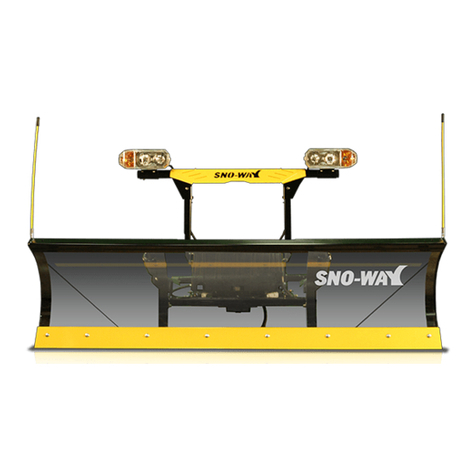

Sno-Way 26V Series Operating instructions

97102169A

INSTALLATION &

OWNER’S MANUAL

26V SERIES SNOW PLOW

WITH SERIAL NUMBERS AFTER:

26V100000

Sno-Way®, Down Pressure® and EIS®are registered trademarks of Sno-Way International, Inc.

ProControl™, MegaBlade™, V-Wing™, Revolution™and MaxAdjust™are trademarks of Sno-Way

International, Inc.

©2019 Sno-Way®International

1

TABLE OF CONTENTS

Page

INTRODUCTION ......................................................................................................... 2

SAFETY ...................................................................................................................... 3

INSTALLATION INSTRUCTIONS............................................................................... 4

General .............................................................................................................. 4

Electrical Installation ........................................................................................ 4

Mechanical Installation..................................................................................... 5

Blade Level Adjustment ................................................................................... 9

Mounting Snow Plow To Vehicle ................................................................... 10

Installing The Cylinder Lock Clamp .............................................................. 13

Removing Snow Plow From Vehicle ............................................................. 13

MAINTENANCE ........................................................................................................ 15

General ............................................................................................................ 15

Periodic Inspection......................................................................................... 15

Special Fasteners Torques and Requirements ............................................ 16

Hydraulic Fittings ........................................................................................... 16

Hydraulic Cylinders ........................................................................................ 16

Electrical Quick Disconnect Plugs................................................................ 16

Fluid Requirements ........................................................................................ 16

Changing Oil and Cleaning Filter Screen ..................................................... 17

Cutting Edge Replacement ............................................................................ 18

Plow Shoe Adjustment................................................................................... 19

Trip Spring Adjustment .................................................................................. 19

PLOWING OPERATION ........................................................................................... 20

Operating Classes .......................................................................................... 20

Before The Season Begins ............................................................................ 20

Transporting Vehicle With Plow Attached .................................................... 20

Plowing Like A Pro ......................................................................................... 21

Using The Down PressureTM (DP) Hydraulic System.................................. 21

Clearing Driveways......................................................................................... 22

Clearing Parking Lots..................................................................................... 22

TROUBLESHOOTING .............................................................................................. 23

Introduction..................................................................................................... 23

Troubleshooting Quick Reference - General................................................ 23

Troubleshooting Guide ................................................................................... 23

THEORY OF OPERATION........................................................................................ 27

Hydraulic Controls.......................................................................................... 27

Electro-Hydraulic Controls ............................................................................ 27

Raise Mode of Operation ............................................................................... 27

Lower Mode of Operation - Gravity Down and Float ................................... 28

Lower Mode of Operation - Down PressureTM Hydraulic (DP) System ..... 28

Wing Angling Mode of Operation - Independent Wing Angling ................. 28

Combination Wing Angling............................................................................ 29

Fuse ................................................................................................................. 29

Power Unit Components ................................................................................ 29

HYDRAULIC SCHEMATIC ....................................................................................... 30

WIRING SCHEMATIC - With S.N. After: 26V100000 .............................................. 31

POWER UNIT SOLENOID FUNCTION, WIRING AND LOCATION......................... 32

MAIN WIRING HARNESS SCHEMATIC EIS® (Energy Interruption SystemTM) . 33

TORQUE SPECIFICATIONS ................................................................................... 34

2

This manual was written for the assembly, installation and

maintenance of your new Sno-Way plow. Most

importantly, this manual provides an operating plan for

safe use. Refer to the Table of Contents for an outline of

this manual.

Please keep this manual with your machine at all times as

reference material and so it can be passed on to the next

owner if the machine is sold.

We require that you read and understand the contents of

this manual COMPLETELY, especially the chapter on

SAFETY, before attempting any procedure contained in

this manual.

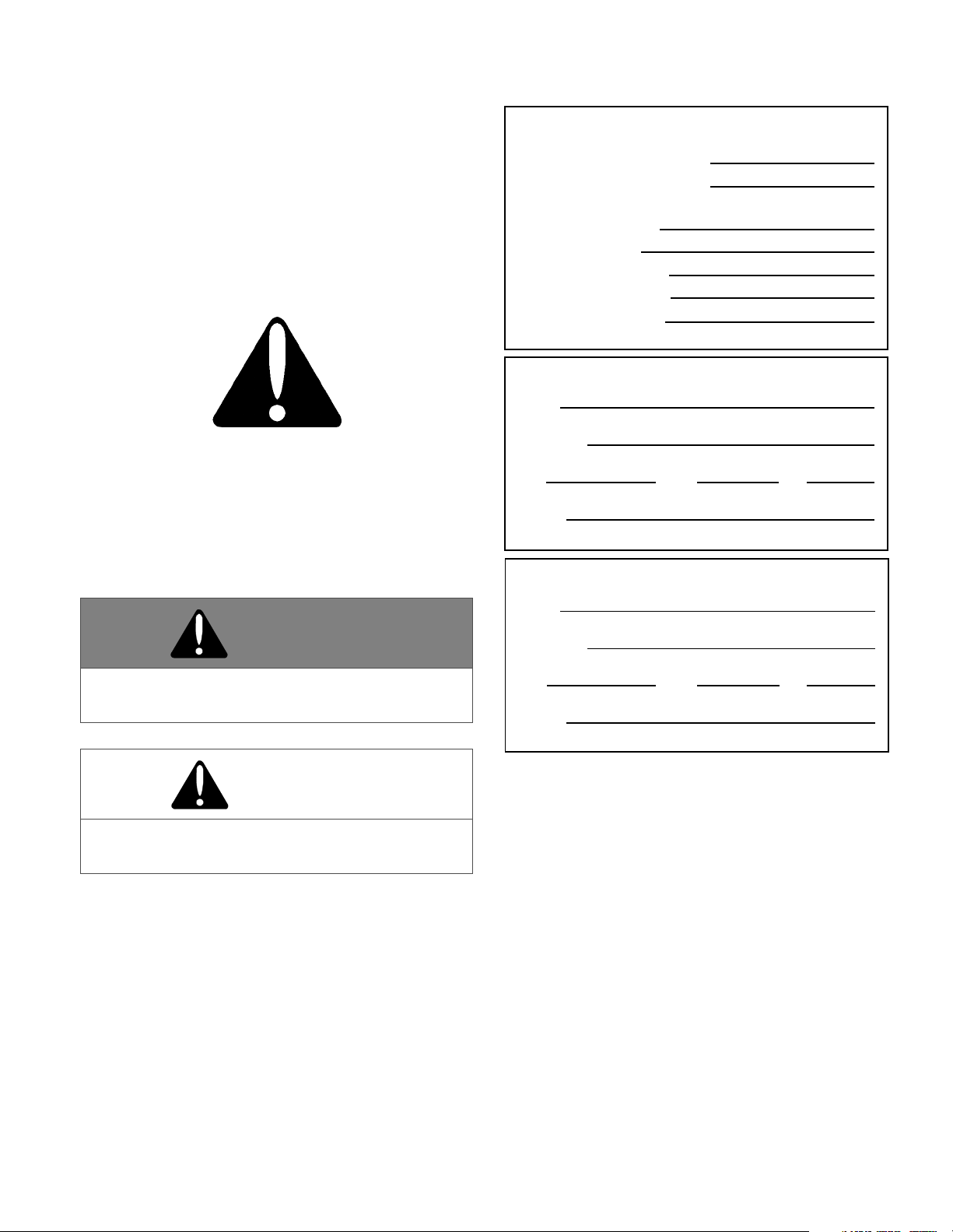

The Society of Automotive Engineers has adopted

this SAFETY ALERT SYMBOL to pinpoint character-

istics that, if NOT carefully followed, can create a

safety hazard. When you see this symbol in this man-

ual or on the machine itself, BE ALERT!, your per-

sonal safety and the safety of others, is involved.

• Defined below are the SAFETY ALERT messages

and how they will appear in this manual.

NOTE: Additional information concerning the equipment

or the procedure that may or may not be contained else-

where in this manual.

BE AWARE! It is illegal to remove, deface or other-

wise alter the safety decals mounted on this equip-

ment.

Record the Power Pack Model Number, Power Pack

Serial Number, Controller Serial Numbers, Blade Model

Number, Blade Serial Number and the Pump Serial

Number in the space provided below as a handy record

for quick reference. The Power Pack Serial Number is

located on the Lower Light Lift Bar (driver’s side), the

blade serial number is located on one of the middle ribs of

the blade. These plates contain information that your

Dealer needs to answer questions or to order

replacement parts, if needed, for your unit.

We reserve the right to make changes or improve the

design or construction of any part(s) without incurring the

obligation to install such parts or make any changes on

any unit previously delivered.

Graphics and illustrations may be used which may show

equipment and/or options not included in every

installation without incurring the obligation to install such

parts or make changes on units previously delivered.

Sno-Way Service Parts Manuals are available on-line or

at your authorized Sno-Way dealer. Request part number

97102170 & 97101915 for the 26V Series Snow Plow.

Factory contact information is available at

www.snoway.com.

WARNING

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH.

CAUTION

Information, that if not carefully followed, can

cause injury or damage to equipment!

DEALER

NAME

PHONE ( ) –

ADDRESS

CITY STATE ZIP

(FILL IN)

ORIGINAL PURCHASER

NAME

PHONE ( ) –

ADDRESS

CITY STATE ZIP

(FILL IN)

NAME PLATE DATA

POWER PACK MODEL NUMBER

BLADE SERIAL NUMBER

PUMP SERIAL NUMBER

(FILL IN)

POWER PACK SERIAL NUMBER

CONTROLLER SERIAL NUMBERS:

BLADE MODEL NUMBER

(Located on Blade Frame)

(Located on Lower Light Lift Bar - Drivers Side)

TRANSMITTER S.N.

RECEIVER S.N.

INTRODUCTION

3

BEFORE ATTEMPTING ANY PROCEDURE IN THIS

BOOK, READ AND UNDERSTAND ALL THE SAFETY

INFORMATION CONTAINED IN THIS SECTION. IN

ADDITION, ENSURE ALL INDIVIDUALS WORKING

WITH YOU ARE ALSO FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

For your safety Warning and Information Decals have

been placed on this product to remind the operator

to take safety precautions. It is important that these

decals are in place and are legible before operation

begins. New decals can be obtained from Sno-Way or

your local dealer.

REMEMBER The careful operator is the best

operator. Most accidents are caused by human error.

Certain precautions must be observed to prevent the

possibility of injury to operator or bystanders and/or

damage to equipment.

NEVER operate Plow when under the influence of

alcohol, drugs or other medications that could hamper

your judgement and reactions. An accident may result in

serious injury or death to other persons or yourself.

ALWAYS operate vehicle in a well-ventilated area. The

carbon monoxide in exhaust gas is highly toxic and can

cause serious injury or death.

NEVER allow hands, hair or clothing to get near any

moving parts such as fan blades, belts and pulleys.

Never wear neckties or loose clothing when working on

the vehicle.

NEVER wear wrist watches, rings or other jewelry when

working on the vehicle or individual equipment. These

things can catch on moving parts or cause an electrical

short circuit that could result in serious personal injury.

ALWAYS wear safety goggles when working on the

vehicle to protect your eyes from battery acid, gasoline,

and dust or dirt from flying off of moving engine parts.

ALWAYS be aware of and avoid contact with hot

surfaces such as engine, radiator, and hoses.

ALWAYS wear safety glasses with side shields when

striking metal against metal! In addition, it is

recommended that a softer (non-chipable) metal material

be used to cushion the blow. Failure to heed could result

in serious injury to the eye(s) or other parts of the body.

NEVER allow children or unauthorized person to

operate this unit.

NEVER exceed 45 m.p.h. when snow plow is attached

to vehicle. Braking distances may be increased and

handling characteristics may be impaired at speeds

above 45 m.p.h.

ALWAYS lock the vehicle when unattended to prevent

unauthorized operation of the plow.

ALWAYS check the job site for terrain hazards,

obstructions and people.

NEVER exceed 10 m.p.h. when plowing. Excessive

speed may cause serious injury and damage of

equipment and property if an unseen obstacle is

encountered while plowing.

ALWAYS position blade so it does not block path of

headlamps beam. Do not change blade positions while

traveling. An incorrect plow position blocking headlamp

beam may result in an accident.

ALWAYS check surrounding area for hazardous

obstacles before operating this unit.

ALWAYS inspect the unit periodically for defects. Parts

that are broken, missing or plainly worn must be replaced

immediately. The unit, or any part of it should not be

altered without prior written approval of the manufacturer.

ALWAYS insert the cylinder lock when plow is not in

use. If the cylinder lock is not installed, the plow blade

could inadvertently drop and cause serious injury.

ALWAYS shut off the vehicle engine, place the

transmission in Neutral or Park, turn the ignition switch to

the “OFF” position and firmly apply the parking brake of

the vehicle before attaching or detaching the blade from

the vehicle or when making adjustments to the blade.

ALWAYS inspect lift system bolts and pins whenever

attaching or detaching the plow, and before traveling.

Worn or damaged components could result in the plow

dropping to the pavement while driving, causing an

accident.

ALWAYS keep hands and feet clear of blade and A-

Frame when attaching or detaching plow.

NEVER stand between the vehicle and blade or directly

in front of blade when it is being raised, lowered or

angled. Clearance between vehicle and blade decreases

as blade is operated and serious injury or death can

result from blade striking a body or dropping on hands or

feet.

NEVER work on the vehicle without having a fully

serviced fire extinguisher available. A 5 lb or larger CO2

or dry chemical unit specified for gasoline, chemical or

electrical fires, is recommended.

NEVER smoke while working on the vehicle. Gasoline

and battery acid vapors are extremely flammable and

explosive.

NEVER use your hands to search for hydraulic fluid

leaks; escaping fluid under pressure can be invisible and

can penetrate the skin and cause a serious injury! If any

fluid is injected into the skin, see a doctor at once!

Injected fluid MUST BE surgically removed by a doctor

familiar with this type of injury or gangrene may result.

REMEMBER it is the owner’s responsibility for

communicating information on the safe use and

proper maintenance of this machine.

SAFETY

4

General

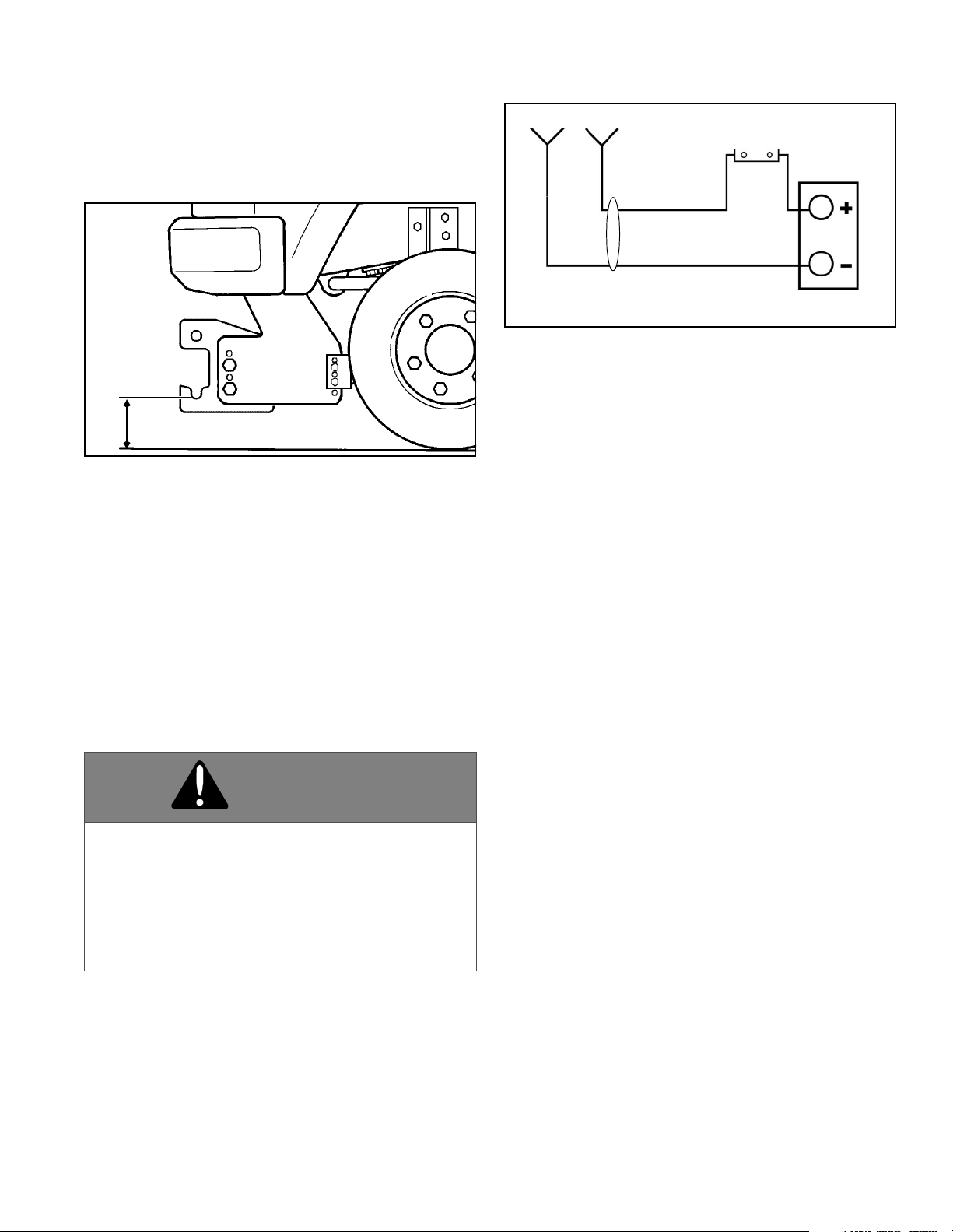

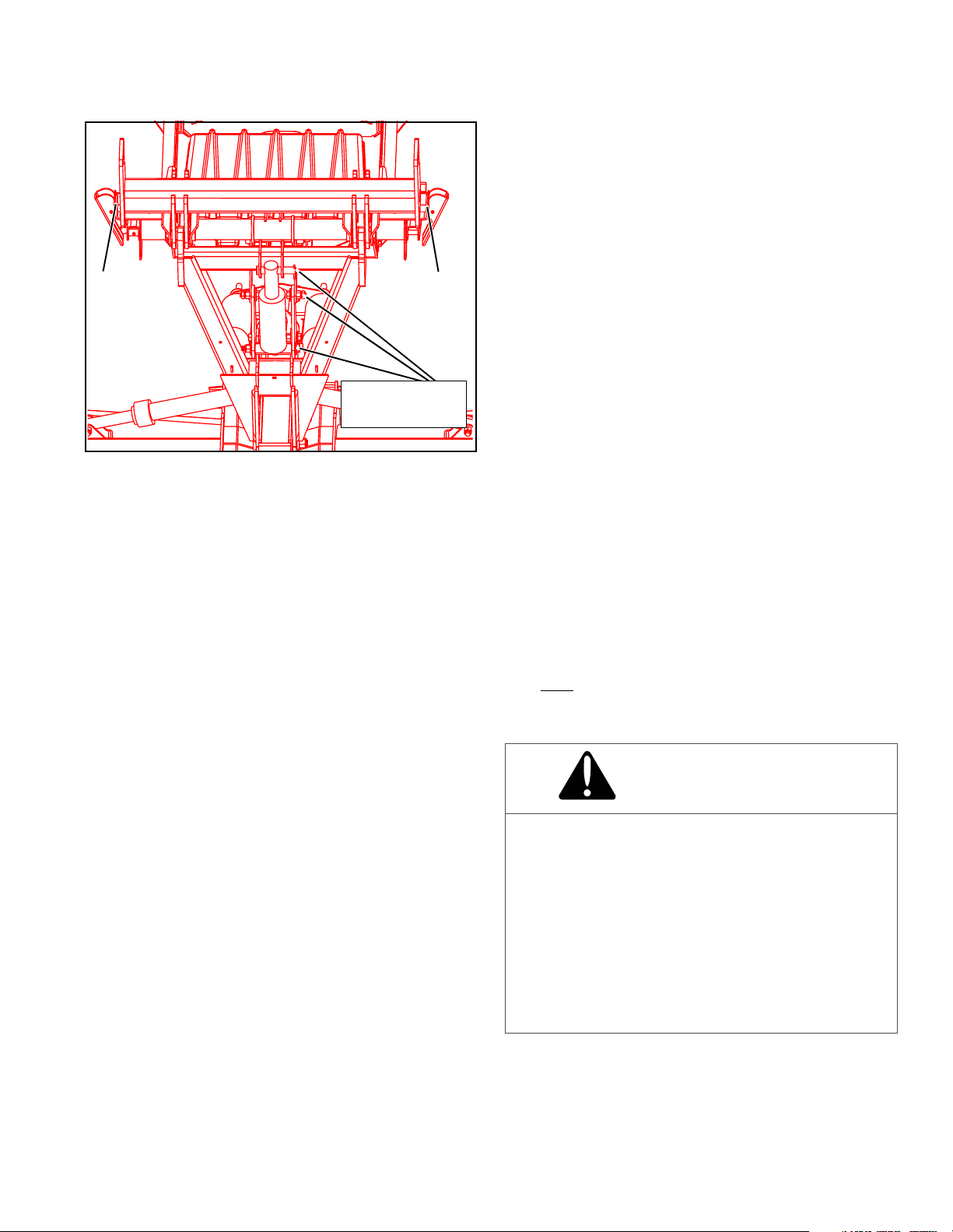

Install the subframe on the vehicle using the instructions

supplied with the subframe package. The pin height

should be 8" - 10" off the ground. (See Figure 1-1.)

Figure 1-1

Electrical Installation

1. Remove the battery power harness and power

harness parts bag from the power pack carton.

NOTE: Take extra time needed to plan the routing of wir-

ing harnesses. Make sure harnesses do not interfere

with, or contact, any moving parts and route wires away

from excessive heat areas. Read all the instructions

carefully to ensure a safe and professional installation.

2. Mount the fuse holder near the battery using (2) #10

x 1" self-tapping screws.

3. Take the cover off of the fuse holder and remove the

nuts on the studs. Place one end of the 2 ft. long power

wire on one stud. (See Figure 1-2.)

Figure 1-2

4. Attach the other end of one 2 ft. long power wire to

the positive terminal on the battery.

5. Attach the power harness red wire to the other

terminal of the fuse holder.

6. Place the fuse between the two studs and replace the

nuts and cover.

7. Route power harness to convenient point on front of

vehicle for connection to plow.

8. Attach the power harness black wire to the NEG. (-)

terminal of the battery and re-connect the negative

battery terminal.

9. Spray all terminal connections with a battery terminal

protective coating.

10. Secure harness with plastic tie straps.

11. Install truck control harness if needed, using

instructions included with controls.

12. Remove the main light harness from the power pack

carton. Route the harness from the headlights to the front

of the truck and through the grille or bumper. The ends

with the green plugs go to the headlights and the ends

with the black plugs go to the front of the truck.

13. Open the adapter harness bag, remove the harness

and plug the proper adapters into the green plugs on the

main harness. Connect the adapters to the truck wiring

following the included instructions.

14. Secure the main harness and adapters. Make sure

that the harnesses are not in contact with moving or hot

engine parts.

15. Plug the male and female black plugs at the front of

the truck together. These must be connected to allow the

truck lights to operate.

WARNING

Disconnect the vehicle NEG. (-) battery cable

while performing steps 2 - 5 to avoid serious

bodily injury from electrical shock, fire, or

explosion. Do not re-connect battery cable until

indicated in step 8.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

8" TO 10" HEIGHT

TRUCK

RED

BLACK

POWER

HARNESS

POWER HARNESS PLUG

BATTERY

FUSE &

FUSE HOLDER

INSTALLATION INSTRUCTIONS

5

16. Apply included dielectric grease to all connectors.

NOTE: An adapter is recommended for vehicles with a

side post battery. (See Figure 1-3.) (Adapters can be pur-

chased from your Sno-Way dealer, Part #96100773.

Figure 1-3

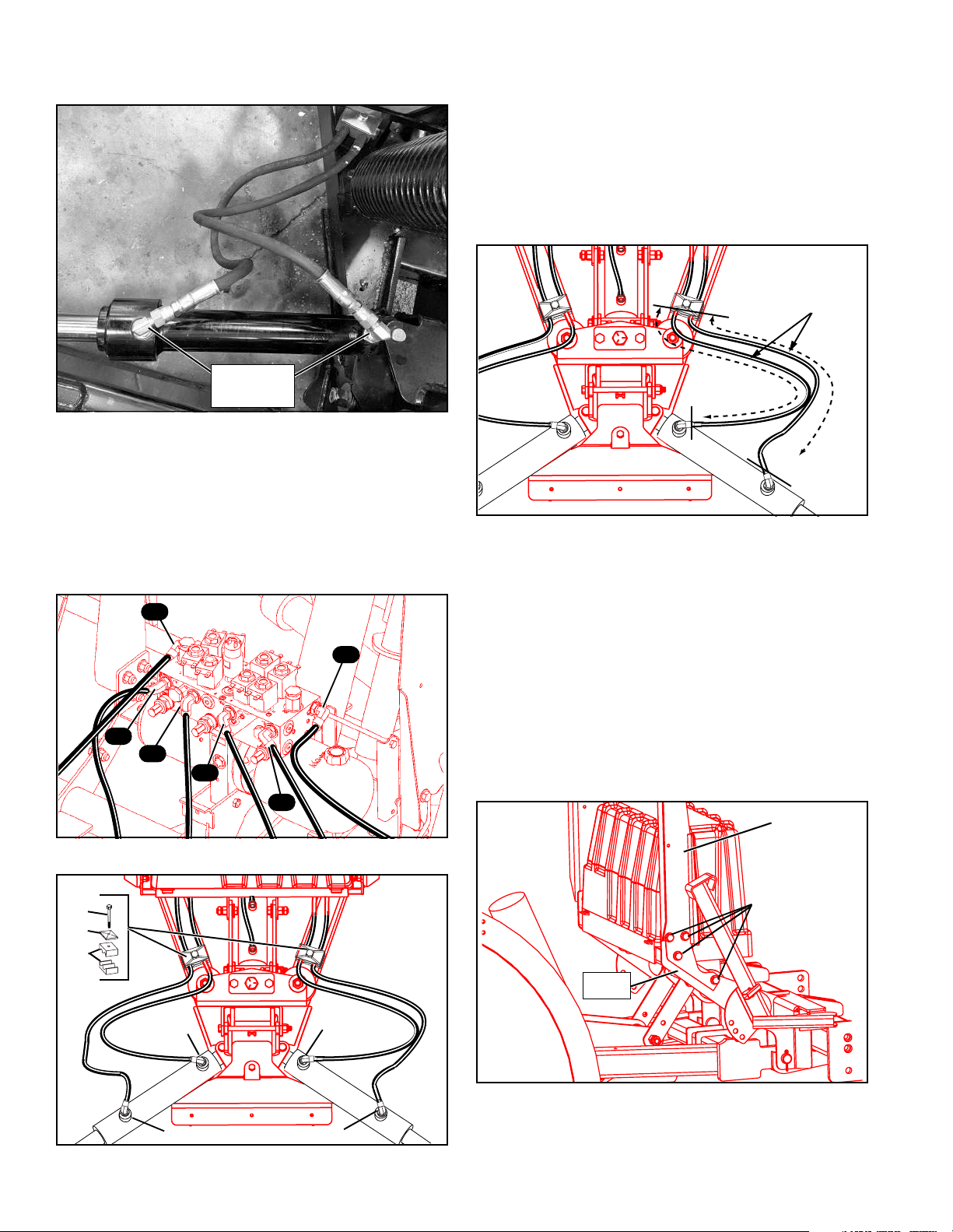

Mechanical Installation

1. Remove the A-frame/tower assembly from the box.

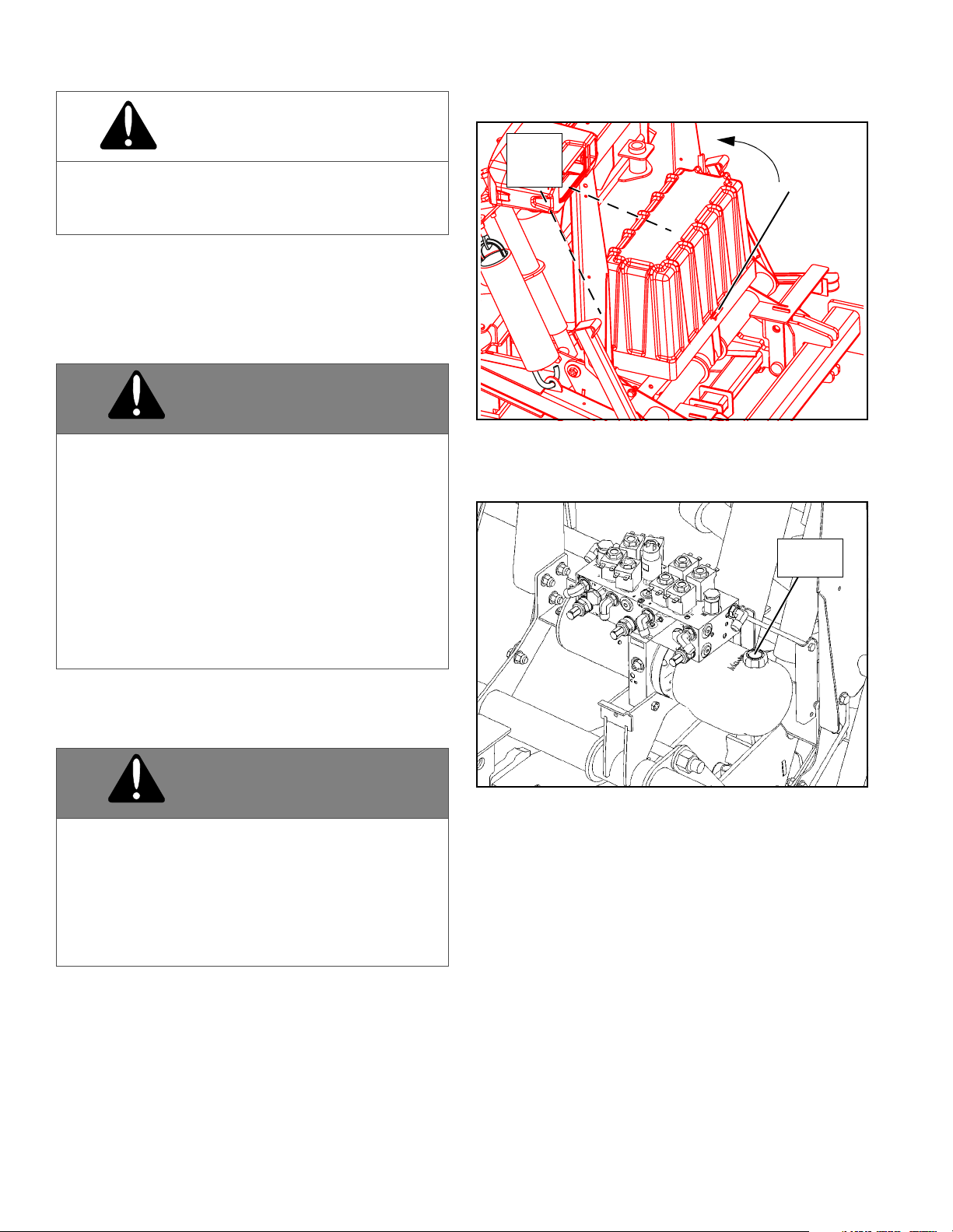

2. Remove pump cover by pulling center rear of cover

off of tab, rotate forward and push off of front two tabs..

Attach lift link to light/lift bar, Install receiver using

instructions included with the controls package. Fill

reservoir on pump with supplied hydraulic fluid until the

oil level reaches the fill line. Do not overfill or oil may leak

from the breather.

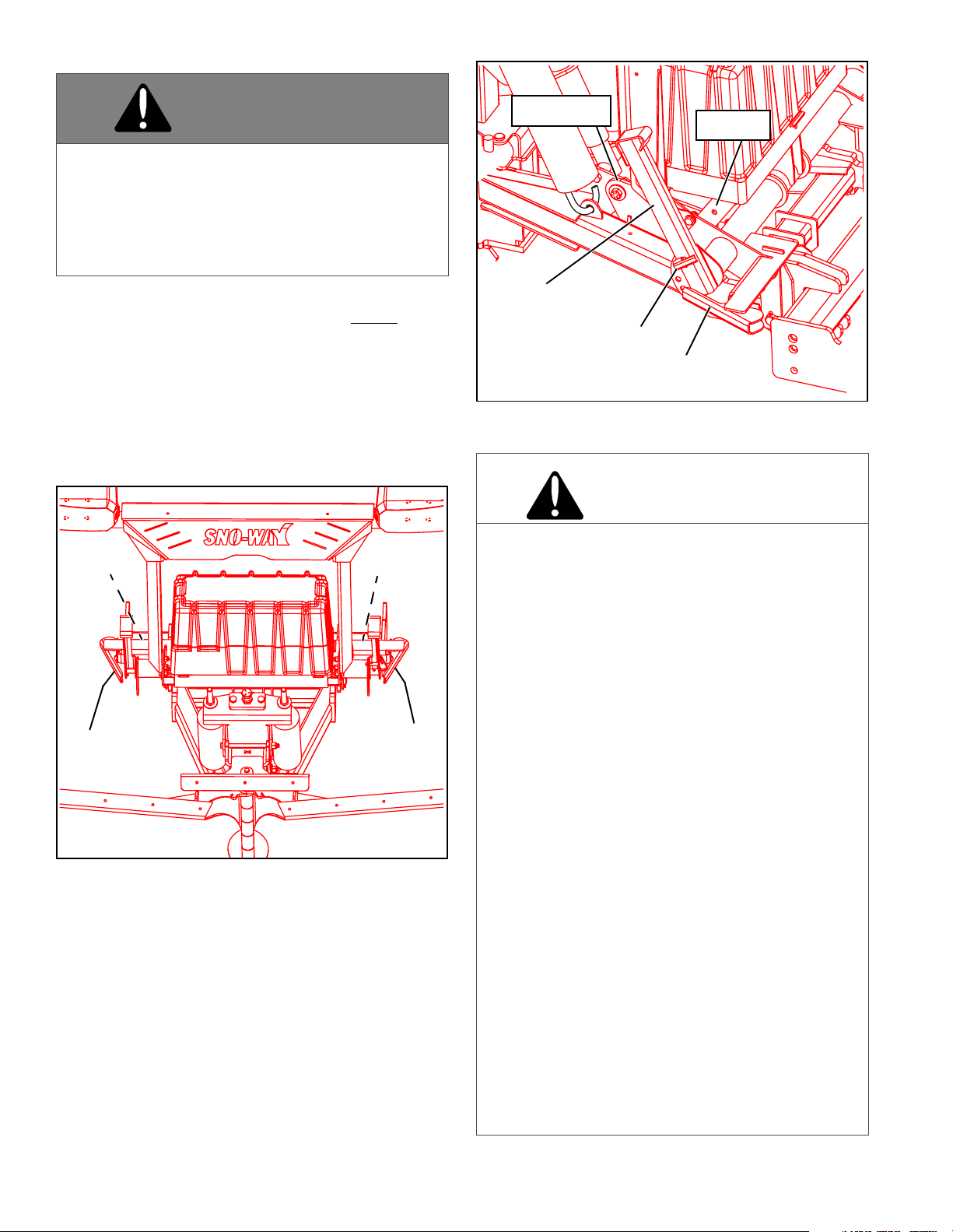

3. Set a-frame/tower assembly lower hitch pins into

slots on truck subframe. (See Figure 1-4.)

Figure 1-4

4. Plug in power and control harness and rotate light/lift

bar into position. Lock in place by rotating cam handles.

Adjust A-frame/tower assembly level using plow control.

5. Once A-frame is level, turn off controller and

disconnect the power. (See "Mounting Snow Plow To

Vehicle" on page 10).

6. Position the drivers side (DS) and passenger side

(PS) wings in front of the A-frame/tower assembly. (See

Figure 1-5.)

Figure 1-5

WARNING

Failure to connect the main light harness on the

truck when plow is not attached will cause truck

lights to not operate, which could cause an

accident.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH.

ADAPTER

2’ RED

BATTERY CABLE

HITCH PINS

SUBFRAME

DS WING

A-FRAME/

TOWER

ASSEMBLY

PS WING

6

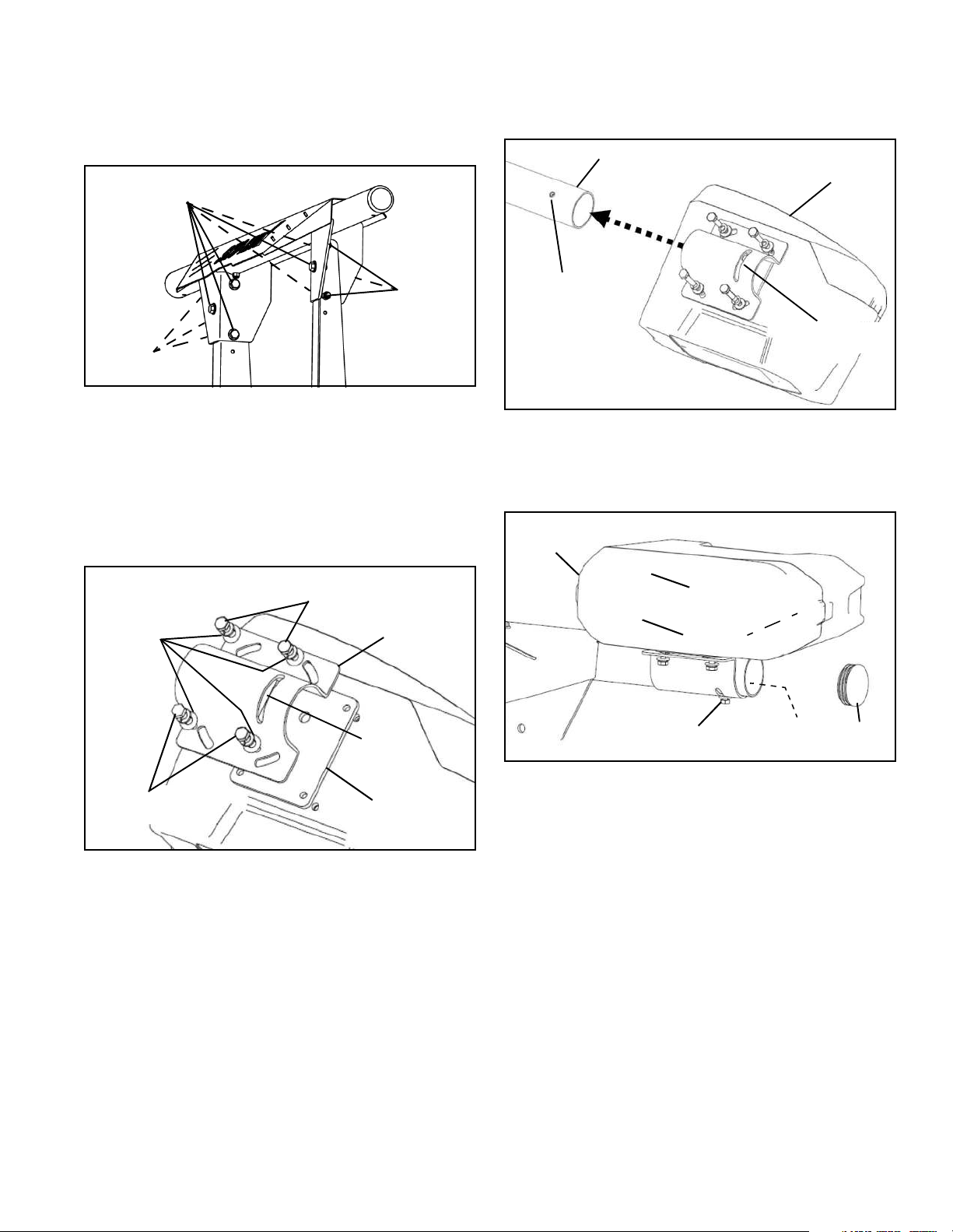

7. Coat main wing pivot pin with grease and insert

through the tower and wings. Leave top of pin

approximately 1" above the tower. (See Figure 1-6.)

Figure 1-6

8. Take deflector and place on tower with the tab on the

wing pivot pin going thru the rectangular hole of the

deflector. Align bolt holes in the wing pivot pin, deflector,

and tower. Push wing pivot pin down to the deflector and

tower. (See Figure 1-7.)

Figure 1-7

9. Secure the wing pivot pin to the tower assembly with

one 3/8" -18 x 1-1/4" cap screw and 3/8"-18

Locknut.(See Figure 1-7.)

10. Attach angle cylinder base to tower with a

5/8" x 2-7/8" clevis pin. Insert cotter pins into clevis pins. .

Attach angle cylinder rod to blade with a 1/2"-13 x 2-1/2"

cap screw and 1/2"-13 locknut. (See Figure 1-8.) Repeat

for opposite angle cylinder.

Figure 1-8

11. Attach a plow marker to each wing as shown and

secure using 5/16" x 1" cap screws and locknuts. (See

Figure 1-9.)

Figure 1-9

DS WING

WING

PIVOT PIN

PS WING

DEFLECTOR

3/8"-18

3/8-18 x 1-1/4"

CAP SCREW

LOCKNUT

1/2"-13

LOCKNUT

CAP SCREW

1/2"-13 X 2-1/2"

CLEVIS PIN

5/8" x 2-7/8"

COTTER PIN

ANGLE

CYLINDER

5/16" x 1"

CAP SCREWS

PLOW

MARKER

7

12. Install 90 deg. elbows into wing cylinder ports.

Orientate as shown in Figure 1-10.

Figure 1-10

13. Loosely connect hydraulic hoses to the wing

cylinders. (See Figure 1-10, Figure 1-11, and Figure 1-

12).

NOTE: C1 through C6 references are hydraulic ports on

the control valve that are marked accordingly. (See Fig-

ure 1-11 and Figure 1-12.)

Figure 1-11-View From Rear of Control Valve

Figure 1-12

14. Loosely position hydraulic hoses in hose clamps (A -

5/16" X 2" self-tapping screw, B - plate, C - clamp blocks)

on each side of the A-frame. (See Figure 1-12.)

15. Adjust each hose length from clamps to hose end

fittings to 26-1/2" and tighten both clamp screws. (See

Figure 1-13.)

NOTE: If installing screw with an impact wrench, ensure

that the wrench in adjusted to its lowest torque setting to

avoid fastener damage.

Figure 1-13

16. Orientate hydraulic hoses as shown in Figure 1-10.

NOTE: Hydraulic hoses must be installed as shown in

Figure 1-10 to avoid interference with the jackstand.

17. Tighten all hydraulic hose fittings securely.

18. Install pump cover by tillting pump cover forward,

sliding pump cover over front two tabs, rotate cover back,

and and pull center rear of cover over rear tab.

19. Remove left and right light support brackets from

power pack carton.

20. Position the DS light support bracket in position

against the lower light lift bar (LLLB). (See Figure 1-14.)

Figure 1-14

21. Install (4) 3/8" x 1.25" cap screws with (8) flat

washers and (4) locknuts from the provided parts into the

light support bracket holes, but do not tighten completely.

90 DEGREE

ELBOWS

C2

C1

C4

C3

C5

C6

A

B

C

C5

C6

C1

C2

26-1/2"

3/8" x 1.25"

CAP SCREWS,

FLAT WASHERS

& LOCKNUTS

DS LIGHT

SUPPORT

LLLB

BRACKET

8

22. Repeat steps 20 & 21 to install the passenger side

(PS) light support bracket to the LLLB.

23. Secure light bar to supports with (6) 3/8" x 1" screws

and (6) lock nuts. Tighten cap screws to 45 lb-ft. (See

Figure 1-15.)

Figure 1-15

24. Align light bar supports to vertical position and tighten

(8) LLLB/light support brackets cap screws to 45 lb-ft.

(See Figure 1-14.)

25. Position a plow light clamp and rubber isolator on the

bottom of each plow light, aligning the corner slots in the

clamp with the four holes in the isolator and light

housings. (See Figure 1-16.)

Figure 1-16

NOTE: The large clamp slot must be facing toward the

turn signal side of each light.

26. Loosely install two 1/4" x 1" screws, with lock and flat

washers, through the front holes (lens side) of the light

clamp and isolator into each plow light housing.

IMPORTANT: If longer screws are installed in the

front holes, the reflective lens of the light will be

broken.

27. Loosely install two 1/4" x 1-1/4" screws, with lock

and flat washers, through the rear holes (back side) of

the light clamp and isolator into the light module housing.

28. Slide the plow lights onto the respective ends of the

light bar bracket, aligning the hole in the bottom of the

bracket with the slot in the plow light clamp. (See Figure

1-17.)

Figure 1-17

29. Install a 1/4" x 7/8" screw with 1/4" washer through

each clamp and light bar and loosely secure with a 1/4"-

20 nut. (See Figure 1-18.)

Figure 1-18

30. Apply dielectric grease to all light harness

connectors. Connect the plow light harness with the

black male connector to the driver side lamp and the

plow light harness with the black female connector to the

passenger side lamp.

31. Check operation of all lamp functions (Low beam

headlamp, high beam headlamp, marker lights and

directional signals).

32. Aim plow lights with plow in the fully raised position.

Lock the lamps in the adjusted position by tightening four

1/4" x 1" and 1/4" x 1-1/4" horizontal adjustment screws

and one 1/4" x 7/8" vertical adjustment screw and 1/4"

nut securely. (See Figure 1-17 and Figure 1-18.)

NOTE: In order to conform to Federal Motor Vehicle

Safety Standards a SAE J602 Approved aiming device

must be used to aim plow lights.

33. Install an end cap in each end of the light bar. (See

Figure 1-18.)

3/8" x 1"

3/8"

CAP SCREWS

LOCKNUTS

3/8"

LOCKNUTS

1/4" x 1-1/4"

SCREWS

PLOW LIGHT

CLAMP

1/4" x 1"

SCREWS

RUBBER

ISOLATOR

1/4" FLAT &

ON FOUR

SCREWS

LOCK WASHERS

LARGE

SLOT

CLAMP

PLOW LIGHT

BOTTOM LIGHT

PLOW LIGHT

ASSEMBLY

LIGHT BAR

BAR BRACKET

HOLE

CLAMP SLOT

DS PLOW

END

CAP

LIGHT SHOWN

1/4"-20

NUT

WITH 1/4" WASHER

1/4" x 7/8" SCREW

9

Blade Level Adjustment

The Sno-Way 26V has a Max AdjustTM feature that is set

when the plow is first installed and when initially run each

plowing season. The adjustment mechanism is designed

to make the plow wearstrip scrape evenly on flat surfaces

without leaving a trail of snow near the center or the edge

of the plow. Change in adjustment may be needed due

to wear conditions and when the plow is switched

between vehicles. Adjustments can be performed with a

few turns of a wrench.

Adjustment Procedure

1. Move vehicle to a level flat surface, such as a large

parking lot, or a garage floor.

IMPORTANT: If plow leveling procedure is being

performed on uneven pavement, the plow will be

difficult to level correctly. Also include all ballast

weight with the truck while adjusting the plow. Any

additional weight added to the truck after the plow is

adjusted may require the Max AdjustTM system to be

adjusted again.

2. Loosen jam nut on the tilt adjustment cap screw

located in the center section of the plow trip mechanism.

(See Figure 1-19.)

Figure 1-19

3. Swing wings to the straight position and lower plow to

the ground.

4. Turn Down Pressure ON.

5. Swing wings forward to the scoop position, with blade

on ground

6. If the center wear-strip begins to rise off of the floor,

stop moving the wings forward and turn the tilt

adjustment cap screw out. This will cause the tower to tilt

back and towards the truck.

7. Continue to move the wings forward (scoop position)

until they are free to move forward and backwards to the

straight position.

8. If the center wear-strip begins to rise off of the floor

when the wings are brought back to the V-Position, turn

the tilt adjustment cap screw in, causing the tower to tilt

forward.

9. Once proper adjustment has been attained, tighten

the jam nut on the tilt adjustment cap screw.

IMPORTANT: Adjusting in Down-Pressure is

different than adjusting in Float. If the plow is leveled

while in Down-Pressure (which is what is explained

in the manual here) the wings will tend to be "off the

ground" in scoop, when the Down-Pressure is turned

Off. Be aware of which level you are plowing the

most in, Down-Pressure-Level, or Float-Level.

NOTE: If you set the Plow-Level when in float, the outer

wing edge of the wear strip will wear first when down

pressure is turned on.

PLOW

MARKER

TILT ADJUSTMENT

CAP SCREW

JAM NUT

10

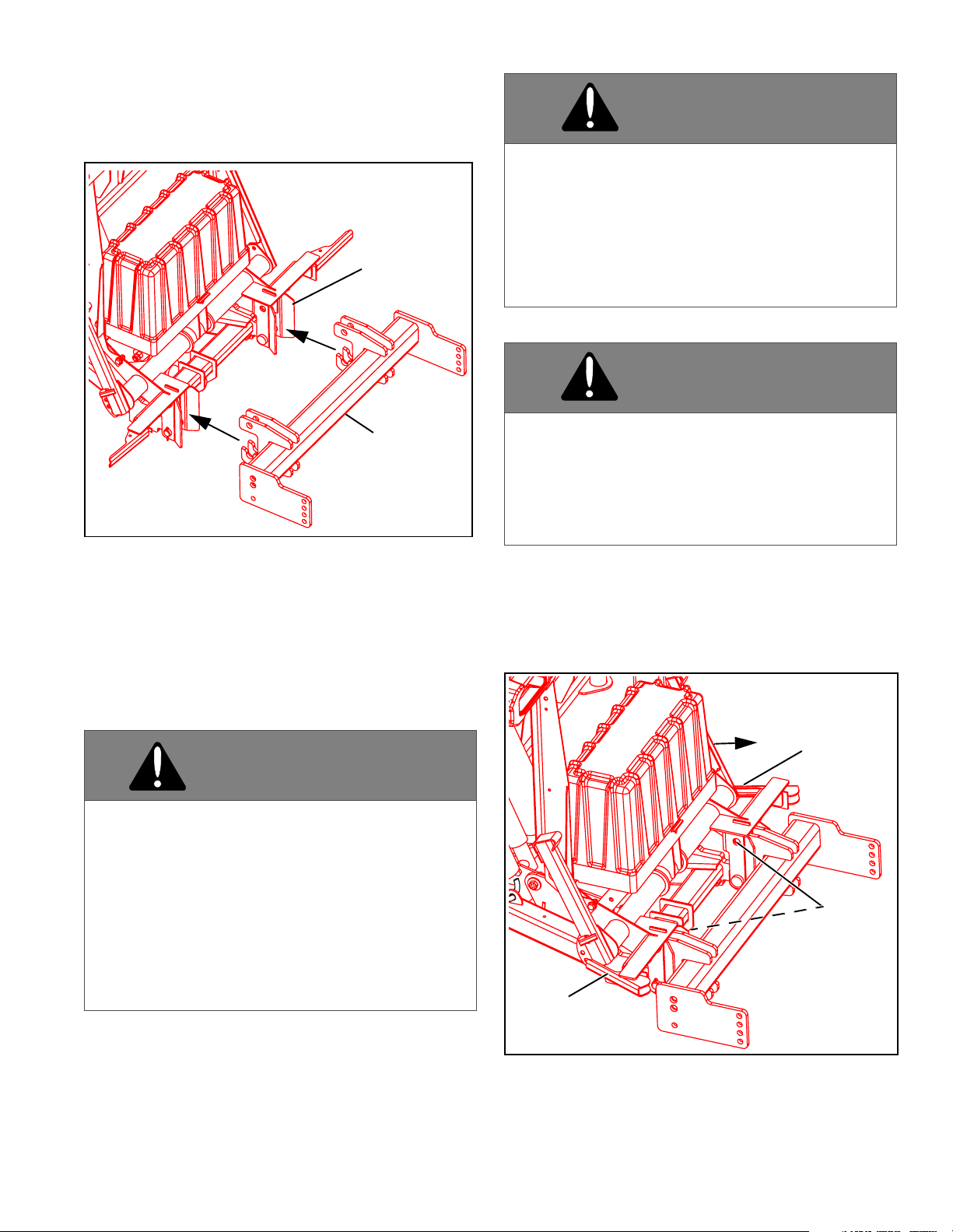

Mounting Snow Plow To Vehicle

1. Drive truck into plow, aligning light/lift bar frame with

subframe lugs. Pins should fit inside slots cut into

subframe lugs. (See Figure 1-20.)

Figure 1-20

NOTE: If pins are too high or low to fit into slots on sub-

frame, adjust the plow height after power is connected in

the next step. Plug hand held controller into the plow con-

trol harness if controller is wired. To lower the pins, turn

on down pressure and press down. To raise the pins,

press up.

2. Connect the plow and truck power harness

connectors together.

3. Remove controller from truck cab (and plug into plow

control harness if control is wired).

4. Rotate light/lift bar into position by turning on down

pressure and pressing the lower button. (See Figure 1-

21.)

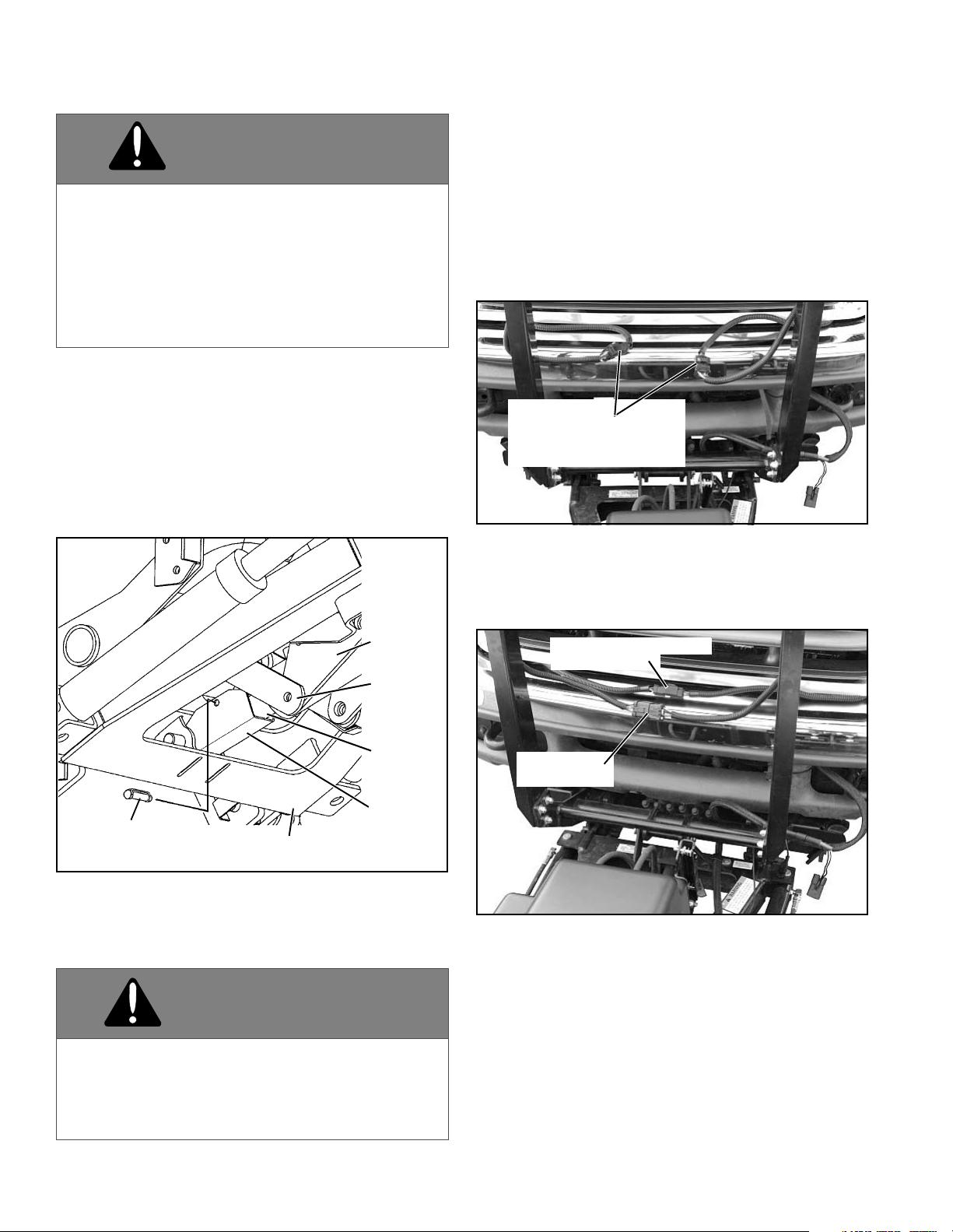

Figure 1-21

5. Rotate mount handles in to lock pins in place. Put

plow into float position by turning down pressure off. (See

Figure 1-21 and Figure 1-22).

WARNING

The power cable in front of the truck is wired

directly to the battery. The power cable is

always energized, even if the truck is turned off.

Always replace the protective cap after

disconnecting the plow power cable. Allowing

an unprotected plug to contact metal parts of

the truck may cause electrical component

damage. Never use a metal object to clean the

plug contacts.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

LIGHT / LIFT

BAR FRAME

SUBFRAME

ON TRUCK

MOUNTED

WARNING

When using the hand held controller to raise or

lower the plow A-frame for mounting the plow

to the vehicle, be especially careful of the

movement of the light bar. This movement will

occur when raising or lowering the A-frame or

jack stand.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

WARNING

Pressing the blade angle functions will result in

the A-frame swinging if it is not secured to the

truck. Do not press the angle function during

plow installation.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

ROTATE

LIGHT/LIFT

BAR

UPPER

INTO SLOT

WILL DROP

HITCH PINS

MOUNT

HANDLE

MOUNT

HANDLE

11

NOTE: Upper hitch pins are fully engaged when mount

handle is tight against pin bracket and you cannot see

the upper hitch pin between the pin bracket and mount

handle.

If upper hitch pins are not fully engaged:

A. Raise plow an inch off the ground, then lower. Or,

B. Turn Down Pressure ON and then OFF.

Upper hitch pins will snap into place. (See Figure 1-21

and Figure 1-22).

Figure 1-22

6. Unplug wired control from plow.

7. Disengage jack stand pin by pulling on pin handle.

Rotate the jack stand to the raised position. Engage the

pin by pushing on the handle. Make sure pin is engaged

in hole by rotating jack stand back and forth. (See Figure

1-23.)

Figure 1-23

WARNING

Make sure that upper hitch pins are engaged

before moving truck. Hitch pins not fully

engaged could result in the plow separating

from the truck.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

UPPER

HITCH PIN

UPPER

HITCH PIN

MOUNT

HANDLE

IN

MOUNT

HANDLE

IN

CAUTION

Many new vehicles are equipped with onboard

circuit sensors designed to display a

dashboard LED when a headlight fails.

Generally, these sensors are activated or

tripped any time the circuit is being called upon

to function while the headlight circuit is

incomplete. This means that if a headlight fails

while the headlight is in operation, the sensor

will trip and the dashboard indicator will light

up. It also means that if a headlamp socket is

left empty—or a faulty lamp is installed—and

the circuit is then activated, the sensor will trip

and the dashboard indicator will light up.

These headlight circuit sensors are often

engineered with pre-designated failure limits.

This means that a sensor may be tripped a

limited number of times. After that limit is

reached the sensor may need to be reset by the

dealer or replaced by the manufacturer.

Sno-Way EIS plow light systems essentially

operate through a planned interruption of the

headlight circuit. When the truck-side

connectors are detached from one another, the

vehicle headlamps are disconnected from the

truck circuits which otherwise power them.

Until those truck-side connectors are attached

to the plow-side light connectors, the truck-

side circuits are open. This means that if the

truck’s onboard sensors are active while the

plow lights are being attached to the truck, the

truck’s sensors may trip.

MOUNT

JACK

PIN

HANDLE

STAND

BELL CRANK

LIFT LINK

HANDLE

12

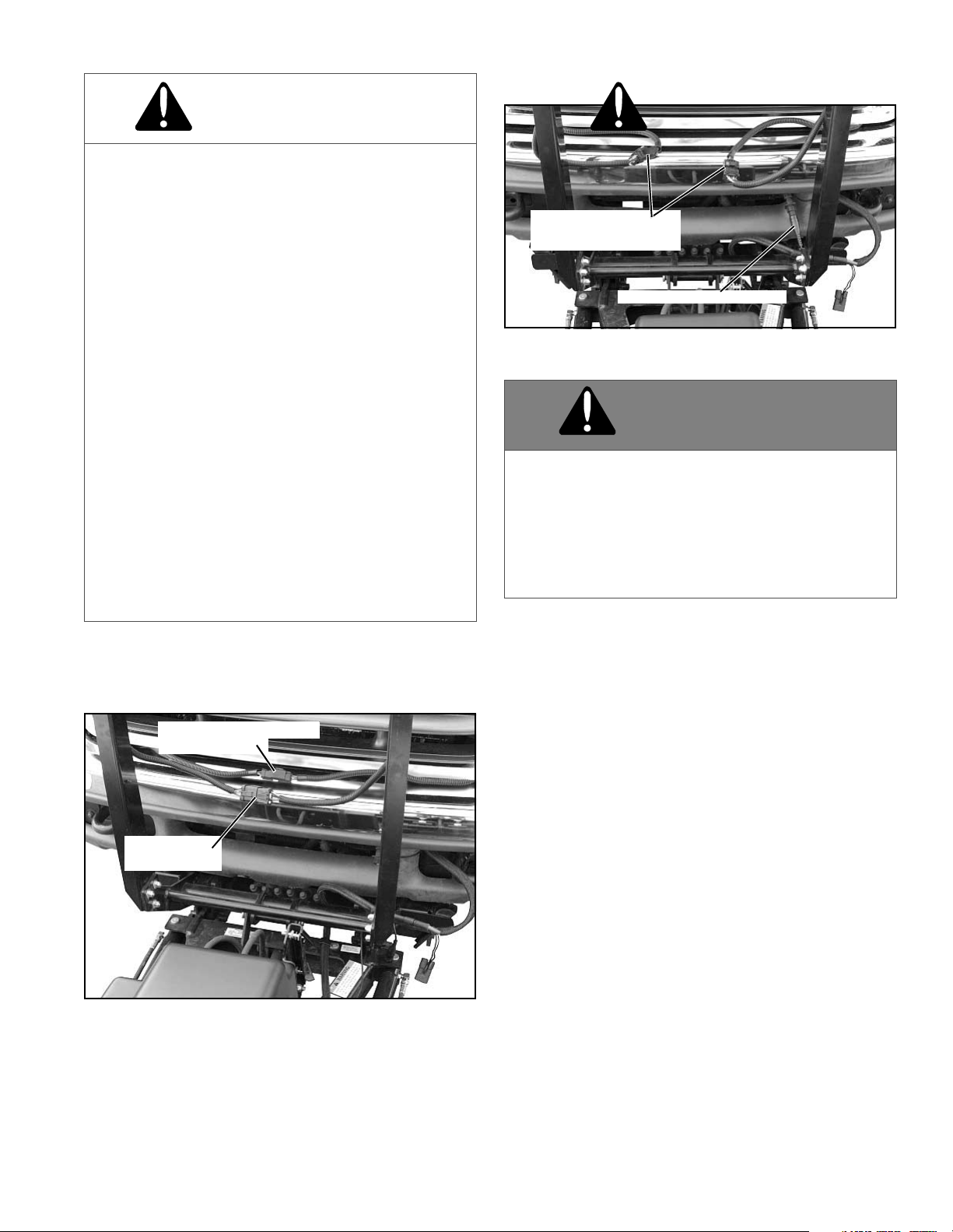

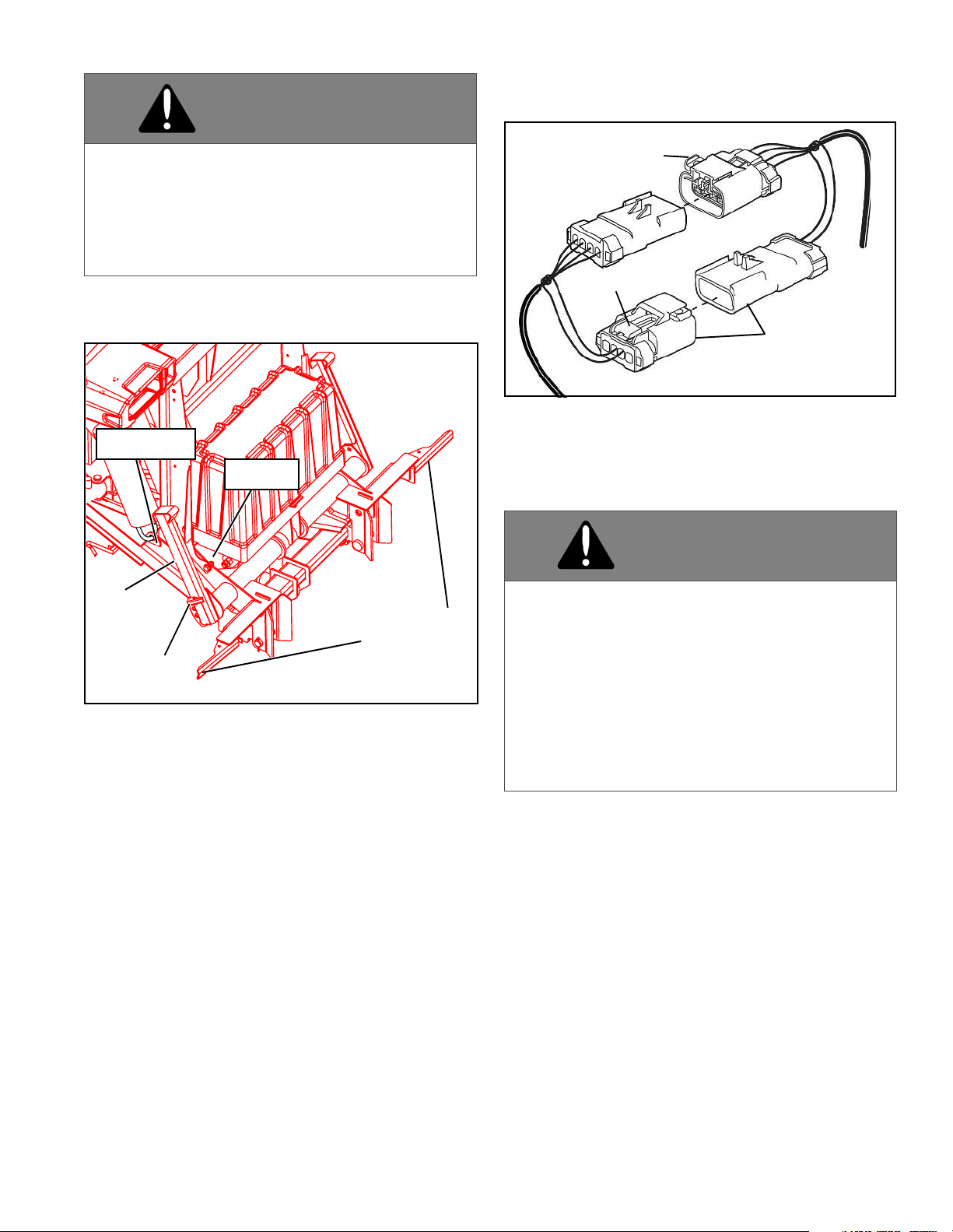

8. Unplug light harness connectors on truck, and light

connectors on plow, which had been plugged together for

corrosion protection during storage. (See Figure 1-24.)

Figure 1-24

9. Plug plow light connectors into mating connectors on

truck light harness. (See Figure 1-25.)

Figure 1-25

10. If control is wired, plug control inside truck cab and

control harness on plow into truck.

11. Raise, lower and angle plow to make sure no hoses

or wires pinch in the plow mechanism.

CAUTION

To avoid unnecessarily tripping the truck’s

sensor, every time the plow lights are being

attached to the truck circuits or the truck

circuits are being reattached to the vehicle

lights, the truck’s lights should be turned off.

Due to the aforementioned concerns, operators

of vehicles equipped with EIS lights should

make themselves aware of whatever circuit

sensors may be installed on their vehicles.

Operators should further become familiar with

their vehicle manufacturer’s description of how

their truck’s sensors are actuated or tripped.

Finally operators should know whether

predesignated failure limits may be engineered

into their truck’s sensors and what repair or

replacement procedures are recommended

should those limits be reached. Currently, the

vehicle models affected are as follows:

2006 and later-Dodge Dakota and Durango - All

packages.

2006 and later-Dodge 1500, 2500 and 3500- All

packages.

2008 Ford F250-F550 - All packages.

PLOW LIGHT

CONNECTORS

TRUCK LIGHT HARNESS

CONNECTORS

WARNING

Failure to properly connect plow lights to

vehicle light harness will prevent plow lights

from functioning. Follow proper procedure to

connect light harnesses and test lights before

operating.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

PLOW CONTROL HARNESS

PLOW LIGHTS

CONNECTED TO TRUCK

LIGHT HARNESS

13

Installing The Cylinder Lock Clamp

1. Raise the plow to the full UP position.

2. Turn the ignition OFF and apply the parking brake.

3. Turn OFF the hand-held controller.

4. Remove the pin from the cylinder lock clamp.

5. Position the cylinder lock clamp around the exposed

(chrome) portion of the lift cylinder with the open side of

the cylinder lock up. Install the pin. (See Figure 1-26.)

Figure 1-26

6. Lower the plow so that cylinder lock clamp is tight

against cylinder.

Removing Snow Plow From Vehicle

Choose a location for the plow storage, which will allow

the plow to be removed from the vehicle and not be

moved after removal. Also, choose a location that will not

allow the plow stand to sink into the ground. A dry,

protected area is recommended.

1. Lower plow to the ground, put vehicle in park, turn off

the engine and set the parking brake.

2. Disconnect the plow light connectors from the truck

harness connectors. (See Figure 1-27.)

Figure 1-27

3. To prevent corrosion on the contacts, plug the male

and female connectors on the plow light harness

together. (See Figure 1-28.)

Figure 1-28

4. To make the truck lights operable, plug the male and

female connectors on the truck light harness together.

(See Figure 1-28.)

WARNING

Always install the cylinder lock clamp when the

plow blade is raised and the operator is not

engaged in plowing operations. Equipment

failure or inadvertent operation of the plow

control while driving could allow the plow blade

to fall, resulting in injury.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

WARNING

Failure to lower plow onto clamp could block

headlights resulting in an accident.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

WIRE LOCK PIN

LIFT

LINK

A-FRAME BOTTOM

BELL

CRANK

CYLINDER

LOCK

CLAMP

CYLINDER

ROD

CONNECTORS FROM

DISCONNECT PLOW LIGHT

TRUCK LIGHT HARNESS

PLOW LIGHT

CONNECTORS

TRUCK LIGHT HARNESS

CONNECTORS

14

5. Disengage jack stand pin by pulling on the pin

handle. (See Figure 1-29.)

Figure 1-29

6. Rotate the jack stand into the lowered position.

Engage the pin handle by pushing on the handle. Make

sure pin is engaged in hole by rotating jack stand back

and forth. (See Figure 1-29.)

7. Remove controller from truck cab (and plug into plow

control harness if control is wired).

8. Turn Down Pressure ON and then OFF.

9. Rotate mount handles out to unlock main pins. (See

Figure 1-29.)

10. Raise A-frame by pressing the controller UP button.

11. Disconnect the plow control harness connectors and

replace the protective storage caps to prevent corrosion

on the contacts. (See Figure 1-30.)

Figure 1-30

12. Disconnect the plow power harness connectors and

replace the protective storage caps to prevent corrosion

on the contacts.

13. Back truck away from plow.

WARNING

Failure to reconnect the main light harness on

the truck when removing plow will cause truck

lights to not operate, which could cause an

accident. Test lights before operating.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

MOUNT HANDLE

STRAIGHT OUT

JACK

STAND

PIN

HANDLE

BELL CRANK

LIFT LINK

WARNING

The power cable in front of the truck is wired

directly to the battery. The power cable is

always energized, even if the truck is turned off.

Always replace the protective cap after

disconnecting the plow power cable. Allowing

an unprotected plug to contact metal parts of

the truck may cause electrical component

damage. Never use a metal object to clean the

plug contacts.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH

LOCKING TAB

SECONDARY LOCK

STORAGE

CAPS

15

General

• Before operating, perform a thorough visual

inspection of the equipment. Look for fluid leaks,

cracked, bent or broken components, loose nuts,

bolts or attachments and proper fluid levels.

• A clean hydraulic system is essential to long pump

life and proper performance.

• When adding oil to the reservoir, wipe the area

around the filler port clean before removing the

breather cap. Use clean oil and a clean funnel, (DO

NOT use a cloth or rag to strain the oil).

IMPORTANT: Sno-Way supplies type 5606 Sno-Way

Hydraulic Oil with the unit from the factory. If

additional oil is added it must be compatible with

Sno-Way oil. If another type of oil has been used in

the system the same type of oil must be used for

topping off system. Improper hydraulic fluid can

cause operating problems in cold weather.

• Do NOT use synthetic oil.

• Oil must contain an anti-foam additive.

• The operational environment for snow plows is an

extremely harsh and corrosive one.

• Ensure all electrical connections are clean and

tight.

• To prevent rust from forming, clean and repaint

exposed metal surfaces.

• NEVER operate the equipment with the protective

covers or guards removed.

Periodic Inspection

After approximately every 20 hours of operation perform

the following inspections procedures:

1. Inspect the plow assembly including the sub-frame

assembly for any damage or excessive wear. Replace

parts as necessary.

2. Inspect all fasteners (Plow & Truck Mount) to ensure

they are properly tightened. Re-tighten loose fasteners to

the proper torque. Loose fasteners on the Bellcrank,

Power Unit to the Pump Platform and Truck Mount must

have the nylock nuts replaced and tightened while using

Sno-Way thread locker 96115529. (Refer to torque

specification chart in this manual).

3. Apply oil or grease to the wing pivot pin between the

hinge tubes and plates. (See Figure 1-31.)

Figure 1-31

4. Apply a small amount of light oil to the wing cylinder

pivot pins and to pivot pins between the blade assembly,

A-Frame, and spring brackets. (See Figure 1-32.)

Figure 1-32

WARNING

Before servicing plow, lower plow to ground

and disconnect main power harness.

FAILURE TO HEED CAN RESULT IN INJURY

OR DEATH.

WING PIVOT

LUBRICATION

POINTS

PIVOT

PINS

DS WING

PIVOTS

CYLINDER

PS WING

PIVOTS

CYLINDER

PIVOT

PIN

MAINTENANCE

16

5. Apply a small amount of light oil to the lift cylinder

assembly pivot pins and both attach lock pins. (See

Figure 1-33 - View From Bottom.)

Figure 1-33 - View From Bottom

Special Fasteners Torques and Require-

ments

IMPORTANT: Incorrectly securing fasteners may

result in incorrect operation, excessive wear, and

early failure of plow components. It may also void

your warranty.

• ALWAYS check to make sure you are using the

correct torque specification for the fastener you are

using.

• DO NOT use any lubricants on the threads of any

fastener unless specifically called for in the

assembly or maintenance story for that component.

• NEVER use liquid locking materials, such as

Locktite™ or Threadmaker™, on any fasteners

unless specifically called for in an assembly or

maintenance story for that component.

Standard Fasteners:

The Torque Specifications Chart on page 34 of this

manual should be used as the guide for fastener torque

requirements for most standard fasteners used on the

plow.

Standard fasteners with special torque requirements will

be noted in assembly or service stories pertaining to the

specific piece of equipment.

Hydraulic Fittings

Hydraulic fittings with lock nuts should be assembled with

at least three full turns of the fitting in the port and then the

lock nut should be tightened to 27 lb-ft.

Hydraulic fittings with 37 degree flare end swivels should

be torqued to 18-20 lb-ft.

Hydraulic Cylinders

To avoid corrosion during storage, coat the exposed

(chrome) portion of the lift and angle cylinders with a light

grease.

Electrical Quick Disconnect Plugs

This plow is equipped with the EIS® (Energy Interruption

SystemTM). Any time the plow is removed from the

vehicle, plug the electrical lighting quick disconnect ends

together to prevent corrosion from forming on terminal

ends.

Fluid Requirements

IMPORTANT: Sno-Way supplies type 5606 Sno-Way

Hydraulic Oil with the unit from the factory. If

additional oil is added it must be compatible with

Sno-Way oil.

It is recommended that the fluid in the hydraulic system be

changed once a season.

Do NOT use synthetic oil.

Oil must contain an anti-foam additive.

•

ATTACH

LOCK PIN

ATTACH

LOCK PIN

LIFT CYLINDER

ASSEMBLY PIVOT

PINS

CAUTION

• Using the proper oil increases the life

expectancy of the most critical part of your

plow; the Hydraulic power unit.

• Failure to use the proper oil can cause

extensive damage to the power unit, seals and

hydraulic rams.

• Improper oil can cause operating problems and

poor performance in cold weather.

17

Changing Oil and Cleaning Filter Screen

NOTE: Oil should be changed at the beginning of every

season. We recommend cleaning the filter screen at

every oil change, this will help ensure maximum life and

maximum performance from the pump assembly.

1. Lower plow assembly to ground, put vehicle in park

and turn off engine. Turn hand-held controller off.

2. To prevent inadvertent short circuit or electrical

shock, disconnect the power harness and control

harness at the vehicle bumper.

3. Remove pump cover by pulling center rear of cover

off of tab, rotate forward and push off of front two tabs..

(See Figure 1-34.)

Figure 1-34

4. Remove the filler/breather cap from the reservoir.

(See Figure 1-35.)

Figure 1-35

5. Using an oil suction gun or similar tool, remove the oil

from the oil reservoir.

NOTE: Be careful to avoid contacting and damaging the

filter screen while removing the oil.

6. Remove the lift cylinder hose(s) from the valve block.

Remove the wing cylinder hoses from the fitting in the

valve block. Mark hoses before removal to be certain

they are reinstalled in the correct location.

7. Place the hoses in a container to catch oil expelled

from cylinders. Cycle the lift cylinder by disconnecting

hitch pins and pushing and pulling on light bar. Cycle

wing cylinders by disconnecting from wing and pushing

and pulling on cylinder rod.

CAUTION

Using the proper oil increases the life

expectancy of the most critical part of your

unit; the Hydraulic power unit.

WARNING

• Allow the system to cool down before draining

oil or handling system components. Serious

burns can result from contact with hot oil.

• Never disconnect any hydraulic line or fitting

with the unit in the raised position. Always

lower the unit and relieve pressure before

removing any lines or caps.

FAILURE TO HEED CAN RESULT IN INJURY

OR DEATH.

WARNING

Ensure engine is OFF and set parking brake

before working on plow. Vehicle movement,

equipment failure or inadvertent operation of

the control switches during maintenance could

result in serious injury

FAILURE TO HEED CAN RESULT IN INJURY

OR DEATH.

REAR

TAB

TWO

FRONT

TABS

FILLER

CAP

18

8. Loosen the clamp securing the oil reservoir to the

pump assembly and remove the oil reservoir being

careful not to damage the filter screen while removing the

oil reservoir. (See Figure 1-36.)

Figure 1-36

9. Pull the filter screens off the return and suction tubes

(hold it by the metal cover, not by the screen) and clean

with a suitable solvent. Blow dry with low pressure

compressed air from the inside.

10. Carefully reinstall the filter screens.

11. Visually check that the pickup tube and filter face

down. (See Figure 1-36.) If not, rotate the pickup tube

until the tube and filter face down.

12. Clean the oil reservoir inside and out with a suitable

solvent.

13. Inspect the O-ring seal for damage, replace if

needed, lubricate with fresh oil and reinstall reservoir

carefully to avoid damaging the O-ring.

14. Reconnect hydraulic fittings and hoses in their

correct position and torque to 20-25 lb-ft. If unit utilizes O-

ring and jam nut type connectors tighten jam nut to 15-20

lb-ft.

15. Fill the hydraulic oil reservoir until the fluid level

registers full on oil level mark on oil reservoir.

NOTE: Vehicle must be parked on level ground, Plow

must be in the lowered position, and Wings must be

folded rearward ("V") in order to properly check the oil

level. Checking oil level with plow elevated or with wings

straight or folded forward will give wrong reading.

16. Refer to plow operation instructions and operate the

plow to purge all air from the hydraulic system.

17. Replenish the fluid in the reservoir until the fluid level

registers full on oil level mark on oil reservoir.

18. Operate system and check for leaks, repair or tighten

as necessary.

19. Install the pump cover.

Cutting Edge Replacement

NOTE: Cutting edge must be replaced when it is worn to

the bottom edge of the frame.

1. Raise plow to full up position.

2. Place a jack stand under both ends of the blade

bottom rail.

With the Down PressureTM Hydraulic System OFF, lower

plow until firmly resting on jack stands

3. With an assistant, remove hardware and worn

wearstrip from plow.

4. Insert one carriage bolt through cutting edge and

blade on either end of the plow and loosely install one

lock nut.

5. Insert one carriage bolt through the opposite end of

the cutting edge and blade on the opposite end of the

plow and loosely install one lock nut.

6. Insert the remaining carriage bolts and loosely install

lock nuts on each.

7. Beginning on either side, tighten all nuts securely.

CAUTION

Do Not use Teflon® tape or pipe compound on

hydraulic fittings. These can dislodge and jam

valves in the hydraulic system.

RETURN TUBE

PICK-UP TUBE

FILTER SCREENS WARNING

The bottom of the cutting edge can be very

sharp. Whenever handling a cutting edge, work

with an assistant and wear suitable protective

gloves to avoid serious injury.

FAILURE TO HEED CAN RESULT IN INJURY

OR DEATH.

19

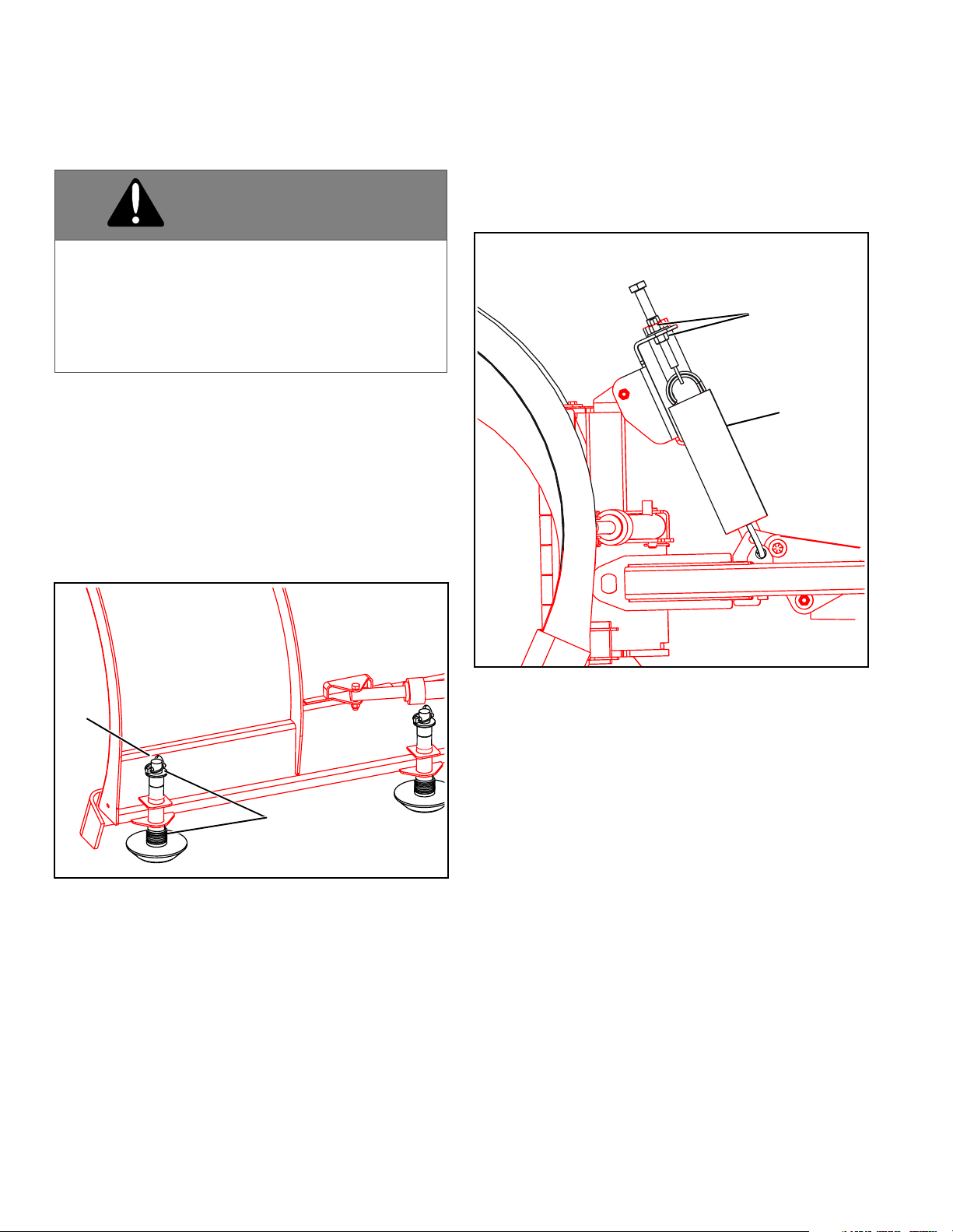

Plow Shoe Adjustment

This plow is equipped with the ability to utilize four (4) plow

shoes. Two plow shoes are located at the outboard end of

each wing, and two plow shoes are located on the inboard

section of each wing, close to the center tower.

Adjust the plow shoes as follows:

1. Raise plow to full up position.

2. Support blade with a jack.

3. Turn vehicle ignition switch and plow control OFF and

apply emergency brake.

4. Adjust shoe assemblies by removing shoe mounting

lynch pin and adding or subtracting washers on the top or

bottom of the shoe-mounting bracket. (See Figure 1-37.)

Figure 1-37

5. After the disk shoe position is properly adjusted place

remaining washer on the shoe stem - above the disk

shoe mounting bracket and below the retaining lynch pin

- to remove all up and down movement of the disk shoe

in the bracket. Failure to do so will result in excessive

wear of the holes in mounting bracket or bending of the

disk shoe stem.

IMPORTANT: Snap lynch pin ring over so that it

contacts the pin. If ring does not contact lynch pin,

rotate the pin and reverse the direction of the ring. If

the ring does not contact the pin it is not locked and

could fall out.

Trip Spring Adjustment

Check the plow shoe adjustment as follows:

1. Level the tower and wings. (See "Blade Level

Adjustment" on page 9).

2. Check gap on springs with a feeler gauge. The gap

between two or more coils should be .015" (A 3x5

postcard is approximately .015" thick). (See Figure 1-38.)

Figure 1-38

If the gap needs adjustment:

a. Loosen the bottom nut on the spring eye bolt(s).

b. Tighten or loosen the top nut until the correct

tension is reached, by measuring with a feeler

gauge.

c. Tighten the bottom nut(s) on all spring eye bolts.

WARNING

Keep hands and feet clear of wings and center

section when setting blocking and lowering

plow. Moving or falling assemblies could result

in serious injury.

FAILURE TO HEED CAN RESULT IN INJURY

OR DEATH.

PIN

WASHERS

0.015" GAP

MAXIMUM

ADJUSTMENT

NUTS

Table of contents

Other Sno-Way Snow Blower manuals