Sno-Way SWS 30 Operating instructions

97101997A

INSTALLATION &

OWNERS MANUAL

SWS 30

ON/OFF CONTROL

99101253

©2016 Sno-Way®International

1

TABLE OF CONTENTS

Page

INTRODUCTION ......................................................................................................... 2

SAFETY ...................................................................................................................... 3

INSTALLATION ........................................................................................................... 4

Introduction ....................................................................................................... 4

Tool List ............................................................................................................. 4

Installation ......................................................................................................... 4

OPERATION................................................................................................................ 6

Theory of Operation ......................................................................................... 6

On/Off Motor Controller Operation.................................................................. 6

Wiring Harnesses ............................................................................................. 6

2

This manual was written for the assembly, installation and

maintenance of your new SNO-WAY®SWS 30.

Most importantly, this manual provides an operating plan

for safe use. Refer to the Table of Contents for an outline

of this manual.

Please keep this manual with your machine at all times as

reference material and so it can be passed on to the next

owner if the machine is sold.

We require that you read and understand the contents of

this manual COMPLETELY, especially the chapter on

SAFETY, before attempting any procedure contained in

this manual.

The Society of Automotive Engineers has adopted

this SAFETY ALERT SYMBOL to pinpoint character-

istics that, if NOT carefully followed, can create a

safety hazard. When you see this symbol in this man-

ual or on the machine itself, BE ALERT!, your per-

sonal safety and the safety of others, is involved.

• Defined below are the SAFETY ALERT messages

and how they will appear in this manual.

BE AWARE! It is illegal to remove, deface or other-

wise alter the safety decals mounted on this equip-

ment.

We reserve the right to make changes or improve the

design or construction of any part(s) without incurring the

obligation to install such parts or make any changes on

any unit previously delivered.

Graphics and illustrations may be used which may show

equipment and/or options not included in every

installation without incurring the obligation to install such

parts or make changes on units previously delivered.

Sno-Way Service Parts Manuals are available on-line or

at your authorized Sno-Way dealer. Request part number

97101915 for the SWS 30 Controllers.

Factory contact information is available at

www.snoway.com.

WARNING

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR INJURY.

CAUTION

Information, that if not carefully followed, can

cause injury or damage to equipment!

INTRODUCTION

DEALER

NAME

PHONE ( )–

ADDRESS

CITY STATE ZIP

(FILL IN)

ORIGINAL PURCHASER

NAME

PHONE ( )–

ADDRESS

CITY STATE ZIP

(FILL IN)

3

SAFETY

BEFORE ATTEMPTING ANY PROCEDURE IN THIS

BOOK, READ AND UNDERSTAND ALL THE SAFETY

INFORMATION CONTAINED IN THIS SECTION. IN

ADDITION, ENSURE ALL INDIVIDUALS WORKING

WITH YOU ARE ALSO FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

For your safety Warning and Information Decals have

been placed on this product to remind the operator

to take safety precautions. It is important that these

decals are in place and are legible before operation

begins. New decals can be obtained from Sno-Way or

your local dealer.

REMEMBER The careful operator is the best

operator. Most accidents are caused by human error.

Certain precautions must be observed to prevent the

possibility of injury to operator or bystanders and/or

damage to equipment.

NEVER exceed vehicle GVWR, GAWR or Vehicle Hitch

Tongue Weight Rating.

NEVER operate spreader when under the influence of

alcohol, drugs or other medications that could hamper

your judgement and reactions. An accident may result in

serious injury or death to other persons or yourself.

ALWAYS operate vehicle in a well-ventilated area. The

carbon monoxide in exhaust gas is highly toxic and can

cause serious injury or death.

NEVER allow hands, hair or clothing to get near any

moving parts such as fan blades, belts and pulleys. Never

wear neckties or loose clothing when working on the

vehicle or Spreader.

NEVER wear wrist watches, rings or other jewelry when

working on the vehicle or individual equipment. These

things can catch on moving parts or cause an electrical

short circuit that could result in serious personal injury.

ALWAYS wear safety goggles when working on the

vehicle to protect your eyes from battery acid, gasoline,

and dust or dirt from flying off of moving engine parts.

ALWAYS be aware of and avoid contact with hot

surfaces such as engine, radiator, and hoses.

ALWAYS wear safety glasses with side shields when

striking metal against metal! In addition, it is

recommended that a softer (non-chipable) metal material

be used to cushion the blow. Failure to heed could result

in serious injury to the eye(s) or other parts of the body.

NEVER allow children or unauthorized person to

operate this spreader.

NEVER exceed 45 m.p.h. when loaded spreader is

attached to vehicle. Braking distances may be increased

and handling characteristics may be impaired at speeds

above 45 m.p.h. It is strongly recommended to load the

spreader at the job site and to dispense all of the

materials at the job site. Transportation of a loaded

spreader causes the material to become impacted and

may cause spreader flow problems.

ALWAYS lock the vehicle when unattended to prevent

unauthorized operation.

ALWAYS check the job site for terrain hazards,

obstructions and people.

ALWAYS check surrounding area for hazardous

obstacles before operating this unit.

ALWAYS inspect the unit periodically for defects. Parts

that are broken, missing or plainly worn must be replaced

immediately. The unit, or any part of it should not be

altered without prior written approval of the manufacturer.

ALWAYS shut off the vehicle engine, place the

transmission in Park, turn the ignition switch to the “OFF”

position and firmly apply the parking brake of the vehicle

before attaching or detaching the spreader from the

vehicle or when making adjustments to the spreader

gates and/or deflectors.

ALWAYS make sure personnel are clear of area being

spread. Material is discharged from spreader at a high

rate of speed and could injure bystanders.

ALWAYS inspect bolts and pins whenever attaching or

detaching the spreader, and before traveling. Worn or

damaged components could result in the spreader

dropping to the pavement while driving, causing an

accident.

NEVER place fingers in mounting frame or mount lug

holes to check alignment when attaching spreader.

Sudden motion of the spreader frame could severely

injure a finger.

NEVER use material in the spreader containing twigs,

brush, plastics, cans or other trash. Foreign materials

could plug drive and discharge and damage unit.

NEVER use wet materials in the spreader. This unit is

not designed to handle wet materials. Use only dry free

flowing materials.

NEVER leave materials in hopper for long periods of

time. Remember salt is hygroscopic and will attract

enough atmospheric moisture to cause it to "cake".

NEVER work on the vehicle without having a fully

serviced fire extinguisher available. A 5 lb or larger CO2

or dry chemical unit specified for gasoline, chemical or

electrical fires, is recommended.

NEVER smoke while working on the vehicle. Gasoline

and battery acid vapors are extremely flammable and

explosive.

NEVER free up a jam or unclog spreader while it is

plugged in. Always turn off vehicle and unplug spreader

when working on it.

NEVER remove a spreader full of material, or even

partially filled with material, from the vehicle. Always

empty spreader prior to removal from the vehicle.

REMEMBER it is the owner’s responsibility for

communicating information on the safe use and

proper maintenance of this machine.

4

Introduction

The information contained in this section will instruct you

on the proper installation and set up of the controller and

wire harness.

REMEMBER After the SWS 30 is installed on the

vehicle, the Pre-Delivery Check List and Delivery

Check List must be completed.

Tool List

Installation

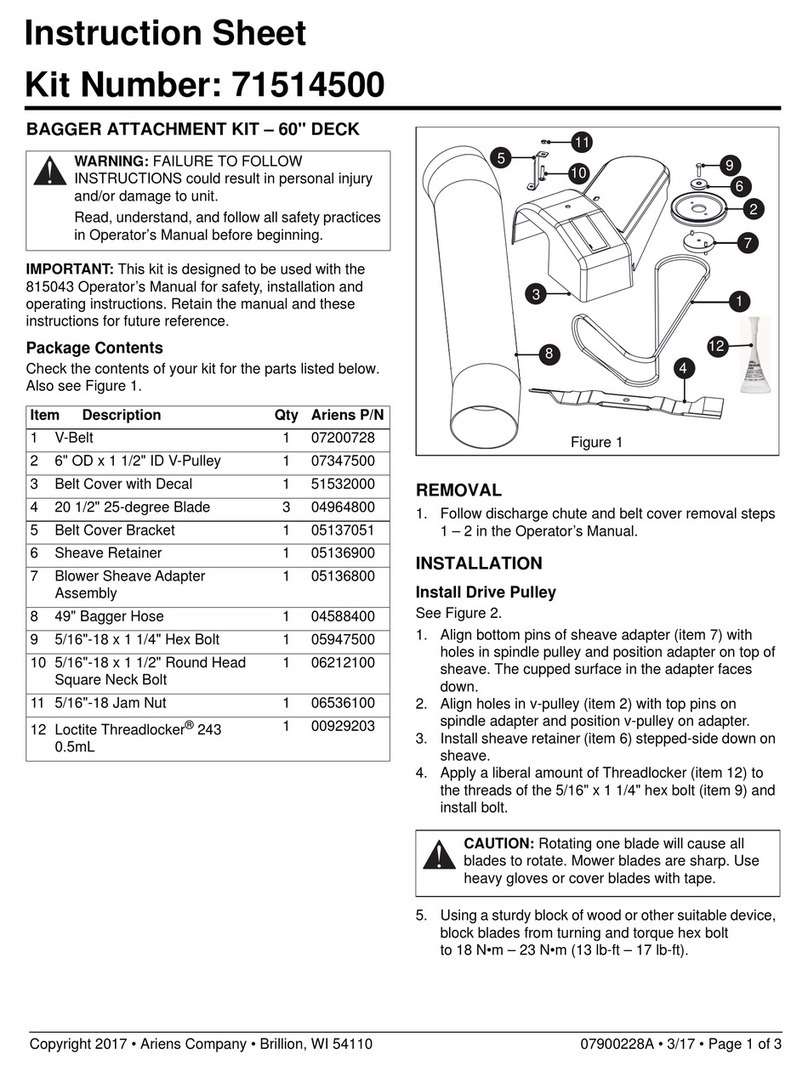

Figure 1-1

1. Locate the following parts:

• Vehicle Power Harness

• Battery Power Harness

• Toggle Switch

• Female Terminal (2)

• 3/8" Ring Terminal

• Cable Ties

• 20A Fuse

2. Disconnect the NEG. (-) battery cable from the

battery.

NOTE: Take the extra time needed to plan the routing of

the wiring harness before drilling any holes or fastening

the harness or toggle switch in place. Read all the

instructions carefully to ensure all the required conditions

are met for a safe and professional installation.

Figure 1-2

3. Uncoil the Battery Power Harness and attach it to the

Positive (+) terminal on the battery.

4. Look for an existing hole in the vehicle firewall. The

hole must be 3/8" or larger.

Safety Goggles

Wire Crimp Tool

Utility Knife

Drill

Drill Bit, 3/8"

20A Fuse

Toggle

Switch

Cable

Tie

Vehicle Power

Harness

Battery Power

Harness

Female

Terminal

3/8" Ring

Terminal

WARNING

Disconnect the vehicle NEG. (-) battery cable

while performing Steps 2 - 13 to avoid serious

bodily injury from electrical shock, fire, or

explosion. Do not re-connect battery cable until

indicated in step 14.

FAILURE TO FOLLOW CAN RESULT IN INJURY

OR DEATH.

BATTERY

FUSE

TOGGLE SWITCH

SWS 30

INSTALLATION

5

5. If an existing hole is not available, look for an area to

drill the hole that satisfies these conditions:

• Hole should be drilled on the same side of the vehicle

firewall (left or right) as the vehicle battery.

• DO NOT put a hole in such a spot that will force the

wiring harness, when installed, to interfere or be routed

behind accelerator pedal, brake pedal, clutch pedal,

parking brake or associated linkage.

• DO NOT drill any holes until a thorough visual

inspection is performed to determine that the area

around the hole to be drilled, on both sides of the firewall,

is clear of any obstacles such as brake lines, linkage or

vehicle wiring.

NOTE: If the hole has to be drilled through carpeting or

insulation, reverse the direction of the drill until the carpet

has been penetrated, remove the carpet from the hole,

then use the forward direction to continue drilling through

the firewall, this should prevent "running" in the carpet.

6. Using a twist drill or hole saw, as necessary, drill a hole

through the vehicle firewall.

7. Insert wiring harness into firewall.

8. Find a location to mount the Toggle Switch that the

wires harness can reach. The drilled hole must be 15/32"

in diameter and in a panel no thicker than 1/8" thick. Use

the nut with the Toggle Switch to fasten it into place.

9 Uncoil the Vehicle Power Harness. Determine a route

from SWS to the bumper of the vehicle, along the frame

rails, and through the vehicle engine compartment to the

battery. Make sure to leave enough harness length at the

back bumper to reach the SWS. Use the supplied Cable

Ties to route the harness.

10. Locate the red power wire within the loom of the

Vehicle Power Harness and insert it through the same

hole in the firewall as the Battery Power Harness. Then

route it to the Toggle Switch.

11. Cut off any excess wire that isn't needed to reach the

Toggle Switch on either harness. Then strip the ends of

the wire and crimp on the Female Terminals.

12. Push the Female Terminals onto the Toggle Switch.

13. Cut off any excess black wire that isn't needed to

reach the battery on the Vehicle Power Harness. Then

strip the end of the wire and crimp on the 3/8" Ring

Terminal.

14. Attach the Vehicle Power Harness black wire to the

Negative (-) terminal on the battery and re-connect the

negative battery terminal.

15. Remove the fuse holder cap from the Battery Power

Harness, install the 20A Fuse, and fasten the fuse holder

cap onto the connector.

16. Plug the SWS 30 to the installed harness. Determine

which direction is ON and OFF for the Toggle Switch,

then label it.

CAUTION

DO NOT drill any holes until a thorough visual

inspection is performed to determine that the

area around the hole to be drilled, on both sides

of the firewall, is clear of any obstacles such as

brake lines, linkage or vehicle wiring.

CAUTION

Keep wiring harness away from moving parts,

sharp edges and areas of extreme heat to avoid

electrical failure and fire.

CAUTION

Keep wiring harness away from moving parts,

sharp edges and areas of extreme heat to avoid

electrical failure and fire.

6

Theory of Operation

The ON/OFF switch only has one speed. Turn the switch

ON and the pump motor turns on full spraying speed. Turn

the switch OFF and the motor turns off and the unit stops

spraying. Since the units spraying speed is not variable,

its best to only use the system when the spreader's auger

speed is at or near it's max.

On/Off Motor Controller Operation

The pump is protected by a 20 amp fuse installed in the

wiring system near the vehicle battery.

Start:

When the ON side of the switch is selected, current will be

directed to the SWS pump motor. When the OFF side of

the switch is selected, current to the system end.

IMPORTANT: If ignition switch is turned off at any

time during operation the pump will not stop

running. This can drain the battery power and

destroy the SWS pump if left running for hours.

Wiring Schematics

An On/Off Control system schematic diagram is located in

your SWS Installation & Owner’s Manual.

CAUTION

The controller input voltage must be a minimum

of 11 volts DC for proper operation. Be sure the

vehicle battery and alternator are in good

operating condition and adequate to provide 11

volts DC to the controller.

OPERATION

Hartford, WI 53027 USA

Website: www.snoway.com

©2016 Sno-Way®International

SNO-WAY®INTERNATIONAL, INC.

Table of contents

Other Sno-Way Snow Blower manuals