Snow Hawk 600HO Service manual

MY2004

Set-up, Service

and Shop Manual

SNOW HAWK 600HO

FOREWORD

Congratulations, and thank you for buying an A.D.

Boivin design inc. Snow Hawk™ vehicle. We

appreciate the confidence in our product that you

have demonstrated by making this purchase.

Several years of design, tests and improvements

were necessary to produce this vehicle which

combines performance, driving pleasure and safety.

Proper maintenance on a regularly-scheduled basis is

essential in order to obtain the performance you have

the right to expect from your machine. In this manual,

you will find all the information needed for adjustments

to and the maintenance of this vehicle.

We sincerely hope that you will have many years of

enjoyment with your Snow Hawk™.

AD Boivin design Inc.

All the information, illustrations, photographs and

specifications found in this manual are based on the

latest available data at the time of publication. Due to

improvements or other changes, it is possible that

you will note a few differences. AD Boivin design Inc.

reserves the right to make changes at any time.

WARNING /CAUTION / NOTICE

Please read this manual and follow the instructions

carefully. Pay particular attention to the boxes

entitled WARNING and CAUTION as well as to the

paragraphs preceded by the word NOTICE.

◆WARNING

This symbol is designed to call attention to

particular instructions and procedures, which,

if not followed to the letter, could cause injury

and even fatal accidents.

▼CAUTION

This symbol is designed to call attention to

particular instructions and procedures, which,

if not followed to the letter, could cause

damage to or even destruction of the vehicle.

●

NOTICE:

The information in the NOTICES is designed to

explain maintenance procedures and to ensure the

best possible use of the vehicle.

IMPORTANT REMARKS

Using this vehicle can be a very pleasurable

experience and we wish you all the enjoyment that it

can bring you. However, if certain rules are not

respected, this sport can become a source of

environmental problems and of interpersonal

conflicts.

Adopting a responsible attitude and behaving in a

responsible manner at all times will help avoid such

problems and conflicts.

PROTECT THE FUTURE OF YOUR SPORT. BE

RESPONSIBLE AND RESPECT LOCAL LAWS AT

ALL TIMES. DEMONSTRATE AN AWARENESS

OF THE IMPORTANCE OF THE ENVIRONMENT

AND RESPECT THE RIGHTS OF OTHERS.

WARRANTY

1. All the parts of this vehicle are covered by the

warranty for a period of one winter season

against any problem related to its assembly

or construction.

2. The labour costs of repairs covered by the

warranty are the responsibility of the vehicle

owner.

3. The company reserves the right to require

that the dealer carrying out the repairs send

back any parts declared or suspected to be

defective.

LOCATION OF THE V.I.N.

IMPORTANT MAINTENANCE WARNINGS:

◆WARNING

Never have the motor running inside a building.

The exhaust fumes contain carbon monoxide, a

colourless, odourless gas which can cause

death or severe injuries.

Allow the motor to run only in a well-ventilated

area.

◆WARNING

When hot, a motor, an exhaust system or a

drive system can cause burns.

Wait until they have cooled before carrying out

maintenance.

◆WARNING

The gas tank can catch fire if it is not handled

correctly. Gas vapours can burst into flames

easily.

Do not smoke while carrying out vehicle

maintenance.

Do not carry out maintenance anywhere near

exposed flames or sparks.

◆WARNING

Brake fluid can be dangerous for people and

animals. These fluids are harmful or fatal if

swallowed and must not come into contact with

the skin or eyes.

◆WARNING

Carrying out maintenance of this vehicle while

the motor is running can be dangerous.

Injuries could result from contact with moving

parts.

Make sure you turn off the motor before

working on the vehicle.

◆WARNING

Working on this vehicle without wearing the

appropriate clothing can be dangerous.

Injuries could result if you are not adequately

protected.

Always wear the necessary equipment when

working on the vehicle: shoes, goggles, gloves

and/or mask if necessary.

Important information concerning maintenance

oReplace any joints, brake shoes, pins and clips

by new ones.

oUse special tools when so indicated.

oUse original parts as well as recommended

products.

oAfter reassembling the vehicle, inspect the parts

and verify the torque on the nuts and bolts.

Replacement parts

Use only A D Boivin parts or their equivalent. A D

Boivin’s original high-quality parts are designed and

manufactured especially for your vehicle.

●

NOTICE:

Using replacement parts that are not equivalent or

are of inferior quality could mean your vehicle will not

be able to perform as it should and could damage

your machine.

MANDATORY SERVICE PRODUCTS

Loctite RC/609, 10 ml

Retaining compound

P/N 413 703 100

Loctite 271, 10 ml

High strength

threadlocker

P/N 293 800 005

Loctite 243, 10 ml

Medium-strength

threadlocker

P/N 293 800 015

Sealing compound, 30 ml

P/N 420 297 905

Loctite Primer, 128g

P/N 413 708 100

Loctite 515, 50 ml

Paste gasket

P/N 413 702 700

MANDATORY SERVICE PRODUCTS (continued)

Loctite 518, 50 ml

Gasket Paste

P/N 293 800 038

Loctite chisel, 510g

Gasket/paint remover

P/N 420 899 763

Molykote PG 54, 10g

P/N 420 899 763

Petamo Grease

P/N 420 899 271

Molykote G-n plus. 50g

P/N 711 297 433

Isoflex Grease, 50g

P/N 293 550 021

RECOMMENDED SERVICE PRODUCTS

Bombardier injection oil

3 x 4 litres P/N 413 803 000

Synthetic injection oil

Bombardier Formula XP-S II

3 x 4 litres P/N 293 600 046

Synthetic injection oil

Bombardier Formula XP-S II

12 x 1 litre P/N 293 600 045

Pre-mix oil

12 x 500ml P/N 413 803 100

Premixed coolant 50/50

16 x 1 litre P/N 293 600 038

Fuel stabilizer

12 x 8 oz P/N 413 408 600

RECOMMENDED SERVICE PRODUCTS (continued)

Storage oil 12 x 350 g

Canada P/N 413 711 600

USA P/N 413 711 900

Synthetic Grease 400 g

P/N 413 711 500

LMZ Grease No 1, 400 g

P/N 413 707 500

Molykote 111, 50 g

P/N 413 707 000

Bombardier lube

12 x 14 oz P/N 293 600 016

Silicone dielectric grease, 3 oz

P/N 293 550 004

RECOMMENDED SERVICE PRODUCTS (continued)

Anti-seize compound, 236 ml

P/N 293 800 070

Brake fluid SRF ( DOT 4 )

P/N 293 600 063

Brake fluid GTLMA (DOT 4)

P/N 293 600 062

Heavy Duty Cleaner

400 g P/N 293 110 001

4 litres P/N 293 110 002

Shock oil 32 oz

P/N 293 600 035

Pulley flange cleaner, 320 g

P/N 413 711 809

RECOMMENDED SERVICE PRODUCTS (continued)

Loctite 592, 50 ml

Pipe sealant

P/N 293 800 018

Loctite 648, 5 ml

High temperature and strength

retaining compound

P/N 413 711 400

Plastic and vinyl cleaner

P/N 413 711 200

Loctite Ultra Copper, 80 ml

High temperature RTV sealant

P/N 293 800 090

Loctite 5150, 300ml

P/N 293 800 066

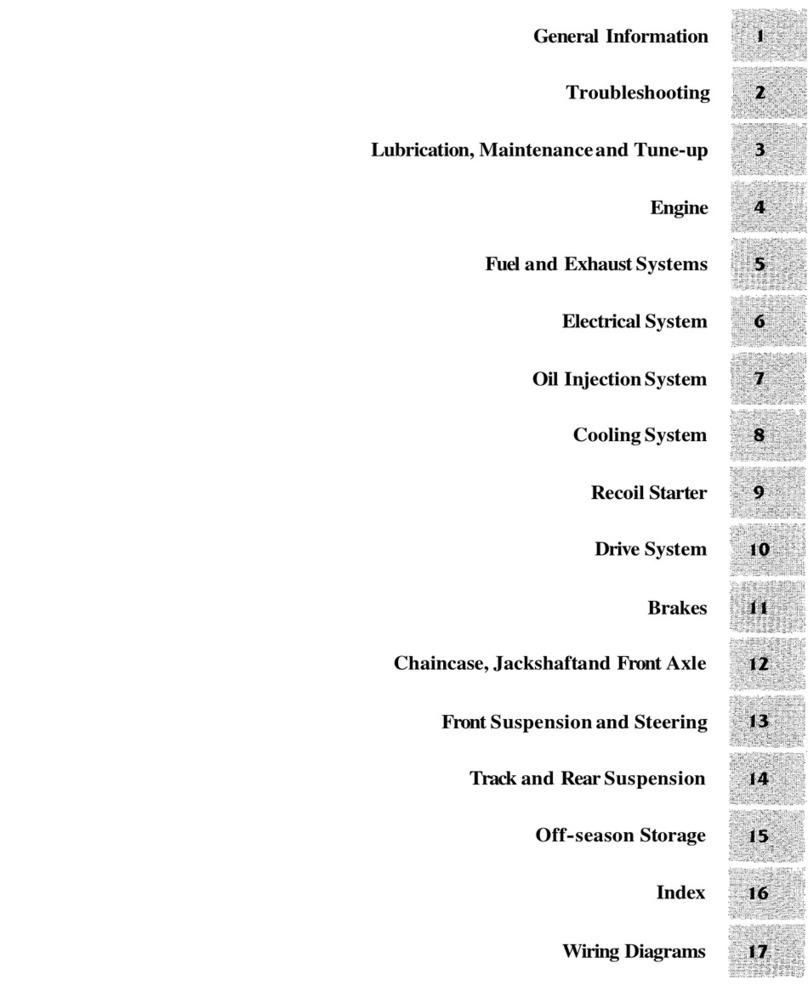

TABLE OF CONTENTS

GENERAL INSTRUCTIONS

PERIODIC MAINTENANCE

FUEL SYSTEM

ENGINE REMOVAL

REWIND STARTER

COOLING SYSTEM

ENGINE (CYLINDERS / HEAD / BASE)

PRIMARY TRANSMISSION SYSTEM

SECONDARY TRANSMISSION SYSTEM

HYDRAULIC BRAKE SYSTEM

FRONT FORK AND TWIN-AXIS SKI

REAR SUSPENSION, SHOCKS AND TRACK

CHASSIS AND STEERING

ELECTRICAL SYSTEM

DIMENSIONS AND TOLERANCES

WIRE, CABLE AND HOSE ROUTING

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

11

GENERAL INSTRUCTIONS 1 - 1

FIRST CONTACT

The SNOW HAWK™ is a completely new type of vehicle.

Technically speaking, it is a cross between a snowmobile and a

motorcycle. However, its behaviour depends on the conditions in

which it is used. Sometimes, it will react more like a bike while

at other times, it will react more like a snowmobile or a jetski.

Describing exactly how the SNOW HAWK™ behaves is difficult.

This is why we recommend that you take the time to become

acquainted with your machine in an area free of any obstacle.

This first contact should take place at low speed, with a series of

basic manoeuvres that will allow you to learn about the reactions

of the vehicle.

A good exercise is to follow a "figure 8" trajectory because this

will allow you to experiment with right- and left-hand turns

followed by accelerating and braking.

Turning can be done by steering right or left, keeping in mind the

speed of the vehicle, the snow conditions and how quickly you

want to change direction.

◆WARNING

Some people enter a turn by stretching out a leg on the

inside of the turn and letting the foot slide over the

ground (a technique used in motocross). We advise

against this practice which could cause severe injuries if

your foot should sink into the snow. We rather suggest

keeping both feet on the footpegs as much as possible.

An upright position, with the knees clutching the gas tank and

the elbows pointing away from the vehicle, will give a sense of

security and provide greater freedom of movement while

accelerating or slowing down.

◆WARNING

The greatest danger in using this vehicle is the perception

you may have of how competent you are. Overestimating

how competent you are can result in hazardous situations

both for yourself and for other trail users.

Do not forget to take all the time that is necessary for you to

practice and feel comfortable at low speeds before attempting

high-speed manoeuvres. You will then be able to fully

appreciate the joy of driving.

GENERAL INSTRUCTIONS 1 - 2

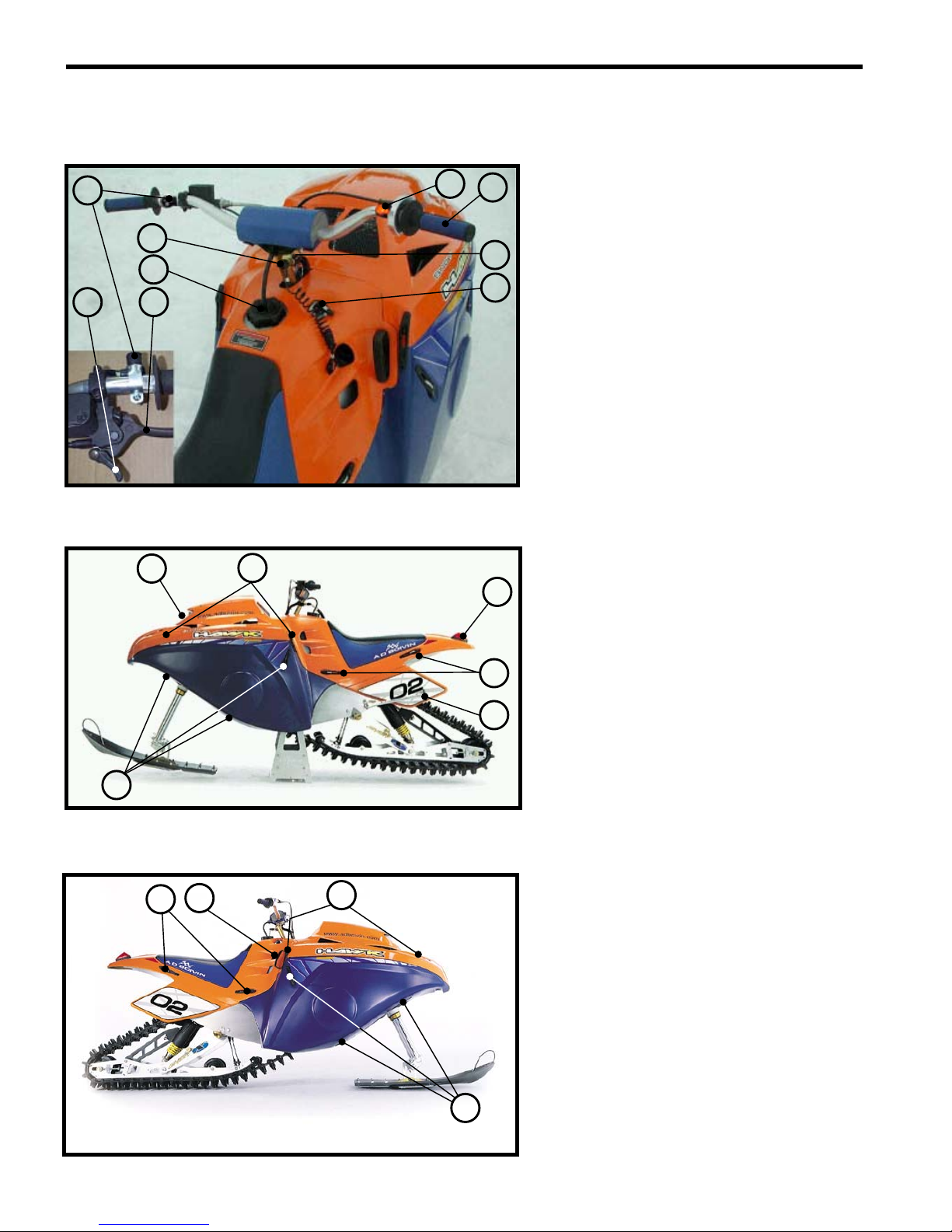

LOCATION OF MECHANISMS AND CONTROLS (503 SHOWN, 600HO IDENTICAL)

1. Throttle control

2. Brake lever

3. Parking brake lever

4. Engine-cutoff (tether)

5. Gas tank cap

6. Dimmer switch

7. Choke control

8. Emergency-stop button

9. Temperature Light

10. Hood latches (4)

11. Rear module latches (4)

12. Bellypan latches (6)

13. Kick stand

14. Headlight

15. Stop and tail light

16. Recoil starter handle

17. Hood latches (4)

18. Rear module latches (4)

19. Bellypan latches (6)

10

11

12

13

14

15

16 17

18

19

6

2

3

1

4

5

7

8

9

GENERAL INSTRUCTIONS 1 - 3

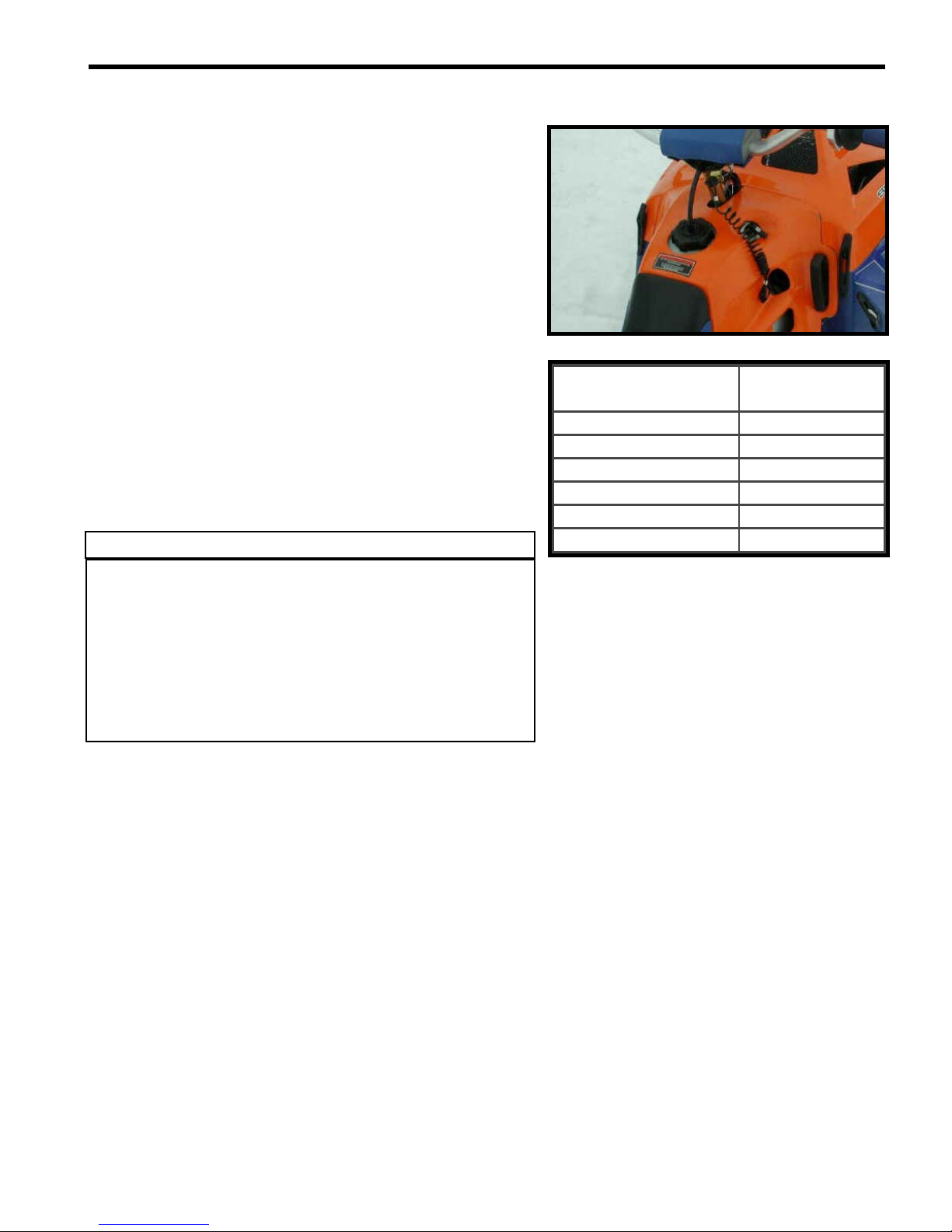

FUEL

This vehicle is powered by a two-stroke engine that uses a pre-

mixed gasoline and oil mixture.

Gasoline: Regular unleaded gas with a minimum octane

rating of 89 (R+M)/2

Motor oil: Bombardier / ROTAX Formula XPS Synthetic

Pre-mix oil (P/N 293600045)

Mixture ratio: 40 : 1 (32 : 1 for break in and CAN safely be

used thereafter if desired)

Fuel tank capacity: 30 L (9.5 gallons)

▼CAUTION

A mixture in which the proportion of oil is too low will

cause piston failure. On the other hand, a mixture in

which the proportion of oil is too high will cause

excessive carbon deposits that will result in fouled spark

plugs and will affect performance.

Always mix in a proportion of 40 parts of gasoline for

each part of oil.

●

NOTICE:

oThe use of isop[ropyl alcohol (commonly known as “gas-

line antifreeze) is recommended in a ratio of 150 mL per

fuel tank in very cold temperatures.

oAvoid mixing oils of different brands.

Gasoline

(

L

)

Oil

(

ml

)

5125

10 250

15 375

20 500

25 625

30 75

0

GENERAL INSTRUCTIONS 1 - 4

OPERATING INSTRUCTIONS

Pre-driving inspection

◆WARNING

A pre-driving inspection is of the utmost importance

before using the vehicle. Do not start the machine until

you are sure all mechanisms and controls are functioning

properly. Failing to proceed in the prescribed manner may

result in severe injuries or even death.

oMake sure the track and the idler wheels are not frozen and

that they move freely.

oDepress the brake lever and make sure the brake is fully

engaged before the end of the lever touches the handlebar.

The lever must return to its original position as soon as it is

released.

oTurn the twist throttle control a few times to make sure it

functions properly. The control must return automatically to

the idle position as soon as it is released.

oMake sure the engine cutoff switch, the stop light, the

headlight (high and low beams) and the tail light are in good

working order.

Starting the engine

oPut the cap of the engine cutoff (tether) switch in place. The

other end of the cord must be securely attached to the

driver.

oIf the engine is cold, use the choke control.

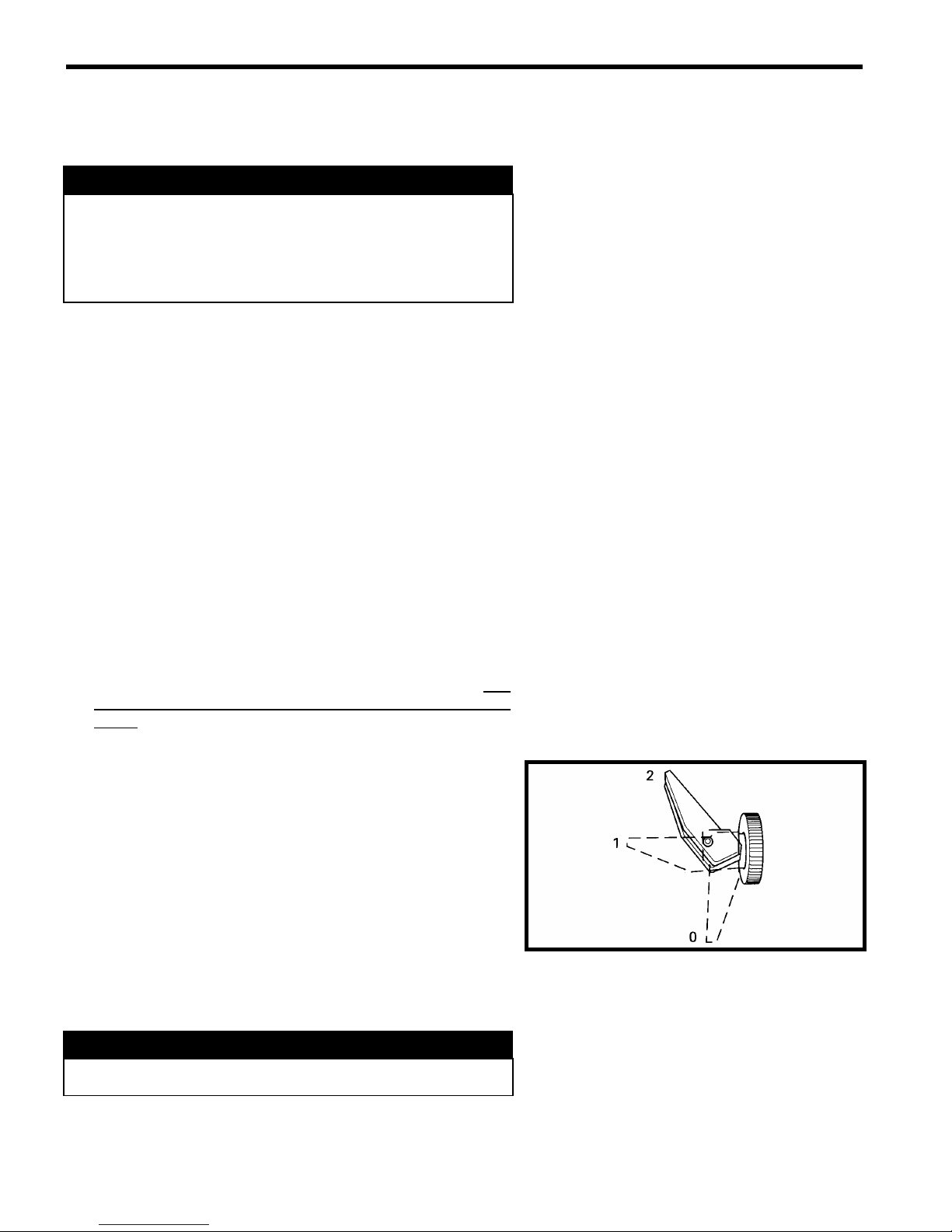

0. Normal position (not activated)

1. Intermediate choke position

2. Full choke position

oStart the engine by firmly pulling the handle of the rewind

starter.

◆WARNING

Do not touch the throttle control while starting the engine.

GENERAL INSTRUCTIONS 1 - 5

Stopping the engine

oWhile the engine is idling, remove the engine cutoff cap

(tether) or press the emergency-stop button.

BREAK-IN PERIOD

Engine

▼CAUTION

A cautious break-in period of 10 to 15 hours is essential

before using the vehicle at full power. Failure to provide a

sufficient break-in period could result in severe engine

damage.

▼CAUTION

The timing of all Snow Hawk 600HO’s is retarded by 3ofor

a period of 1-hour during the first stages of the break-in

period. You may notice a slight increase in performance

and a reduction in fuel consumption after this time.

During the break-in period, the throttle control should not be

turned more than ¾ of its range. However, occasional periods

of brief, brisk acceleration and frequent speed variations

contribute to a good break-in. On the other hand, periods of

long, high acceleration, sustained high speed and engine

overheating are harmful during the break-in period.

◆WARNING

This vehicle is equipped with a liquid cooling system.

ALWAYS ride with the rear deflector pad installed and in

conditions where there is enough snow to properly cool

the engine. If the red temperature light on the steering

column should ever illuminate, stop immediately and let

the vehicle cool down, and then find some snow. NEVER

continue to operate the vehicle with the temperature light

illuminated as severe engine damage will occur.

▼CAUTION

A fuel : oil mixture of 32 : 1 MUST be used during the

engine break-in period.

◆WARNING

During the first hour of the break-in period the fluid levels

in the coolant reservoir and the small water pump oil

reservoir will go down slightly. This is perfectly normal.

Be sure to top-up these fluids with proper coolant (P/N

293600038) and proper oil (P/N 293600045).

GENERAL INSTRUCTIONS 1 - 6

Drive Belt

A new drive belt must be submitted to a 5-hour break-in period.

Avoid high-speed driving and brisk accelerations during this

period.

Inspection – 10 hours

A general inspection is recommended after the first 10 hours of

use. This inspection must be carried out by an authorized

SNOW HAWK ™ dealer.

●

NOTICE:

oMost of the wear in this vehicle occurs during the break-in

period.

oBolts and nuts can easily become loose in a new machine.

Make sure you check them regularly during this period.

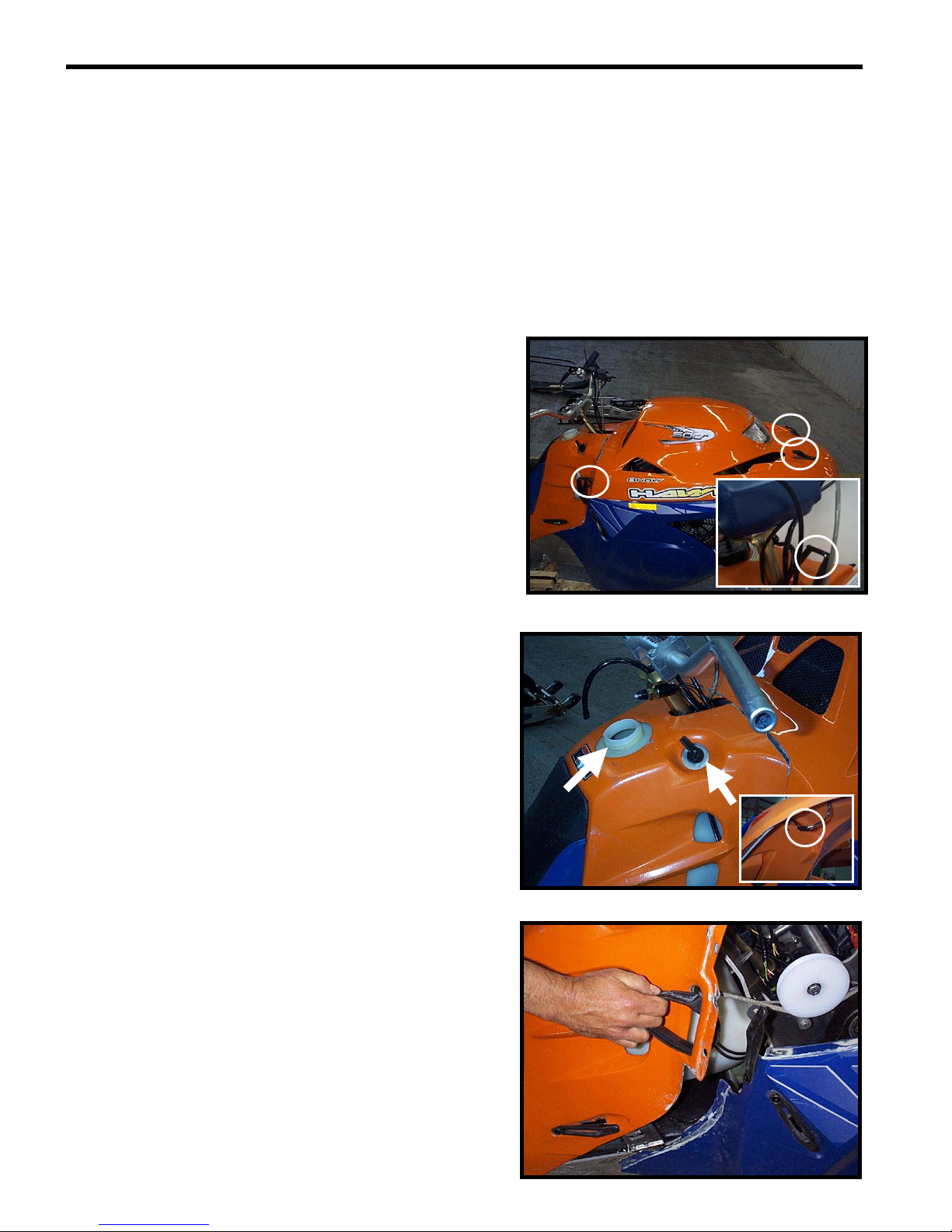

REMOVAL OF THE BODY PANELS (HOOD, REAR

MODULE AND BELLYPAN)

In order to work on the vehicle more easily and to access the

anchor ties, we suggest that you remove the rear module from

the vehicle. To do so, you must first remove the hood. Proceed

as follows:

oDisconnect the front headlight.

oUnhook the 4 rubber latches (2 / side).

oRemove the hood.

oRemove the fuel tank cap.

oSet the choke to the full position.

oUnplug the tail light connector located under the light

itself, underneath the rear fender.

o Release the rear module from its four rubber latches,

slip the rewind starter handle through the space

provided and remove the rear module.

GENERAL INSTRUCTIONS 1 - 7

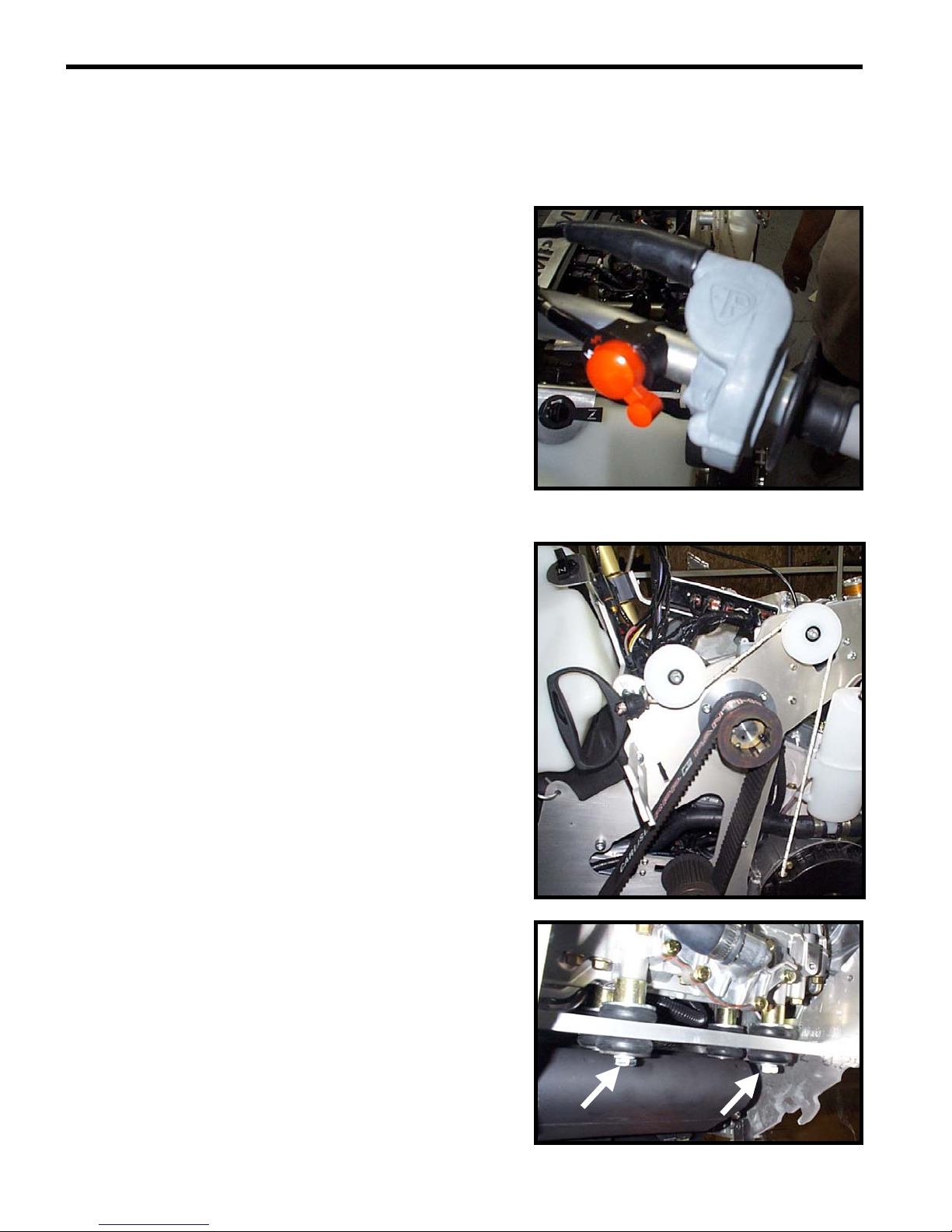

Roll the two O-rings down and pull the two white plastic

collars down over the fork legs. To ensure that they will not

interfere, let them hang loose at the base of the fork leg.

o Remove the circular fork disc

o De-latch the two rubber latches on the sides of the belly

pan (towards the rear of the vehicle)

o De-latch the four rubber latches on the bottom of the

belly pan.

o Descend the belly pan to floor level; most maintenance

can be performed with the belly pan in this position.

However, if it is required to completely remove the belly

pan, remove the single bolt attaching the ski to the fork.

At this point, a second person can lift the front of the

vehicle slightly and the belly pan can be slid out from

underneath.

PERIODIC MAINTENANCE 2 - 1

●

NOTICE:

Regular inspection and maintenance of the Snow Hawk is of utmost importance. Follow the guidelines in the table

below for optimum vehicle performance. Suggested intervals must be reduced if the vehicle is subjected to severe

usage conditions.

●

NOTICE:

V = Verify, A = Adjust, C = Clean, R = Replace one or several part(s), F = Replace fluid

Interval (Hrs)

Item

Fuel lines and connections

V

--

V

Carburetor ad

j

ustment

V

--

V

Throttle cable

V

- A - -

V

- A

Air Intake Filter

V

--

V

- C

Carburetor support bracket ---V

Starter cord

V

--

V

C

y

linder head bolts

V

--

V

En

g

ine support bolts

V

--

V

Exhaust s

y

stem

V

-

V

V

Coolant level

V

- A -

V

V

- F

Oil level

(

water pump oil reservoir

)

V

- A -

V

V

Cooling System (hose connections) V--V

Primar

y

drive belt

V

V

-

V

- R

Primar

y

and secondar

y

clutch

V

-

V

V

- C

Primar

y

clutch bolt

V

--

V

Secondary clutch pre-tension V - A - - V - A

Secondar

y

drive belt

(

co

g

belt

)

V

--

V

Co

g

sprockets

V

--

V

Tor

q

ue Limiter

V

--

V

- A

Taper Locks V--V

Brake fluid

V

--F

Brake pads

V

-

V

- R

V

- R

Brake microswitch V--V

Front Fork F-FF

Fork rubber cushion and bolt

V

-

V

V

Fork air bleeder screw

V

- A

V

- A

V

- A

V

- A

Twin axis ski bushin

g

s / nuts

V

- A -

V

- A

V

- A

Ski and runners VV-R

Suspension

V

-

V

-

Shocks

V

-

V

F

Track V - A - V - A V - A

Handlebar bolts

V

--

V

Steerin

g

components

V

-

V

V

Assembly bolts / nuts V--V-C

Spark plu

g

s

V

- A - R -

V

- A - R

V

- A - R

Spark plu

g

g

ap

V

- A - -

V

- A

Fuse

V

--

V

Headli

g

ht pro

j

ection/aim ---

V

- A

Lighting system, stop lamp and

emergency stop switch VV-V

2.7 Rear suspension and

track

2.9 Electrical system

15 Hrs

2.5 Brake system

2.4 Secondary

transmission system

2.6 Front suspension and

ski

2.8 Chassis

V - R as needed

65 Hrs

(yearly)

2.1 Carburetion

2.3 Primary transmission

system

2.2 Motor

Break-in

( ~ 10 Hrs. ) 5 Hrs

PERIODIC MAINTENANCE 2 - 2

2.1. CARBURETION

Fuel lines and connections

Check all hoses and connections in order to find and fix leaks

and/or to help prevent them.

Carburetor adjustment

For carburetor adjustment, refer to Chapter 3 - Fuel system

section.

Throttle cable

The throttle cable can be adjusted by setting the adjustment

mechanism on the throttle end of the throttle cable.

Air intake filter

The air intake filter must be cleaned at least once a year, or

more often under severe usage conditions. Clean the filter in a

solution containing a non-flammable cleaning solvant (such as

hot soapy water). Once dry, apply some light engine to the filters

to prevent the infiltration of water and dust.

2.2. ENGINE

Recoil starter cord

Pull gently on the handle to unwind the full length of the cable.

Inspect the cable visually to detect any wear or other damage

that could eventually cause the cord to break.

Cylinder head bolts

Refer to the appropriate procedure in Chapter 7 – Engine

(Cylinders/Head/Base).

Engine support bolts

To carry out this operation, refer to the appropriate procedure in

Chapter 7 – Engine (Cylinders/Head/Base).

PERIODIC MAINTENANCE 2 - 3

Cold

Level

Exhaust system

Using a torque wrench, check the torque of the retaining bolts of

the exhaust manifold. Apply a torque of 10 N-m (1 kg-m, 7.4 lbf-

ft).

Then, proceed to a visual inspection of the system to detect any

leak or abnormality in the gasket material.

Cooling system

Inspect the coolant level in the coolant reservoir located on the

MAG side of the vehicle. If the coolant level is below the “Cold”

coolant mark when the vehicle is not warm or has not been

ridden within 30mins or more, add coolant until this line. Check

all of the hoses / hose connections and ensure that there are no

fluid leaks in the system.

Other manuals for 600HO

1

Table of contents

Other Snow Hawk Offroad Vehicle manuals

Popular Offroad Vehicle manuals by other brands

Yamaha

Yamaha MM700A manual

Aria Child

Aria Child PowerSport W420AC-F01 Owner's manual and assembly instructions

Explorer

Explorer Patriot 430 Service manual

KAYO MOTOR

KAYO MOTOR AT125-B Service manual

Polaris

Polaris RZR XP TURBO S 2019 Owner's manual for maintenance and safety

Power Wheels

Power Wheels DLX39 owner's manual