking brake of the

vehicle and turn “OFF” the plow controller before

attaching or detaching the blade from the vehicle or when

making adjustments to the blade.

ALWAYS inspect lift system bolts and pins whenever

attaching or detaching the plow, and before traveling.

Worn or damaged components could result in the plow

dropping to the pavement while driving, causing an

accident.

ALWAYS keep hands and feet clear of blade and A-

Frame when attaching or detaching plow.

NEVER place fingers in A-frame or mount lug holes to

check alignment when attaching snow plow. Sudden

motion of the plow could severely injure a finger.

NEVER stand between the vehicle and blade or directly

in front of blade when it is being raised, lowered or

angled. Clearance between vehicle and blade decreases

as blade is operated and injury or death can result from

blade striking a body or dropping on hands or feet.

NEVER work on the vehicle without having a fully

serviced fire extinguisher available. A 5 lb or larger CO2

or dry chemical unit specified for gasoline, chemical or

electrical fires, is recommended.

NEVER smoke while working on the vehicle. Gasoline

and battery acid vapors are extremely flammable and

explosive.

NEVER use your hands to search for hydraulic fluid

leaks; escaping fluid under pressure can be invisible and

can penetrate the skin and cause injury! If any fluid is

injected into the skin, see a doctor at once! Injected fluid

MUST be surgically removed by a doctor familiar with this

type of injury or gangrene may result.

REMEMBER it is the owner’s responsibility for

communicating information on the safe use and

proper maintenance of this machine.

SAFETY

4

General

Install the subframe on the vehicle using the instructions

supplied with the subframe package. The pin height

should be 8" - 10" off the ground. (See Figure 1-1).

Figure 1-1

Electrical Installation

1. Remove the battery power harness and power

harness parts bag from the power pack box.

NOTE: Take extra time needed to plan the routing of wir-

ing harnesses. Make sure harnesses do not interfere

with, or contact, any moving parts and route wires away

from excessive heat areas. Read all the instructions

carefully to ensure a safe and professional installation.

2. Mount the fuse holder near the battery using (2) #10

x 1" self-tapping screws.

3. Take the cover off of the fuse holder and remove the

nuts on the studs. Place one end of the 2 ft. long power

wire on one stud. (See Figure 1-2).

Figure 1-2

4. Attach the other end of the 2 ft harness to the positive

terminal of the primary battery or vehicle specific

accessory power post.

NOTE: Some vehicle manufacturers request to attach

any power cables for accessories to a specified location

near the battery, rather than attaching directly to the posi-

tive battery post.

5. Attach the red wire from the battery power harness to

the other stud of the fuse holder.

6. Place the fuse between the two studs and re-attach

the nuts and cover.

7. Route the battery power harness to convenient point

out to the front of the vehicle for connection to a plow.

Attach the dust cap to the molded end of the harness.

8. Attach the black wire from the battery power harness

to the NEG (-) terminal of the battery and re-connect the

negative battery terminal.

9. Spray all terminal connections with a battery terminal

protective coating.

10. Secure harness with plastic tie straps.

11. Apply included dielectric grease to all connectors.

WARNING

Disconnect the vehicle NEG. (-) battery cable

while performing steps 2 - 5 to avoid serious

bodily injury from electrical shock, fire, or

explosion. Do not re-connect battery cable until

indicated in step 8.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

8" TO 10" HEIGHT

WARNING

The power cable in front of the truck is wired

directly to the battery. The power cable is

always energized, even if the truck is turned off.

Always replace the protective cap after

disconnecting the plow power cable. Allowing

an unprotected plug to contact metal parts of

the truck may cause electrical component

damage. Never use a metal object to clean the

plug contacts.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

TRUCK

RED

BLACK

POWER

HARNESS

POWER HARNESS PLUG

BATTERY

FUSE &

FUSE HOLDER

INSTALLATION INSTRUCTIONS

5

Mechanical Installation

IMPORTANT: Graphics and illustrations may be

used which may show equipment and/or options not

included in every installation.

Assemble Blade, Swing Frame, and Trip Springs

NOTE: The 22 Series 2 blade uses blade stops. Make

sure the proper stops are installed.

1. Open the power pack carton and remove the blade

parts bag (part number 96107547). The blade stops are

in the blade parts bag.

2. Place stops between the lugs on the swing frame.

Secure with 3/8" x 1-3/4" bolts and locknuts. (See Figure

1-3). The bolts and nuts are in the blade parts bag.

Figure 1-3

3. Lay blade face down on floor.

4. Place swing frame on blade, positioning the two

inside ribs between the swing frame lugs. insert a 3/4" x

1-5/8" clevis pin from blade parts bag to fasten each side.

(See Figure 1-4).

Figure 1-4

5. Insert washer on end of each clevis pin and secure

with cotter pin.

NOTE: Make sure cotter pin is properly bent as in Figure

1-5 or pin may work loose.

Figure 1-5

6. Remove the springs from the power pack carton.

Hook springs onto blade with open end of loop facing up.

(See Figure 1-6).

Figure 1-6

7. Hook other end of spring onto eyebolt. Insert one

eyebolt on each side of the blade into the hole on the

swing frame spring bracket. Use a nut on either side of

bracket to secure. (See Figure 1-6).

8. Tighten springs until a .015" feeler gauge can pass

between two or more coils. (A 3x5 postcard is

approximately .015" thick.)

3/8"x 1-3/4" BOLT

3/8"x 1-3/4" BOLT

3/8" LOCKNUT

3/8" LOCKNUT

3/4" x 1-5/8"

CLEVIS PIN

WASHER

WASHER

COTTER

PIN

COTTER

PIN

3/4" x 1-5/8"

CLEVIS PIN

CAUTION

Do not over tighten trip springs. If more than

.015" (1/64") gap appears between coils

damage could occur during plowing.

Spring must be installed with open end of top

loop facing vehicle. Bottom loop position will

vary.

FAILURE TO FOLLOW COULD RESULT IN

MINOR OR MODERATE INJURY.

COTTER PIN

CLEVIS PIN

0.015" GAP

INSTALL WITH

OPEN END OF LOOP

FACING VEHICLE

JAM NUT

EYE BOLT

6

Final Installation

1. Remove power unit from carton. Remove pump

cover and install receiver using instructions included with

controls package. Fill reservoir on pump with supplied

hydraulic fluid.

2. Set lower hitch pins into slot on truck subframe. Plug

in power and control harness and rotate lift bar into

position. Lock in place by rotating cam handles.

3. Set A-frame level using plow control. Once A-frame is

level, turn off controller and disconnect power. See

"Mounting Snow Plow To Vehicle" on page 7 for more

information.

4. Remove 3/4" locknut, washer and 3/4" bolt. Slide

swing frame into A-frame. Replace 3/4" bolt, washer and

locknut. Tighten hardware.

See Figure 1-7 and Figure 1-8.

Figure 1-7

Figure 1-8

5. Remove cotter pins, clevis pins and spacers from rod

end of cylinders. Reconnect the power and control.

Extend cylinders using plow control to align holes in

cylinder rod and swing frame. Replace spacers, clevis

pins and cotter pins, making sure that spacer is on

bottom of rod. (See Figure 1-7).

6. Cycle all plow functions and refill reservoir. Repeat

until all air is removed from hydraulic system.

IMPORTANT: Review the "Break In Period" section

on page 10 of the Maintenance section to determine

if the 3/4" bolt installed in step 4 is tightened

appropriately.

7. Install side marker into pre-drilled holes on blade

frame using hardware included in package.

8. Remove the cable clamp from the parts bag. Insert

the Power and Control Harnesses into the clamp. Secure

clamp to the back of the A-Frame using 1/4" x 1" Screw,

1/4" Washer, and 1/4" Locknut.

9. Install pump cover by tilting pump cover forward,

sliding pump cover over front two tabs, rotate cover back,

and pull rear of cover over rear tabs. Replace screws and

washers at rear of pump cover.

WARNING

Install caps on both wing cylinder hydraulic lines

before operating hydraulic system in step 3.

Failure to cap both lines may allow high

pressure hydraulic fluid to be unintentionally

discharged.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

3/4"-16 BOLT

3/4"-16 LOCKNUT

SPACER

3/4" WASHER

COTTER PIN

SPACER

PIN

COTTER

NOTE: SHOWN WITH LIFT BAR / BELLCRANK ASSEMBLY

AND POWER UNIT REMOVED

1/2" x 2-3/8"

CLEVIS PINS

3/4" LOCKNUT

3/4" WASHER

NOTE: SHOWN WITH PUMP AND PUMP COVER REMOVED

7

Mounting Snow Plow To Vehicle

1. Drive truck into plow. Align lift bar frame outside of

subframe lugs. Pins should fit inside slots cut into

subframe lugs. (See Figure 1-9).

Figure 1-9

NOTE: If pins are too high or low to fit into slots on sub-

frame, adjust the height by plugging in the plow and hand

held controller. To lower the pins, turn on down pressure

and press down. To raise the pins, press up.

2. Plug in power harness and control harnesses.

3. Rotate lift bar into position by turning on down

pressure and pressing the lower button.

(See Figure 1-10).

Figure 1-10

WARNING

When using the hand held controller to raise or

lower the plow A-frame for mounting the plow

to the vehicle, be especially careful of the

movement of the lift bar. This movement will

occur when raising or lowering the A-frame or

jack stand.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

WARNING

Pressing the blade angle functions will result in

the A-frame swinging if it is not secured to the

truck. Do not press the angle function during

plow installation.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

SUBFRAME

LIFT

BAR FRAME

MOUNTED

ON TRUCK

WARNING

The power cable in front of the truck is wired

directly to the battery. The power cable is

always energized, even if the truck is turned off.

Always replace the protective cap after

disconnecting the plow power cable. Allowing

an unprotected plug to contact metal parts of

the truck may cause electrical component

damage. Never use a metal object to clean the

plug contacts.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

PIN WILL DROP

INTO SLOT

8

4. Rotate pin handles forward to lock upper hitch pins in

place. (See Figure 1-11). Put plow in float position by

turning down pressure off.

NOTE: Upper hitch pins are fully engaged when pin han-

dle is tight against pin bracket and you cannot see the

upper hitch pin between the pin bracket and pin handle.

If upper hitch pins are not fully engaged:

A. Raise plow an inch off the ground, then lower. Or,

B. Turn Down Pressure ON and then OFF.

Upper hitch pins will snap into place.

Figure 1-11

5. Disengage both jack stand pins by pulling on

handles. Raise the jack stand and engage the bottom pin

by pushing on the handle. Make sure pin is engaged in

hole by rotating jack stand back and forth. (See Figure 1-

12).

Figure 1-12

6. Raise, lower, and angle plow to make sure no hoses

or wires pinch in the plow mechanism.

Installing The Cylinder Lock Clamp

1. Raise the plow to the full UP position.

2. Turn the ignition OFF and apply the parking brake.

3. Turn OFF the hand-held controller.

4. Remove the pin from the cylinder lock clamp.

5. Position the cylinder lock clamp around the exposed

(chrome) portion of the lift cylinder with the open side of

the cylinder lock up. Install the pin. (See Figure 1-13).

Figure 1-13

6. Lower the plow so that cylinder lock clamp is tight

against cylinder.

WARNING

Make sure that upper hitch pins are engaged

before moving truck. Hitch pins not fully

engaged could result in the plow separating

from the truck.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

PIN HANDLE

FORWARD

UPPER HITCH PIN

BELL CRANK

LIFT LINK

UPPER PIN

HANDLE

LOWER PIN

HANDLE

JACK STAND

WARNING

Insert cylinder lock clamp when plow is not

engaged in plowing operations. Failure to do so

can allow plow to drop to unsafe position.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

WIRE LOCK PIN

LIFT

LINK

A-FRAME BOTTOM

BELL

CRANK

CYLINDER

LOCK

CLAMP

CYLINDER

ROD

9

Removing Snow Plow From Vehicle

Choose a location for the plow storage, which will allow

the plow to be removed from the vehicle and not be

moved after removal. Also, choose a location that will not

allow the plow stand to sink into the ground. A dry,

protected area is recommended.

1. Lower plow to the ground, put vehicle in park, turn off

the engine and set the parking brake.

2. Disengage lower jack stand pin by pulling on handle.

Lower the jack stand and engage the top pin by pushing

on the handle. Make sure pin is engaged in hole by

rotating jack stand back and forth. (See Figure 1-14)

Figure 1-14

3. Turn Down Pressure ON and then OFF.

4. Push pin handles toward truck to unlock main pins.

(See Figure 1-15)

Figure 1-15

5. Rotate jack stand down and raise A-frame by

pressing the up button. (See Figure 1-16)

Figure 1-16

6. Disconnect power and control harnesses, replace

protective caps, and back truck away from plow.

BELL

CRANK

JACK

STAND

LIFT LINK

UPPER PIN

HANDLE

PIN HANDLE

STRAIGHT OUT

PIN HANDLE

STRAIGHT OUT

10

General

• Before operating, perform a through visual

inspection of the equipment. Look for fluid leaks,

cracked, bent or broken components, loose nuts,

bolts or attachments and proper fluid levels.

• A clean system is essential to long pump life and

proper performance.

• When adding oil to the reservoir, wipe area around

the filler port clean before removing the breather cap.

Use clean oil and a clean funnel (DO NOT use a cloth

or rag to strain the oil).

IMPORTANT: Sno-Way supplies type 5606 Sno-Way

Hydraulic Oil with the unit from the factory. If

additional oil is added it must be compatible with

Sno-Way oil. If another type of oil has been used in

the system the same type of oil must be used for

topping off the system. Improper hydraulic fluid can

cause operating problems in cold weather.

• Do NOT use synthetic oil.

• Oil must contain an anti-foam additive.

• Ensure all electrical connections are clean and

tight.

• To prevent rust from forming, clean and repaint

exposed metal surfaces.

• NEVER operate the equipment with the protective

covers or guards removed.

Break In Period

The plow will go through a break in period during which

the A-frame and swing frame will settle in. After 15-20

hours of operation check for free play of the A-frame and

swing frame pivot.

1. Raise the plow and insert a jack stand under the A-

frame.

2. Push down on end of blade as far as it will go on the

right or left side. Measure and record the distance from

the ground to the bottom edge of the wear strip.

3. Pull upwards on the same end of the plow as far as it

will go. Measure and record the distance from the ground

to the bottom edge of the wear strip.

4. Subtract the two measurements. If the number is

greater than 1-1/2" then the free play needs to be

adjusted.

To Remove Excessive Free Play

1. Tighten the pivot bolt nut (typically 1/6 to 1/3 turn, one

or two flats).

Periodic Inspection

After every 20 hours of operation perform the following

inspections:

1. Inspect plow assembly including sub frame for any

damage or excessive wear. Replace parts as necessary.

2. Inspect all fasteners (Plow & Truck Mount) to insure

they are properly tightened. Re-tighten loose fasteners to

the proper torque. Loose fasteners on the Bellcrank,

Pump Platform to A-Frame, Power Unit to the Pump

Platform, and Truck Mount must have the locknuts

replaced and tightened while using Sno-Way thread

locker 96115529. (Refer to torque specification chart in

this manual).

3. Apply a small amount of light oil to: Quick-tatch pin

and handle assemblies, pivot pins between the blade and

swing frame, and pivot pins at lift and swing cylinders.

Also lubricate jackstand pins. (See Figure 2-1)

Figure 2-1

WARNING

Before servicing plow, lower plow to the

ground or onto cylinder lock clamp and

disconnect main power harness.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

SWING

PIVOTS

CYLINDER

QUICK-TATCH

PIN / HANDLE

JACKSTAND PIN

LIFT

LINKAGE

PIVOTS

LIFT

CYLINDER

PIVOTS

BLADE

PIVOT

PINS

MAINTENANCE

11

Plow Storage

When storing the plow for long periods of time use the

following guidelines.

1. If the plow will not be stored on pavement, place a

board under the jack stand to prevent it from sinking into

the ground.

2. To prevent corrosion, coat the exposed portion of the

cylinders with light grease.

3. Grease all pivot points.

4. Fill hydraulic reservoir to the fill line to minimize

trapped air.

5. Place dielectric grease on the terminals of all

electrical plugs, including those under pump cover. Make

sure protective caps are in place or connectors are

plugged together.

6. Check and replace any worn or damaged

components, such as cutting edges, deflectors, and

bushings.

7. For additional protection, use a 99101213 plow parka

cover.

Polycarbonate Blade Care

• DO NOT use abrasive or highly alkaline cleaners on

polycarbonate blade.

• Never scrape polycarbonate blade with squeegees,

razor blades or other sharp instruments.

• Benzene, gasoline, acetone or carbon tetrachloride

should never be used on polycarbonate blade.

• DO NOT clean polycarbonate blade in hot sun or at

elevated temperatures.

Polycarbonate Blade Cleaning

Instructions

Wash with a mild soap or detergent and luke-warm water

using a clean cloth or soft sponge. Dry thoroughly with a

chamois or moist cellulose sponge to prevent water spots.

Special Fasteners Torques and

Requirements

IMPORTANT: Incorrectly securing fasteners may

result in incorrect operation, excessive wear, and

early failure of plow components. It may also void

your warranty.

• ALWAYS check to make sure you are using the

correct torque specification for the fastener you

are using.

• DO NOT use any lubricants on the threads of any

fastener.

Standard Fasteners

The Torque Specifications Chart on page 27 of this

manual should be used as the guide for fastener torque

requirements for most standard fasteners used on the

plow.

Standard fasteners with special torque requirements will

be noted in assembly or service instructions pertaining to

the specific piece of equipment.

Hydraulic Fittings

Hydraulic fittings with locknuts should be assembled with

at least three full turns of the fitting in the port and then the

locknut should be tightened to 27 lb-ft.

Hydraulic fittings with 37 degree flare end swivels should

be torqued to 18-20 lb-ft.

Fluid Requirements

IMPORTANT: Sno-Way supplies type 5606 Sno-Way

Hydraulic Oil with the unit from the factory. If

additional oil is added it must be compatible with

Sno-Way oil.

It is recommended that the fluid in the hydraulic system be

changed once a season.

NOTE: Type 5606 oil is rated to -60 deg. F, when Type

5606 is not available Exxon UNIVIS J13 or equivalent

may be used.

Do NOT use synthetic oil.

Oil must contain an anti-foam additive.

NOTICE

• Using the proper oil increases the life

expectancy of the most critical part of your

plow; the hydraulic power unit.

• Failure to use the proper oil can cause

extensive damage to the power unit, seals and

hydraulic cylinders.

• Improper oil can cause operating problems and

poor performance in cold weather.

FAILURE TO FOLLOW COULD LEAD TO

PROPERTY DAMAGE.

12

Changing Oil and Cleaning Filter Screen

NOTE: Change oil and clean filter screen at the begin-

ning of every season. This will help ensure maximum life

and maximum performance from the pump assembly.

1. Move plow to a clean, dry area with a solid surface.

Lower the plow to the ground, put vehicle in park, turn off

the engine, and set the park brake. Turn off the plow

controller.

2. To prevent inadvertent short circuit or electrical

shock, disconnect the power harness and

communication harness at the vehicle bumper.

3. Remove the two screws at the lower back of the

pump cover. Pull the back of the pump cover off the rear

tabs and rotate the cover slightly forward. Push the cover

off the front tabs and remove. (See Figure 2-2)

Figure 2-2

4. Remove the filler/breather cap from the reservoir.

(See Figure 2-3)

Figure 2-3

5. Using a suction gun or similar tool, remove the oil

from the reservoir.

NOTE: Be careful to avoid contacting and damaging the

filter screen while removing oil.

6. Remove the lift cylinder hoses from the valve block.

Remove the swing cylinder hoses from the fitting in the

valve block. Mark hoses before removal to be certain

they are reinstalled in the correct location.

7. Place the hoses in a container to catch oil expelled

from cylinders. Cycle the lift cylinder by disconnecting

hitch pins and pushing and pulling on lift bar. Cycle swing

cylinders by disconnecting from swing frame and pushing

and pulling on cylinder rod.

8. Reconnect swing cylinders and install hitch pins.

WARNING

• Allow the system to cool down before draining

oil or handling system components. Burns can

result from contact with hot oil.

• Never disconnect any hydraulic line or fitting

with the plow in the raised position. Always

lower the plow and relieve pressure before

removing any lines or caps.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY

WARNING

Ensure engine is OFF and set parking brake

before working on plow. Vehicle movement,

equipment failure or inadvertent operation of

the control switches during maintenance could

result in serious injury

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

TWO

FRONT

TABS

TWO

SCREWS

FILLER

CAP

13

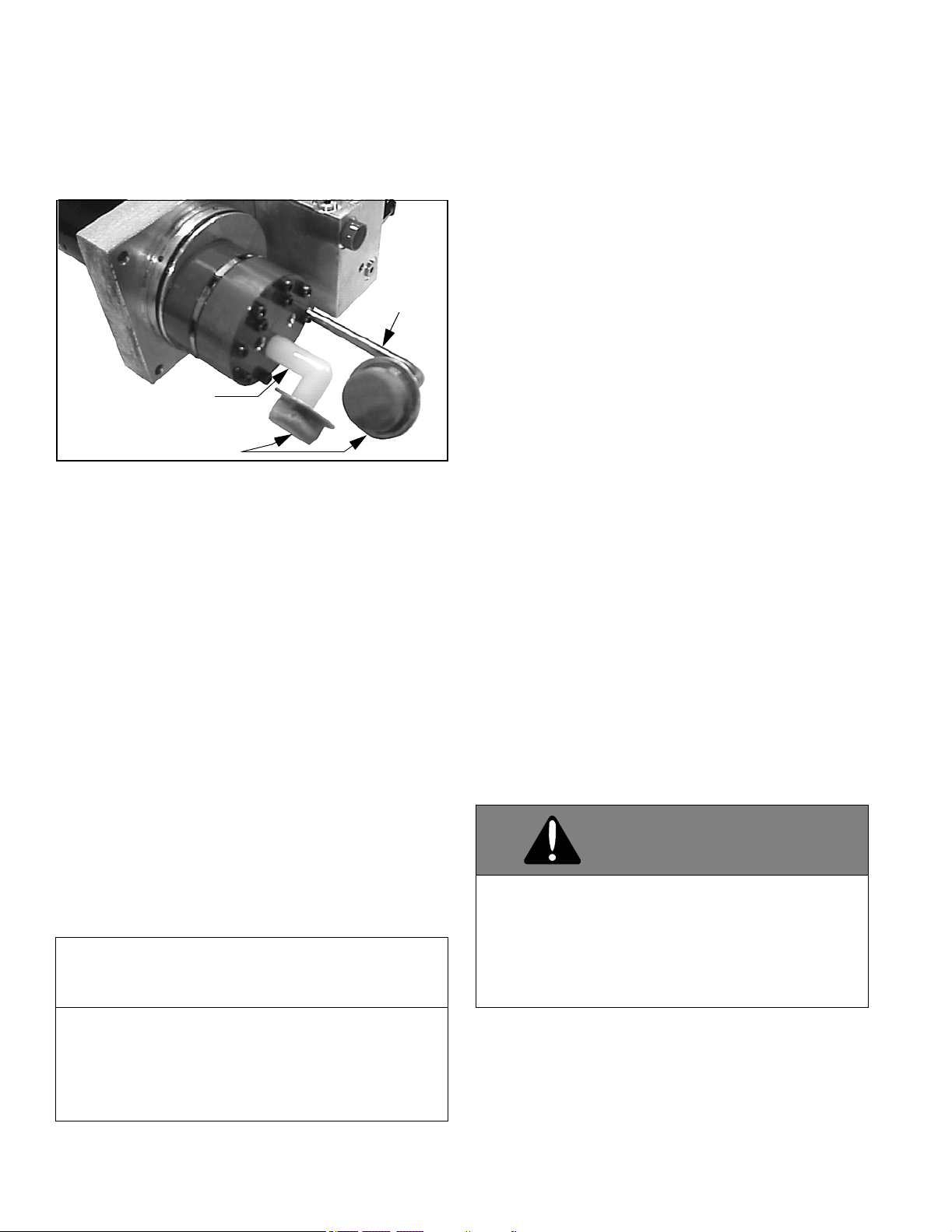

9. Loosen the band clamp, which holds the reservoir to

the pump assembly. Pull and twist the reservoir until it

separates from the pump assembly. Be careful not to

damage the filter screen. (See Figure 2-4)

10. Note the position of the reservoir oil pick-up tube and

be sure the tube is in the same position when the filter is

removed and installed. (See Figure 2-4)

Figure 2-4

11. Pull the filter screens off the return and suction tubes

(hold it by the metal cover, not the screen) and clean.

Blow-dry with low-pressure air from the inside. (See

Figure 2-4).

12. Carefully re-install the filter screens. Use care when

handling the screens to avoid damage.

13. Visually check that the pickup tube and filter are in

the proper orientation (See Figure 2-4). If not, rotate the

pickup tube until the tube and filter are in the proper

orientation.

14. Clean the inside and outside of the reservoir.

15. Inspect the O-ring seal for damage. Replace if

needed. Before installing, lubricate with fresh oil, and

reinstall reservoir carefully to avoid damaging the O-

Ring.

16. Tighten band clamp that holds the reservoir to power

unit.

17. Reconnect hydraulic fittings and hoses in their

correct position and torque to 20-25 lb-ft. If unit utilizes O-

Ring and jam nut type connectors tighten jam nut to 15-

20 lb-ft.

18. Fill the hydraulic reservoir with type 5606 hydraulic

fluid until the fluid registers full on the oil level mark on

reservoir.

NOTE: Vehicle must be parked on level ground and plow

must be in lowered position in order to properly check the

reservoir level.

19. Refer to controls manual and cycle plow to remove

air from hydraulic system. Refill reservoir as needed.

20. Operate system and check for leaks. Repair and

replace components as necessary. Install pump cover.

Cutting Edge

IMPORTANT: Cutting edge MUST be replaced when

it is worn to the bottom edge of the plow frame.

1. Raise the plow to full up position.

2. Place a jack stand under both ends of the blade

bottom rail.

3. With the Down Pressure Hydraulic System OFF,

lower plow until firmly resting on jack stands.

4. The blade skin must be retained prior to removing

cutting edge. This can be done using a pair of 6" C-

clamps located at the center of the curved portion of the

blade.

5. With an assistant, remove hardware and worn

wearstrip from plow.

6. Insert two carriage bolts, one on each end of the

blade, through the cutting edge and blade. Loosely install

two locknuts.

7. Insert the remaining carriage bolts and loosely install

locknuts on each bolt.

8. Beginning on either side, tighten all nuts securely.

NOTICE

• Do Not use Teflon tape or pipe dope on hydraulic

fittings. These can dislodge and jam valves in the

hydraulic system.

FAILURE TO FOLLOW COULD LEAD TO

PROPERTY DAMAGE.

FILTER

SCREEN

PICK-UP

TUBE

RETURN

TUBE

WARNING

The bottom of the cutting edge can be very

sharp. Whenever handling a cutting edge, work

with an assistant and wear suitable protective

gloves to avoid serious injury.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

14

Plow Shoe Adjustment

1. Raise plow to full up position.

2. Support blade with a jack.

3. Turn vehicle ignition switch and plow control OFF and

apply emergency brake.

4. Adjust shoe assemblies by removing shoe mounting

lynch pin and adding or subtracting washers on the top or

bottom of the shoe-mounting bracket. (See Figure 2-5).

Figure 2-5

5. After the plow shoe position is properly adjusted

place washer on the shoe stem - above the plow shoe

mounting bracket and below the retaining lynch pin - to

remove all up and down movement of the plow shoe in

the bracket. Failure to do so will result in excessive wear

of the holes in mounting bracket or bending of the plow

shoe stem.

IMPORTANT: Snap lynch pin ring over so that it

contacts the pin. If ring does not contact lynch pin,

rotate the pin and reverse the direction of the ring. If

the ring does not contact the pin it is not locked and

could fall out.

Trip Spring Adjustment

See "Mechanical Installation" on page 5.

Blade Stop Replacement

Replace the blades stop at least every 3 years by

following in reverse order: the steps under "Assemble

Blade, Swing Frame, and Trip Springs" on page 5 in the

Mechanical Installation section.

Emergency Plow Raise

If your snowplow becomes inoperable for any reason,

follow the instructions below to raise the plow for transport

to your nearest Sno-Way Dealer.

1. Move truck to level hard ground.

2. Place a jack under the swing frame as close to the A-

frame as possible.

3. Raise jack until the A-frame is at approximately 30

degrees with the ground.

4. Make sure the plow and jack are stable. Place a jack

stand or wood blocking under the A-frame to prevent the

plow from suddenly dropping.

5. Install cylinder lock clamp. (See "Installing The

Cylinder Lock Clamp" on page 8.)

6. Remove Jack and Jack stand.

7. Drive to your nearest Sno-Way dealer for service.

WASHERS

PIN

WARNING

Failure to place a jack stand under the plow

could result in the plow rapidly falling.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

15

Operating Class

The 22 Series 2 Sno-Way plow is specifically designed for

applications on light duty trucks and SUVs.

NOTE: The loaded vehicle, including any ballast weight

and optional equipment, must not exceed the Gross

Vehicle Weight (GVW) or front or rear Gross Axle Weight

(GAW) ratings specified on the Safety Compliance Certi-

fication Label located on the driver's side door opening.

For additional information, refer to your dealer and the

Sno-Way Application Guide for proper vehicle applica-

tions.

Before the Season Begins

1. Inspect plow vehicle’s electrical system for proper

operation.

2. Inspect plow assembly including sub frame for any

damage or excessive wear. Replace parts as necessary.

3. Inspect all fasteners to insure they are properly

tightened. Re-tighten loose fasteners to the proper torque

(Refer to torque specification chart in this manual).

4. Apply a small amount of light oil to: Quick-tatch pin

and handle assemblies, pivot pins between the blade and

swing frame, and pivot pins at lift and swing cylinders.

Also lubricate jackstand pins. (See Figure 2-1).

5. Clean and repaint any exposed metal parts with

corrosion resistant enamel.

6. Check free play between the a-frame and swing

frame pivot. Adjust if necessary. (See "Break In Period"

on page 10).

7. Check the oil level and repair any oil leaks. (See

"MAINTENANCE" on page 10).

8. Inspect electrical connectors. Make sure the contacts

are clean, and apply a small amount of dielectric grease.

9. If ballast is required, position and secure ballast

behind rear wheels, for optimum performance.

Transporting Vehicle With Plow Attached

1. Always install the cylinder lock clamp when the plow

is raised and the operator is not engaged in plowing

operations. See "Installing The Cylinder Lock Clamp" on

page 8.

2. Position the blade out of the beam path of the

headlights before driving.

3. Do not exceed 45 M.P.H. when driving with the

snowplow attached. Braking distance is increased and

handling impaired at speeds above 45 M.P.H.

4. Reduce speed when crossing railroad tracks or when

road conditions deteriorate.

5. Never change blade angle or height while driving.

6. Inspect plow and attaching hardware for damage

before transporting or plowing.

Plowing Like A Pro

NOTICE

• Remove the plow when driving extended

distances at temperatures above 40 deg. F, the

plow blocks enough airflow to cause it to overheat

at temperatures above 40 deg. F.

FAILURE TO FOLLOW COULD LEAD TO

PROPERTY DAMAGE.

WARNING

Check your local laws with regards to

transporting plow mounted to vehicle on public

roads.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

WARNING

Wear your seat belt! Contact with a hidden

obstruction can cause serious personal injury

from bodily contact within the vehicle cab or

whiplash from sudden stops.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

WARNING

• Never exceed 10 m.p.h. when plowing! Serious

personal injury can result, as well as damage

to equipment and property, if an unseen

obstruction is encountered while plowing.

• Never plow with your head protruding from the

vehicle side window. Serious head or neck

injuries can result from sudden stops or

coming into contact with tree branches, signs

or other stationary objects.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

PLOWING OPERATION

16

NOTE: The air bag is factory set to deploy at a certain

acceleration level. The air bag will deploy with the plow

attached if an obstruction is hit with enough force to

reach this level. Always plow within the recommended

plowing speeds and know the area you are plowing to

avoid any obstructions.

NOTE: For better clean up of hard packed snow; raise

the plow shoes so that the cutting edge of the blade

comes into direct contact with pavement. Use the lowest

possible gear to place maximum power behind the cut-

ting edge.

For instructions on using the plow controller to manipulate

the plow see the manual included with your plow control

package.

1. Become familiar with the area to be plowed and mark

potential hazards before the snow falls. Many immovable

objects cannot be seen when covered with snow.

Developing a plan early can save valuable time and

equipment damage. Allow sufficient room to pile snow,

out of the traffic area, with enough space for when the

next storm comes.

2. Plow with the storm. The "Pros" are out early

removing only several inches at a time. Allowing snow to

accumulate to unmanageable levels can cause removal

problems and wear and tear on equipment. The plow is

not a "Ram" or a "Bulldozer". If used properly, it will give

many years of safe and reliable service.

3. Research municipal ordinances for restrictions on the

disposal of snow. Many municipalities do not allow snow

to be placed in or moved across roads or highways.

4. Research state department of transportation rules on

maximum width restrictions for snow plows. Certain

blades may require permits.

Using The Down Pressure (DP) Hydraulic

Systems

The DP system was designed for removing hard packed

snow from hard surfaces that has been driven on prior to

plowing.

The system should be turned OFF when plowing surfaces

such as gravel, dirt, sand, etc., to prevent cutting into the

surface.

Activating the system applies down pressure to the down

pressure side of the lift cylinder. This down pressure will

force the cutting edge through hard packed snow. If down

pressure decreases as a result of a low spot, more down

pressure will be applied to the lift cylinder. When a high

spot is encountered the down pressure will be relieved to

allow the plow to follow the contour without lifting the front

of the truck.

Clearing Driveways

1. Head into driveway with the blade angled to move

snow away from buildings. Continue to widen the drive

path by rolling snow away from buildings on successive

passes.

2. If there is a garage at the end of the driveway, plow to

within several vehicle lengths of the garage and push the

snow off the driveway.

3. Raise the blade and drive through the snow up to the

garage. Drop the blade and "Back Drag" the snow 1-1/2

vehicle lengths back. Repeat as necessary.

4. Back the vehicle to garage door and plow forward

toward street, removing the remaining snow.

NOTICE

Excessive stacking of snow causes undo

stress to the snowplow and vehicle. Repeated

loading of this nature may result in the failure

of plow components designed to protect the

snowplow and vehicle from major damage.

FAILURE TO FOLLOW COULD LEAD TO

PROPERTY DAMAGE.

17

Introduction

Whenever service is necessary, your local dealer knows

your plow best and is interested in your complete

satisfaction. Return your snowplow to your local dealer for

maintenance service or any other assistance you may

require. If you are unable to do so, this troubleshooting

guide should help you determine the problem. However,

before attempting the servicing of your plow, you should

possess good mechanical abilities and a total

understanding of the mechanism.

PLEASE: Before calling parts and service personnel be

certain that:

1. You have read this guide carefully and are certain

that all of the suggestions pertaining to your problem

have been attempted.

2. You have the following available:

A. Date snowplow was originally installed

B. Power Pack Serial Number

This information should be recorded on page 2 of this

Owners Manual.

Troubleshooting Guide - Quick Reference

1. Check vehicle electrical system for proper operation.

2. Check all wiring to be sure that battery terminals are

clean and connections to battery, fuse, solenoid, and all

connectors on plow harness are clean and tight.

3. Check for external leakage at cylinders, hoses, and

power unit.

4. Check the voltage at the coils which operate solenoid

valves. For proper operation, Pro Control system

solenoid coils require a minimum of 10 volts DC.

5. Check oil level in hydraulic system reservoir.

WARNING

First read all warning instruction, the safety

messages, and directions before attempting

any adjustments or repairs to your unit!

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Motor will not run/

motor runs slow

Fuse Blown Check the circuit breaker / 250A fuse at your battery as well as the 10A fuse

on the pump harness. If either fuse has blown check over all electrical wiring

to determine why the fuse blew and replace fuse

Motor solenoid failed Replace Motor solenoid.

Motor seized Remove and replace motor, torque motor bolts between 50 to 60 inch

pounds.

Motor brushes worn Replace motor.

Seal between motor and

pump damaged allowing

oil to enter motor housing

Remove the motor. Drain oil from the reservoir. Loosen the clamp and

remove the reservoir. Remove the 4 Allen screws and remove the pump

from the base block. Remove pump seal and replace. If the motor can be

salvaged, clean out motor and reassemble. If the motor can not be salvaged

replace motor.

Motor continues to

run and will not shut

off

Wires shorted out Check all wires starting at solenoid working your way back to the vehicle.

Solenoid shorted

internally

Replace solenoid.

TROUBLESHOOTING

18

Blade will not lift

(motor runs)

Hydraulic fluid level low Fill hydraulic fluid up to the fill line on the reservoir using Sno-Way hydraulic

fluid.

Improper main system

pressure relief valve

setting

Using a 3000 psi gauge plumbed into the gauge port (GP), run plow over

relief. Adjust main pressure relief screw to the proper main system pressure

for the series of plow. This can be found in the back of your owners manual

or online at SNOWAY.com.

Breather cap plugged Remove and replace breather cap.

Coil on valve (F) Check if there is magnetism on coil (F). If there is not swap coil with the coil

(A). If the problem moves to the angle function the coil is bad and needs to

be replaced.

Lower valve (F) stuck Check valve to make sure there is magnetism on the "F" coil. Remove the

"F" valve and swap it with the "E" valve. If the blade lifts your valve was stuck

closed. Remove and replace the valve.

Raise cylinder binding Check all linkages in the bell crank area. Replace and damaged

components.

Pick up tube filter plugged Remove hydraulic fluid from the tank. Remove the tank and observe the pick

up tube screen. Clean or replace if necessary.

Worn/failed pump Using a 3000 psi gauge plumbed into the gauge port (GP), run plow over

relief. Adjust main pressure relief screw. If the pressure will not raise and the

angle functions work remove hydraulic fluid and tank. Replace pump.

Pick up tube is not

submerged in fluid

Remove hydraulic fluid and tank. Turn pick up tube so it is angled down to

the bottom of the tank.

Down pressure valve (E)

stuck open

Check valve to make sure there in not magnetism on the "E" coil. Remove

the "E" valve and swap it with the "F" valve. If the blade lifts, your valve was

stuck open. Replace the valve.

Raise Valve (C) not

functioning

Check "C" coil for magnetism. Remove the "C" valve and inspect. Make sure

the lower part of the valve moves free and there is no debris causing the

valve to stick. If stuck and cant be freed up replace valve.

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

19

Blade lifts slowly Hydraulic fluid level low Fill hydraulic fluid up to the fill line on the reservoir using Sno-Way hydraulic

fluid.

Breather cap plugged Remove and replace breather cap.

Improper main system

pressure relief valve

setting

Using a 3000 psi gauge plumbed into the gauge port (GP), run plow over

relief. Adjust main pressure relief screw to the proper main system pressure

for the series of plow. This can be found in the back of your owners manual

or online at SNOWAY.com.

Pick up tube filter plugged Remove hydraulic fluid from the tank. Remove the tank and observe the pick

up tube screen. Clean or replace if necessary.

Improper oil viscosity for

outside air temperature/

Ice in hydraulic tank

Change oil with Sno-Way hydraulic fluid.

Weak system pump Using a 3000 psi gauge plumbed into the gauge port (GP), run plow over

relief. Adjust main pressure relief screw. If the pressure will not raise and the

angle functions work remove hydraulic fluid and tank. Replace pump.

Low vehicle battery

voltage

Check voltage at both the battery and at the solenoid during function. The

battery may show 12V when the plow is not under load. If the voltage drops

below 9V when operating the plow, trouble shoot power system on your

vehicle.

Plow lifts but does

not hold - New plow

first action

Dirt in check valve Cycle raise and lower system to flush debris.

Dirt in lower valve (B) Cycle raise and lower system to unstick valve.

Plow lifts but does

not hold - second

action

Dirt or Debris in check

valve

Cycle raise and lower system to unstick valve if this does not work replace

valve.

Lower valve (B) stuck Check valve to make sure there in not magnetism on the "B" coil. Remove

the "B" valve and swap it with the "F" valve. If the blade lifts your valve was

stuck open. Replace the valve.

Seals, O-ring(s) on lower

valve (B) damaged

Remove the lower valve (B) and inspect the O-rings to see if they are

damaged. If damaged replace the O-ring if there is one available. If not

replace the valve.

Piston seals leaking

(Internal) on raise cylinder

Raise the plow up in the air and support the blade with a hydraulic floor jack.

Remove the hose off of the rod side of the lift cylinder. Slowly lower the floor

jack and watch to see what direction the fluid flows from the lift cylinder. If the

fluid sucks into the lift cylinder the seals are good. If the fluid flows out of the

lift cylinder, fluid is leaking past the seals and the cylinder needs to be

replaced.

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Table of contents

Other Sno-Way Snow Blower manuals